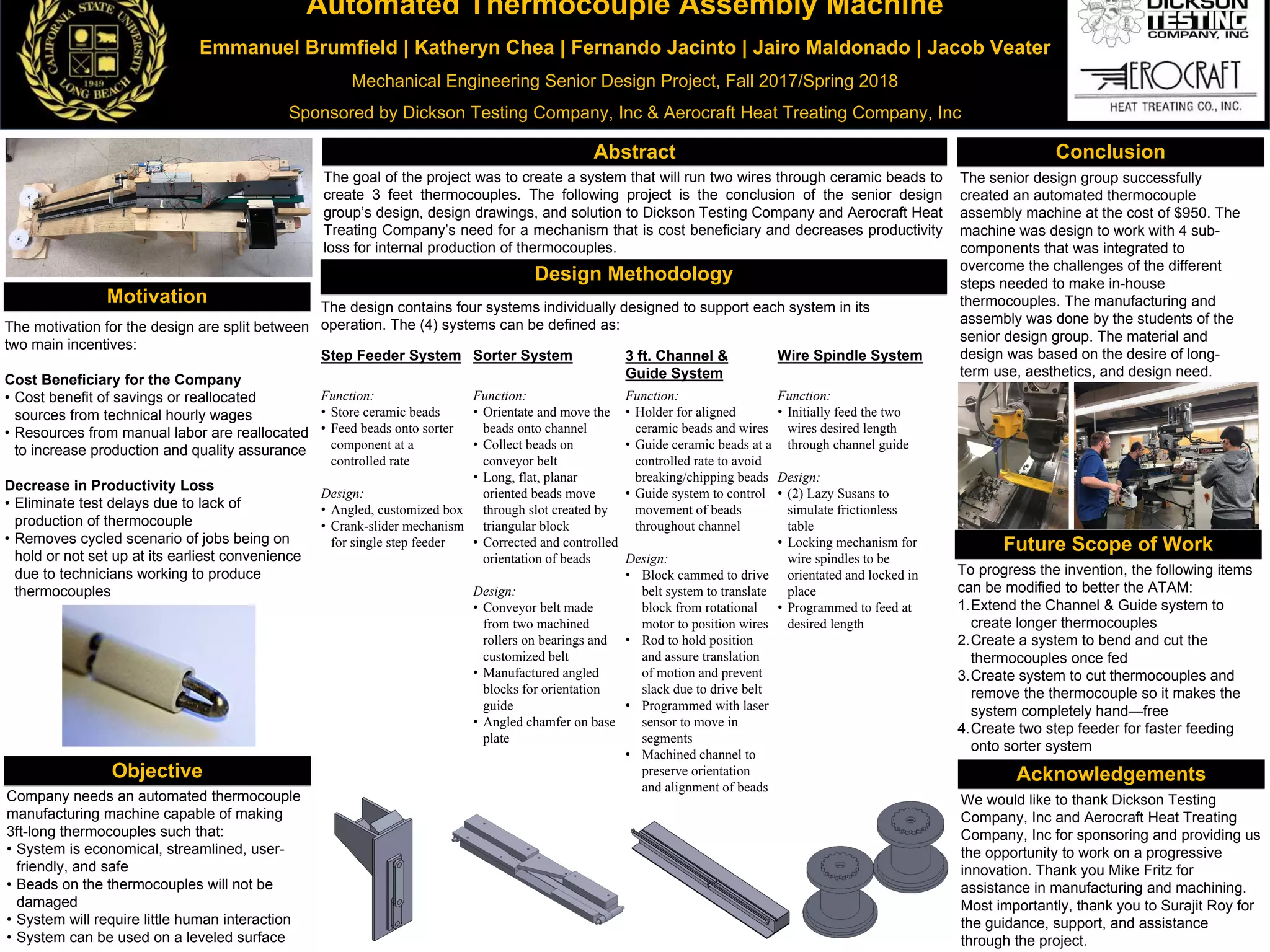

The document describes an automated thermocouple assembly machine designed by a senior design group to address the needs of Dickson Testing Company and Aerocraft Heat Treating Company. The machine feeds ceramic beads onto wires to create 3-foot long thermocouples using four subsystems: a step feeder to store and feed beads, a sorter to orient the beads, a 3-foot channel and guide to move the beads along the wires, and a wire spindle system to feed the wires. The total cost of the machine was $950 and it was designed to complete the thermocouple assembly process with little human interaction in a streamlined and economical manner.