This document provides guidance on best practices for log-based shiitake cultivation in the Northeast United States. It was created through a research grant and draws on the expertise of experienced growers. The document covers topics such as acquiring logs, inoculating logs, incubation, forcing, harvesting, storage, marketing, and enterprise viability. It also references ongoing research at Cornell University and a listserv that connects mushroom growers. The goal is to help beginning growers in the region establish successful shiitake operations.

![Spawn Run & Incubation

27

“For perspective I look back in amaze-

ment at my first group of 100 shiitake

logs I did back in the 1980s. I had way

too many projects going on at the time

and these logs were left to their own

fate. In retrospect the laying yard was

crummy ... a hardwood forest that let

too much light and wind in. I never ever

soaked these logs.

“These logs amazingly produced shiita-

kes for eight years, generally one flush

per year before we gave up on them.

Even though this was an impractical

set-up it taught me that the logs are

very resilient.

“NowsinceIamtryingtorelyonaweek-

ly harvest promised out to restaurants, I

try to keep the logs humming along as

best I can without going crazy about

maintaining moisture content. I always

remember my early logs and know that

disaster will not ensue if I just don’t have

the time to water. “

-Steve Sierigk, Hawk Meadow Farm

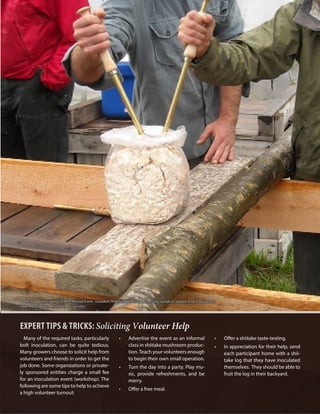

EXPERTTIPS: Putting it all in Perspective weight. [%M = FW-DW/FW]. You could use this to judge the necessity of a

maintenance soak. However this process is very time consuming and is not

often appropriate for commercial enterprises. Moreover, profession electronic

moisture meters designed for the forest products industry are not a reliable

way to determine log moisture content for mushroom logs.

Instead, most experts decide whether or not to initiate a maintenance

soaking based of the age of the log, tree species, weather and laying yard con-

ditions. When deciding for yourself when to perform a maintenance soak,

keep in mind that different wood species seem to retain moisture better than

others. Red oak logs hold their moisture fairly well; bitternut hickory logs

lose water much faster. It’s important to use your personal observations and

intuition in determining when to perform maintenance soakings.

Contamination by Competitive Fungi

Excerpt by Steve Sierigk, Hawk Meadow Farm

Avoiding Contamination

Fungal competitors of your shiitake logs are always an issue even with the

best management. It is impossible to block other wood-inhabiting fungi from

the logs used in outdoor shiitake cultivation, because the spores of competi-

tive fungi are naturally carried in the air. These spores can quickly establish a

new colony when exposed to a suitable substrate under favorable conditions.

However if the growing environment is properly managed, pest fungi should

not present a serious problem.

Good timing of log felling and timely inoculation can help minimize fungal

competitor access to your logs. If logs are felled in late winter or early spring,

fungal competitors are minimized. Keeping logs stacked out of direct sun

and wind will keep internal moisture content of logs high. At the same time,

keeping log surfaces relatively dry is helpful as competitive spores can gain a

foothold. Timely inoculation can also insure that your shiitake is the initial

colonizer of the log, a great reason to get on to inoculation early. The lower

temperatures of early spring also retards the growth of competitive fungi.

There are ideal circumstances and then there is reality; it is not always the

case that we get to inoculate all of our logs in the early spring. It is sometimes

the case that other fungal competitors get a toehold in to some of your logs.

One important factor when inoculating and prepping your logs is to try to

minimize especially the amount of direct strong sunlight that hits your log

surfaces. Especially dark-colored barks can heat up in the sun and destroy

mycelial growth, so take care to not expose your logs to excessive sunlight

especially later in the season. Competitors such as hypoxlyon are favored by

such conditions.

“Growers should be aware of the fungal

competitors that are out there, some ba-

sic ID tools, and ways to minimize their

occurrence. Even if you notice competi-

tive fungi growing on a log, don’t lose

hope; ultimately shiitakes will probably

still hang in there to some degree. Hy-

poxylon seems to be the worst and can

be largely avoided by avoiding excessive

exposure to direct sun for extended pe-

riods.”

-Steve Sierigk, Hawk Meadow Farm

EXPERTTIPS: Fungal Competitors](https://image.slidesharecdn.com/shiitakeguide-150418181704-conversion-gate02/85/Shiitake-guide-27-320.jpg)