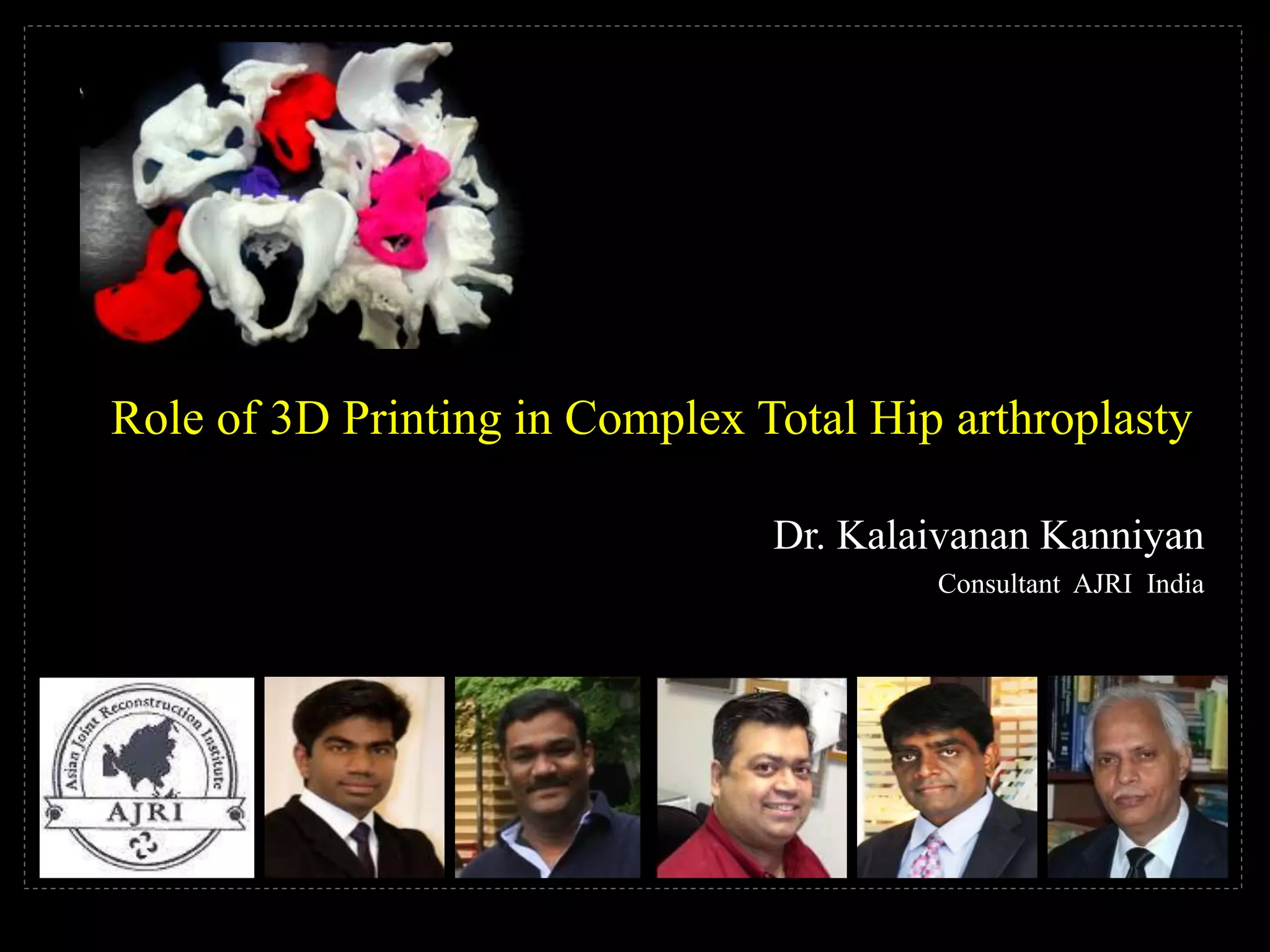

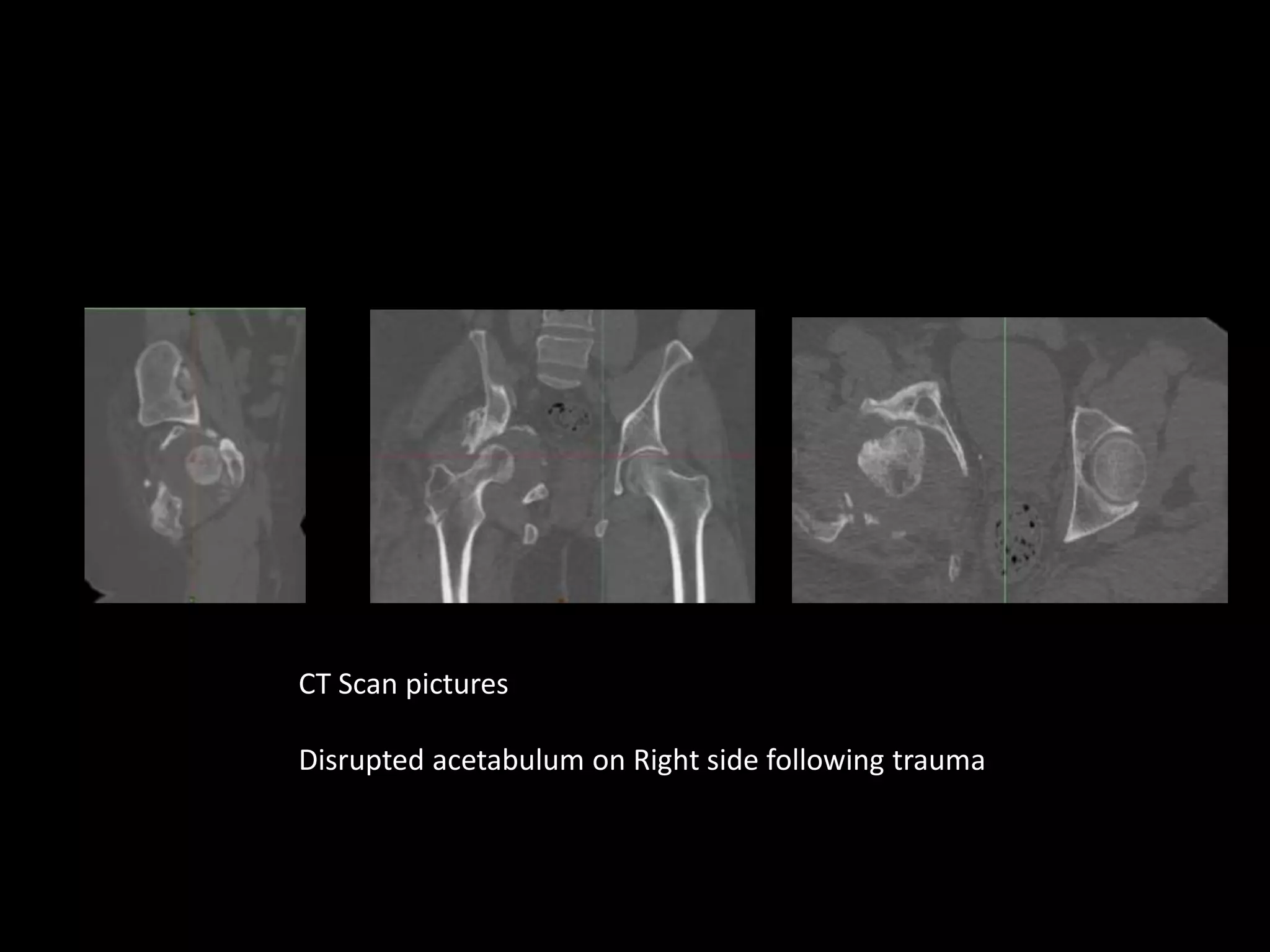

The document discusses the role of 3D printing in complex total hip arthroplasty, detailing the historical development and various technologies involved, including stereolithography and fused deposition modeling. It highlights current applications in orthopedics, such as custom implants and preoperative planning, and outlines the steps involved in 3D printing and modeling. Additionally, it addresses misconceptions around 3D printing in clinical settings and provides cost comparisons of different 3D printing methods.