The document is the final report for an automated welding system developed by a senior design team to improve the process of installing PVC roofing membranes. The system uses induction heating to fuse metal plates adhered to insulation to the membrane in a non-destructive manner. The team's prototype aims to semi-automate the plate locating and welding processes to improve job quality, consistency and reduce time compared to existing manual tools. It features a sensor array to locate plates, an induction coil for heating, and integrated systems to automate critical functions while maintaining performance. Testing showed the prototype was able to successfully locate and weld plates meeting strength specifications.

![1

I. Introduction

1.1 Background

In the commercial flat roofing industry, there are a variety of systems that can be used to protect a

roof from the elements. These systems include tar and ballast, expandable foam, and mechanical

attachment. Focused on trying to capture this growing market, the sponsor asked the senior design team to

come up with an innovative solution to address the challenges of mechanical attachment. The process

begins with the fastening of a steel deck onto purling’s that run the length of the roof. Insulation is then

laid on top of this decking. Adhesive-coated metal plates are placed atop the insulation and

fasteners are driven through into the steel decking below. A layer of PVC or TPO membrane is then

placed on the roof, thus hiding the resin coated plates. A device must then be used to not only locate these

plates but also heat the resin in a way which does not destroy the membrane. After heating the plate, a

magnetic heat sink is placed on the plate to cool the resin and complete the adhesion of the membrane to

the plate surface. These layers can be seen in detail in Figure 1 below.

Figure 1: Roof Layers Illustration [1]

In today’s market there are only two systems which perform the task of locating and heating these

metal plates. Both devices utilize induction heating but perform this task with varying accuracy. The

sponsor’s device, for example, will not perform the induction process on fastener plates which are off-

centered from the induction coil whereas the competitor’s device will perform the induction process on

plates inside a much larger induction coil perimeter. Though the sponsor’s tool ensures maximum bond

strength, it exhibits challenges when positioning the induction coil. On the other hand, the other device is

less taxing on the user but can be less consistent when it comes to the overall bond strength of the welds.

Another flaw both of these devices possess is that the user must tarnish (mark) the roof in order to

determine the general plate locations before positioning the device to perform the weld.

1.2 Stakeholders and Needs

The main needs that the senior design team sought to meet, indicated by the sponsor, were finding

plates underneath the membrane, heating the plates without damaging the membrane, and reducing or

eliminating the tedious manual nature of the overall process all while maintaining the accuracy and

quality of the sponsor’s current device. In an effort to capture more of the market, the design team took

into consideration the needs of those who would be using this device on a daily basis. Their main

concerns were user friendliness, durability, and job time savings. Lastly, flat roof building owners were

surveyed for their perspective on creating a new device. The outcome was to minimize the amount of

marking or scuffing that needs to be done to their new roofs. These stakeholders and their needs can be

found more in depth in Table 10 in Appendix B.](https://image.slidesharecdn.com/bf33ab22-7fdc-4be0-981d-17717efcf339-150830155600-lva1-app6892/85/43-Report-Spring-6-320.jpg)

![2

1.3 Mission Statement

Our mission, as a design team, was to improve the mechanical attachment of roofing membrane

by creating a working proof of concept prototype that addresses as many priority one needs as possible. In

the end, this prototype would provide enough evidence to convince the sponsor to further pursue the

project into the next developmental stage.

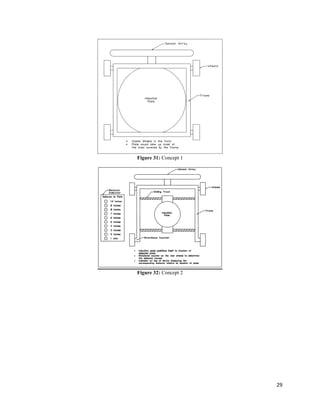

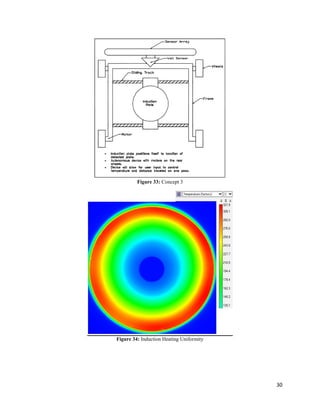

II. Methods

The engineering method implemented for this project was a condensed version of the

methodology outlined by Ulrich and Eppinger [2]. As illustrated by the framework shown in Figure 30

Appendix B, the first step was to define the problem. Next, the design team determined the goals of the

project. Minimally, the design team hoped to develop an improved design of the current product but

ultimately agreed with the sponsor to develop a completely new device. With the ground work laid, in-

depth product research and background information was gathered in order to gain a full understanding of

the technologies available. Stakeholders were then polled for their opinions on what they needed to have

in a commercial flat roofing tool. Each need was matched with a quantifiable specification to ensure the

solution adequately agreed with the stakeholder requirements. Once multiple concepts were developed an

evaluation matrix had been used to determine which concept best coincided with the determined needs

and specifications. Lastly, a virtual and physical prototype was then constructed which would be put

through testing and data recording for performance evaluation.

Engineering principles utilized for this project included; basic thermodynamics, static and

dynamic equations, geometric analysis, computer logic analysis, circuit analysis as well as design, ethics,

and economics. Engineering tools include two and three dimensional CAD software, FEA simulation

packages, computer programming software, as well as various data and documentation organization

software.

III. Design Description

3.1 Specifications

In order to provide a device which addressed the sponsors concerns of accuracy and quality, the

design team worked with the sponsor to outline basic specifications paralleling their current device’s

capabilities. Of the needs which relate to accuracy and quality, the most important are distance from

center, heating temperature, and load strength. The distance from center is refereeing to the distance the

center of the induction coil is away from the center of the membrane plate being heated. A half inch was

determined as a nominal value due to sponsor data and results from thermal image tests performed in the

winter term. At this value, the strength of the bond is still within the acceptable limits but it is not as

strong as when the offset is zero. Though the sponsor’s tool does not perform a weld unless this value is

zero, the competitor’s tool claims that strong adhesion can still be achieved an inch off center. The

heating temperature metric was determined by SFS data which stated that 225 °C was the optimum

temperature for heating. The last specification describes the amount of tensile load a plate membrane

bond can withstand before failure. In order to ensure viable data, the speed of the pull would have to be

set to 2 inches per minute, a standard determined by Factory Mutual (FM). At this speed, the bonded

plates would then have to reach a load of at least 583lbf. If the prototype did not meet the load of the

sponsor’s current device, at the speed specified, then this product would have very little hope of gaining

traction in the industry.

Concerning the customer needs, most of these specifications came from interviews with

contractors who have had experience using the sponsor’s current device. Looking at the time

specifications, most are not concrete numbers but are instead percentages. This was done on purpose due

to the extreme variability which exists on job sites. These variables include user familiarity with the tool,

number of plates on a roof, plate patterns and spacing, and weather. To address durability, the impact and

load values of 50 lbf and 200 lbf were chosen by the design team to mimic an average user kicking,

standing, or falling onto the device. Ergonomics was also a concern as per interviewed users conveyed to

the design team. A 50 pound maximum weight limit, for example, was determined due to the limitation of](https://image.slidesharecdn.com/bf33ab22-7fdc-4be0-981d-17717efcf339-150830155600-lva1-app6892/85/43-Report-Spring-7-320.jpg)

![6

sensor stops detecting metal. At this point in time the linear actuator stops moving and records the value

that the ultrasonic sensor is reading. This ultrasonic reading is the left edge of the vertical center of the

metal plate that needs to be welded. The linear actuator then adds exactly 5.5 centimeters (plate radius) to

the recorded ultrasonic value and moves back to the right until the ultrasonic sensor reading is equal to the

left edge of the plate plus 5.5 cm. The induction coil is now fully centered over the located metal plate

and is ready to perform the weld.

The induction coil is then powered on and remains on for a 10 second interval. This ensures that a

strong sufficient weld is created between the membrane and metal plate. After the welding process has

been completed, the total number of welds is increased by one and the entire process repeats until the total

number of welds is equal to the total number of plates specified by the operator during the initial setup.

An Arduino Mega was chosen to drive the control system for the prototype and the code created to

replicate this logic is shown in Figure 38, Appendix B.

3.5. B Frame

The frame functions as the platform for which all other components come together and forms the

functional prototype. The cross-sectional area of the frame had been estimated to be 17”x22” to fit a 15”

linear actuator to the prototype, offering 10” of lateral translation for the heating coil. The 22” length

enables placement of the front axle, rear drive motors and heating coil housing completely within the

body of the prototype with some excess room for improvement initiatives described in Section 7. It had

been constructed out of 1/8” thick Aluminum 6063-T5 Angle, with structural rigidity and corrosion

resistance in mind [3] due to exposure to elements like water in the flat roofing environment. A Finite

Element Analysis had been performed on the frame, in various loading situations, to insure the material

selection and dimensions would satisfy the stakeholder need of being durable. The first simulation mimics

a 250 lbf person stepping in the center of one of the 22” long aluminum bars. By applying the load in the

center it mitigates the contribution the legs have at dispersing the load and is a better test for finding the

stresses at the welded joints. After running the simulation, the maximum Von Mises (28 ksi) and shear

(16 ksi) stresses occurred between the outer leg connection and the square frame. These results are shown

in Figures 2 and 3.

Figure 2: Von Mises Stresses with Footstep Load Figure 3: Shear Stresses with Footstep Load

Considering the fact that this device needs to be able to be transported, the next two tests were

performed in order to see how someone picking up the device will propagate stress. Constraining one of

the 22” long aluminum bars and applying gravity, the device experienced its greatest stresses on the

inside joint connections between the length and width pieces of the frame. For this scenario the maximum

Von Mises stress was 5.4 ksi and the maximum shear stress was 3.1 ksi. When only constraining one leg

and applying gravity, these stresses decreased to 1.1 ksi and 620 psi. The results can be seen below.](https://image.slidesharecdn.com/bf33ab22-7fdc-4be0-981d-17717efcf339-150830155600-lva1-app6892/85/43-Report-Spring-11-320.jpg)

![7

Figure 4: Von Mises Stresses Holding the Frame Figure 5: Shear Stresses Holding the Frame

Figure 6: Von Mises Stresses Holding One Leg Figure 7: Shear Stresses Holding One Leg

The last simulation mimics a human being pushing near the bottom of one of the legs with 30 lbf

of force. The stresses exhibited in figures 8 and 9 are among the weakest and are 11.6 psi and 6.5 psi.

These maximums occur along the edge where the leg and the square frame meets.

Figure 8: Von Mises Stresses Pushing with 30lbs Figure 9: Shear Stresses Pushing with 30lbs

Comparing the Von Mises and shear stresses to the yield and shear strength properties of

aluminum 6063, which are specified in Table 1, all stresses fall below these critical values except the first

test. The design team felt like this situation was the most uncommon and if these stresses needed to be

addressed that additional braces or bolts could be added to the design to alleviate them. Due to the

importance of being weather resistant, as well as having square 90 degree bends, the design team still

chose aluminum 6063. Lastly, a height clearance of 6” was implemented in the design of the frame to

accommodate for the height of the linear actuator and heating coil housing, while retaining the ability to

adjust the height of the heating coil beneath the prototype.

Table 1: Material Properties [4]

Ultimate Tensile Strength

(psi)

Yield Strength

(psi)

Shear Strength

(psi)

27,000 21,000 17,000

Aluminum 6063-T5](https://image.slidesharecdn.com/bf33ab22-7fdc-4be0-981d-17717efcf339-150830155600-lva1-app6892/85/43-Report-Spring-12-320.jpg)

![8

3.5. C Drivetrain

The vehicle drivetrain was developed based on the proposed design for performance and

functionality. In order to satisfy design constraints, the drivetrain needed to be able to support and move

the maximum projected gross vehicle weight (GVW) of 50 lbs. This weight was based on the allowances

of the roof insulation surface and ability to transport the device to the rooftop. A size wheel diameter of

6” was selected to allow ample ground clearance for the mounted sensors and induction device, as well as

to propel the vehicle over small debris. The front wheels have a maximum load rating of 35lb each,

sufficient for the projected GVW. The front axle, a ½” aluminum shaft, was supported by two pillow

block bearings, which were selected after calculating the manufacture load and velocity specifications

below in Equations 1 and 2 [5].

𝑳𝒐𝒂𝒅 = 𝑷 =

𝑩𝒆𝒂𝒓𝒊𝒏𝒈 𝑳𝒐𝒂𝒅

(𝑫 𝒔𝒉𝒂𝒇𝒕∗𝑩𝒆𝒂𝒓𝒊𝒏𝒈 𝑳𝒆𝒏𝒈𝒕𝒉)

=

𝟒𝟖𝒍𝒃𝒔

(𝟎.𝟓"∗𝟎.𝟔𝟐𝟓")

= 𝟏𝟓𝟑. 𝟔𝒑𝒔𝒊 [Eq. 1]

𝑽𝒆𝒍𝒐𝒄𝒊𝒕𝒚 = 𝑽 = 𝑽 𝒔𝒉𝒂𝒇𝒕 ∗ 𝟎. 𝟐𝟔𝟐 ∗ 𝑫 𝒔𝒉𝒂𝒇𝒕 = 𝟗𝟓𝒓𝒑𝒎 ∗ 𝟎. 𝟐𝟔𝟐 ∗ 𝟎. 𝟓" = 𝟏𝟐. 𝟒𝟓𝒇𝒕/𝒎𝒊𝑛 [Eq. 2]

The selected pillow block bearings were rated at values of P=2000psi and V=1200 ft/min, which

confirm their feasibility for our maximum load and velocity conditions [5]. Below, Figures 10 through 12

are images of the wheels, motor assemblies, and pillow block bearings.

Figure 10: Front Wheel [6] Figure 11: Rear Motor Assembly [7] Figure 12: Pillow Block Bearing [8]

The rear wheels were designed to have two DC motors, one on each side, to propel the vehicle.

The projected maximum GVW was used once again, as well as the maximum desired speed and wheel

diameter to determine the required motor specifications. Equations 3 through 5 were used to calculate the

forces due to maximum roof gradient angle, rolling resistance due to surface friction, and acceleration [9].

The maximum roof gradient and surface friction, the highest approximated coefficient occurring between

the membrane and tire, were utilized for the most severe roof conditions that the device may encounter

[10].

𝑮𝒓𝒂𝒅𝒆 𝑹𝒆𝒔𝒊𝒔𝒕𝒂𝒏𝒄𝒆 = 𝑮𝑹 = 𝑾 𝑮𝒓𝒐𝒔𝒔 ∗ 𝐬𝐢𝐧(𝑮𝒓𝒂𝒅𝒆 𝑨𝒏𝒈𝒍𝒆) = 𝟓𝟎𝒍𝒃𝒔 ∗ 𝐬𝐢 𝐧(𝟏𝟒°) = 𝟏𝟐. 𝟎𝟗 𝒍𝒃𝒔 [Eq. 3]

𝑹𝒐𝒍𝒍𝒊𝒏𝒈 𝑹𝒆𝒔𝒊𝒔𝒕𝒂𝒏𝒄𝒆 = 𝑹𝑹 = 𝑾 𝑮𝒓𝒐𝒔𝒔 ∗ 𝐂 𝑭𝒓𝒊𝒄𝒕𝒊𝒐𝒏 = 𝟓𝟎𝒍𝒃𝒔 ∗ 𝟎. 𝟎𝟒 = 𝟐. 𝟎𝟎 𝒍𝒃𝒔 [Eq. 4]

𝑻𝒐𝒕𝒂𝒍 𝑻𝒓𝒂𝒄𝒕𝒊𝒗𝒆 𝑬𝒇𝒇𝒐𝒓𝒕 = 𝑻𝑻𝑬 = 𝑮𝑹 + 𝑹𝑹 = 𝟏𝟒. 𝟎𝟗 𝒍𝒃𝒔 [Eq. 5]

Once the total force needed to propel the vehicle, or TTE, was determined, the required torque

was calculated using Equation 6 and additional variables of wheel radius and a general resistance factor

from the gear drive system [9].

𝑻𝒐𝒓𝒒𝒖𝒆 𝑹𝒆𝒒𝒖𝒊𝒓𝒆𝒅 = 𝑻𝑻𝑬 ∗ 𝑹 𝑹𝒂𝒅𝒊𝒖𝒔 ∗ 𝑹𝑭 𝑹𝒆𝒔𝒊𝒔𝒕𝒂𝒏𝒄𝒆 𝟏𝟒. 𝟎𝟗𝒍𝒃𝒔 ∗ 𝟑" ∗ 𝟏. 𝟏𝟐𝟓 = 𝟒𝟓. 𝟓𝟓𝒍𝒃 ∗ 𝒊𝒏 [Eq. 6]

The selected motors came equipped with mounting brackets, wheels, tires, and encoders. The

maximum payload rating for both motors is 60lbs, and the maximum torque output is 85 in-lbs each,](https://image.slidesharecdn.com/bf33ab22-7fdc-4be0-981d-17717efcf339-150830155600-lva1-app6892/85/43-Report-Spring-13-320.jpg)

![9

therefore a total torque of 170 in-lbs which is within our minimum requirements of 45.55in-lbs. The kit

included encoders to track the rotation of each wheel with 144 positions allowing linear accuracy within

0.14”. The motors also operate up to 95 rpm using a 12V and 8A power source, however 31.8 RPM will

be sufficient for our maximum target vehicle speed of 25 ft/min, as per Equation 7 [7].

𝑹𝑷𝑴 𝑻𝒂𝒓𝒈𝒆𝒕 = 𝑽 𝑺𝒉𝒂𝒇𝒕 =

𝑽 𝑻𝒂𝒓𝒈𝒆𝒕

𝟎.𝟐𝟔𝟐∗𝑫 𝒔𝒉𝒂𝒇𝒕

=

𝟐𝟓 𝒇𝒕/𝒎𝒊𝒏

𝟎.𝟐𝟔𝟐∗𝟑"

= 𝟑𝟏. 𝟖 𝑹𝑷𝑴 [Eq. 7]

3.5. D Sensors

A very important part of the team’s design is the front mounted sensor array used for detecting

the metal plates beneath the membrane. Multiple sensors were considered and researched before the team

decided to pursue an inductive proximity sensor. These sensors use an oscillator driven coil to create an

electromagnetic field and when a metallic object comes in close contact to the face of the sensor, the

electromagnetic field decreases and the switch closes [11]. These sensors are relatively inexpensive, yet

are used in a wide variety of applications and are very accurate and reliable. The team chose a digital

sensor manufactured by Automation Direct, Model No. AT1-AN-3A. This model is shielded meaning the

sensor can only detect metal directly in front of the device [11]. It can operate from a distance of up to

15mm away from the metal object, it has a diameter of 30mm, and it has an NPN-normally open

configuration [11]. NPN configuration simply means that when no metal has been detected the sensor will

output slightly less than the voltage value that is being input, and when metal has been detected the output

will be connected to ground and read zero volts. This configuration was chosen due to the fact that no

stray voltage would cause a faulty or inaccurate reading since the “metal detected” state is zero volts.

Figure 13 displays the physical sensor and Figure 14 displays the NPN configuration in more detail.

Figure 13: Proximity Sensor AT1-AN-3A [11] Figure 14: NPN Output Configuration [11]

3.5. E Sensor Array

The function of the sensor array is to detect the location of the metal fastening plates that lie

under the roofing membrane without causing damage to the membrane itself. The array was designed to

prevent the metal fastening plates from going undetected when passing between the physical outer limits

of the array. This is done by spacing the individual sensors, as seen in Appendix B Figure 36, at

calculated intervals to allow for the fastening hex nuts on the sensors to be tightened without interference,

to have the minimal number of sensors required for accurate readings, and allow for the position of the

plates to be determined based on the layout of the sensors in relation to one another. The sensor diameter

is 30mm and the hex nut minor diameter is 36mm. The hex nut major diameter was determined from the

minor diameter of the hex nut and the geometric properties of a standard hexagon.

𝑫𝒊𝒂𝒎𝒆𝒕𝒆𝒓 𝒎𝒂𝒋𝒐𝒓 = 𝑫𝒊𝒂𝒎𝒆𝒕𝒆𝒓 𝒎𝒂𝒋𝒐𝒓 ∗ 𝐭𝐚𝐧(𝟑𝟎°) +

𝑯𝒆𝒙 𝑵𝒖𝒕 𝑴𝒊𝒏𝒐𝒓 𝑫𝒊𝒂𝒎𝒆𝒕𝒆𝒓

𝟐∗𝐜𝐨𝐬(𝟑𝟎°)

= 𝟏. 𝟔𝟑𝟔𝟓𝟖 𝐢𝐧 [EQ. 8]

Based on these criteria, the frame of the array was to be the same width as the frame of the

overall device and the sensors would occupy the same width as the maximum range of the linear actuator,

10 inches. The outer sensors need to have their centers coincidental to the outer most range of the linear

actuator. This meant that the number of sensors needed is dictated by the following equation with the

sensors being placed as close to one another as possible for better sensing resolution.](https://image.slidesharecdn.com/bf33ab22-7fdc-4be0-981d-17717efcf339-150830155600-lva1-app6892/85/43-Report-Spring-14-320.jpg)

![10

𝑵𝒖𝒎𝒃𝒆𝒓 𝒐𝒇 𝒔𝒆𝒏𝒔𝒐𝒓𝒔 =

𝑨𝒄𝒕𝒖𝒂𝒕𝒐𝒓 𝑹𝒂𝒏𝒈𝒆

𝑯𝒆𝒙 𝑵𝒖𝒕 𝑴𝒂𝒋𝒐𝒓 𝑫𝒊𝒂𝒎𝒆𝒕𝒆𝒓

+ 𝟏 = 𝟕. 𝟏𝟏 ≈ 𝟕 [EQ. 9]

The “+1” term is to allow for the outer sensors to be centered at the range of the actuator. This

shows that seven is the ideal number of sensors. Between each sensor is half an inch of region that cannot

sense metallic objects but since the plates being located are three inches in diameter this does not affect

the ability of the array.

3.5. F Induction Coil

The hot plate would serve as a critical component to the function of the prototype, delivering

electrically induced magnetic fields to the fastener plate which in turn generate heat due to the materials

resistance to the flow of induced current. This then results in a permanent weld, or bond, between the

material and fastener plate. The design team had initially set out to design a job-specialized hot plate from

scratch, however it was quickly realized that it would have been a separate design challenge in itself and

would stray from the scope of the project. Instead, research had been conducted to select a hot plate that

would best realize the mission goal and thus reducing job time, weld error, and manpower. A portable

induction cooktop had been selected based on 2 characteristics, namely the controllability of the device

and its maximum power output at 1800W. Controllability can be further broken down into 3 key aspects,

utilized in the design of the prototype deliverable. These include the ability to enable the device,

switching it on or off, regulating the power level, 0W to 1800W, and being able to strike the device into

oscillation, otherwise initiating the inductive heating process. All 3 of these aspects are handled by the

cooktops onboard computer, with the logic circuitry having already been developed for simple I/O

(Input/Output) and power regulation by Pulse Width Modulation (PWM), therefore making it simple to

commandeer. The connections to the cooktop controller had then been bypassed and distributed to an

Arduino microcontroller board for implementation of a custom control algorithm. The maximum power

output of 1800W had been dependent on the hotplate model itself, due to salvaging components which

would be included in the design of the overall prototype. This maximum of the cooktop is ideal because it

translates to a peak work-piece temperature of approximately 232°C [12] just slightly above the ideal

welding temperature of the fastener plate and membrane. Note that ideal welding temperature had been

pre-determined, through research performed by the project sponsor, to be 225°C [13] making it just

within the capabilities of the cooktop.

In order to calculate a specific heating time, an approximate value can be obtained using

Equation 10 for specific heat capacity below combined with knowledge of the work coils power output.

Mass of the fastener plate is approximated to be ½ lb.

𝒅𝑸 = 𝒎𝑪 𝒑∆𝑻 = 𝒎𝑪 𝒑(𝑻 𝟐 − 𝑻 𝟏) [Eq. 10]

Table 2: Variables Definitions

Sample Calculations 𝒅𝑸 = (. 𝟏𝟏𝟑)(𝟎. 𝟒𝟗)(𝟐𝟐𝟓 − 𝟐𝟎) = 𝟏𝟏. 𝟑𝟓𝑲𝑱

𝑷 =

𝒅𝑸

𝒕

→ 𝒕 =

𝒅𝑸

𝑷

=

𝟏𝟏. 𝟑𝟓

𝟏𝟖𝟎𝟎

= 𝟔. 𝟑𝟎𝟓𝒔

Quantity Description Value

dQ(KJ) Required Energy to Achieve Temperature Differential 22.782

mass (kg) Fastener Plate Mass 0.113

Cp (KJ/kg) Carbon Steel Specific Heating, Constant Pressure 0.49

T1 (⁰C) Ambient, Initial Temperature 20

T2 (⁰C) Final Temperature 225

Power (W) Power Output 1800](https://image.slidesharecdn.com/bf33ab22-7fdc-4be0-981d-17717efcf339-150830155600-lva1-app6892/85/43-Report-Spring-15-320.jpg)

![11

Equation 10 can also be used as necessary for later implementation in the prototype design for

accommodating various surface temperatures. This initial temperature parameter could then be modified

in the controller program to compensate for warmer or cooler days. Further testing had been conducted to

characterize the heating pattern of the metal plates as well as record equilibrium temperatures with which

various power levels had been capable of achieving. This information was used to develop an ideal

heating cycle which would best reach the steady state temperature of 225°C, and then maintain steady

state, discussed further in Section 3.3.

The physical construction of the prototypes heating mechanism began with extraction of the

heating coil and printed circuit board containing the electrical circuit for necessary functionality. The

printed circuit board would essentially be separated from its compact design in the cooktop to a

completely isolated area on the top of the prototype for protection from the elements. In contrast to the

electrical components, the coil needed its own specialized housing, shown below in Figure 15. The

housing material is made of an electrically insulating Noryl PPO selected for its material properties. It is

rated for temperatures up to 220°F (104°C) and temperatures as low as -40°F (-40°C), making it suitable

to withstand both the coldest and hottest days, as well as indirect heating from the fastener plates. It also

provides moisture resistance and high impact tolerance [14], making it ideal for outdoor applications.

Lastly, the material is electrically insulating keeping the high current, being passed through the heating

coil, contained and safe for operation to on-site personnel. An order of 3/8” thick, 12”x12” material had

been ordered and machined into the housing configuration below. The housing had also been machined

with two holes for the electrical leads to pass through which will later be completely sealed with silicon or

rubber grommets. Finally, the coil was mounted to the linear actuator on the interior of the prototype so

that it may translate laterally to the location of fastener plates beneath the membrane.

Figure 15: Coil Housing

3.5. G Induction Coil Sensor

The overall accuracy of the positioning of the induction coil based on the front sensor array alone

proved to be much lower than the team had initially calculated, so an important addition was designed to

create higher accuracy. This new addition consisted of another Automation Direct Model No. AT1-AN-

3A, NPN inductive proximity sensor placed at the center of the induction coil. The induction coil being

utilized for the prototype had an existing hole in the center of it with a diameter of 35mm, 5 mm larger

than the diameter of the sensor. The sensor was placed at the center of the coil with offset spacing of

approximately 5mm behind the induction coil. This offset spacing was incorporated so that the induction

coil’s magnetic field would not interfere with the operation of the sensor. This single center sensor would

then be utilized to map the outside points of the detected metal plate, and use the points to calculate the

center of the plate and relay that information to the linear actuator and motors of the prototype to position

itself accordingly. Due to the addition of this sensor, the devices detection accuracy was calculated to be

74%. This measurement takes into account the 0.2in tolerance of the ultrasonic sensor, and the 0.14in

tolerance of the motor encoders, to find the difference of area overlay of the heating coil and metal plate.

More information on this overall process is discussed in the Logic Design section of the Detailed Design

Section.](https://image.slidesharecdn.com/bf33ab22-7fdc-4be0-981d-17717efcf339-150830155600-lva1-app6892/85/43-Report-Spring-16-320.jpg)

![12

3.5. H Linear Actuator & Ultrasonic Sensor

Since it was decided that the device was to follow a linear path for simplicity, it would need a

way to position the induction coil assembly in order to match the position of the plates as they are

detected by the sensor array. This required some sort of linear translating device. A few early ideas were

to use a motorized pulley design, but the predicted issues were cable/belt slippage or motor coasting that

would affect the accuracy of the position of the coil assembly. The strength of a system like this was also

under question. The method decided on by the project group was to use a system that utilized a motorized

power screw. This would be a robust and accurate solution to allow for linear translation of the coil

assembly. The linear actuator being used was chosen since it was the correct dimension and used a

common voltage and amperage. The chosen linear actuator was manufactured by Firgelli Automation and

has a linear span of 15”. This actuator, however, does not have any kind of encoder that allows for the

position of the actuator to be communicated or recorded to the microprocessor. The addition of an

ultrasonic sensor was chosen by the team to monitor, record, and adjust the physical position of the linear

actuator. The ultrasonic sensor is produced by Parallax and is called the PING Ultrasonic Distance

Sensor. A bracket was constructed out of left over aluminum from the frame to work in connection with

the ultrasonic to record and modify the distance of the linear actuator. Figure 16 displays the ultrasonic

sensor and Table 4 displays the relevant specifications on the sensor. The weight of the coil assembly is

also calculated to be significantly less than the limitations of the actuator shown in Table 3.

Table 3: Linear Actuator Parameters [16]

Table 4: Ultrasonic Sensor Specifications [17]

Figure 16: Picture of Ultrasonic Sensor [17]

3.5. I Pressure Roller

The sponsor’s current product required heat-dissipating magnets to be placed on top of the

membrane after each plate was welded. In order to compliment this feature on the prototype, a rear

mounted roller was designed and constructed. The roller’s purpose was to apply a steady pressure to the

membrane as the prototype rolled past a welded plate. This would eliminate any air gap between the plate

and membrane ensuring a close bond to the plate. Brackets were designed on the rear legs of the frame,

those of which utilized two rotating arms, positioned at approximately 45° from the horizontal. In order to

calculate the spring constant needed to apply the desired downward pressure on the roller, the bracket and

arm dimensions, roller diameter, and weight of the prototype were used with Figure 17 and Equation 11

below. The spring utilized on the prototype had a spring rate of 9.3 lbs/in, therefore it would be able to

supply approximately 5lbs of pressure downward to the membrane.

Parameter Value

Linear Rate 2 in/s

Static Force 70 lbf

Dynamic Force 30 lbf

Specification Value

Operating Voltage 5 VDC

Range 2cm to 3m

Communication Positive TTL Pulse](https://image.slidesharecdn.com/bf33ab22-7fdc-4be0-981d-17717efcf339-150830155600-lva1-app6892/85/43-Report-Spring-17-320.jpg)

![13

𝒌 =

𝑭

𝒙

=

𝟓𝒍𝒃𝒔

𝟎.𝟓"

~𝟏𝟎𝒍𝒃𝒔/𝒊𝒏 [Eq. 11]

Figure 17: Pressure Roller Drawing

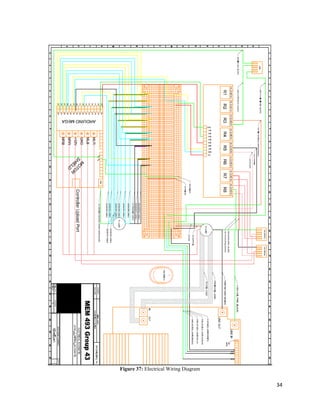

3.5. J Control System

Research was performed to determine the controller needed to drive the control system for the

prototype. Some of the topics considered when conducting the controller research included operating

voltage, number of input/output pins, flash memory, SRAM and clock speed. The Arduino platform was

chosen due to the fact that Arduino’s products are rather inexpensive, and it is an open-source electronic

prototyping platform. There is a vast amount of example projects and sketches available for use along

with a great amount of support for both design and troubleshooting related issues. The Arduino Mega

2560 was chosen as the physical controller. The Mega 2560 has a standard operating voltage of 5 volts,

54 digital input/output pins, 16 analog input pins, and a clock speed of 16 MHz which are all values that

theoretically match the needs of the physical prototype [15]. Table 5 summarizes the important

information pertaining to the overall performance of the Mega 2560. The team estimated approximately

20 input/output pins would be needed for most of the prototype’s components including the sensors,

linear actuator, and induction coil.

The motors needed to drive the prototype were separately considered from the other components

as an h-bridge as well as other electrical components would be needed to gain full control of the motors.

An Arduino compatible motor shield was chosen to be used for the prototype as the shield contains all of

the necessary hardware to fully control the speed, direction and faults of the motors. The motors chosen

for the project operate at a higher voltage and current level, specifically 12 volts and up to 8+ amps for

full operation. Thus, the Pololu Dual VNH5019 Motor Driver Shield was selected as it has the capability

to drive motors rated for 5.5 to 24 volts, and up to 12 amps [18]. The shield allows for easy control as it

also comes with an Arduino library specifically for controlling speed, brakes, and direction. The selected

motor shield utilizes 8 digital pins and 2 analog pins, meaning 46 digital pins and 14 analog pins remain

for other selected components. A relay board was utilized for proper functionality of the linear actuator

and induction hotplate. This allowed the induction hotplate to be powered on or off, and the linear

actuator to be adjusted in either direction. All of the various components were connected and soldered to

create a reliable control system. An electrical project bow was purchased to house all of the various

wiring and connections, and three fans were installed to ensure that all of the components maintained an

appropriate temperature.

Table 5: Summary of the Arduino Mega 2560 [15]

Controller Attribute Value

Operating Voltage 5 V

Digital I/O Pins 54 (15 for PWM)

Analog Input Pins 16

DC Current per I/O pin 40 mA

Flash Memory 256 KB

SRAM 8 KB

Clock Speed 16 MHz](https://image.slidesharecdn.com/bf33ab22-7fdc-4be0-981d-17717efcf339-150830155600-lva1-app6892/85/43-Report-Spring-18-320.jpg)

![15

The core objectives of the test had been to record the total job duration from an un-readied

position to completion of the final weld, record the time from weld to weld, and then test the weld

strength using a tensile testing machine. Results from the design team’s device were then compared to the

performance of the sponsor’s current device. Figure 23 illustrates the prototype traversing the test section

with magnets placed atop the already heated plates. Figure 24 illustrates the tensile test setup from which

all weld strength data had been derived.

Figure 23: Prototype Executing Test Figure 24: Pull Test Setup

A series of 6 weld duration tests had been executed prior to the main testing mentioned

previously, which would serve to optimize the devices welding potential. The design team now had

access to the tensile testing machine, and could therefore determine the strength results of various heating

durations. It had been known from thermal tests conducted in the winter term that the plate had been able

to reach the optimal temperature of 225 ℃ [13] in 6 seconds however it was unknown if this time was

ideal to tell if the adhesive coating across the plates surface had been thoroughly bonded with membrane.

Therefore, bond strength had been tested with a heat time of 6s, 7s, 8s, 9s, 10s and 12s respectively.

Results had shown that 6 seconds had hardly melted the adhesive coating, the plate retaining its pink color

shown in Figure 25, while 12 seconds had thoroughly burned the coating away, illustrated in Figure 27.

The burning is detrimental to the strength of a weld just as much as not welding the plate thoroughly

enough. Of the remaining test results, the 10s heating time had proven to show the most promise. Figure

26 shows the weld quality of a 10s heating duration while Table W shows the tensile strength achieved by

each heating time. Notice the difference between the 6s duration and 10s duration. The 6s duration

illustrates a weld failure, while the 10s duration shows a material failure.

Table 6: Various Heating Durations Quantitative and Qualitative Results

Heat Time (s) Plate Appearance Membrane Appearance Weld Strength (lbf)

6 NA NA 332.59

7 NA NA 283.49

8 NA NA 520.47

9 NA Rubber slightly melted around welded edges 468.05

10 Slight discoloraion around welded edges Rubber slightly melted around welded edges 582.25

12 Resin burnt off around welded edges Rubber melted around welded edges 619.28](https://image.slidesharecdn.com/bf33ab22-7fdc-4be0-981d-17717efcf339-150830155600-lva1-app6892/85/43-Report-Spring-20-320.jpg)

![22

IX. References

[1] “Mechanical Fastening Systems for Flat Roofs.” SFSintec.biz. SFS Intec, 6 Aug. 2013. Web. 23 Nov. 2014.

http://sfsintec.biz/en/web/industry_solutions/construction/flat_roof/flat_roofing.html

[2] Eppinger, Steven D., and Browning, Tyson R.. Engineering Systems : Design Structure Matrix Methods and

Applications. Cambridge, MA, USA: MIT Press, 2012. ProQuest ebrary. Web. 23 November 2014.

[3] Metalsdepot.com, 'MetalsDepot® - Buy Aluminum Angle 6063 Online', 2015. [Online]. Available:

http://www.metalsdepot.com/products/alum2.phtml?page=aangle&LimAcc=%20&aident. [Accessed: 25- Feb-

2015].

[4] Asm.matweb.com, 'ASM Material Data Sheet', 2015. [Online]. Available:

http://asm.matweb.com/search/SpecificMaterial.asp?bassnum=MA6063T5. [Accessed: 27- Feb- 2015].

[5] Mcmaster.com, 'McMaster-Carr', 2015. [Online]. Available: http://www.mcmaster.com/#about-sleeve-

bearings/=w2kjjm. [Accessed: 25- Feb- 2015].

[6] Lowes.com, 'Shop Arnold 6-in x 1-1/2-in Plastic Wheel at Lowes.com', 2015. [Online]. Available:

http://www.lowes.com/pd_543181-442-490-320-

0002_4294612675__?productId=50119663&Ns=p_product_qty_sales_dollar|1&pl=1¤tURL=%3FNs%3Dp_

product_qty_sales_dollar%7C1&facetInfo. [Accessed: 25- Feb- 2015].

[7] Parallax.com, 'Motor Mount & Wheel Kit - Aluminum', 2015. [Online]. Available:

http://www.parallax.com/product/28962. [Accessed: 25- Feb- 2015].

[8] Mcmaster.com, 'McMaster-Carr', 2015. [Online]. Available: http://www.mcmaster.com/#standard-plummer-

block-mounted-bearings/=w56aod. [Accessed: 25- Feb- 2015].

[9] Whitedriveproducts.com, 'WHITE DRIVE PRODUCTS, INC.', 2015. [Online]. Available:

http://www.whitedriveproducts.com/. [Accessed: 25- Feb- 2015].

[10] Metalconstruction.org, 'Low Slope Roofs', 2015. [Online]. Available:

http://www.metalconstruction.org/index.php/applications/low-slope-roofs. [Accessed: 1- Mar- 2015].

[11] Automationdirect.com, 'AT1-AN-3A | 30mm Inductive Proximity Sensor (proximity switch): NPN, 15mm

range', 2015. [Online]. Available: http://www.automationdirect.com/adc/Shopping/Catalog/Sensors_-z-

_Encoders/Inductive_Proximity_Sensors_-z-

_Proximity_Switches/30mm_Round_Industrial_Automation/Extended_Sensing_Distance_(30mm)/AT1-AN-3A.

[Accessed: 25- Feb- 2015].

[12] Product Data Sheet, Max Burton Deluxe Induction Cooktop, 1st ed. Gardnerville, NV: Aervoe Industries Inc.,

2015, pp. 1-2.

[13] SFS intec Ltd, 'Investigation of the Inductive Heating Behavior of Plates for Roof Mounting', Christian

Lammel, Ismaning, Germany, 2011.

[14] Mcmaster.com, 'McMaster-Carr', 2015. [Online]. Available: http://www.mcmaster.com/#noryl/=w2fid1.

[Accessed: 25- Feb- 2015].

[15] Arduino.cc, 'Arduino - ArduinoBoardMega2560', 2015. [Online]. Available:

http://arduino.cc/en/Main/ArduinoBoardMega2560. [Accessed: 25- Feb- 2015].

[16] Firgelli Automation, ‘Mini Track Linear Actuator’, 2015. [Online]. Available:

https://www.firgelliauto.com/products/mini-track-actuator

[17] Parallax Inc., ‘PING))) Ultrasonic Distance Sensor’, 2015. [Online]. Available:

https://www.parallax.com/product/28015

[18] Pololu.com, ‘Pololu Dual VNH5019 Motor Driver Shield Users Guide’, 2015. [Online]. Available:

https://www.pololu.com/docs/pdf/0J49/dual_vnh5019_motor_driver_shield.pdf. [Accessed: 25- Feb- 2015].](https://image.slidesharecdn.com/bf33ab22-7fdc-4be0-981d-17717efcf339-150830155600-lva1-app6892/85/43-Report-Spring-27-320.jpg)

![28

Figure 30: Methods Approach [2]

SFS Quality

"One missed weld can comprimise the integrity of the

entire roof"

2 Detect good or bad welds

Monitor Induction Coil

Frequency

No Yes

SFS Quality

"The device will ocasionally weld through double

membrane overlaps"

2

Account for different PVC membrane

thicknesses

Number of Programable

Conditions

1 6

SFS Quality "There are a variety of materials on the market today" 2 Account for different membrane materials

Number of Programable

Conditions

1 6

SFS Quality

"Sometimes contractors will accidentaly drill the

membrane plates in on an angle"

2 Account for angled or recessed plates

Membrane Plate Angle

(Degrees)

0° ≤ 15°

SFS Quality

"Over driving the membrane plates is another common

issue"

2 Account for angled or recessed plates

Membrane Plate Depth

(Inches)

0" ≤ 0"

Contractor Time "It would be nice to be able to multi task on the job site" 2 Reduce personel time

Reduction Rate

(percentage)

< 50% ≥ 50%

Contractor

User

Friendliness

"The current device does not have the proper leverage

to easily carry it"

2 Easily lifted/moved

Arm Positon While

Carrying

Arm Bent

Full Arm

Extension

Contractor

User

Friendliness

"It is nice to know that the device is working" 2 Visually show plate locating Information User Interface LED Array LCD

Contractor

User

Friendliness

"We generally have gas powered generators to run all

of our equipment"

2 Lower Power Consumption Input Voltage (V) 220 V 120 V

SFS Quality

"To prevent damage the device adjusts induction power

based on ambient temperature"

3 Adapt to the environment

Ability to Monitor

Temperature

No Yes

SFS Quality

"To prevent damage the device adjusts induction power

based on ambient temperature"

3 Adapt to the environment

Temperature Accuracy

(°C)

(+/-) 10 °C (+/-) 1 °C

SFS Quality

"The last step is to place a magnet on the plate to keep

the membrane in contact while it cools"

3 Apply pressure to heated area

Ability to Hold Membrane

Againts Plate Surface

No Yes

SFS Quality

"The last step is to place a magnet on the plate to keep

the membrane in contact while it cools"

3

Cool the heated area before removing

pressure

Desired Temperature (°C) No ?

SFS Repairability "If a tool breaks it needs to be sent away for repairs" 3 Easily repaired

Unskilled Personel able to

Repair the Device

No Yes

SFS Repairability "If a tool breaks it needs to be sent away for repairs" 3 Easily repaired

Percentage of Off-Shelf

Parts (%)

≥ 30% ≥ 50%

SFS Repairability "If a tool breaks it needs to be sent away for repairs" 3 Easily repaired

Specialized Parts Come

from Vendor

No Yes

Green - achieved

Red – not achieved

Blue – not proven](https://image.slidesharecdn.com/bf33ab22-7fdc-4be0-981d-17717efcf339-150830155600-lva1-app6892/85/43-Report-Spring-33-320.jpg)