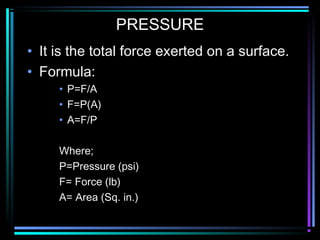

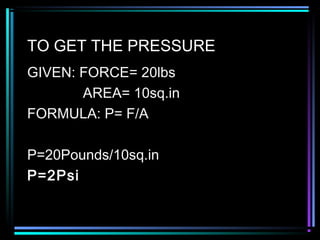

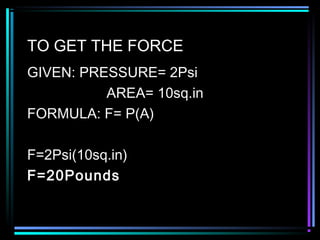

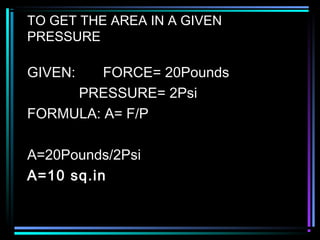

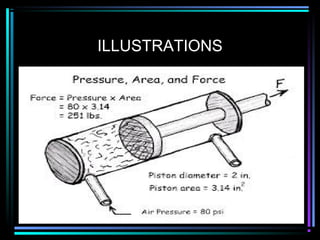

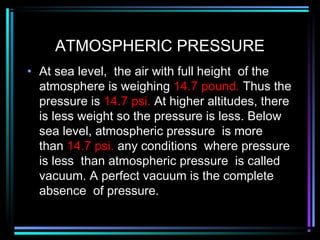

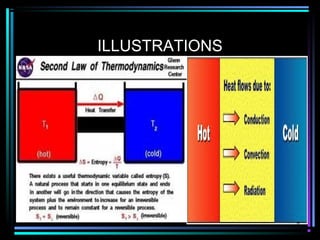

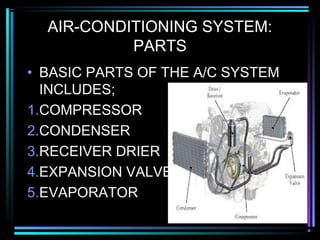

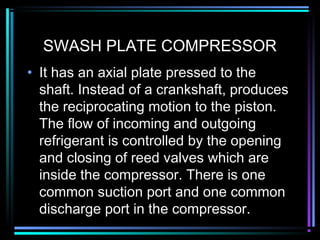

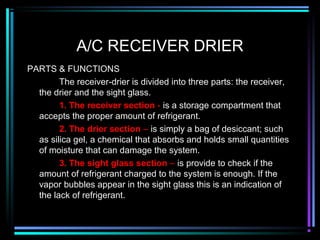

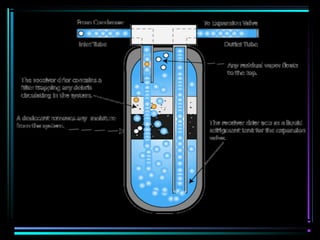

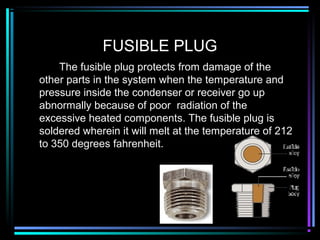

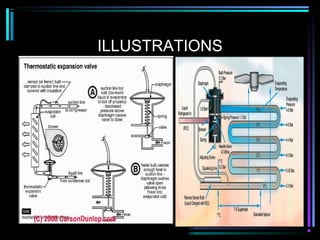

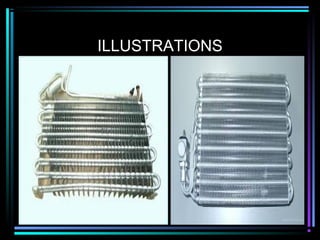

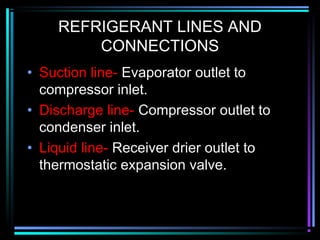

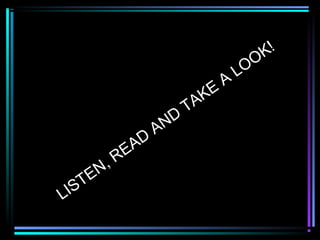

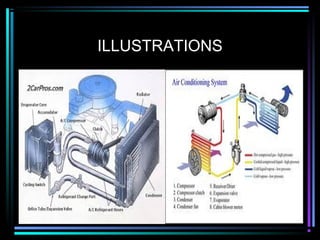

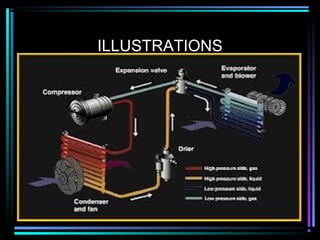

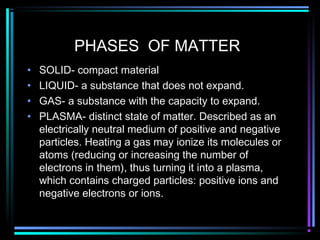

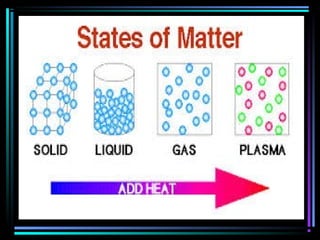

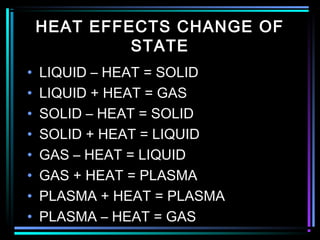

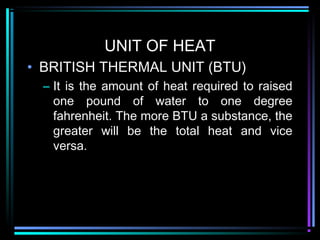

This document provides an overview of automotive air conditioning systems, including their history, how they work, and maintenance. It discusses how refrigeration systems use compression, condensation, expansion, and evaporation cycles to cool air. The main components of an air conditioning system are described as the compressor, condenser, receiver drier, expansion valve, and evaporator. Different types of compressors like reciprocating and swash plate compressors are also summarized. The document outlines refrigeration cycles and thermodynamics concepts like pressure, temperature, humidity and the laws of thermodynamics.

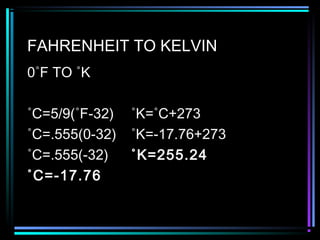

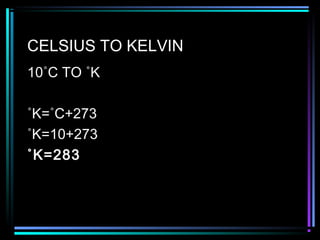

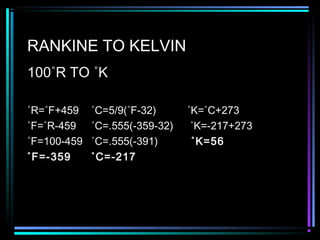

![KELVIN TO RANKINE

100˚K TO ˚R

˚K=˚C+273 ˚ F=(9/5X˚C)+32 ˚R=˚F+459

˚C=˚K-273 ˚ F=[1.8X(-173)]+32 ˚R=-279.4+459

˚C=100-273 ˚ F=-311.4+32 ˚R=179.6

˚C=-173 ˚ F=-279.4](https://image.slidesharecdn.com/at211-pptforprelim-180119082449/85/AUTOMOTIVE-AIR-CONDITIONING-SYSTEM-33-320.jpg)

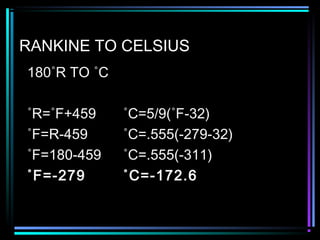

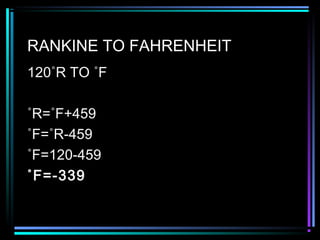

![KELVIN TO FAHRENHEIT

200˚K TO ˚F

˚K=˚C+273 ˚F=(9/5X˚C)+32

˚C=˚K-273 ˚F=[1.8(-73)]+32

˚C=200-273 ˚F=-131.4+32

˚C=-73 ˚F=-163.4](https://image.slidesharecdn.com/at211-pptforprelim-180119082449/85/AUTOMOTIVE-AIR-CONDITIONING-SYSTEM-35-320.jpg)