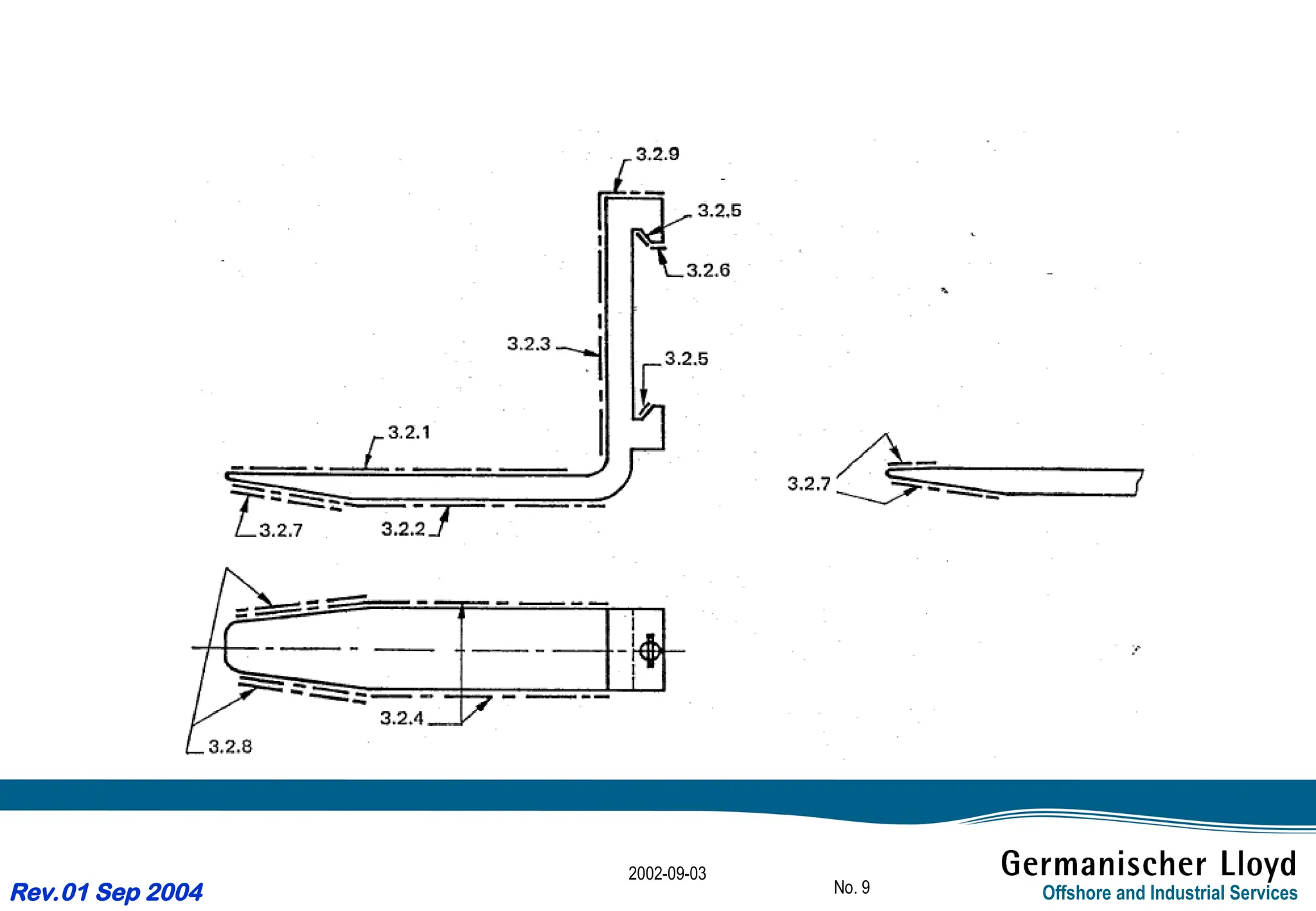

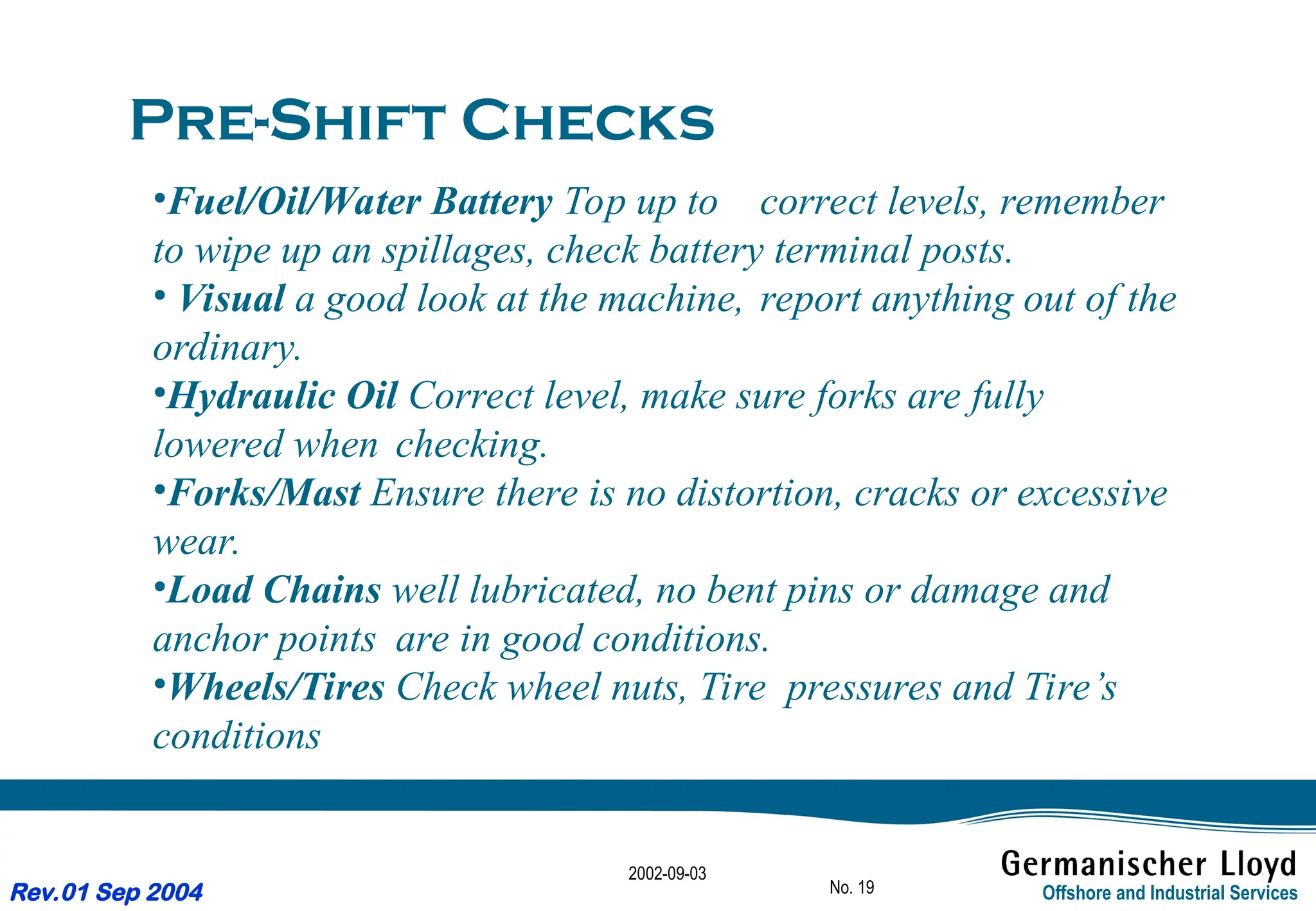

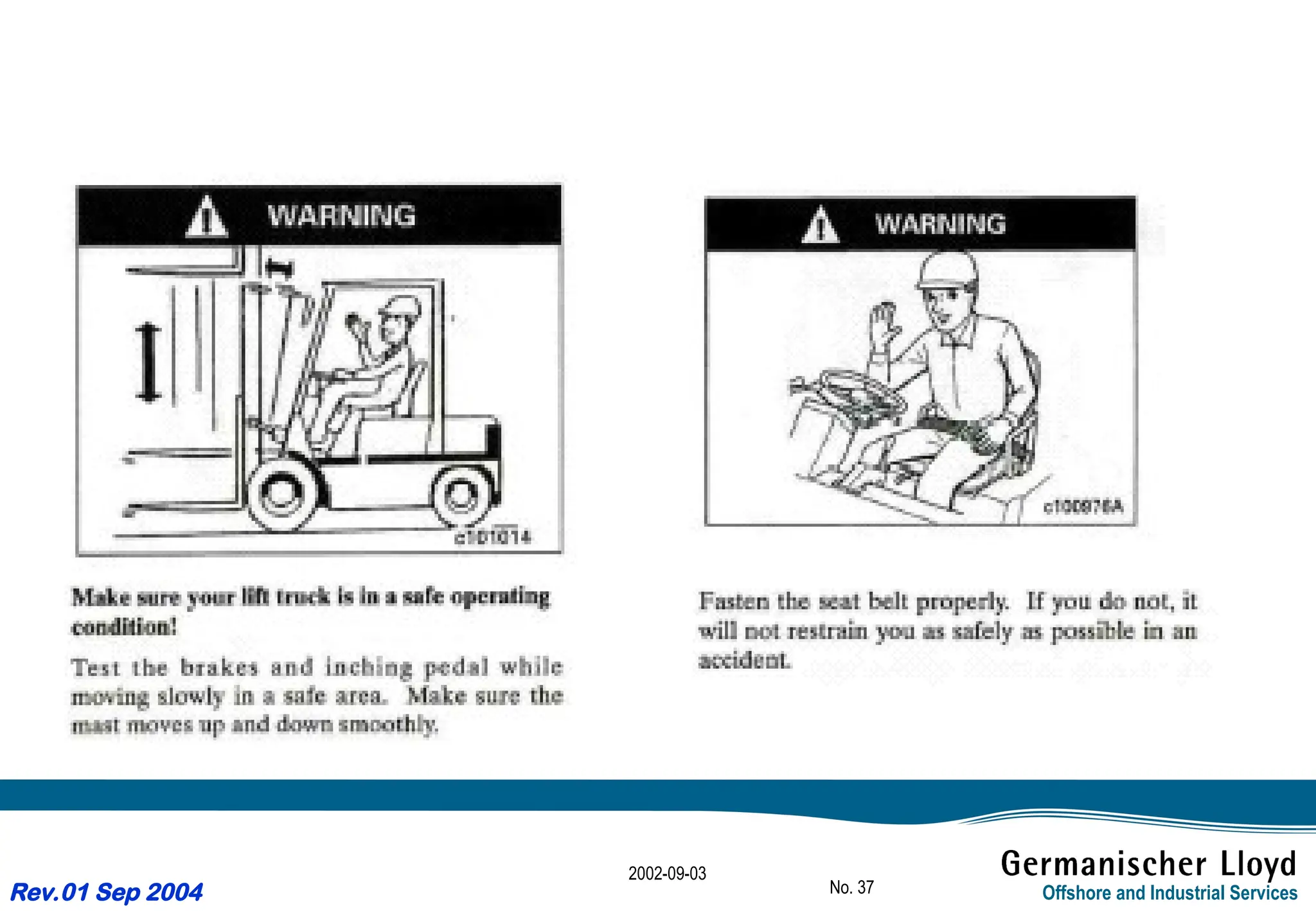

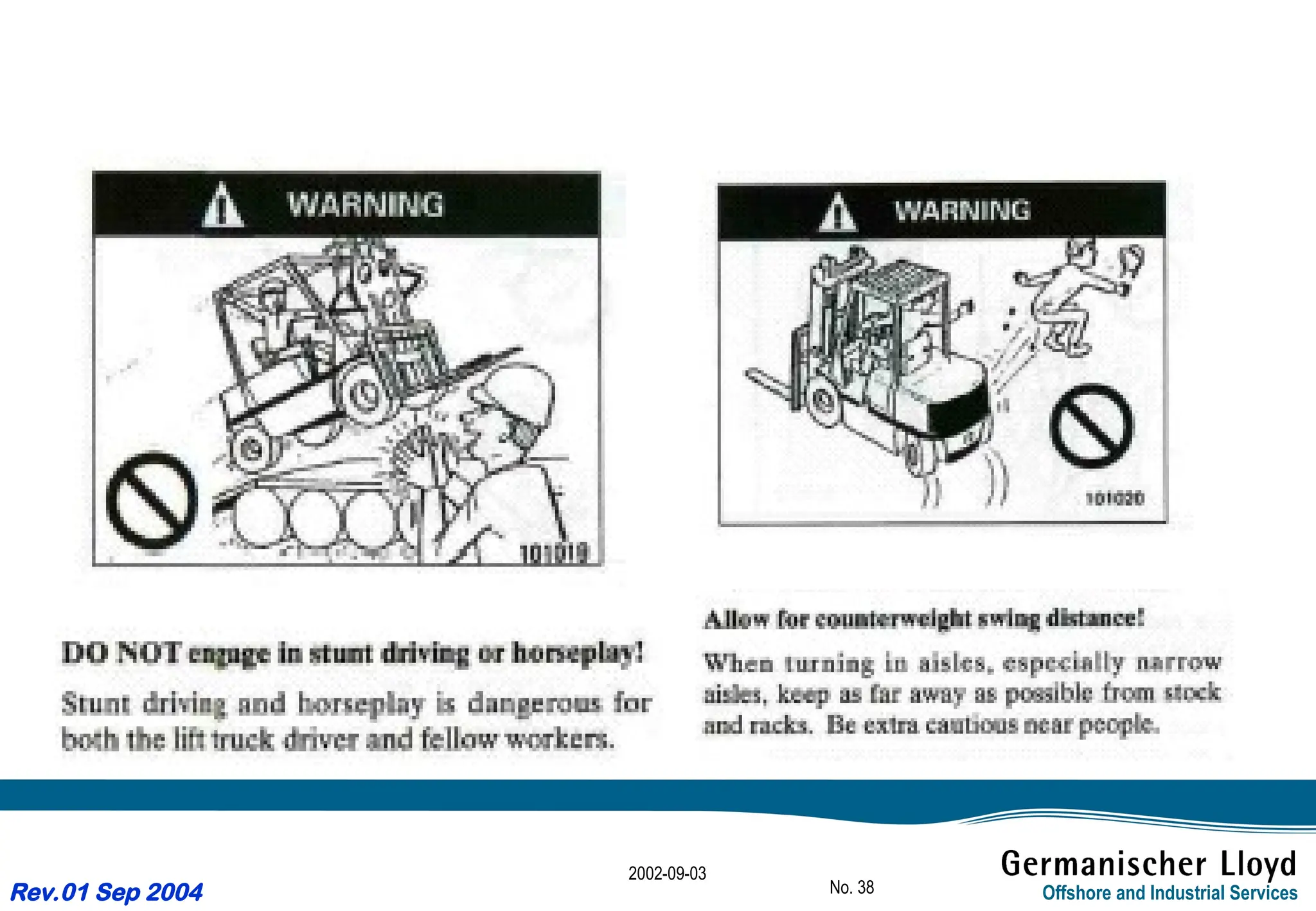

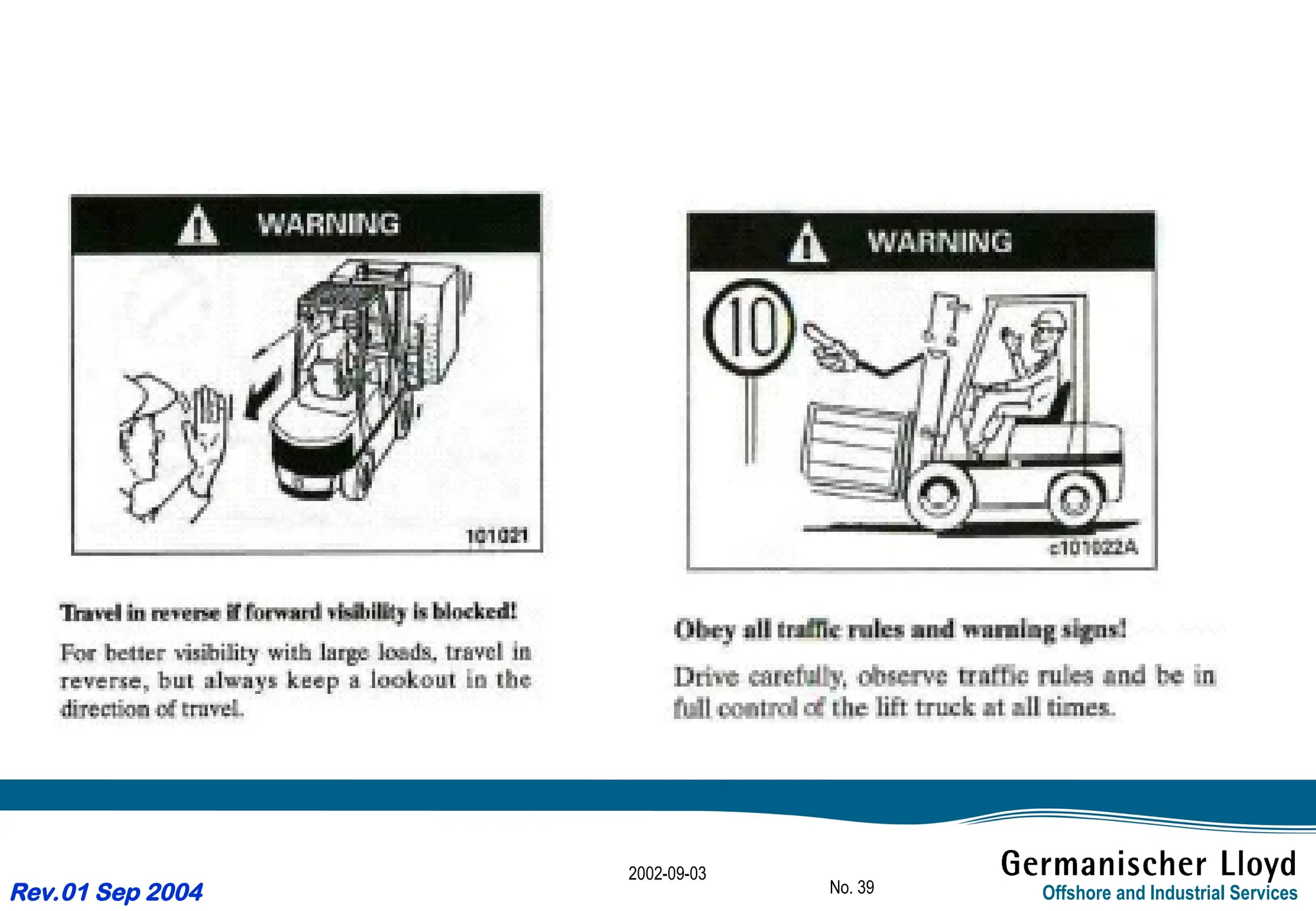

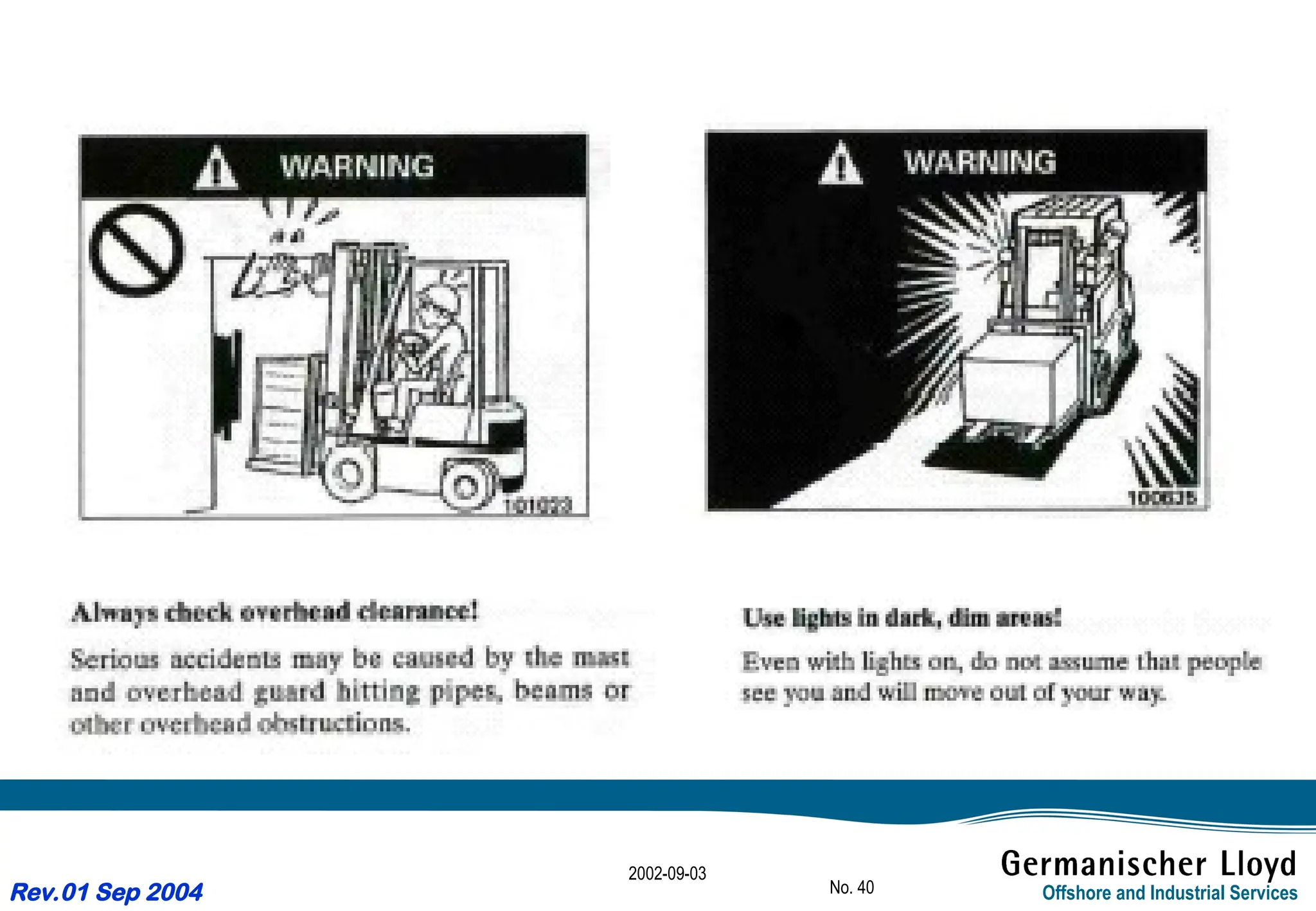

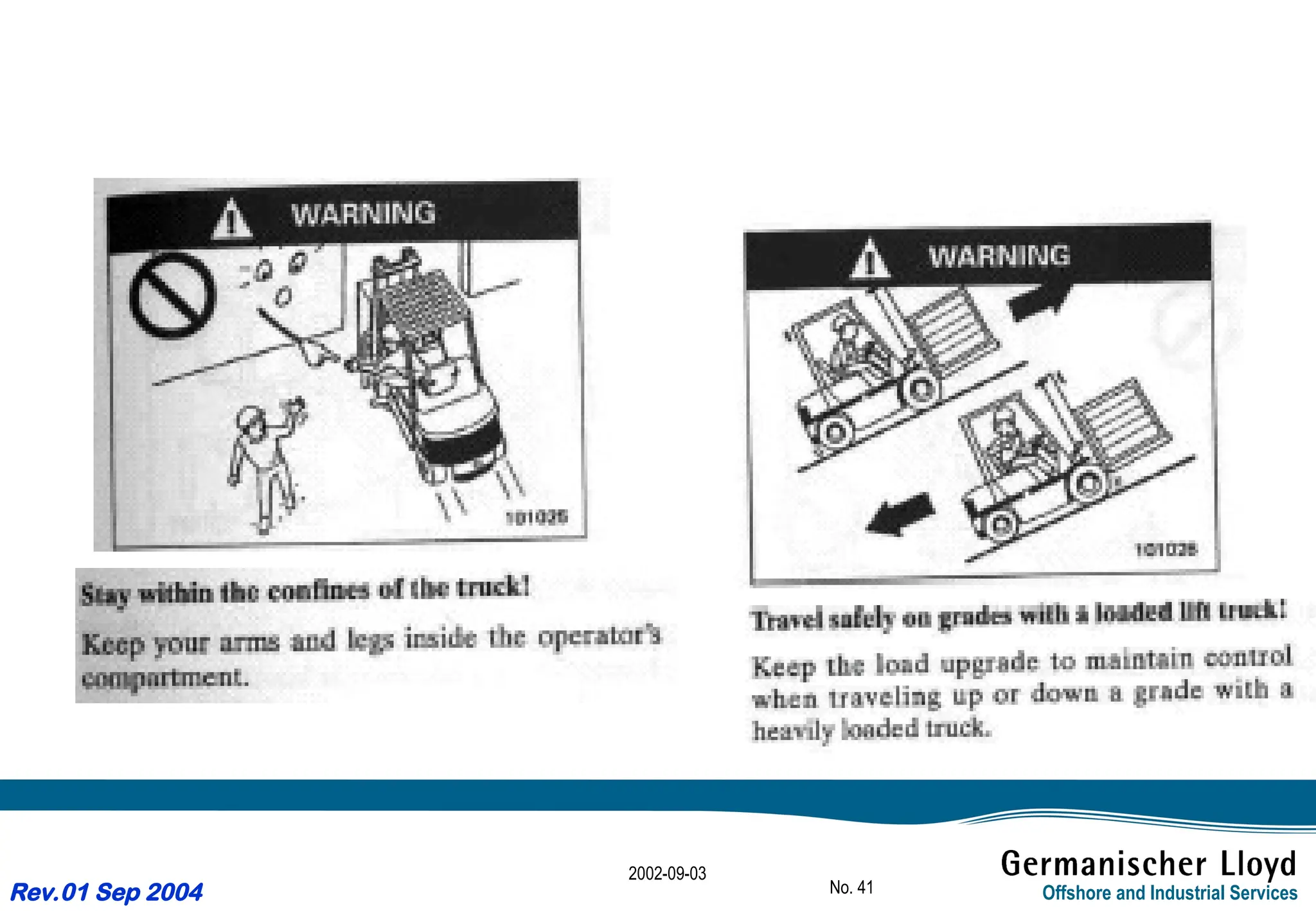

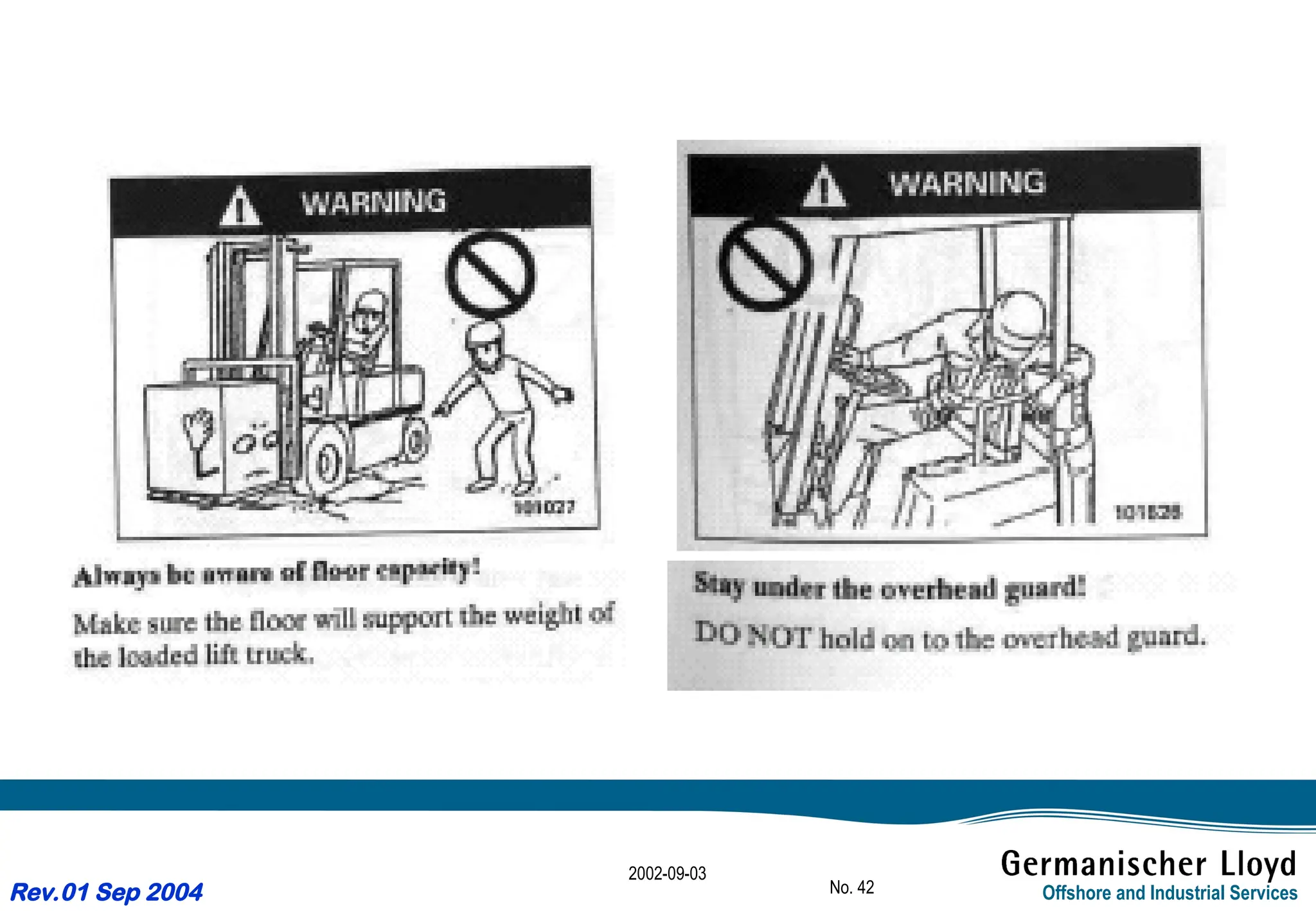

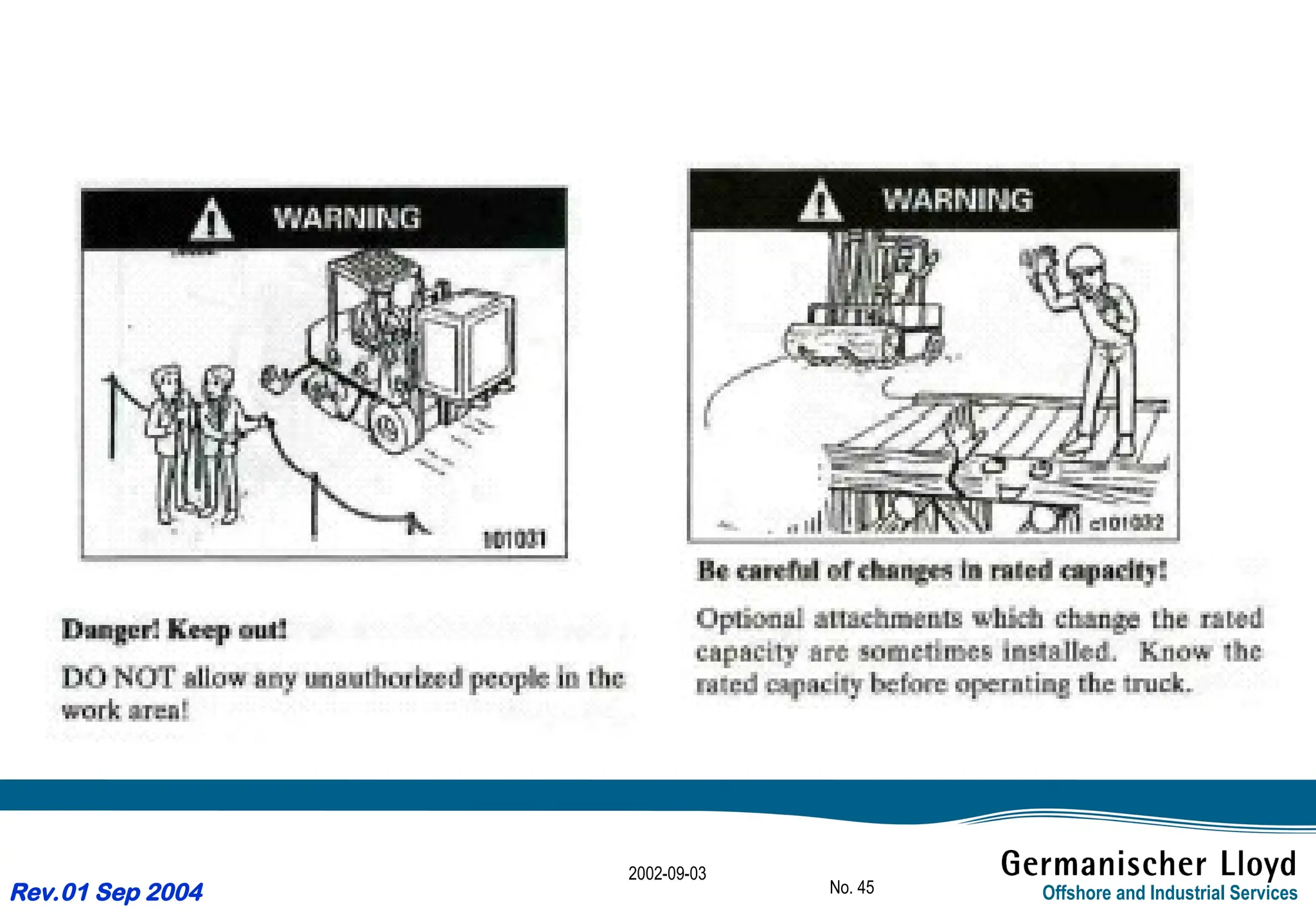

The document outlines operational guidelines and safety procedures for forklift operators at Offshore and Industrial Services GmbH. It includes instructions on equipment checks, load management, safe operation, and battery charging procedures. Emphasis is placed on safety measures to prevent accidents and ensure proper handling of materials during operation.