This document discusses milling processes used in pharmaceutical applications. It describes various types of mills and factors to consider for mill selection. The key points are:

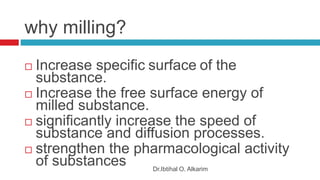

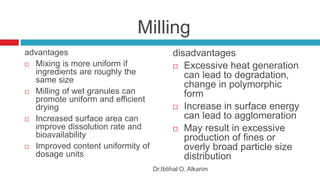

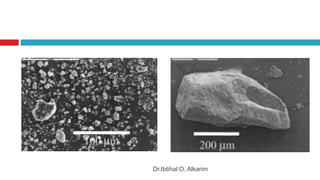

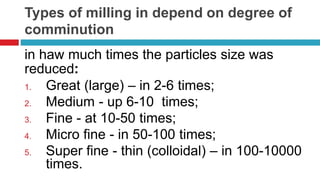

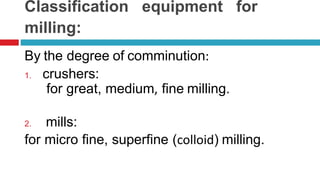

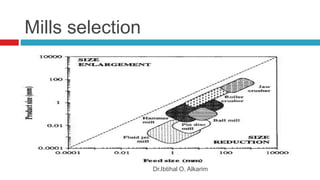

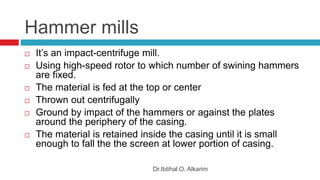

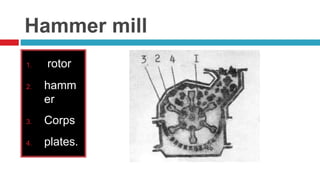

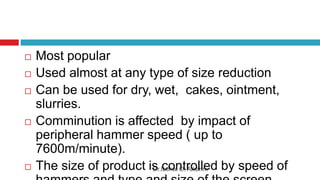

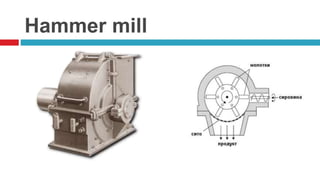

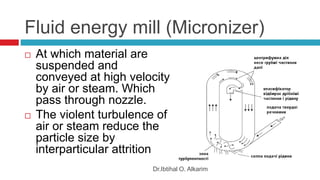

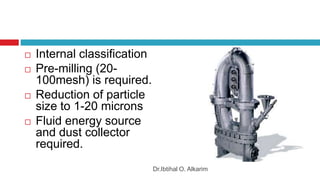

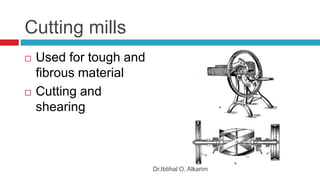

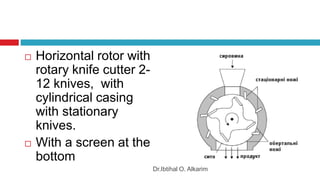

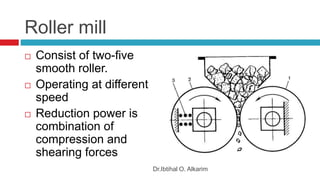

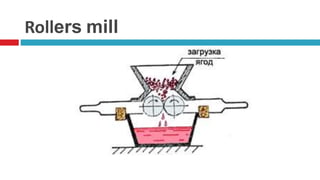

1. Milling is used to reduce particle size for improved dissolution and bioavailability. Common mills include hammer, ball, fluid energy and roller mills.

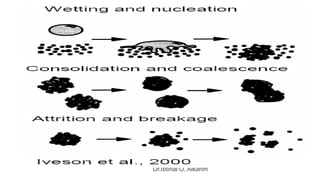

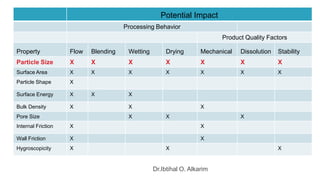

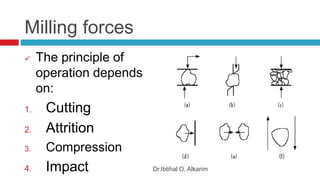

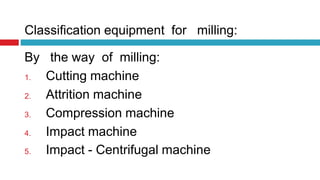

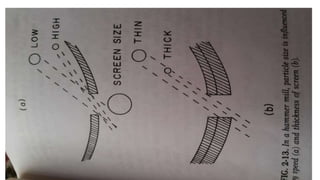

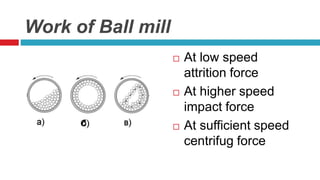

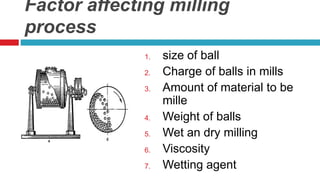

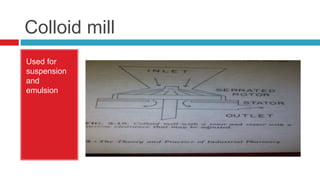

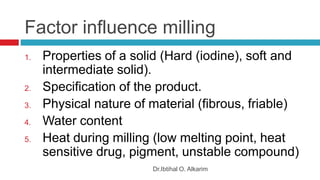

2. Selection depends on the material properties, desired particle size, capacity needs, and whether wet or dry milling is required. Attrition, impact and cutting forces can be applied.

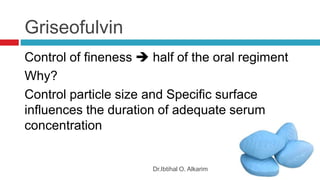

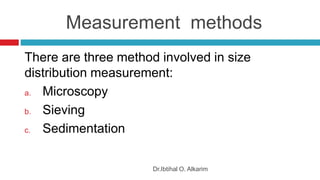

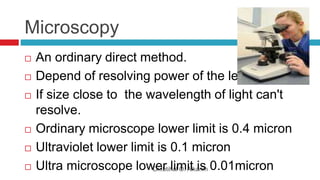

3. Particle size distribution is important and can be measured via microscopy, sieving or sedimentation. Narrow distributions are desirable for consistent drug effects.