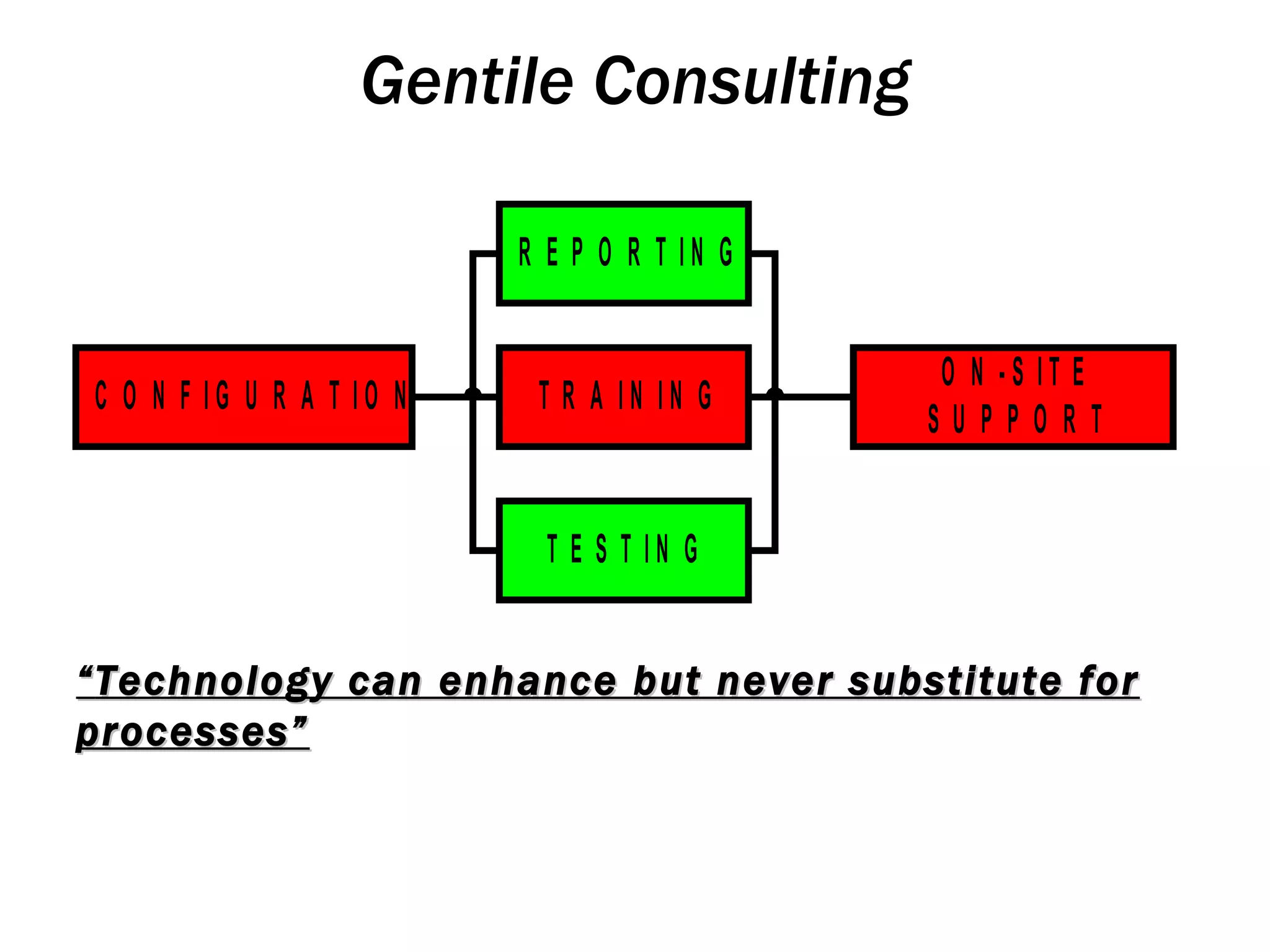

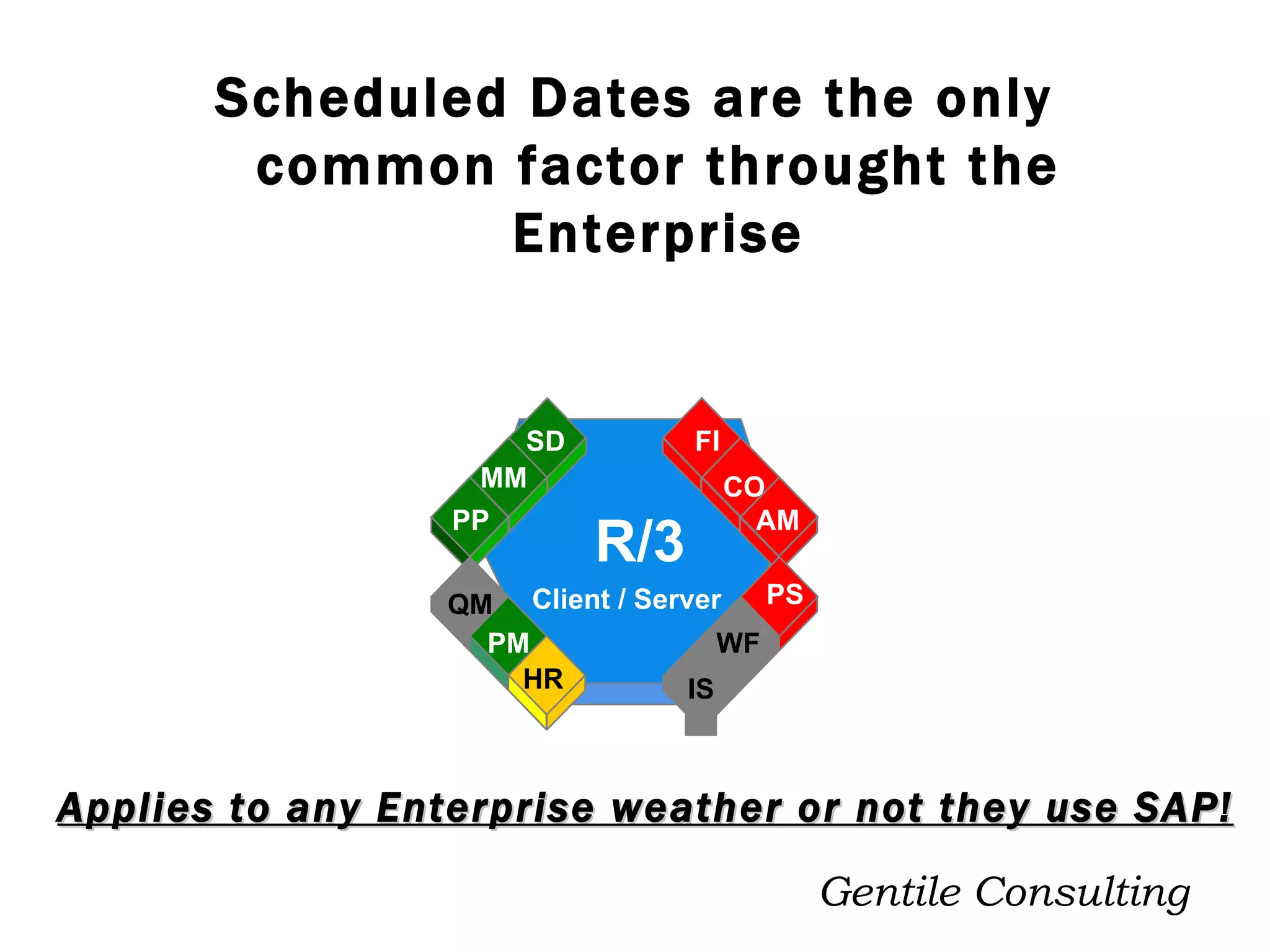

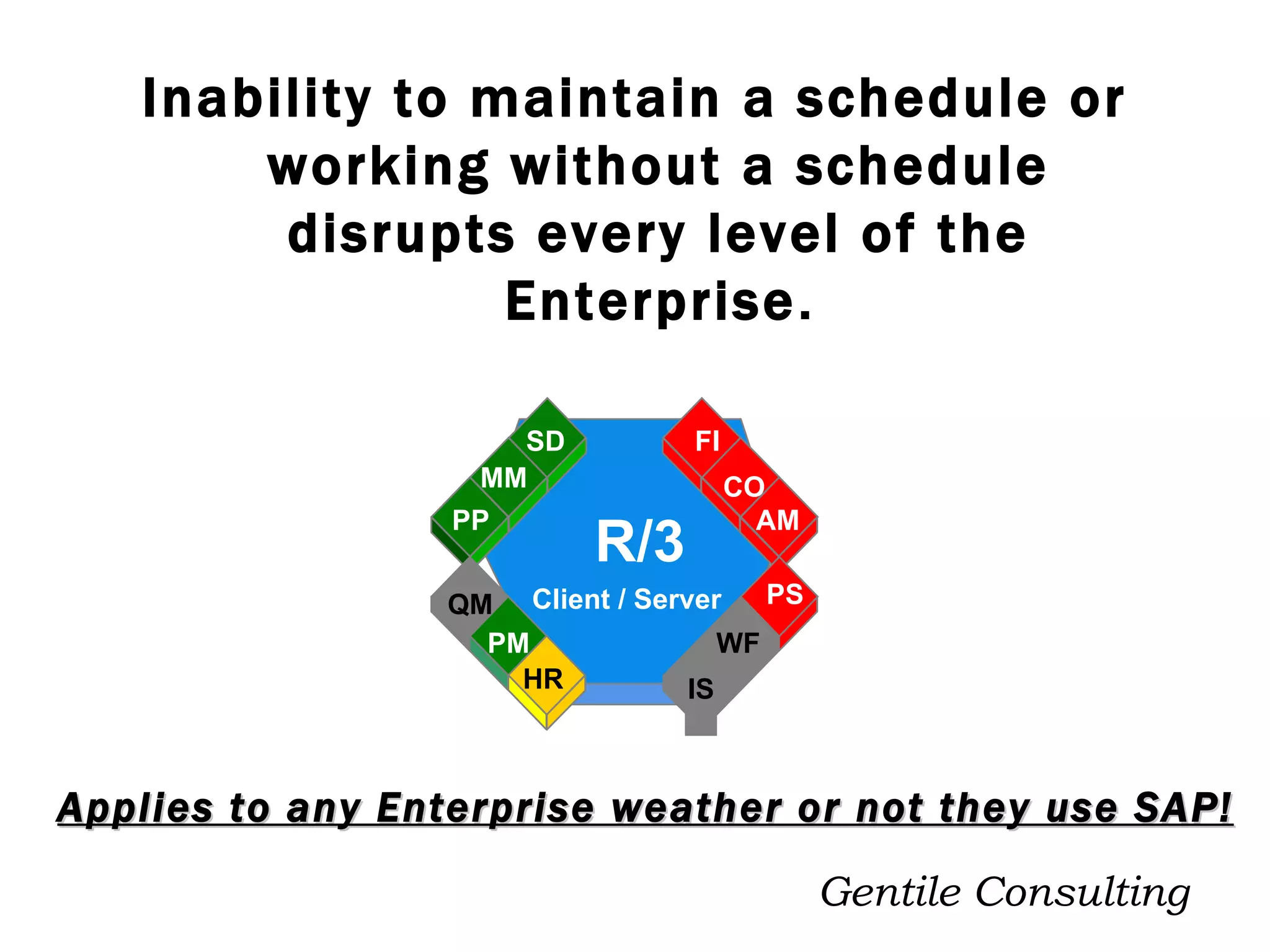

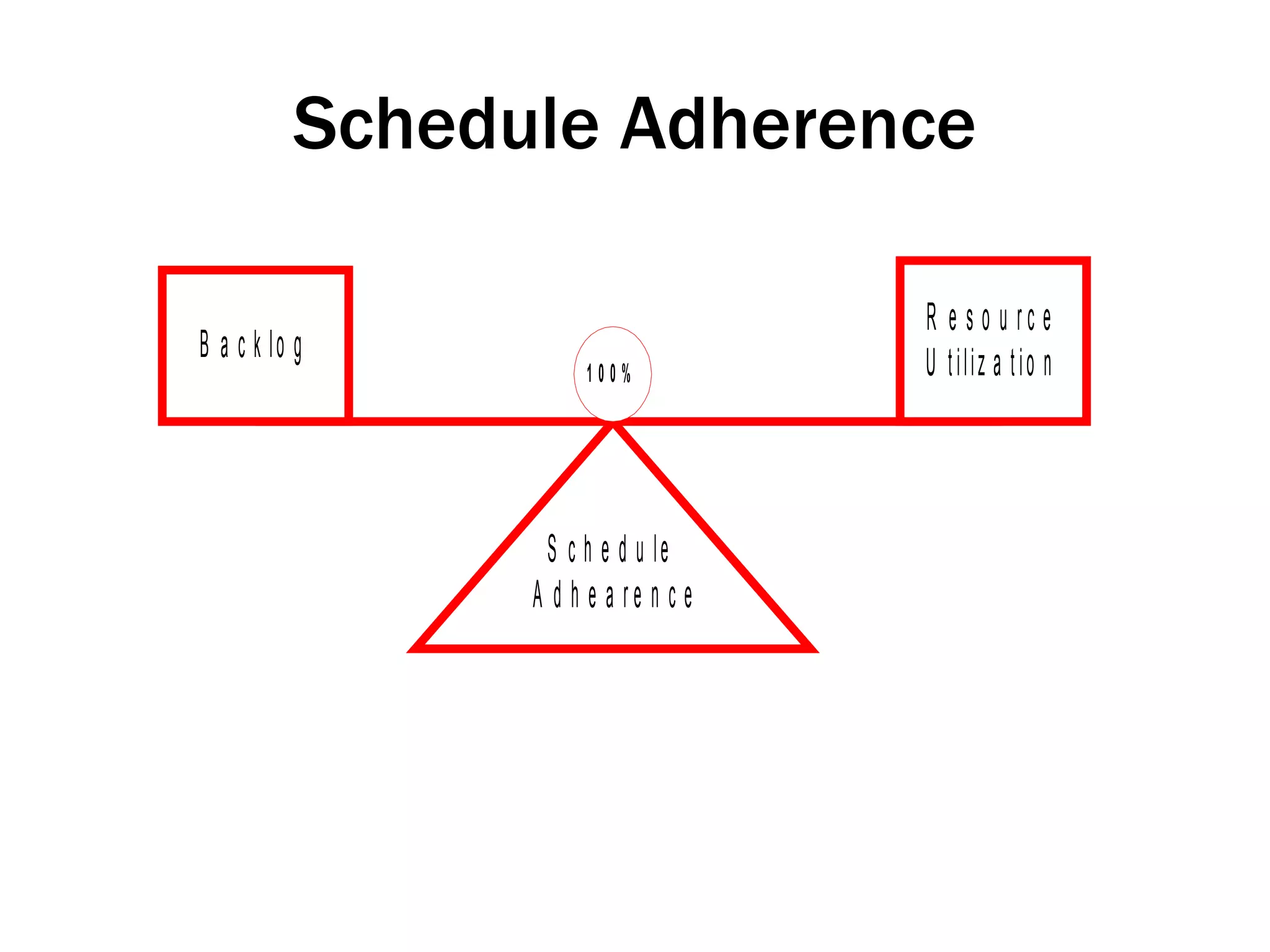

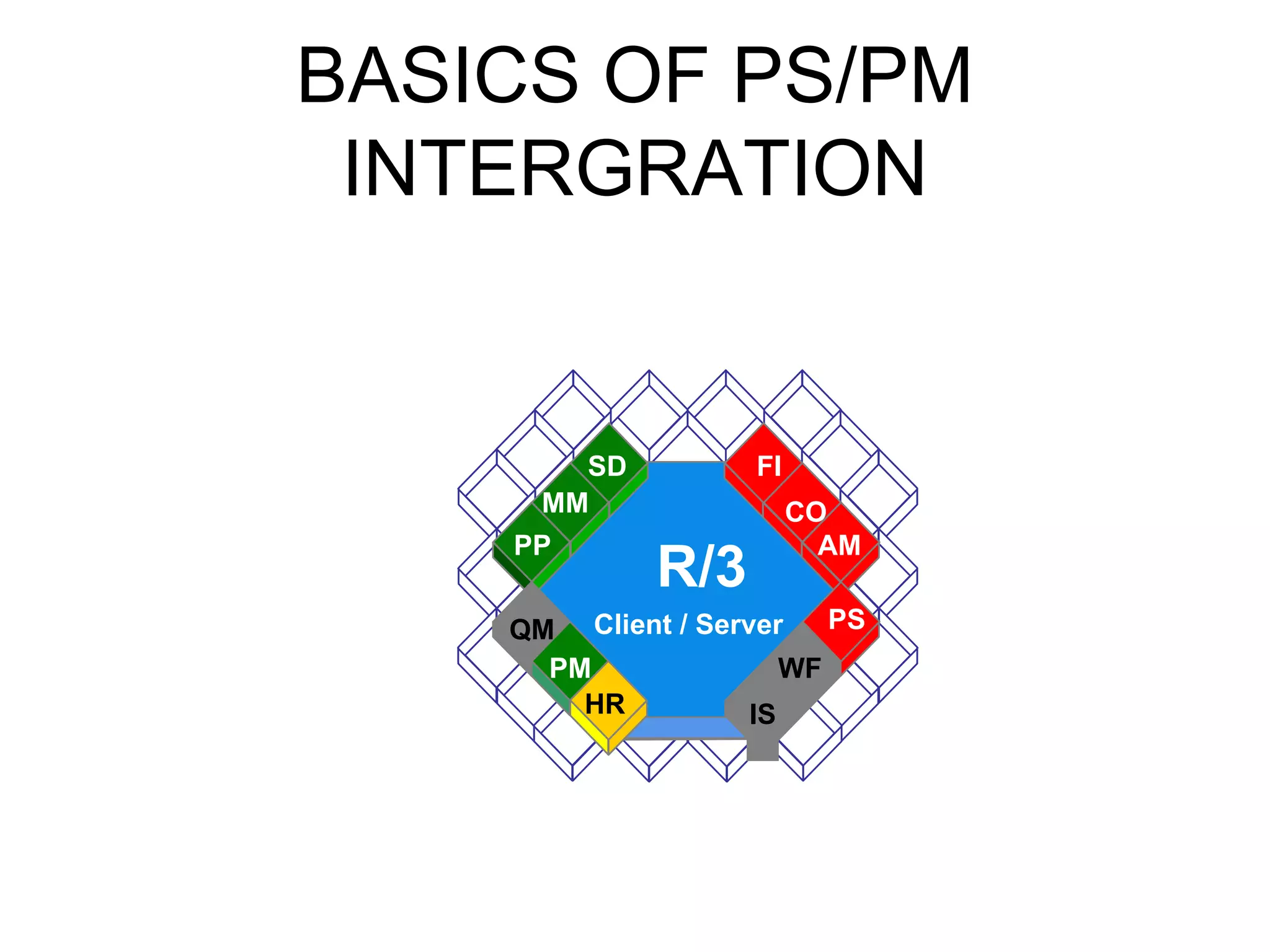

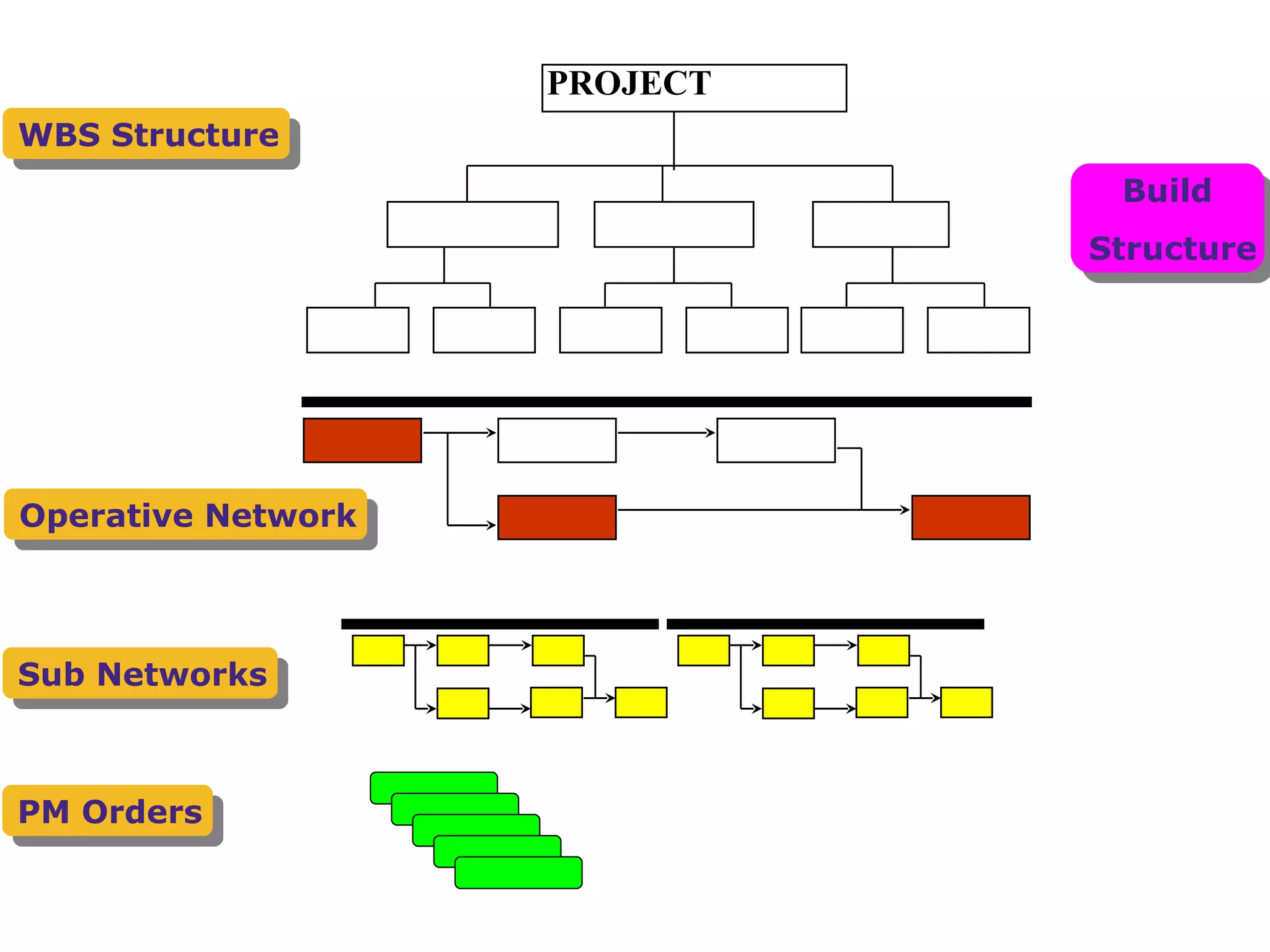

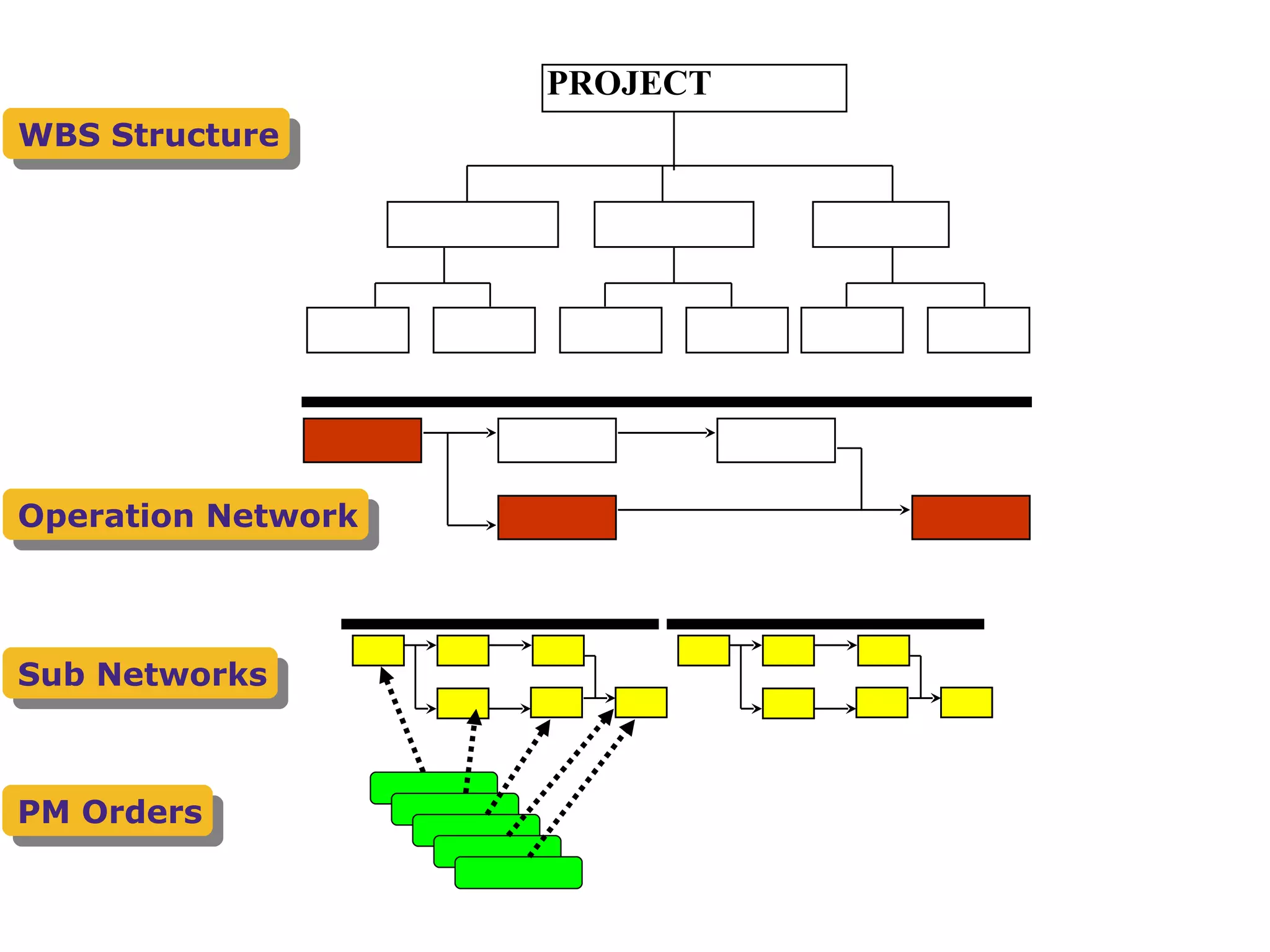

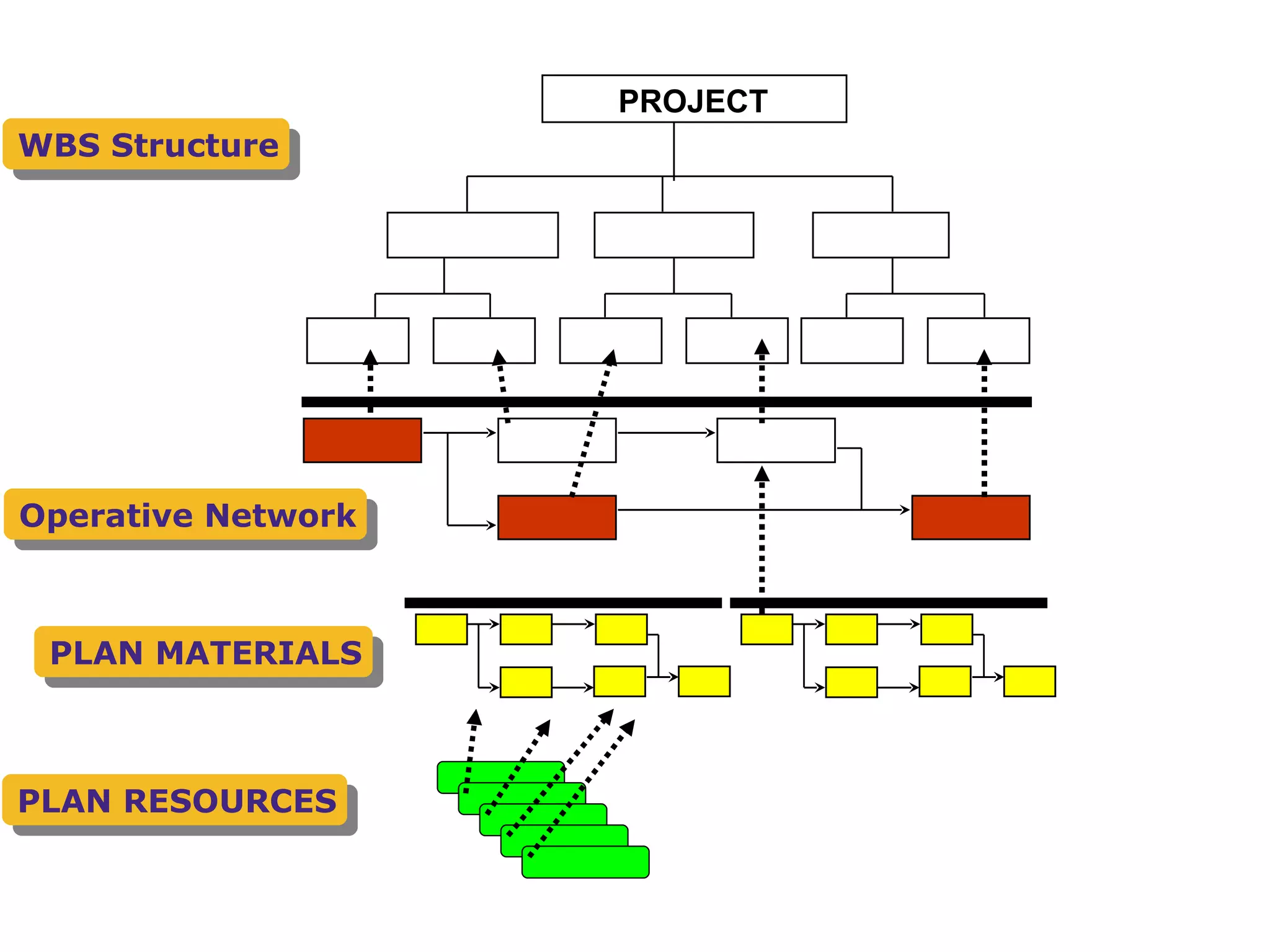

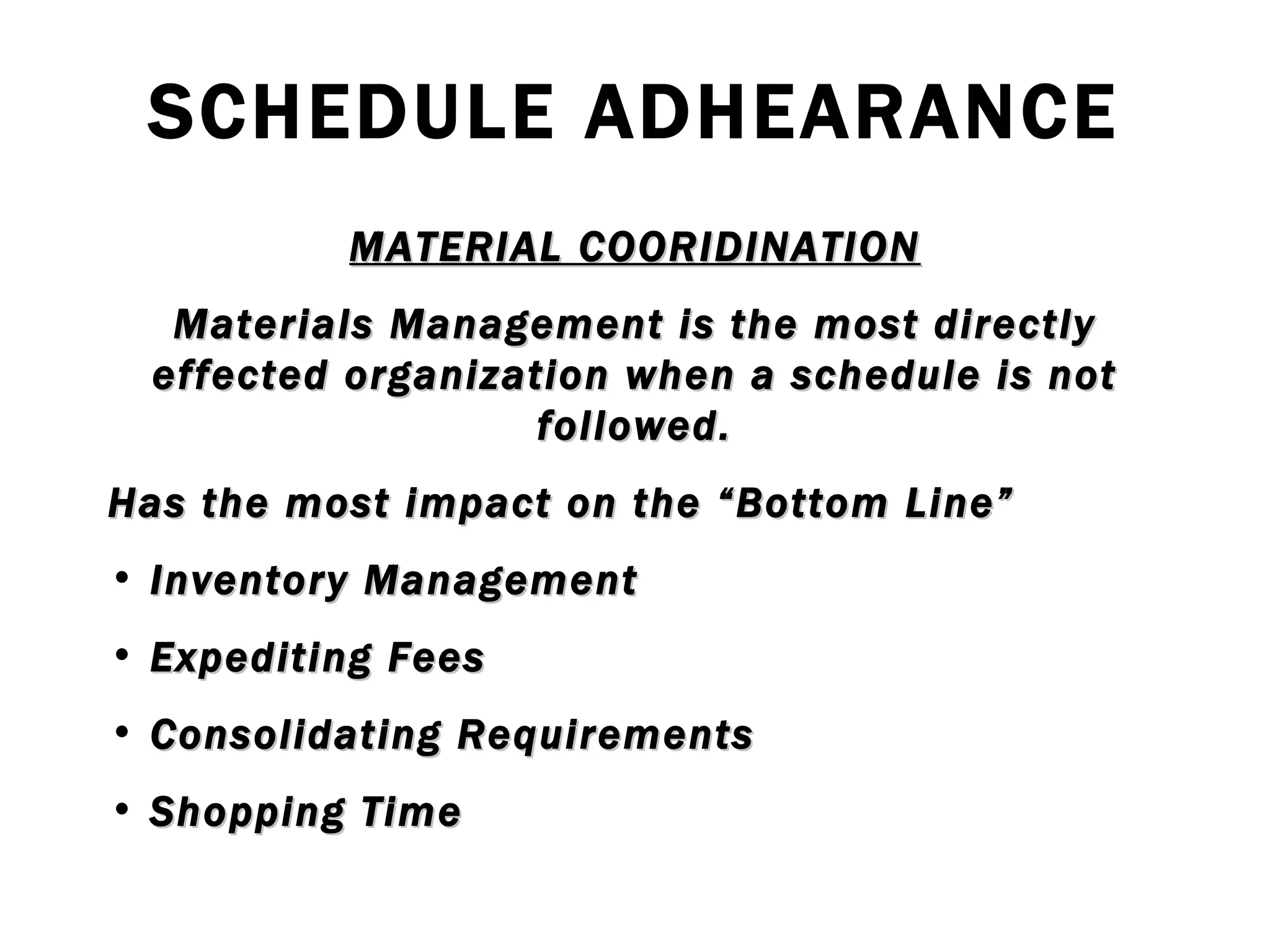

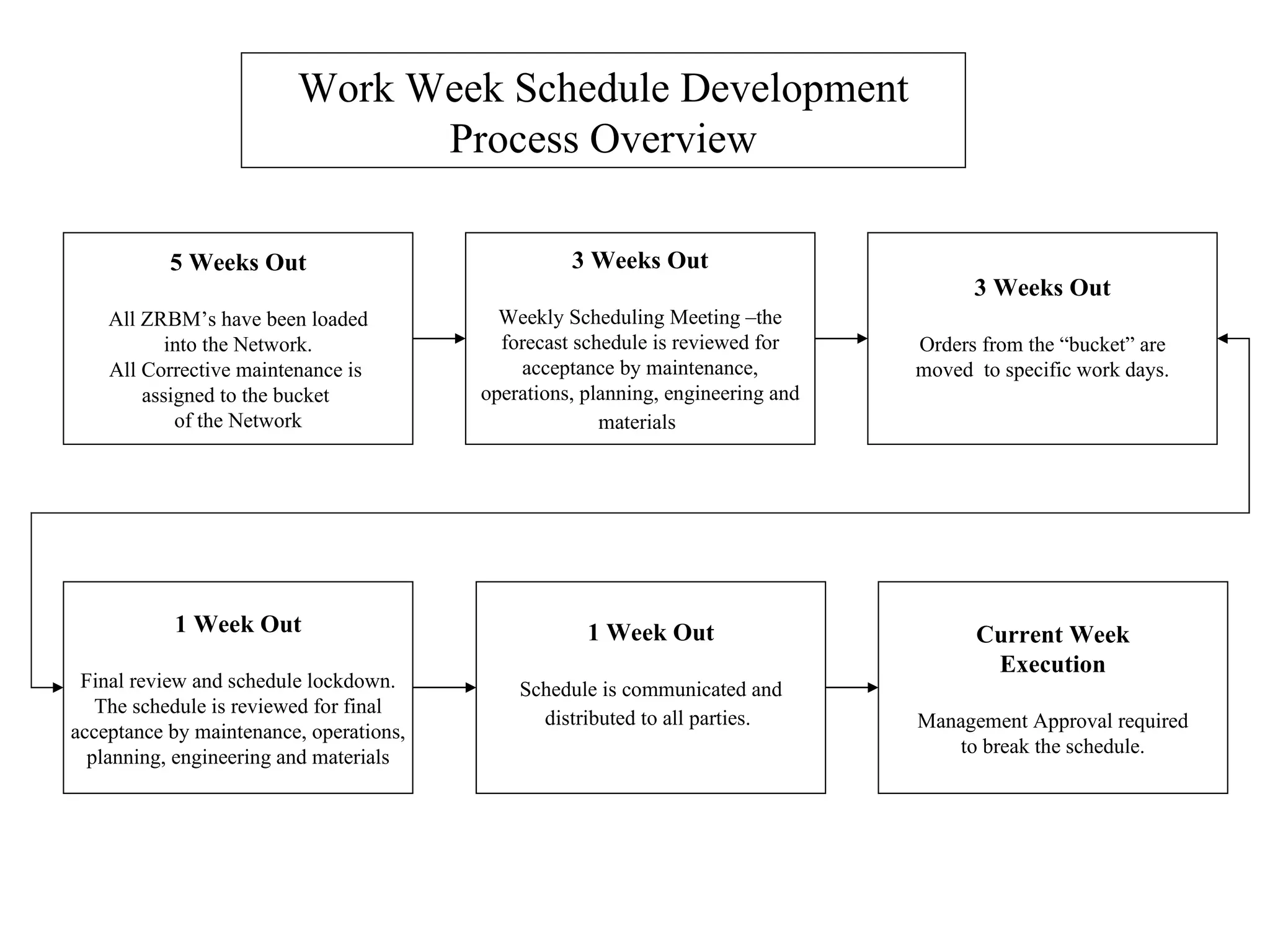

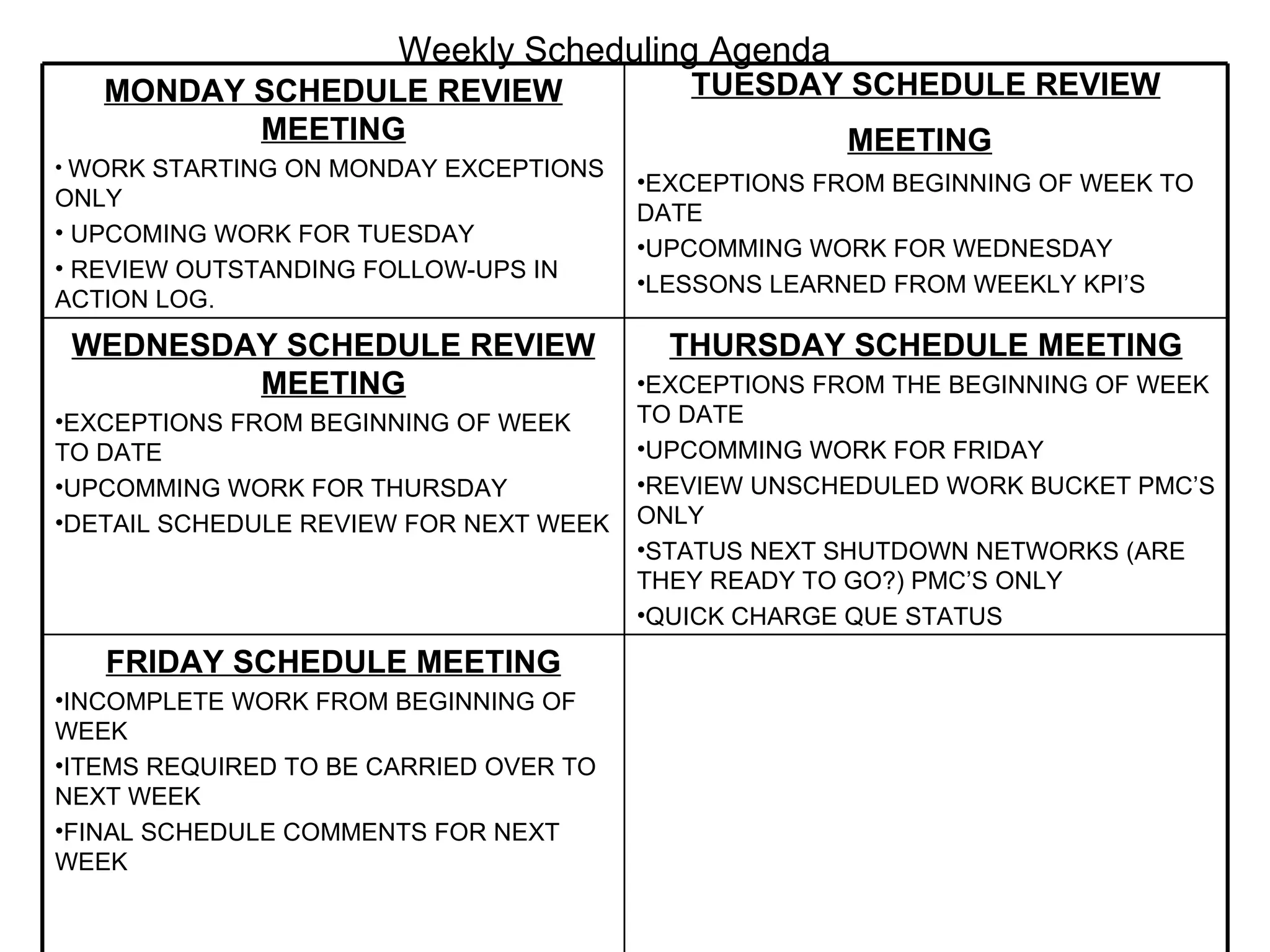

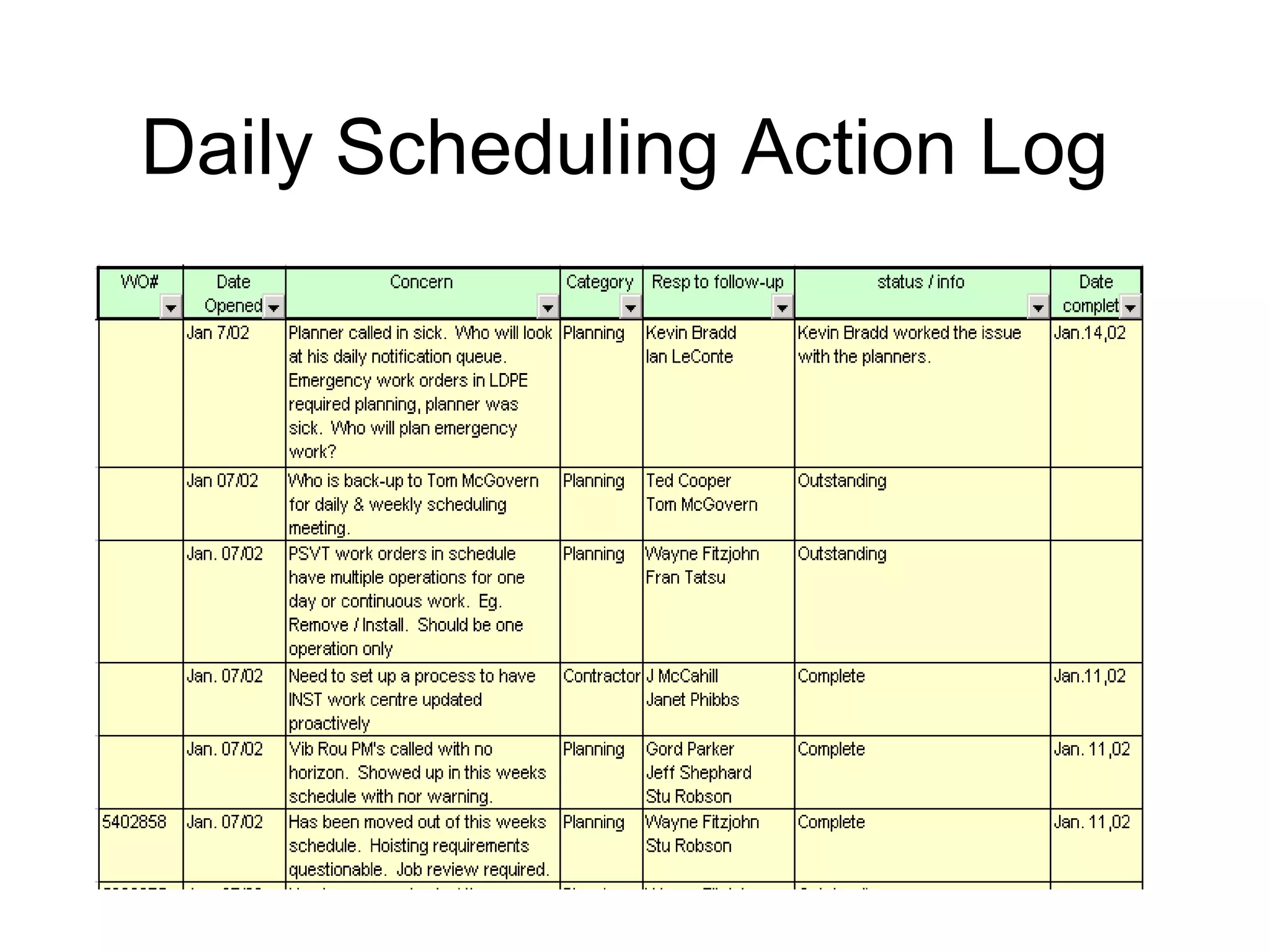

The document discusses Gentile Consulting and their expertise in SAP Plant Maintenance (PM) and Production Scheduling (PS) solutions for utilities and other process industries. Key points include Gentile's 11 years of experience with SAP PS and PM modules, their focus on capacity planning and scheduling, and experience managing scheduling and resource planning for nuclear and fossil fuel power plants. The document also outlines the benefits of integrated scheduling in SAP PS and PM, such as visibility across the enterprise and improved schedule adherence.