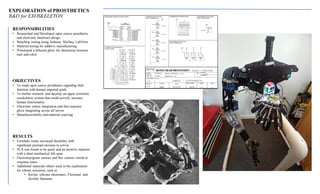

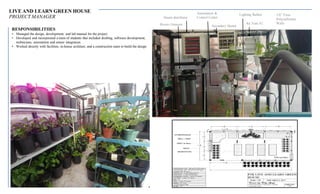

Samuel Nessenthaler's portfolio highlights his extensive experience in prosthetics R&D, focusing on exoskeleton systems and automation for air mobility solutions. He has successfully managed various projects, including the design of a four-season greenhouse and a hydroponic system that increased efficiency and reduced costs. His collaboration in creating a 3D bronchial model for respiratory education demonstrates his ability to integrate technology and education effectively.