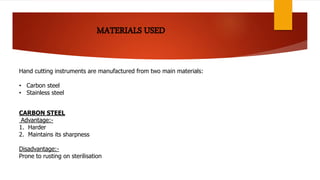

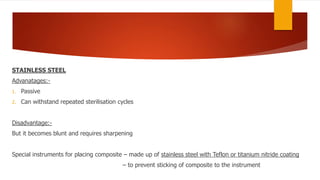

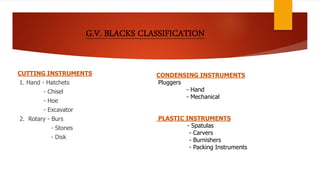

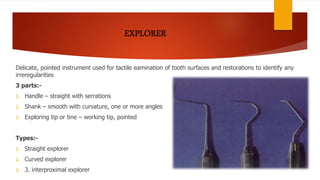

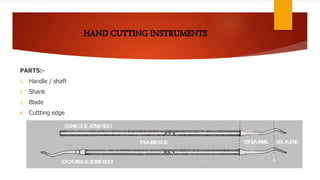

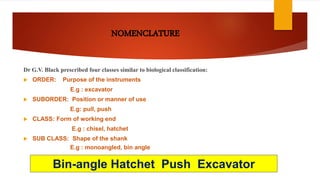

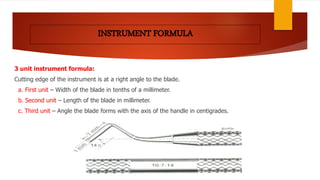

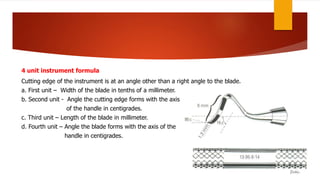

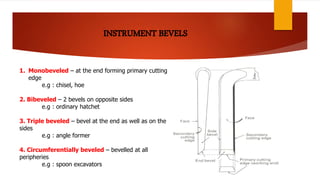

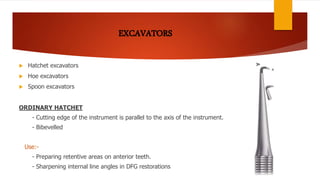

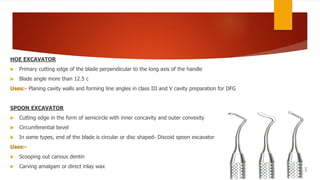

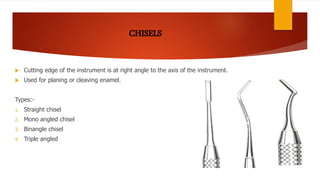

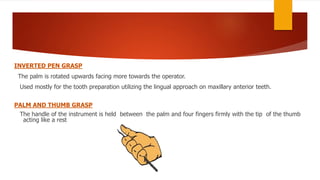

The document discusses various hand instruments used in dentistry, including their materials, advantages/disadvantages, and uses. It covers cutting instruments like hatchets and chisels made of carbon steel or stainless steel, as well as condensing, plastic, finishing, isolating, exploring, restoring, and sharpening instruments. Grasps for holding instruments including pen, modified pen, inverted pen, and palm and thumb are also outlined.