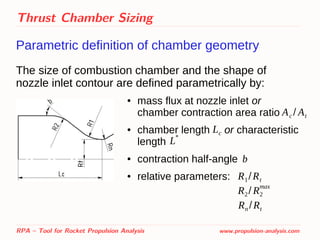

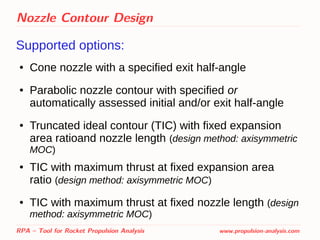

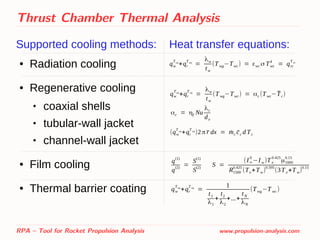

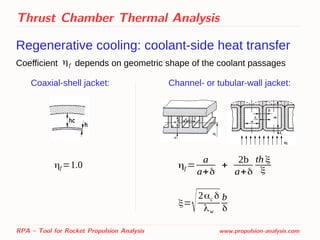

RPA is a computational tool for analyzing rocket propulsion systems in conceptual and preliminary design phases. It features modules for thermodynamics analysis, thrust chamber performance prediction, chamber sizing, nozzle contour design, and thermal analysis. The tool uses simplified physical models and semi-empirical relationships to rapidly analyze systems with minimum input parameters while providing sufficient accuracy for early design studies. RPA assists in education and allows variation of design parameters to assess impacts on performance.

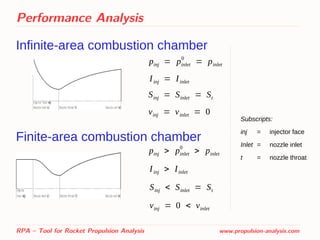

![Performance Analysis

Delivered performance of thrust chamber

● Specific impulse in vacuum:

● Specific impulse at ambient pressure :

● Characteristic velocity:

● Thrust coefficient in vacuum:

● Thrust coefficient at ambient pressure :

Correction factors are obtained from semi-empirical relations [1]

[1] For more details see: Ponomarenko, A. RPA: Tool for Rocket Propulsion Analysis. Assessment of

Delivered Performance of Thrust Chamber. March 2013.

RPA – Tool for Rocket Propulsion Analysis www.propulsion-analysis.com

(Isp

vac

)d = ζc ζn Isp

vac

(Isp

a

)d=(Isp

vac

)d−

pa

ve ρe

(Cf

vac

)d = ζn Cf

vac

(Cf

a

)d = ζn Cf

a

(c*

)d = ζc c*

pa

pa](https://image.slidesharecdn.com/sp2014pres2967435ponomarenko-140522153109-phpapp01/85/RPA-Tool-for-Rocket-Propulsion-Analysis-14-320.jpg)

![Nozzle Contour Design

Direct optimization of nozzle contour

RPA – Tool for Rocket Propulsion Analysis www.propulsion-analysis.com

Cf = (Cf )2D (1−ζf ) → max

(Cf )2D = 2

Ae

At

∫

0

1

(1−

γ−1

γ+1

λ

2

)

1

γ−1

[1+λ

2 γ(2cos

2

β−1)+1

γ+1 ]̄r d̄r

To obtain the contour with the

maximum thrust coefficient at

specified conditions (area

ratio or nozzle length)

ζf = 1 −

2̄δe

**

1 +

1

γ Me

2

δ**

=

( 2

γ−1)

0.1

Rew0

0.2

(

0.015

̄Tw

0.5

)

0.8 (1+

γ−1

2

Mwe

2

)

γ+1

2(γ−1)

Mw

ν+1

̄S0.2

̄re

2

[∫

0

̄S

̄r1.25

M1+1.25ν

(1+

γ−1

2

Mw

2

)

1.36 γ−0.36

γ−1

d ̄S

]

0.8](https://image.slidesharecdn.com/sp2014pres2967435ponomarenko-140522153109-phpapp01/85/RPA-Tool-for-Rocket-Propulsion-Analysis-19-320.jpg)

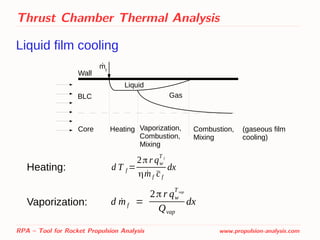

![Thrust Chamber Thermal Analysis

Supported methods to obtain gas-side heat flux:

● Radiation heat transfer:

● Convective heat transfer

Bartz method:

Ievlev method[1,2]

:

1. Lebedinsky E.V., Kalmykov G.P., et al. Working processes in liquid-propellant rocket engine and their simulation. Moscow,

Mashinostroenie, 2008

2. Vasiliev A.P., Kudryavtsev V.M. et al. Basics of theory and analysis of liquid-propellant rocket engines, vol.2. 4th Edition. Moscow,

Vyschaja Schkola, 1993

RPA – Tool for Rocket Propulsion Analysis www.propulsion-analysis.com

qr=εe σ(εr

T ∞

T∞

4

− εr

T w

Tw

4

)

εe=εw /[1−(1−εw)(1−εr

T w

)]

qw = αT (Taw−Tw) αT =

[0.026

Dt

0.2

(μ∞

0

)0.2

cp∞

0

(Pr∞

0

)

0.6 (pc

0

c

* )

0.8

(Dt

R )

0.1

] (At

A )

0.9

σ

σ=

[1

2

Tw

Tc

0 (1+

γ−1

2

M

2

)+

1

2]

−0.68

[1+

γ−1

2

M

2

]

−0.12

Taw=Tc

0

[1+Pr1/3

(γ−1

2 )M2

1+(γ−1

2 )M2

]

qw = αT ρx v∞(I∞

0

−Iw) αT =

( z

zT

)

0.089 Pr−0.56

(1−0.21

1−Pr

Pr

4/3

β

2

1− ̄Tw

)

0.9225

(307.8+54.8 log

2

( Pr

19.5))Pr

0.45

z

0.08

−650](https://image.slidesharecdn.com/sp2014pres2967435ponomarenko-140522153109-phpapp01/85/RPA-Tool-for-Rocket-Propulsion-Analysis-20-320.jpg)

![Thrust Chamber Thermal Analysis

Regenerative cooling: coolant-side heat transfer

RPA – Tool for Rocket Propulsion Analysis www.propulsion-analysis.com

Nu = 0.021Rec

0.8

Prc

0.4

(0.64+0.36

T c

Twc

) for kerosene

[1]

for liquid hydrogen

[1]

for methane

[1]

for other coolants

[2]

Nu = 0.033Rec

0.8

Prc

0.4

(Tc

Twc

)

0.57

Nu = 0.0185 Rec

0.8

Prc

0.4

(Tc

T wc

)

0.1

Nu = 0.023Rec

0.8

Prc

0.4

1. Lebedinsky E.V., Kalmykov G.P., et al. Working processes in liquid-propellant rocket engine and their simulation. Moscow,

Mashinostroenie, 2008

2. Vasiliev A.P., Kudryavtsev V.M. et al. Basics of theory and analysis of liquid-propellant rocket engines, vol.2. 4th Edition. Moscow,

Vyschaja Schkola, 1993](https://image.slidesharecdn.com/sp2014pres2967435ponomarenko-140522153109-phpapp01/85/RPA-Tool-for-Rocket-Propulsion-Analysis-22-320.jpg)

![Thrust Chamber Thermal Analysis

Gaseous film cooling

RPA – Tool for Rocket Propulsion Analysis www.propulsion-analysis.com

BLC

Core (O/F)core

, Tcore

(O/F)f

, Tf[(O/F)b

, Tb

]1

mf

.

[(O/F)b

, Tb

]2

Wall

Combustion,Mixing

At each point downstream of

injection point, the mixing rate is

a function of distance from the

injection point and the relative

mass flow rate of the film.](https://image.slidesharecdn.com/sp2014pres2967435ponomarenko-140522153109-phpapp01/85/RPA-Tool-for-Rocket-Propulsion-Analysis-24-320.jpg)

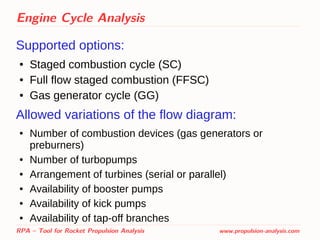

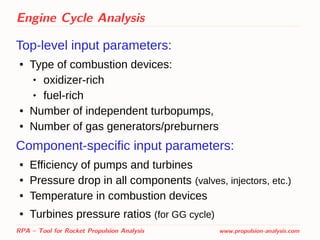

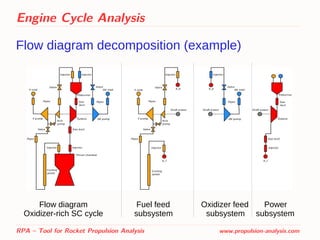

![Engine Cycle Analysis

Parameters of components

The pump shaft power:

The power developed by

gas turbine:

The power developed by

hydraulic turbine:

RPA – Tool for Rocket Propulsion Analysis www.propulsion-analysis.com

Np =

˙m

ηp

( pout− pin)

ρ

Nt = ˙mt ηt

γ

γ−1

R0

Tt in

0

[1−(1

δt

)

γ−1

γ

]

Nt = ˙mt ηt

( pout−pin)

ρ](https://image.slidesharecdn.com/sp2014pres2967435ponomarenko-140522153109-phpapp01/85/RPA-Tool-for-Rocket-Propulsion-Analysis-29-320.jpg)

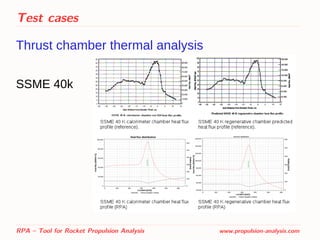

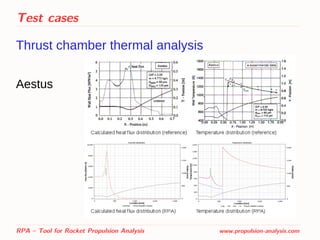

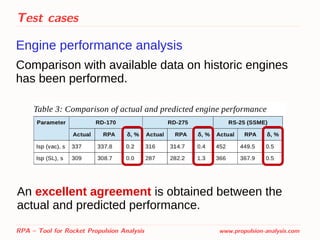

![Test cases

Thrust chamber thermal analysis

Comparison with available reference data has been

performed:

– SSME 40k [1]

– Aestus [2]

RPA – Tool for Rocket Propulsion Analysis www.propulsion-analysis.com

[1] Scaling Techniques for Design, Development, and Test.

Carol E. Dexter, Mark F. Fisher, James R. Hulka, Konstantin P. Denisov,

Alexander A. Shibanov, and Anatoliy F. Agarkov

[2] Simulation and Analysis of Thrust Chamber Flowfields: Storable Propellant Rockets.

Dieter Preclik, Oliver Knab, Denis Estublier, and Dag Wennerberg](https://image.slidesharecdn.com/sp2014pres2967435ponomarenko-140522153109-phpapp01/85/RPA-Tool-for-Rocket-Propulsion-Analysis-35-320.jpg)