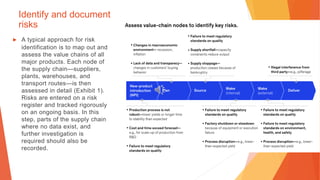

This document discusses various risks that can disrupt supply chains, including supply risks, demand risks, operational risks, and geopolitical risks. It also covers how economic challenges like inflation and disruptions from climate change and the need to comply with ESG standards present risks. Managing these modern supply chain risks effectively requires strategies like diversifying suppliers, risk management planning, forecasting analytics, and collaboration within the supply chain network.