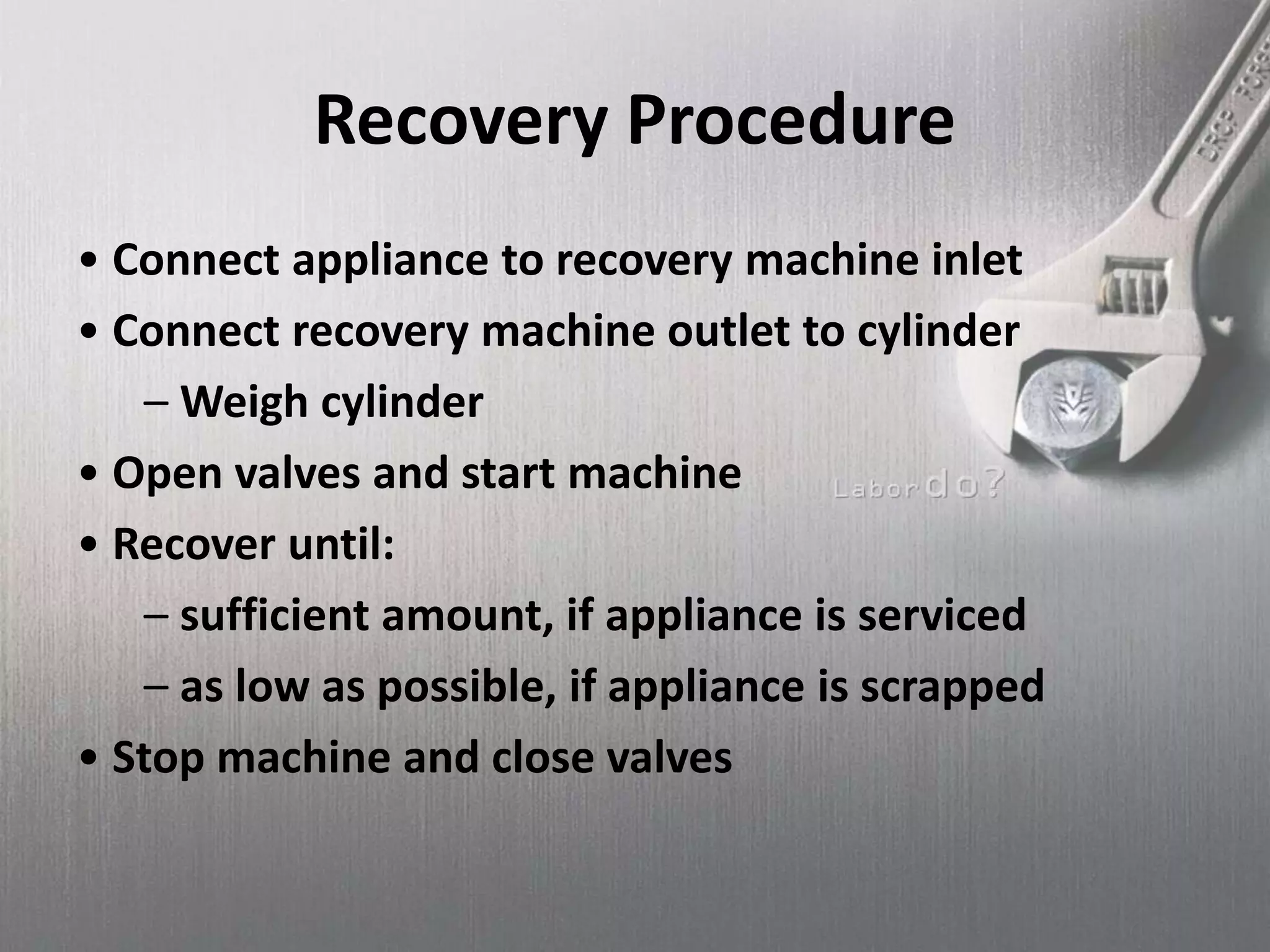

This document discusses refrigerant recovery and why it is important. It notes that 30% of CFC releases into the atmosphere come from mobile air conditioners during service and repair. Using a refrigerant recovery unit is important to prevent these harmful releases into the atmosphere and damage to the ozone layer. It then provides details on the components and operation of a typical refrigerant recovery system, which uses a vacuum pump to pull refrigerant out of an appliance and into a recovery cylinder to be filtered and reused. International standards generally require recovery and recycling of refrigerants rather than venting them.