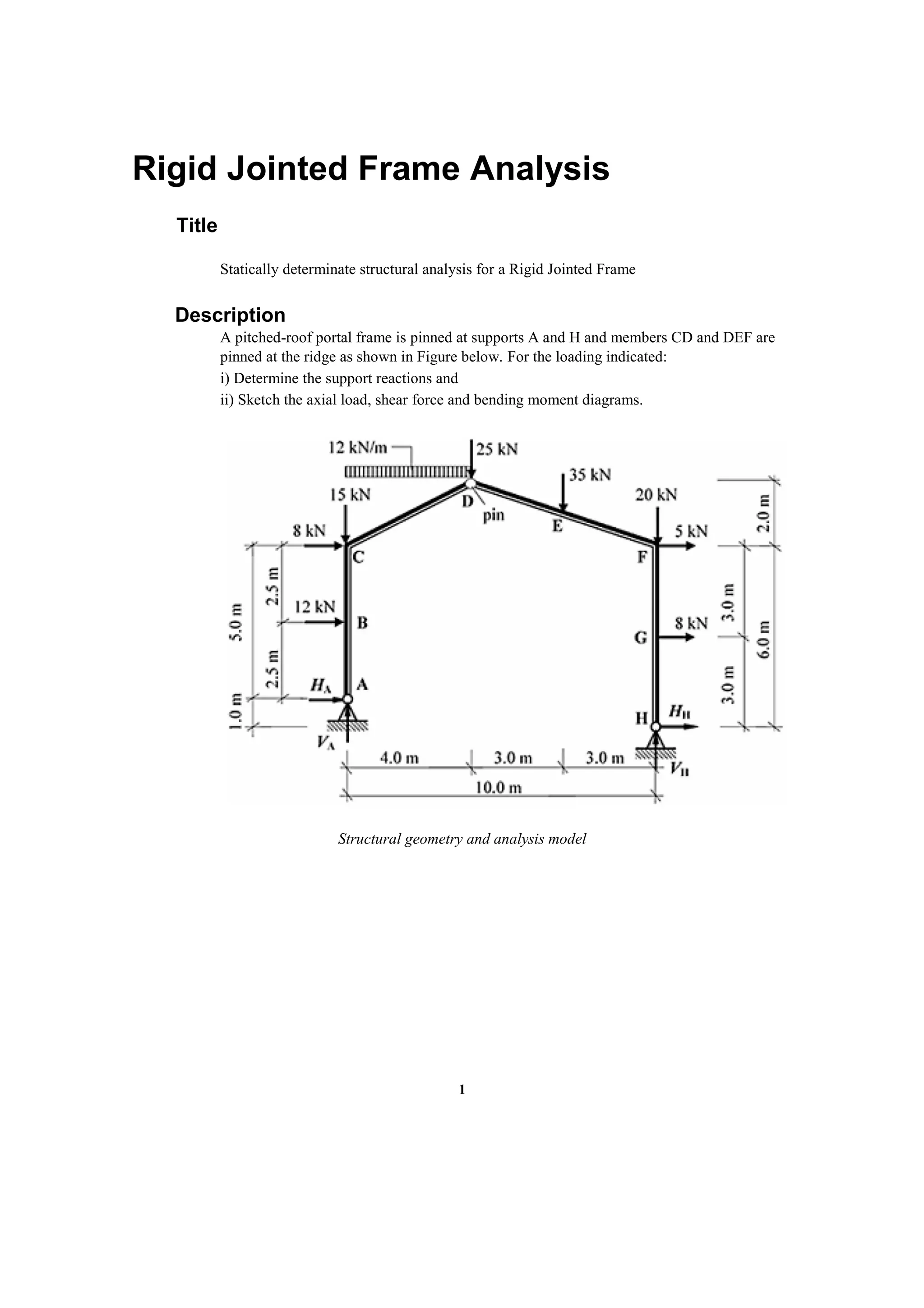

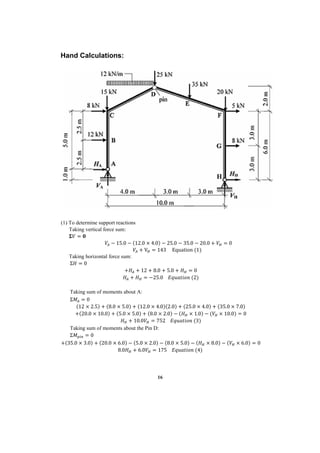

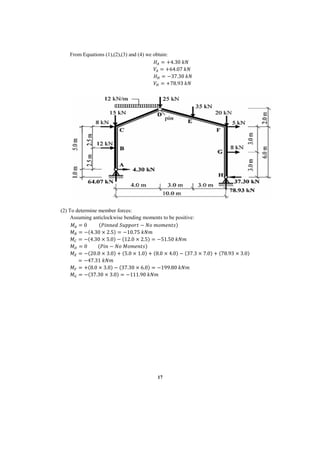

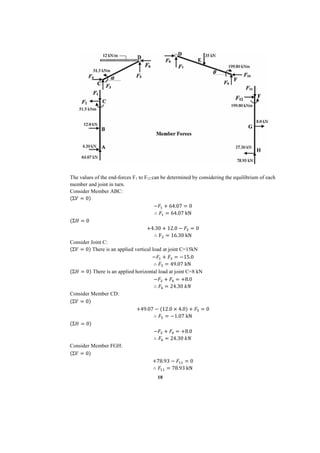

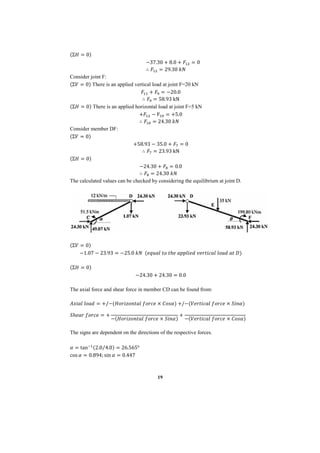

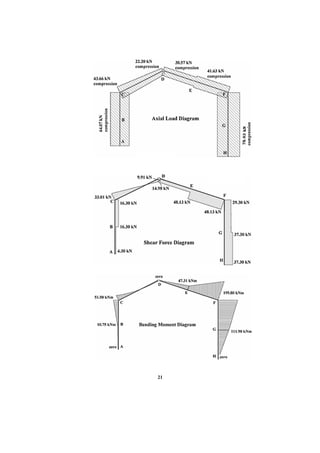

This document describes a finite element analysis of a rigid jointed frame structure. It provides the geometry, material properties, boundary conditions and loading of the frame. It then outlines the steps to model the frame in finite element software, apply the loading, perform the analysis, and view the results for support reactions, axial forces, shear forces, and bending moments. Hand calculations are also shown to verify the analysis results.