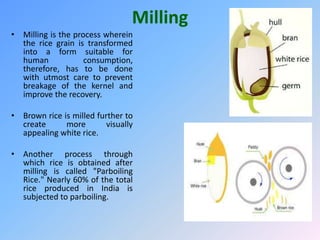

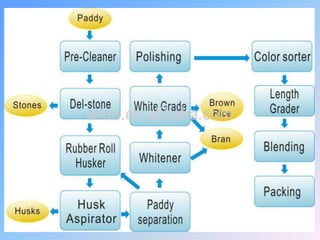

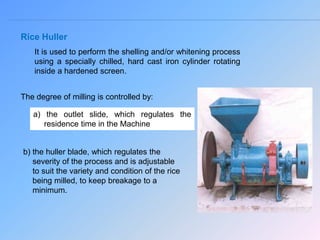

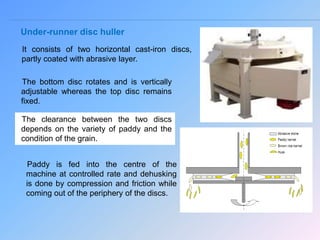

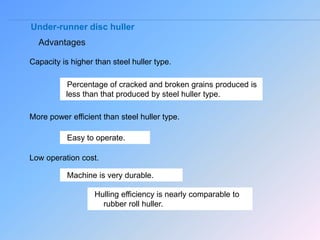

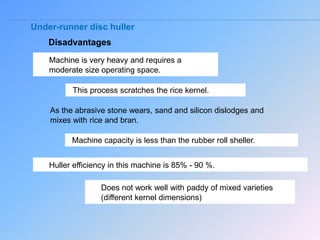

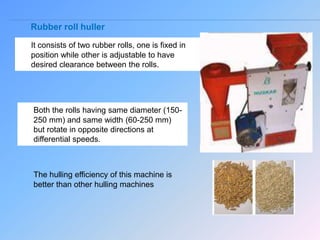

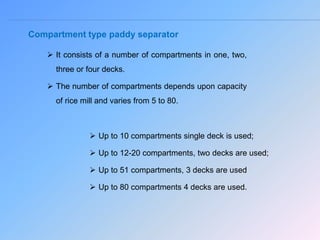

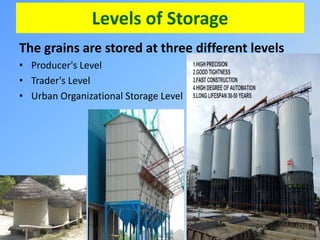

This document discusses post-harvest management of rice from threshing through milling. It begins with an overview of rice production in India and reasons for post-harvest losses. It then covers threshing methods, drying techniques, parboiling, and milling processes. For milling, it describes the hulling and separation steps used to remove the husk and separate components. The goal of post-harvest management is to process rice while maintaining high quality and minimizing losses between harvest and consumption.