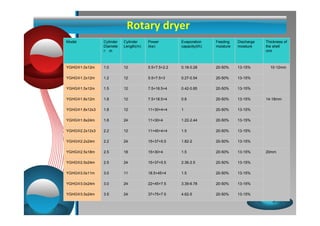

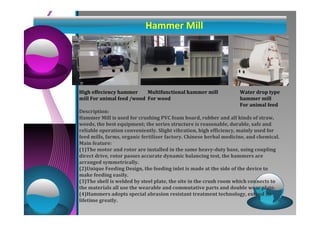

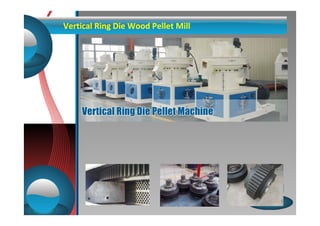

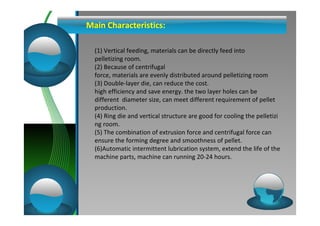

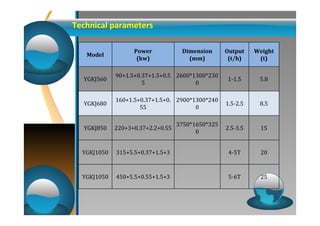

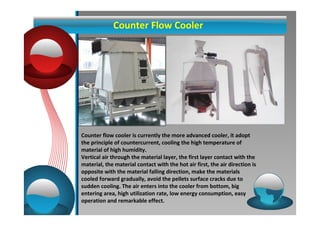

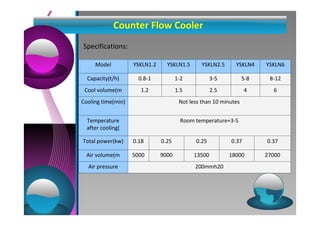

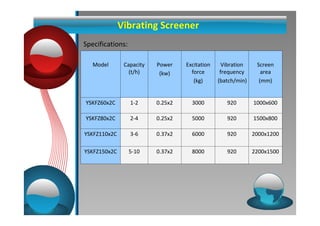

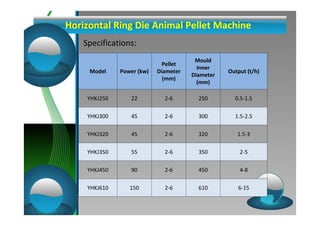

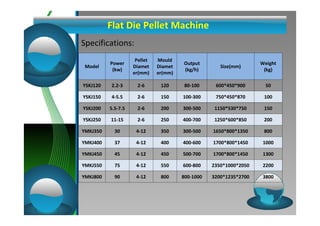

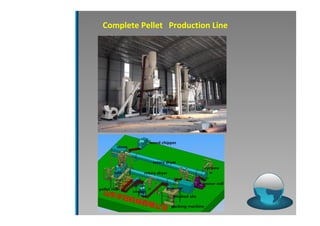

Rotexmaster specializes in manufacturing various machinery for processing wood and animal feed, including wood chippers, rotary dryers, hammer mills, pellet mills, and coolers. The document outlines specifications, advantages, and applications of their products such as wood chips, sawdust machines, counter flow coolers, and transformers. It concludes with an invitation to visit their factory and see their production lines.