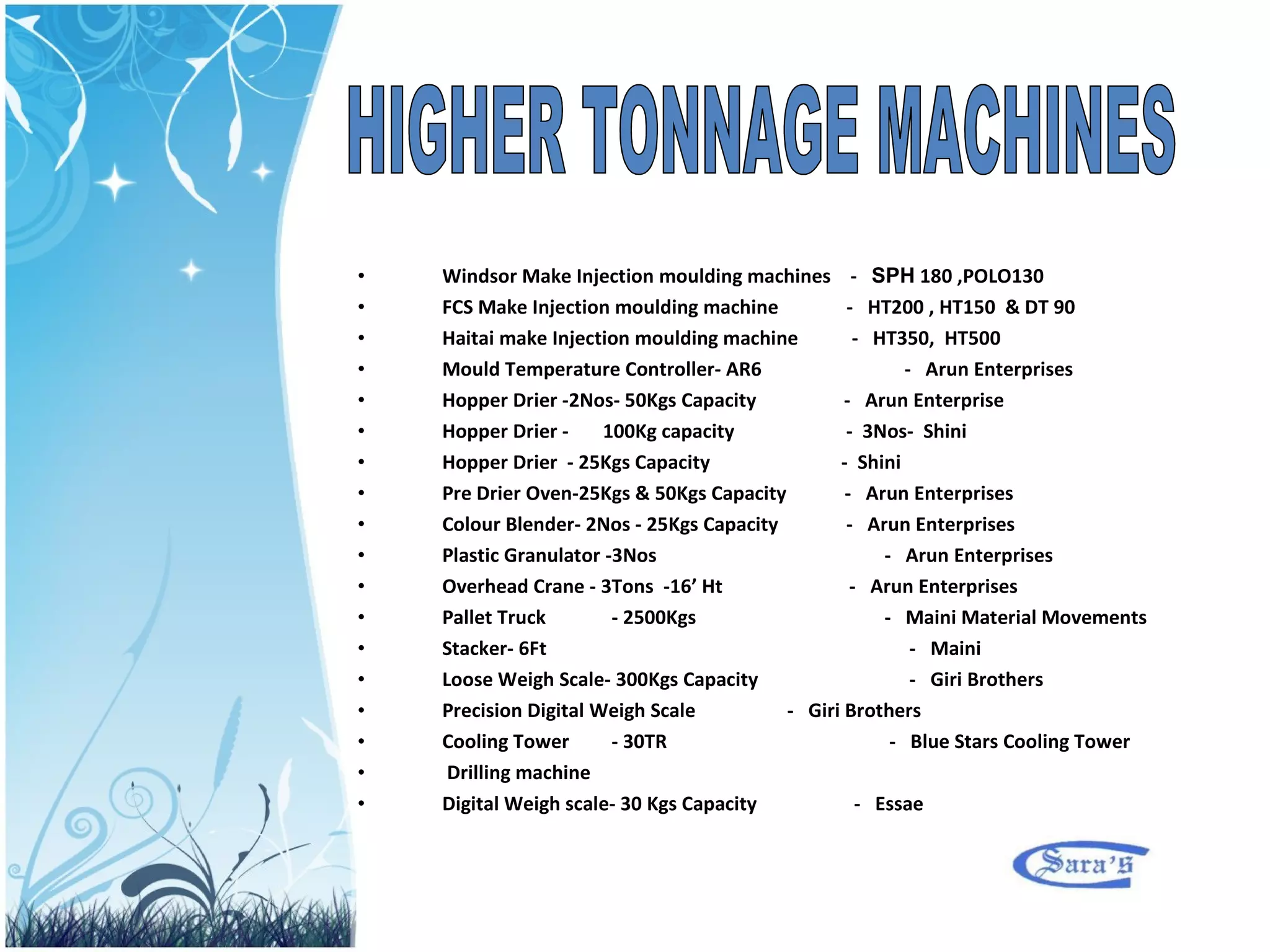

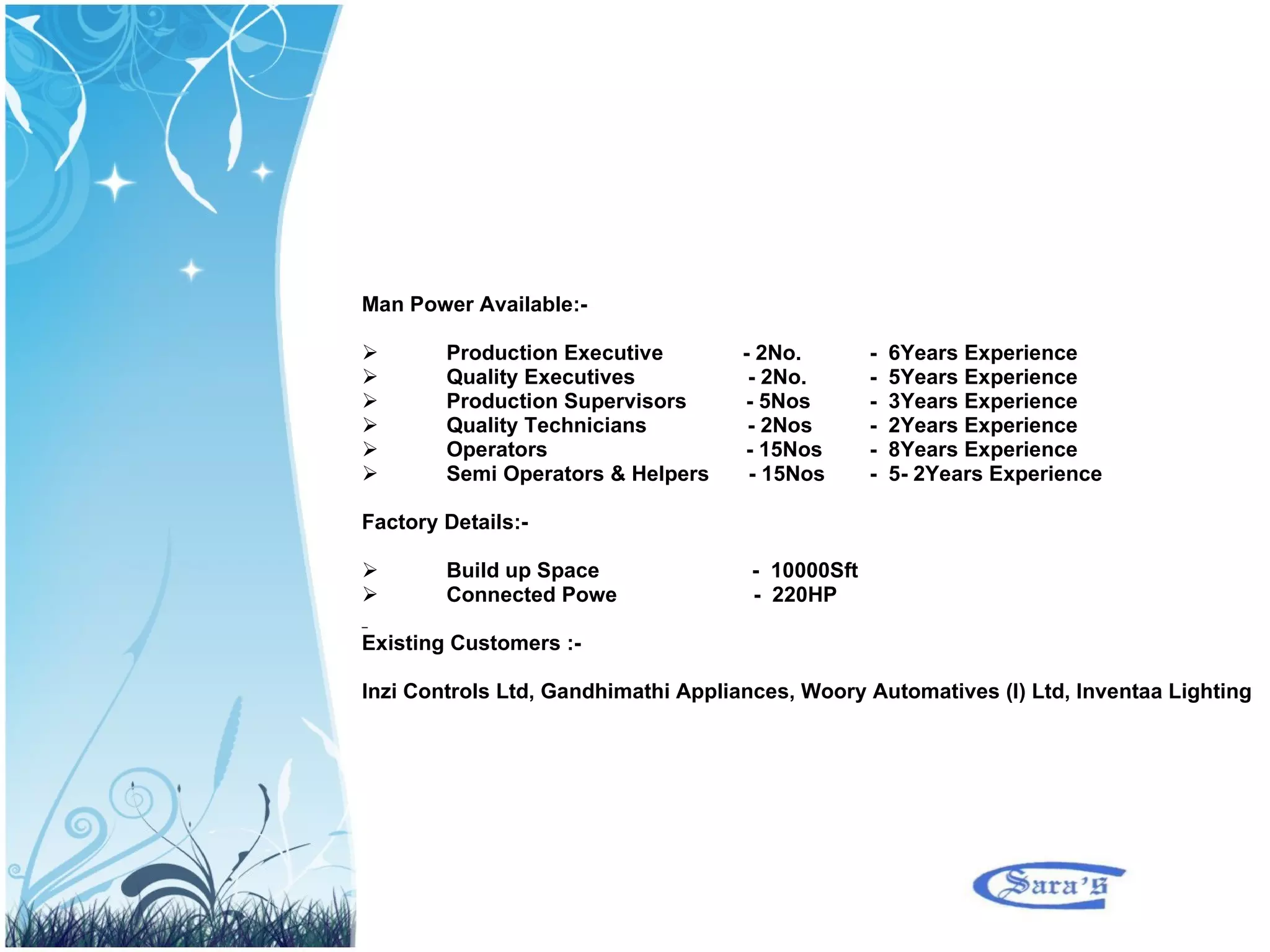

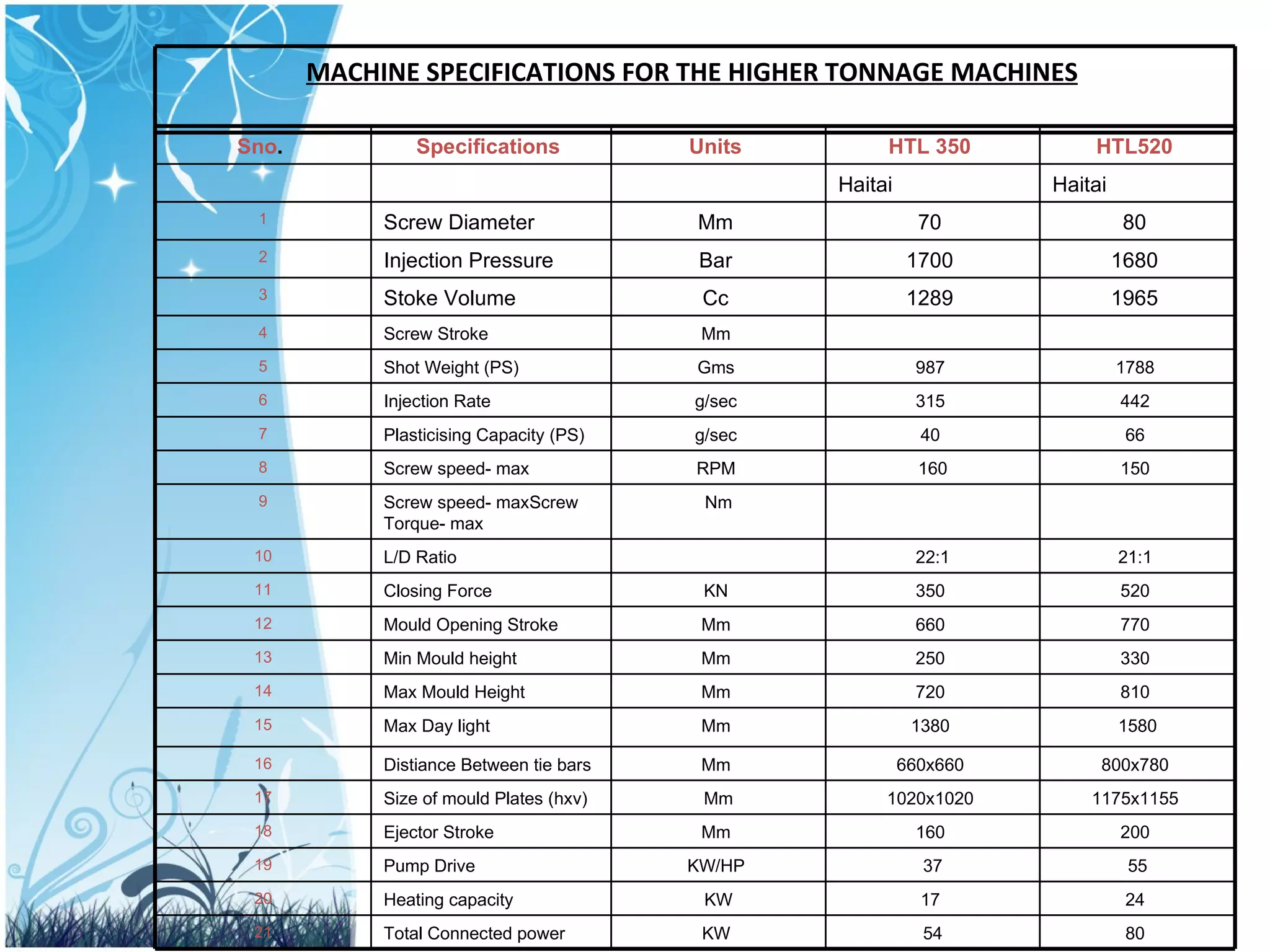

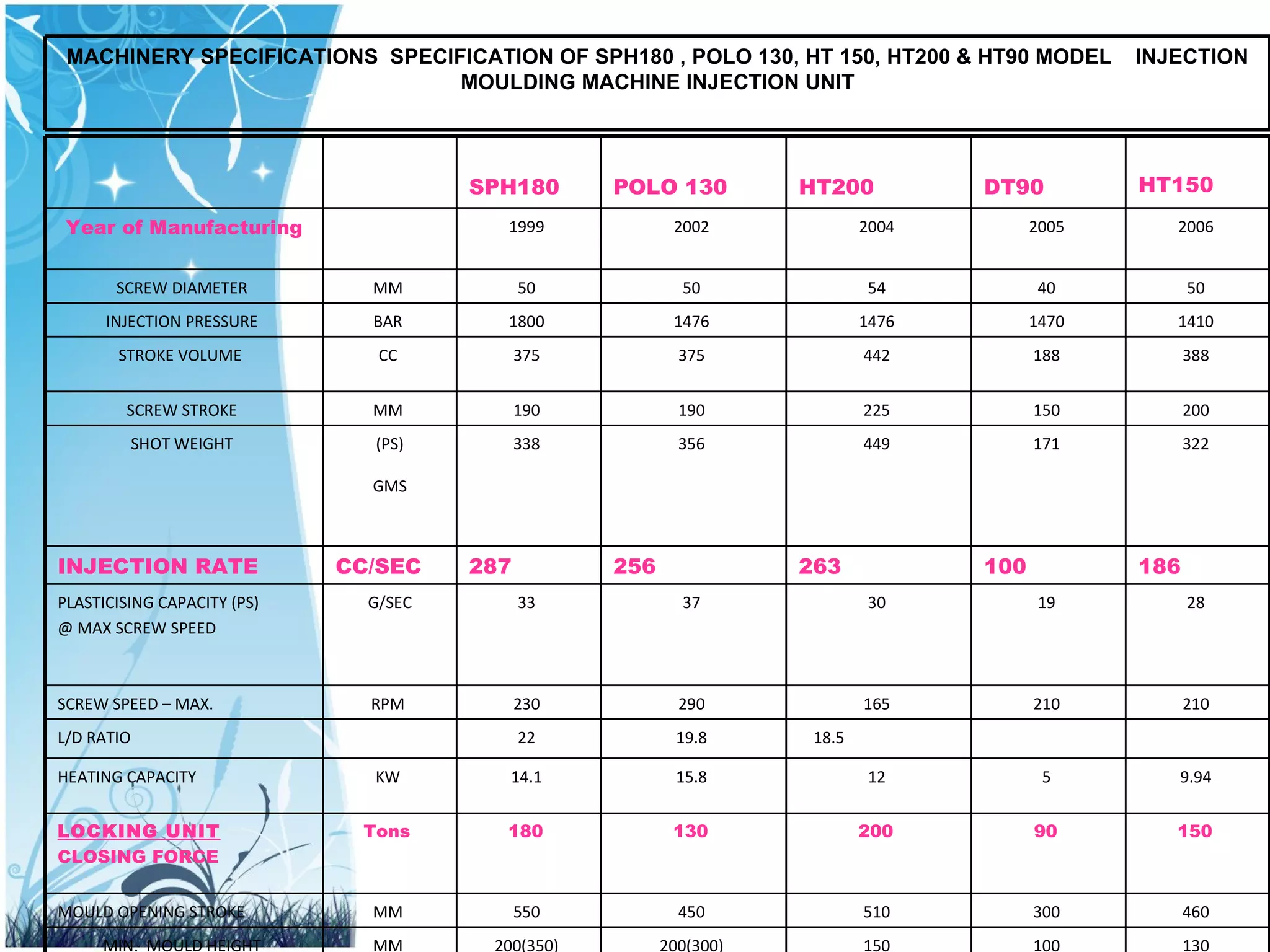

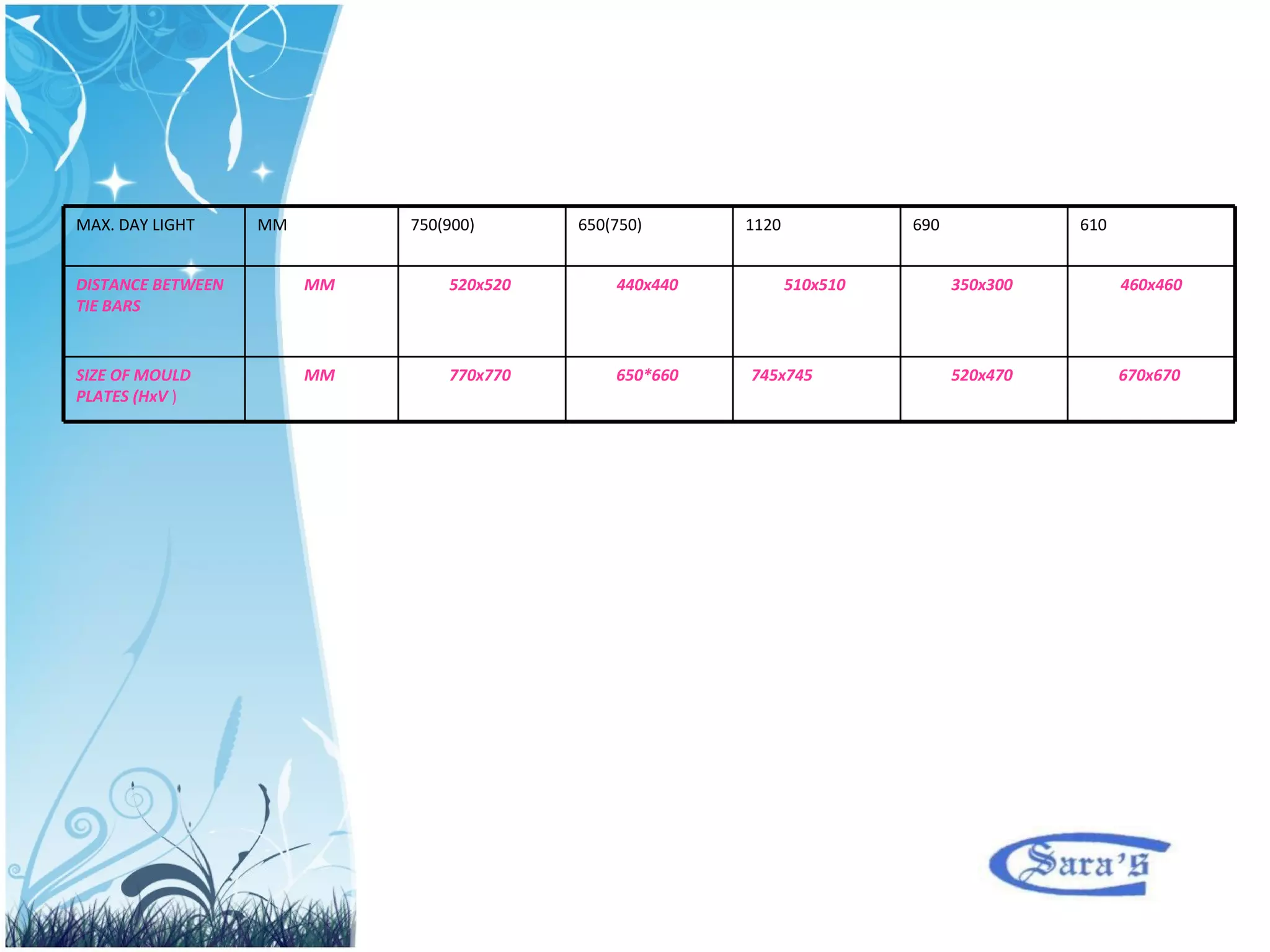

Sara Plastic is an ISO 9001:2000 certified injection moulding company located in Chennai, India. They have several injection moulding machines ranging from 90 to 500 tons. Their main customers are in the automotive and appliances industries and they mould various engineering plastics like polycarbonate and nylon. The company aims to serve customers better with high quality moulding and on-time delivery.

![Company Profile Sara Plastic Industries , An ISO 9001: 2000 Certified Company. Under Central Excise Registration No. 7B, Leo Industrial Estate, Pallikaranai, Velachery- Tambaram Road, Chennai – 601 302. Factory Ph No. (044)22460228; Fax-(044) 2246 1725; Mobile :- 09381017164, Res:- (044)65496896 Proprietor – V.Ravichandran BE., PGDPE Email:- [email_address]](https://image.slidesharecdn.com/sara123-100521123559-phpapp01/75/Sara123-2-2048.jpg)