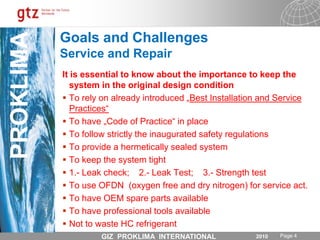

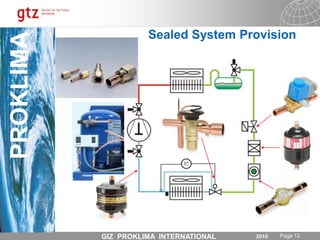

1) The document discusses servicing and safety standards for R-290 air conditioning systems, including the importance of keeping systems sealed and leak-free.

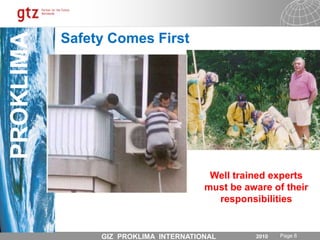

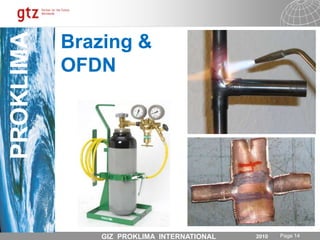

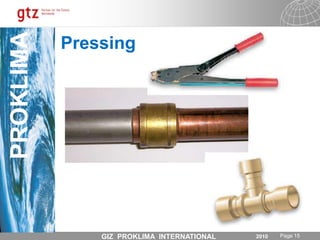

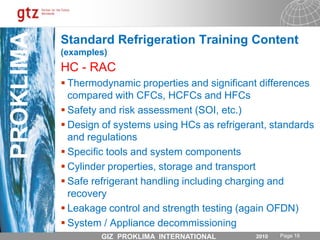

2) It emphasizes that only well-trained experts who are aware of their responsibilities should service HC refrigerant systems, and outlines what content should be included in standard refrigeration training, such as principles of refrigeration, components, refrigerants, and safety practices.

3) The training is intended for all personnel working with HC appliances and systems, from design to disposal, and certification of both individual technicians and companies is recommended.