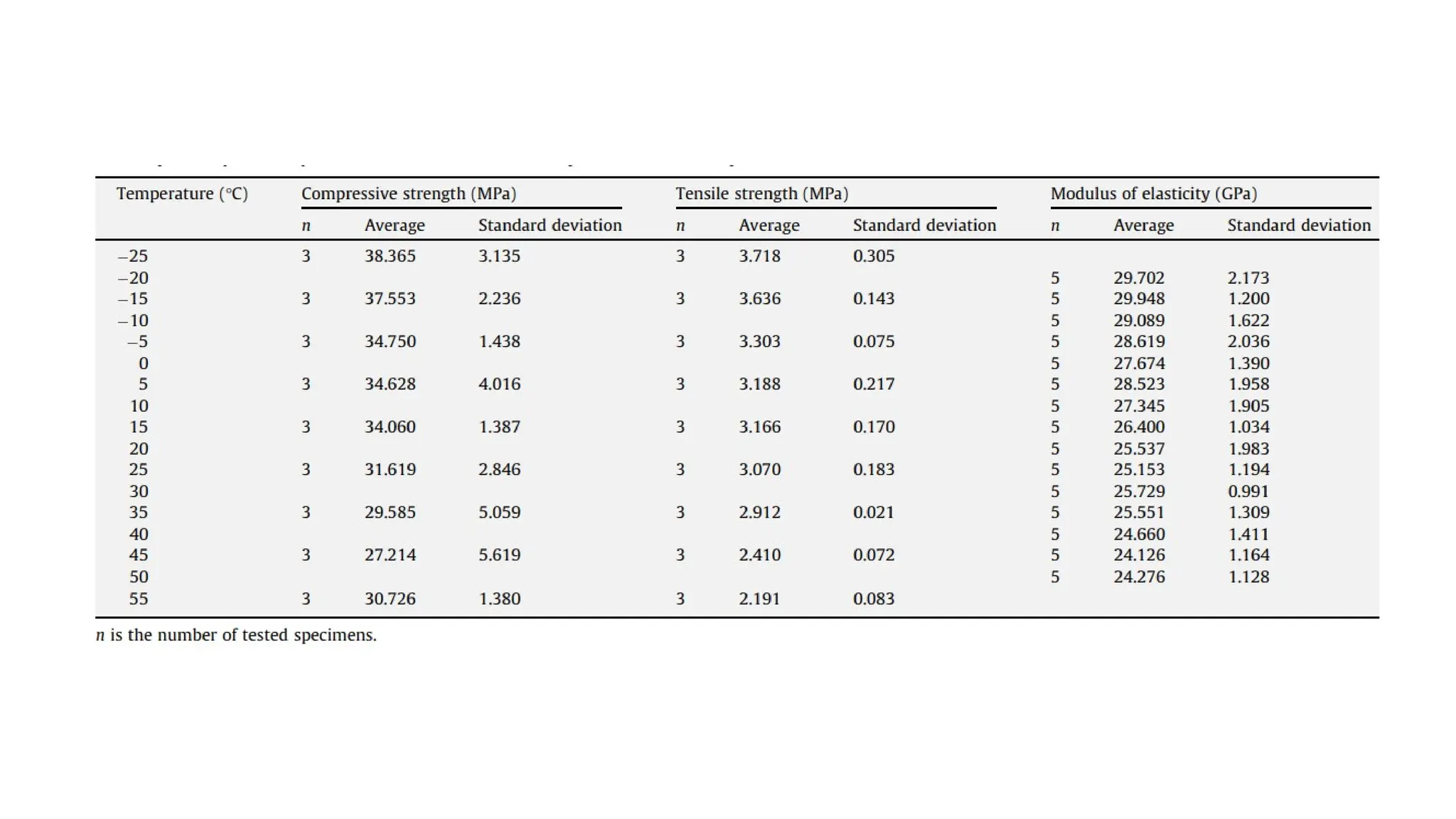

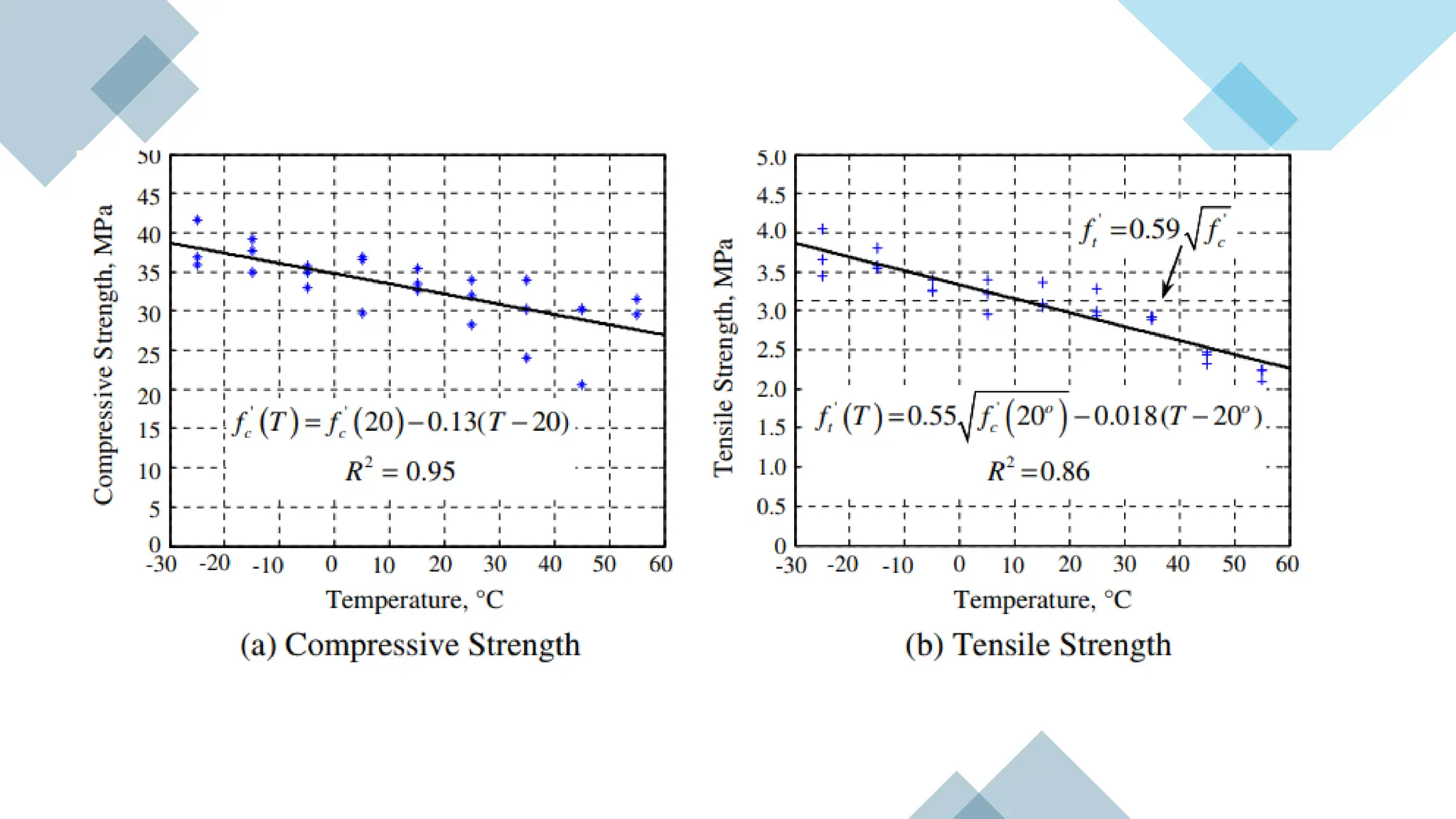

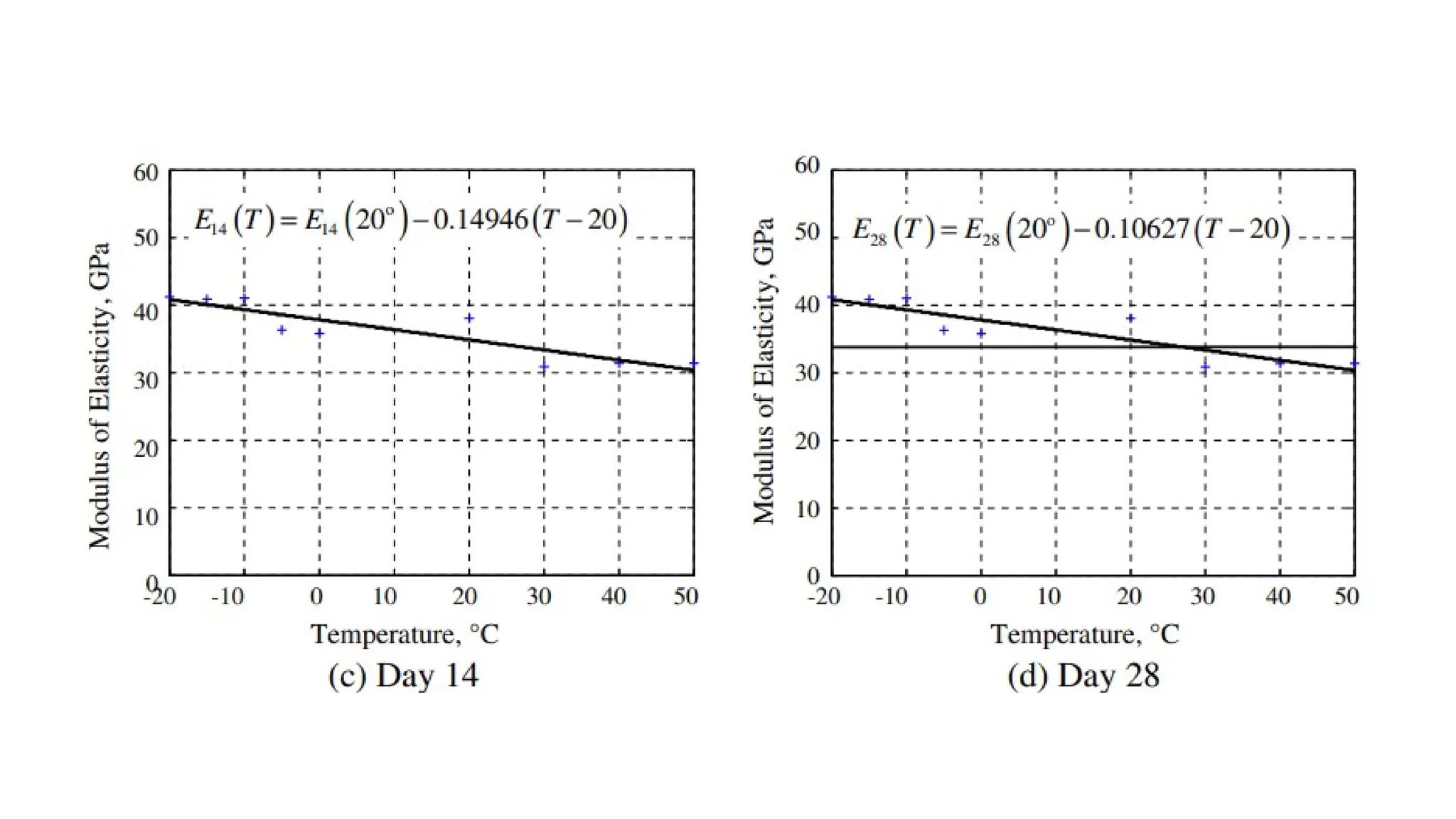

Extreme environmental conditions during the pouring and curing of concrete significantly affect its mechanical properties, leading to potential construction delays if not managed properly. Research indicates that increased temperatures and moisture levels can substantially decrease both compressive and tensile strength, with a notable 38% reduction in compressive strength observed at 80°C. Proper curing practices and considerations of these environmental impacts are essential for ensuring the durability and structural integrity of concrete structures.

![introductio

n

• Concrete's mechanical and physical properties

are significantly influenced by the

environmental conditions during pouring and

curing. Extensive research shows that

extreme conditions—cold, dry, damp, humid,

hot—impact its curing process. Construction

may need to be delayed unless precautions

like heating or wetting surfaces are taken. The

main concern is how cured concrete behaves

under varying conditions. Studies indicate

that changes in temperature and moisture

affect concrete's compressive strength and

elasticity. For example, Lawson et al. [12]

found a 100°C rise in temperature causes a

50% loss in compressive strength. Proper

curing practices are essential for the

durability of concrete structures.](https://image.slidesharecdn.com/nagiib-240829231002-21c4155d/75/reinforced-concrete-for-diffrent-temperature-1-2048.jpg)