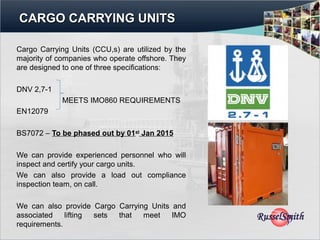

This document provides information on the Lifting Equipment Integrity department of RusselSmith Group which ensures safety standards for lifting equipment inspections. The department offers various services such as statutory inspections, LOLER audits, crane surveys, proof load testing, and cargo carrying unit inspections. It aims to raise safety standards, minimize risk, and ensure safety comes first in clients' lifting operations. The department has operational capabilities across various regions and its team of engineers are certified in lifting equipment standards and testing.