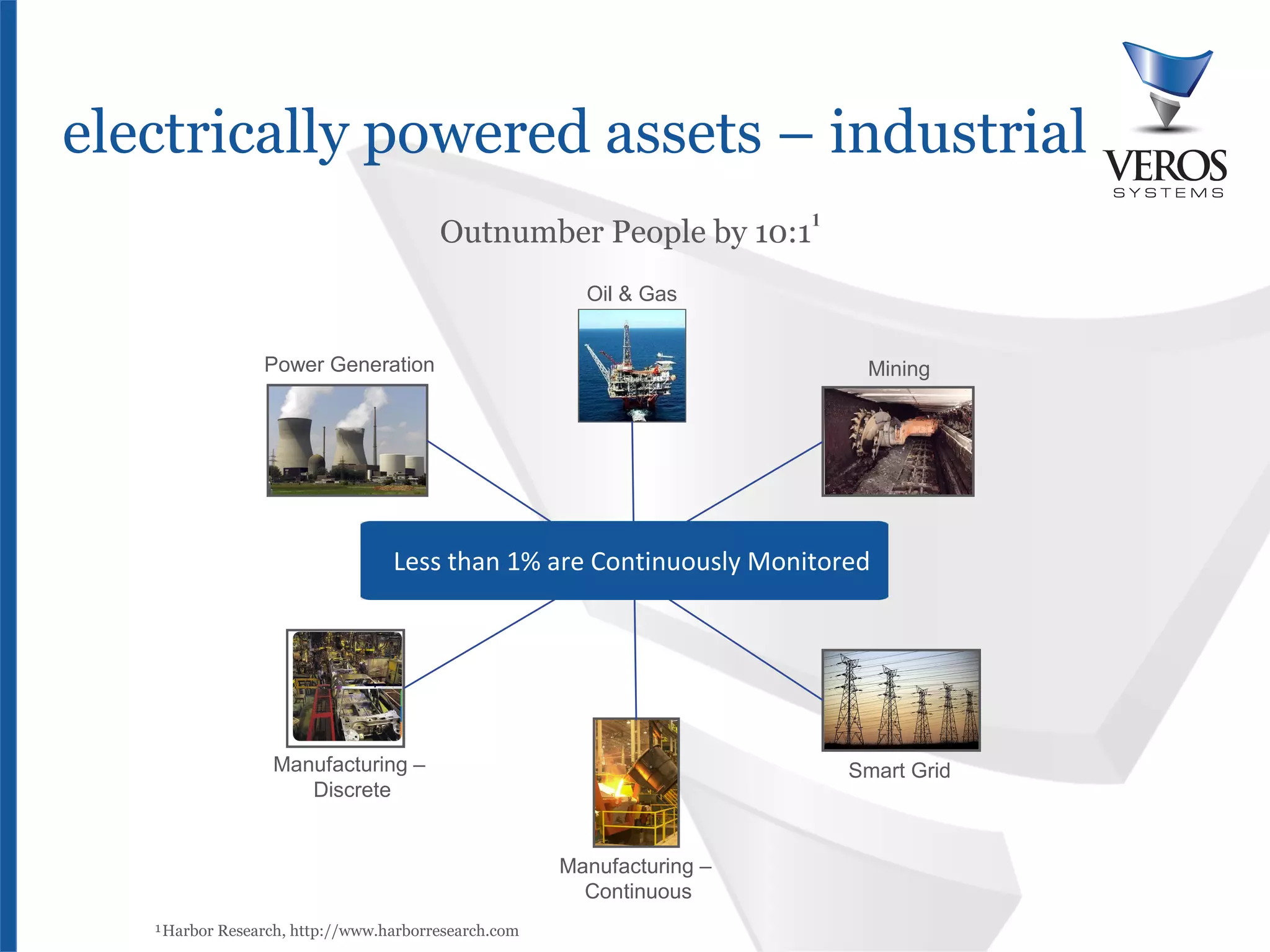

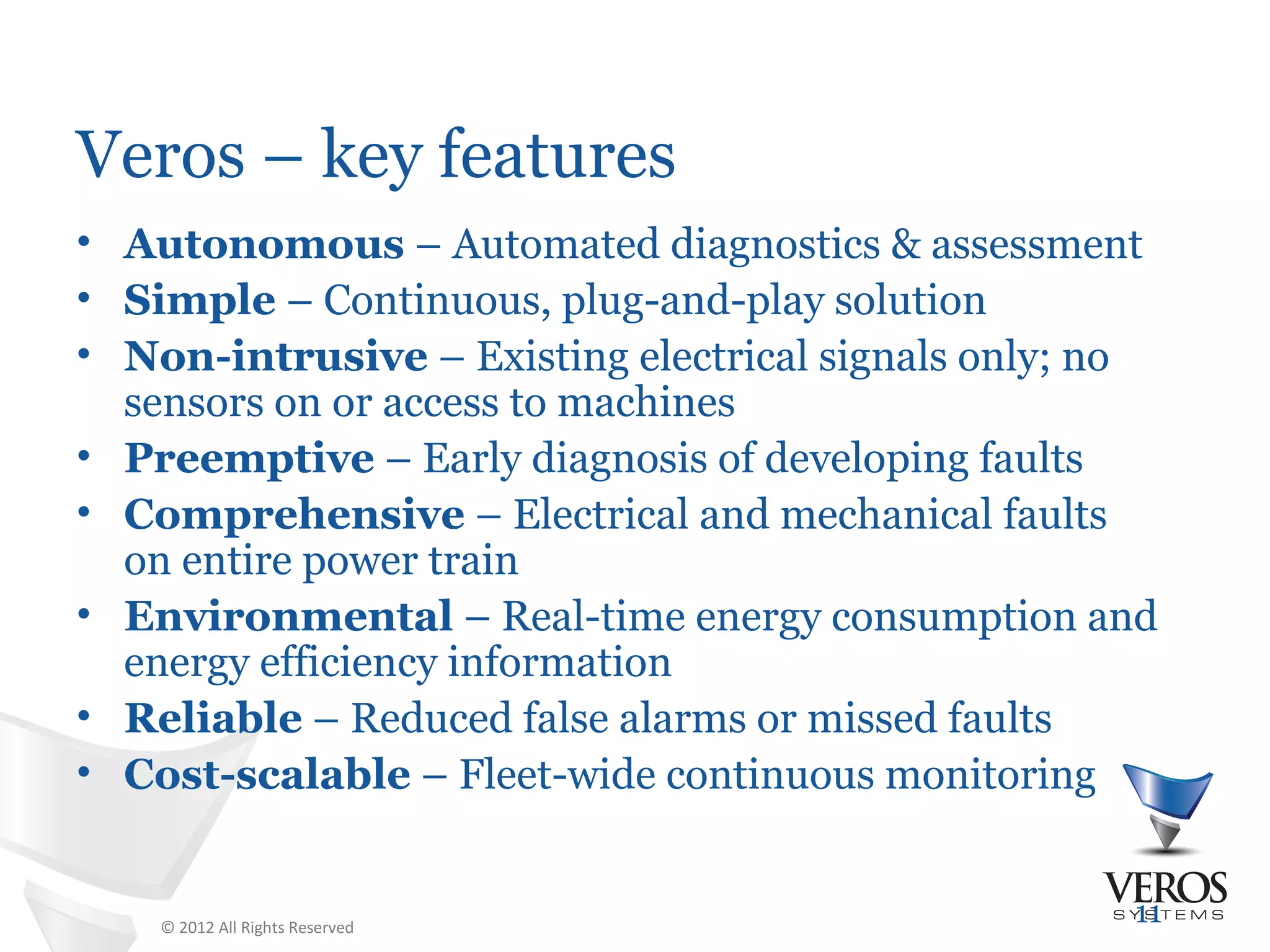

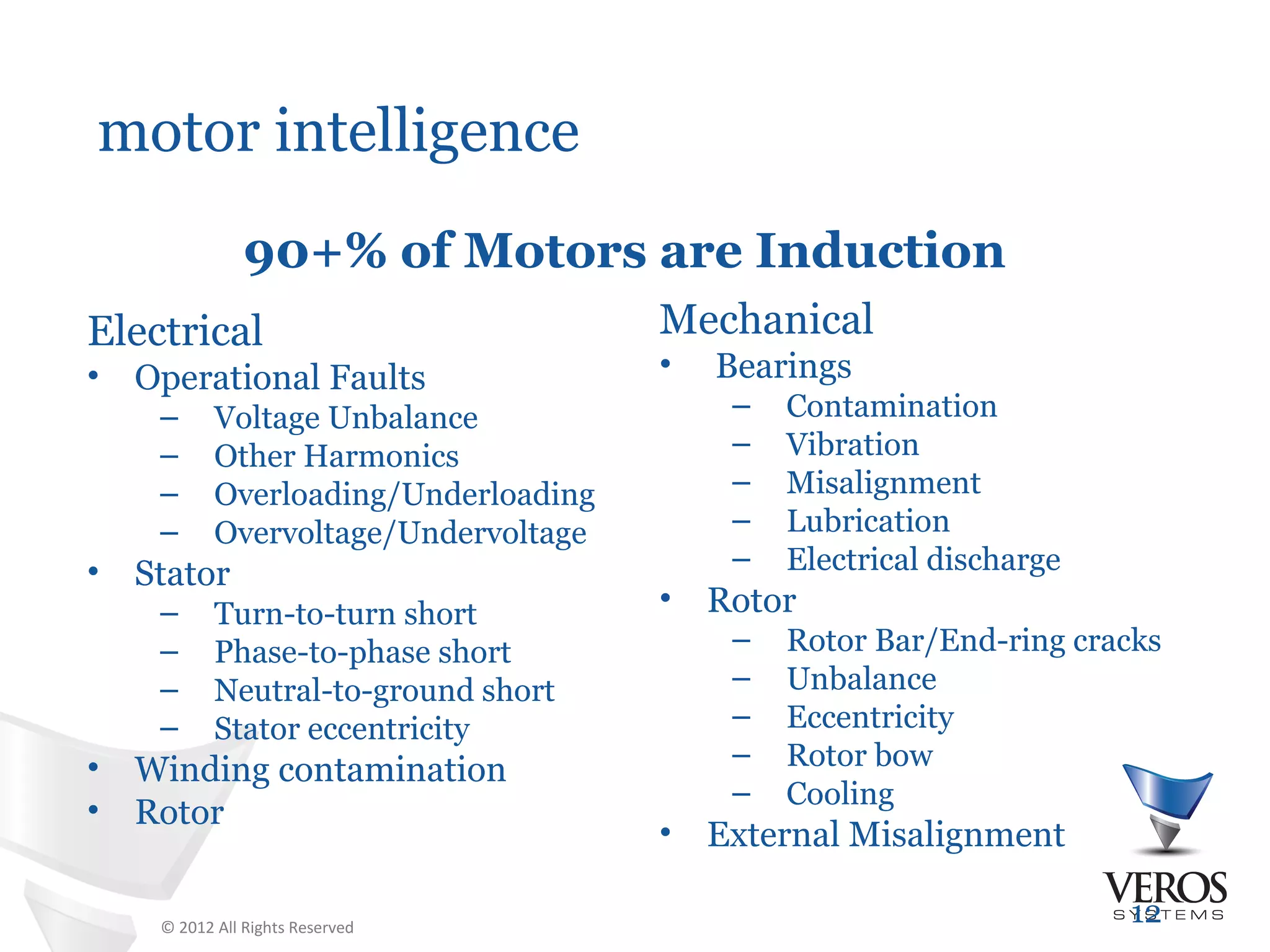

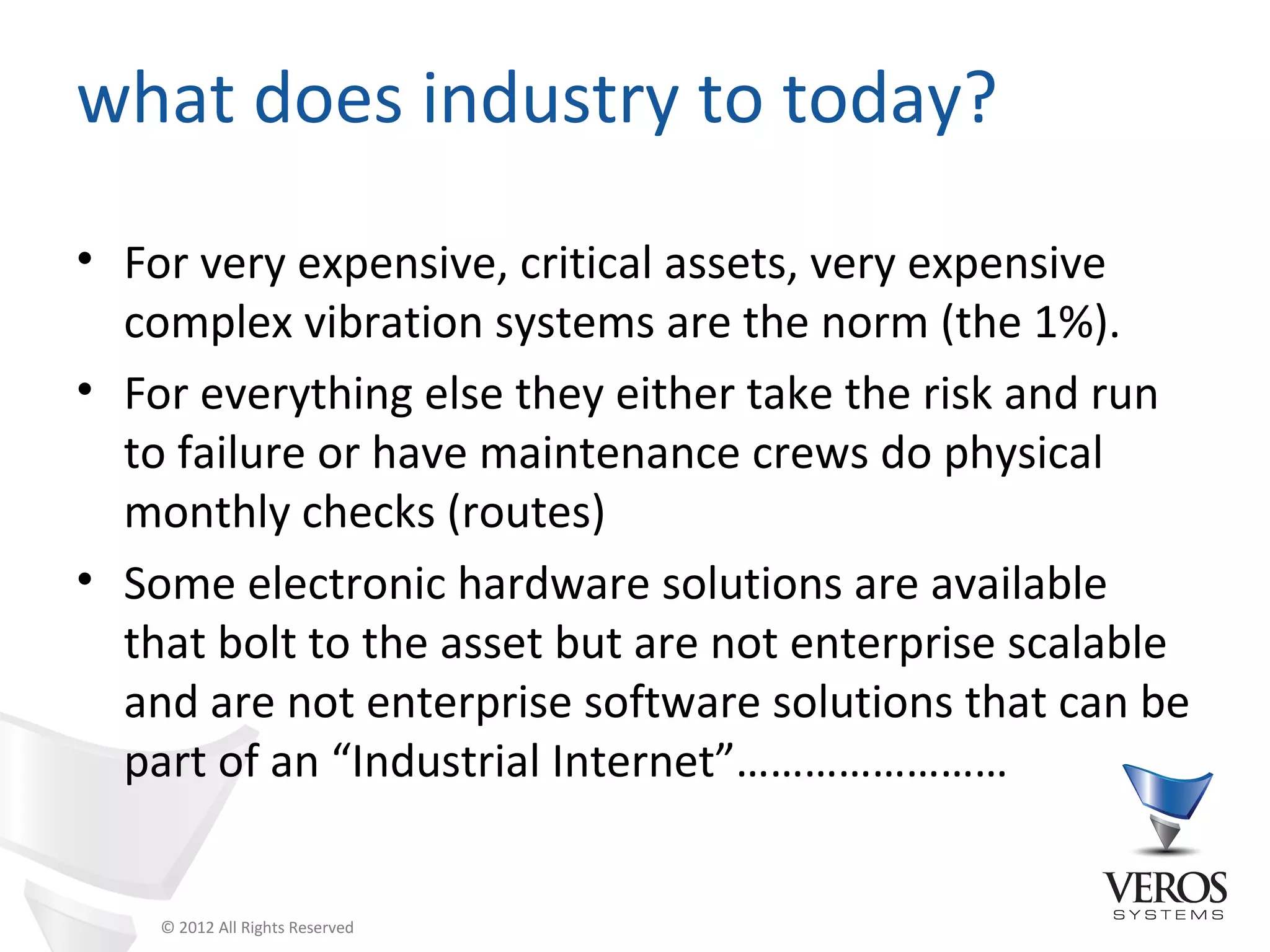

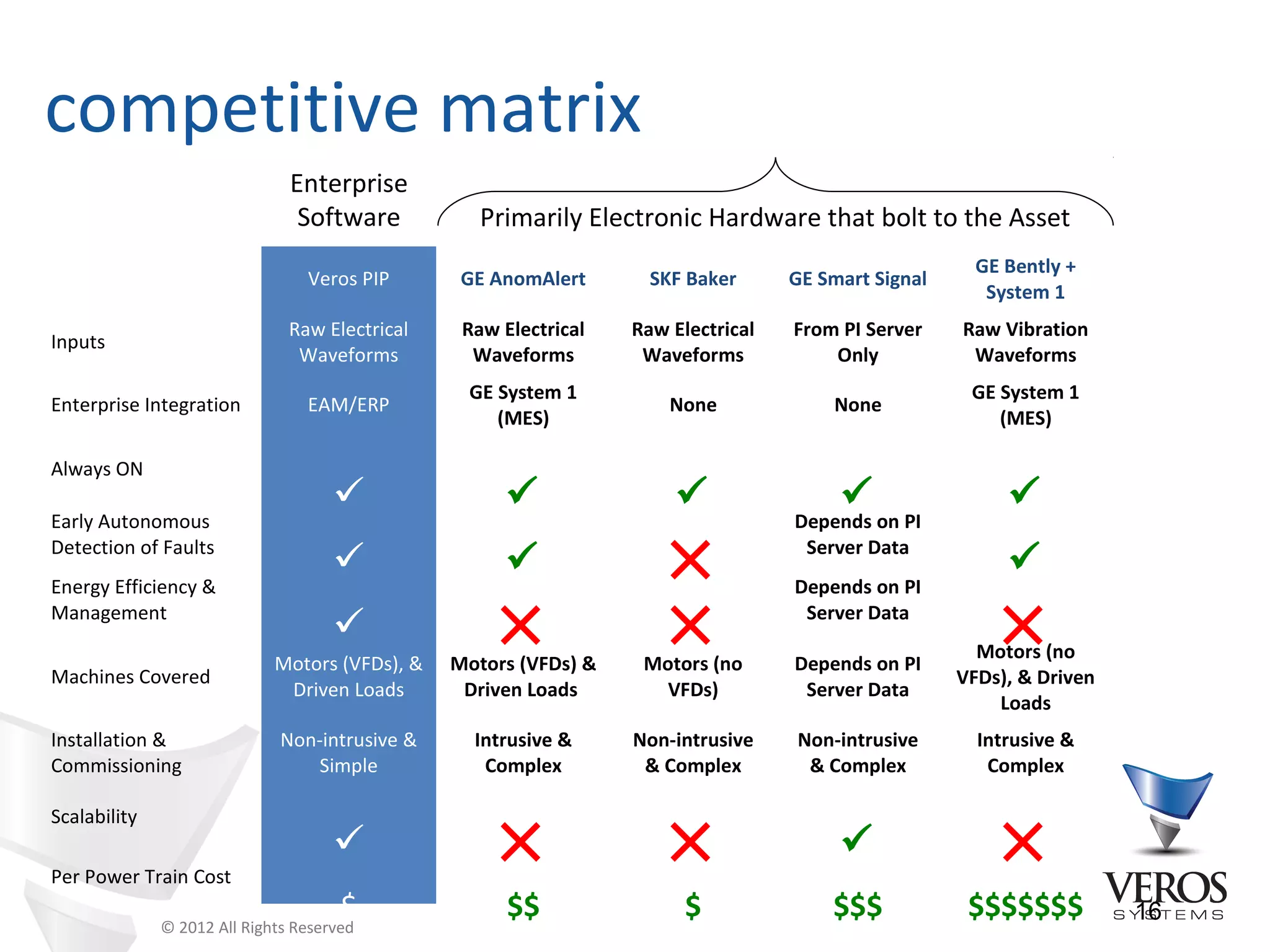

The Veros System provides a breakthrough software solution that uses non-invasive monitors to continuously monitor electrically powered rotating assets. It analyzes electrical waveform data using predictive analytics to detect emerging problems early, maximize asset reliability, improve efficiency, and ensure energy sustainability. Less than 1% of assets are currently continuously monitored, but the Veros System provides an affordable, easy to deploy solution to monitor the overwhelming majority of critical assets for the first time.