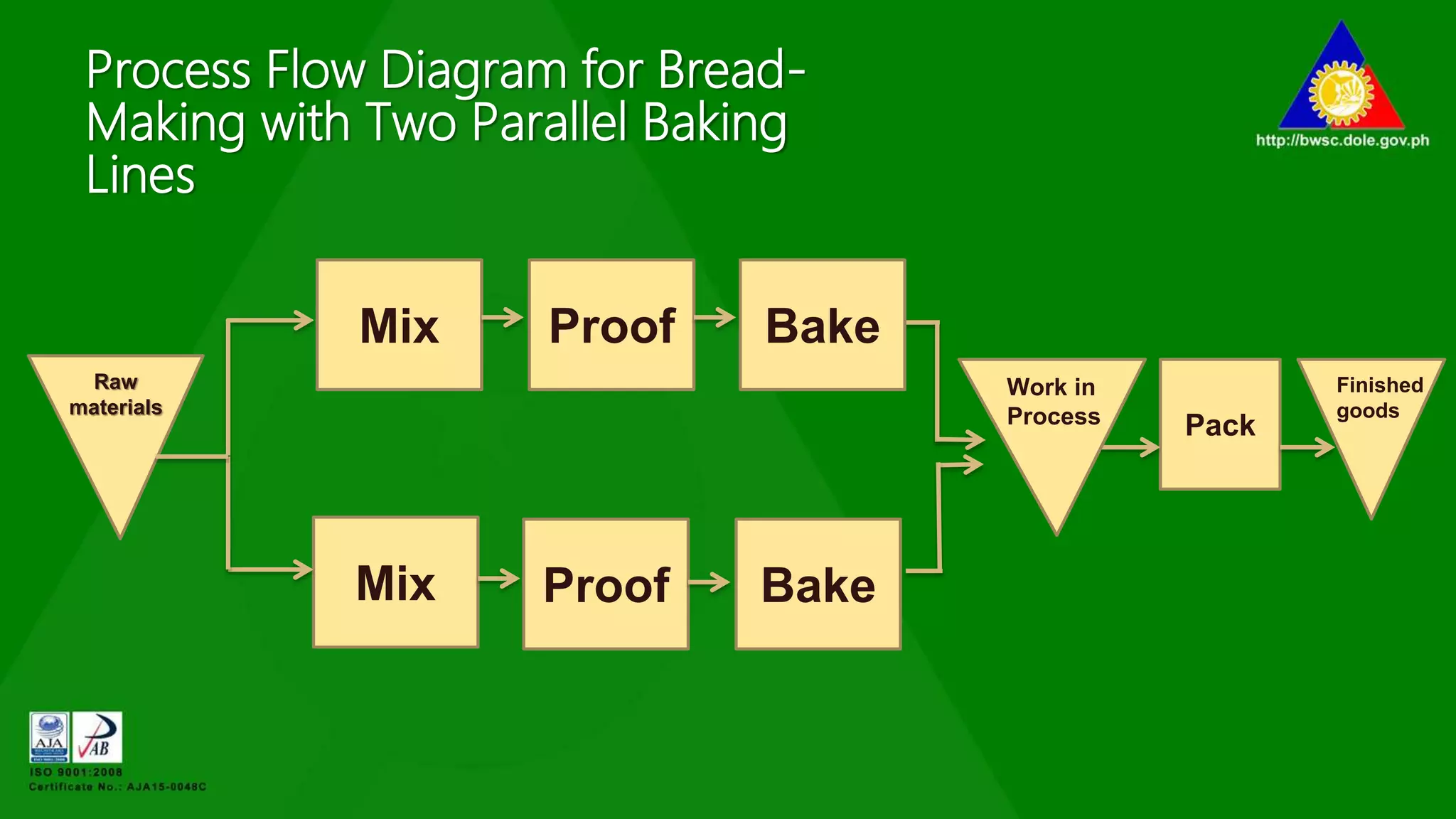

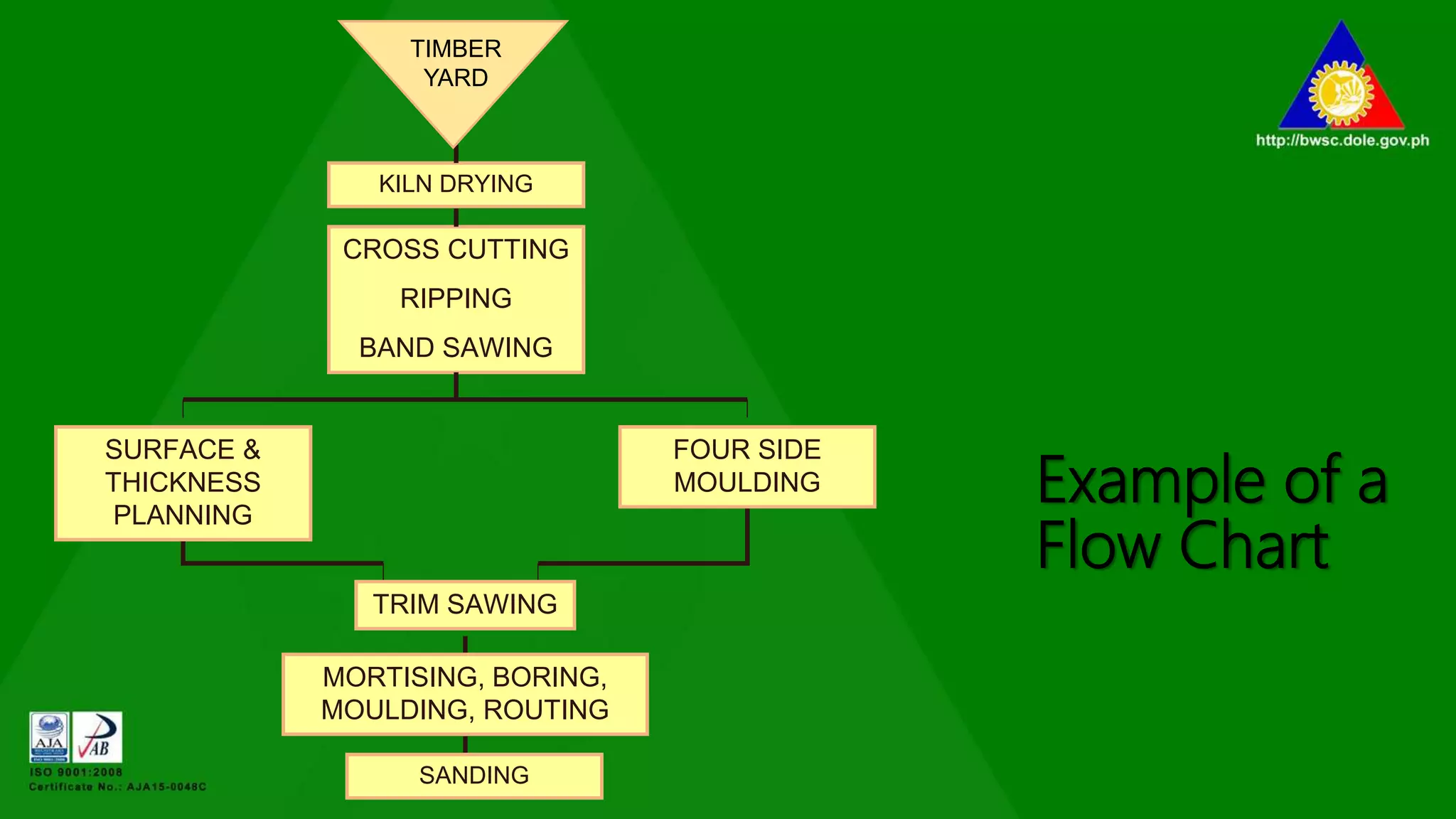

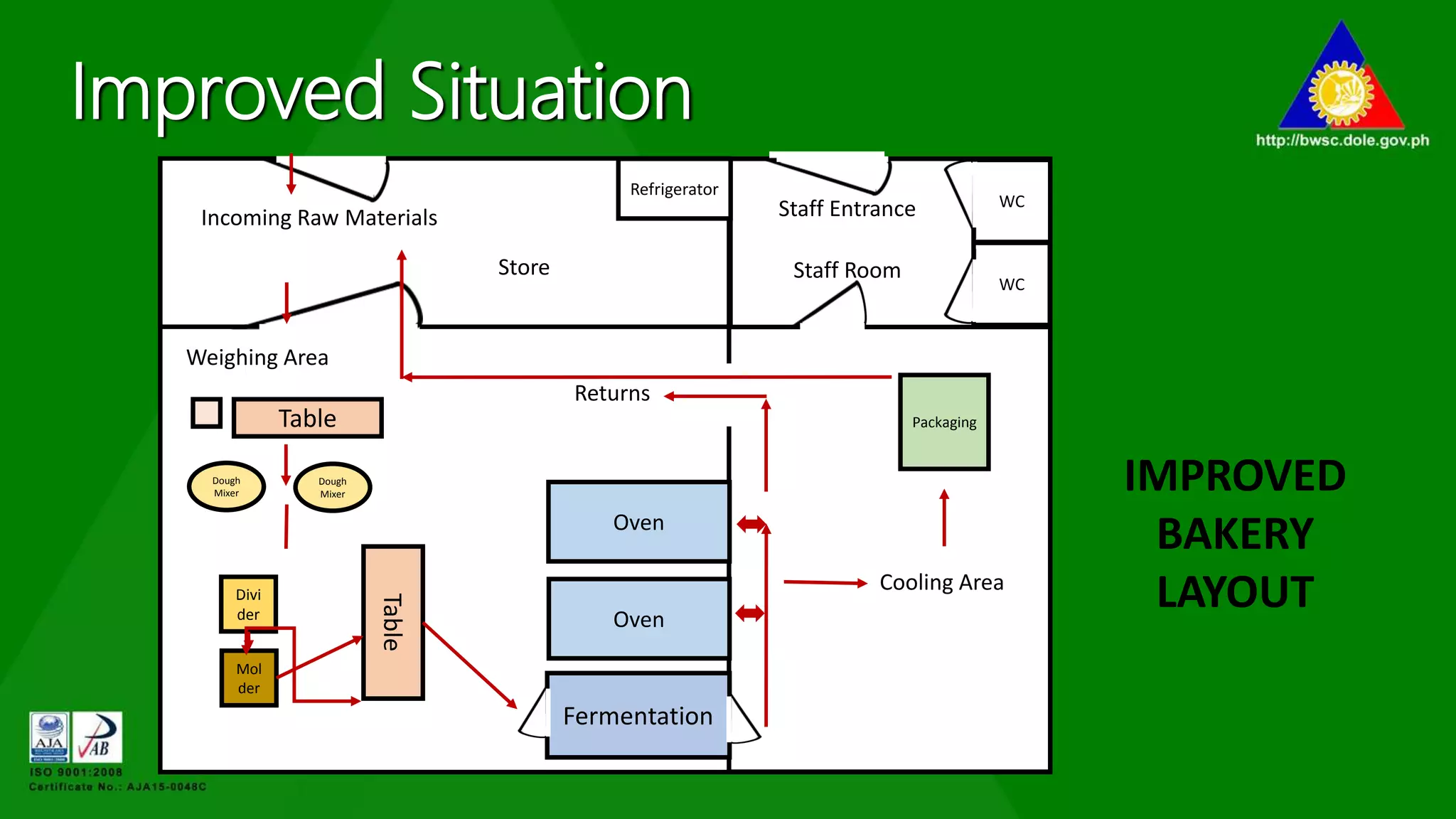

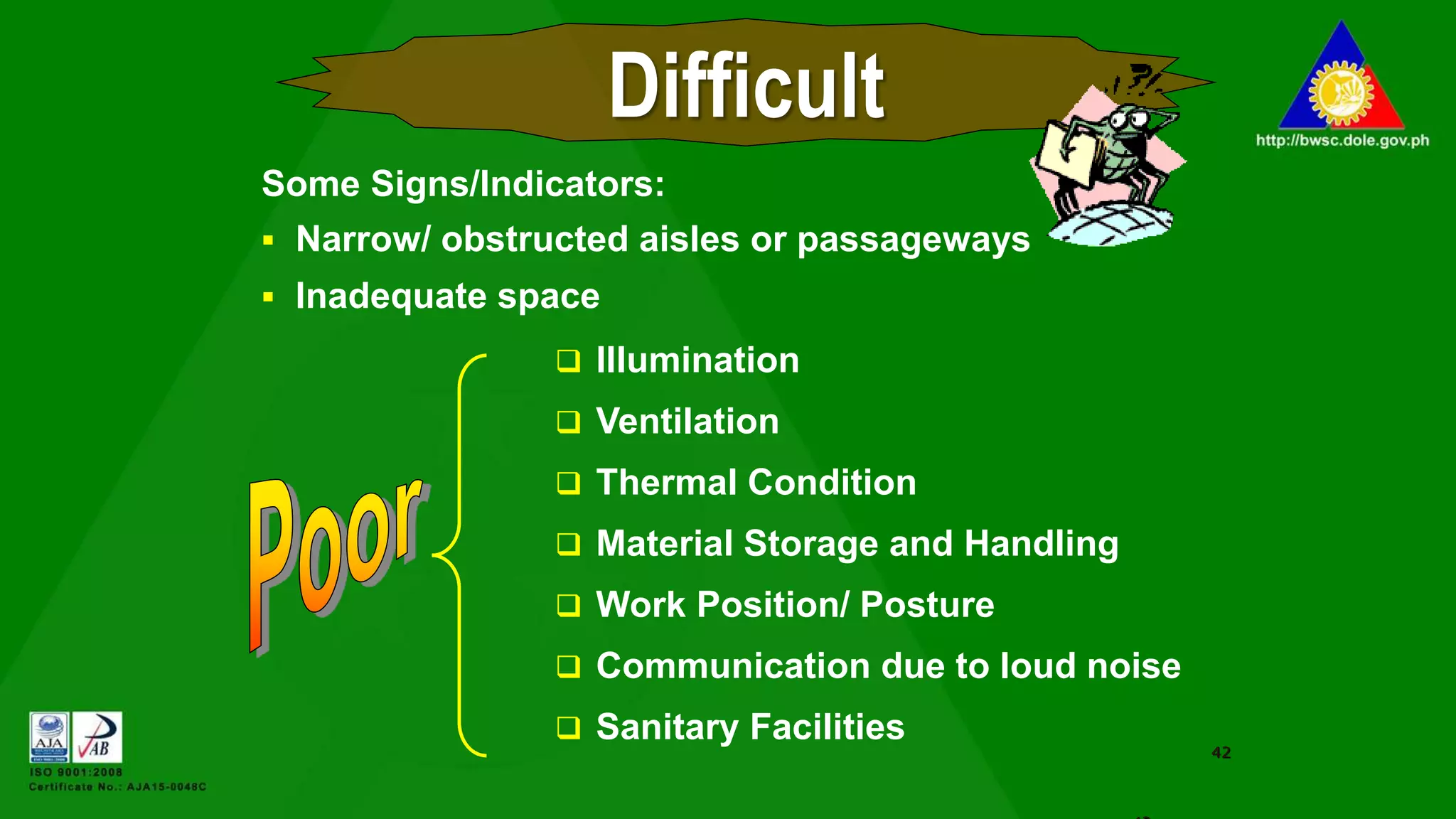

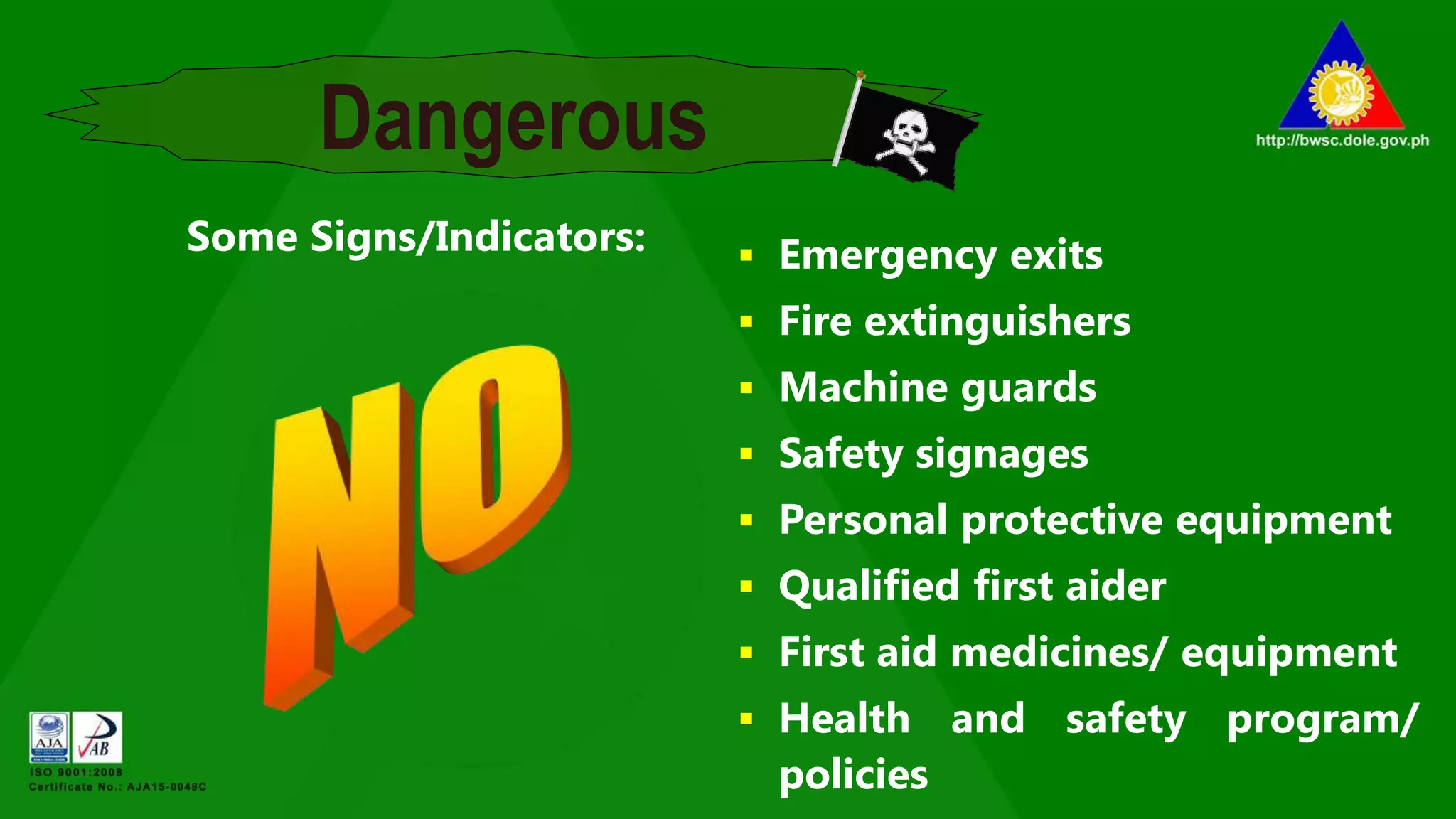

The document provides an overview of production management, emphasizing its role in efficiently producing goods and services while maintaining quality and cost-effectiveness. It discusses key concepts such as work process flow, routing diagrams, work simplification, production costing, and occupational safety and health. Practical exercises are included to demonstrate production management principles through hands-on activities.