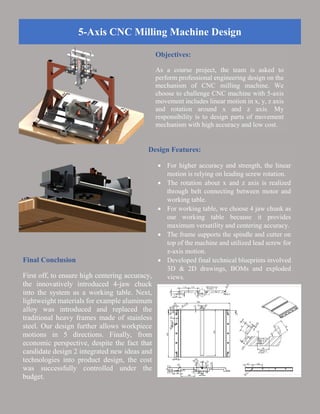

This document is an engineering design portfolio for Tsuyoshi Yokoyama. It includes contact information, education background, and details of various mechanical engineering and design projects completed. Projects include designs of a motor performance testing platform, 5-axis CNC milling machine, wine opener, tensile members, fluid dynamics analysis, robot programming, and closed-loop quadcopter control. For each project, the document describes the objectives, design features, and conclusions. The portfolio demonstrates Yokoyama's skills in CAD, FEA, mechatronics design, and passion for practical engineering challenges.