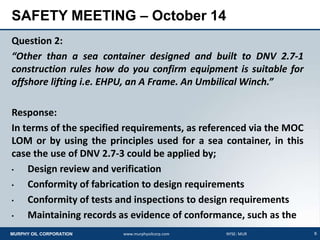

This document summarizes the key points from a Murphy Oil Corporation safety meeting on October 14th about lifting equipment and appliances. The meeting addressed 4 questions related to determining if equipment is suitable for offshore lifting and deployment. It was explained that a risk assessment should be performed if equipment is deemed unsuitable for lifting and that standards like DNV 2.7-1, DNV 2.7-3, and ISO 13628-8 provide guidance on confirming equipment specifications and verifying that design, fabrication, testing and maintenance meet requirements. Maintaining documentation like certificates of conformity was emphasized as evidence that lifted equipment meets defined lifting criteria.