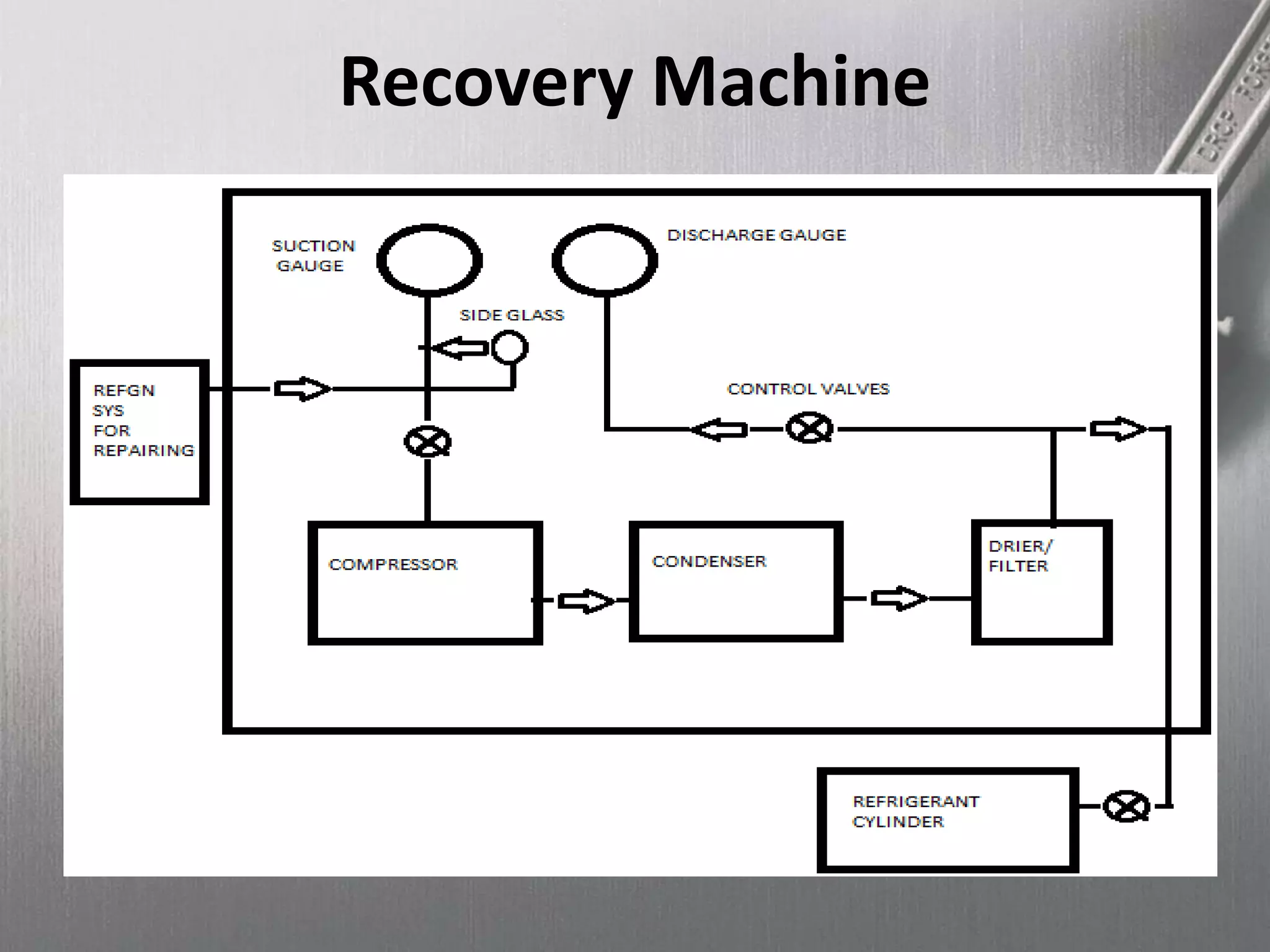

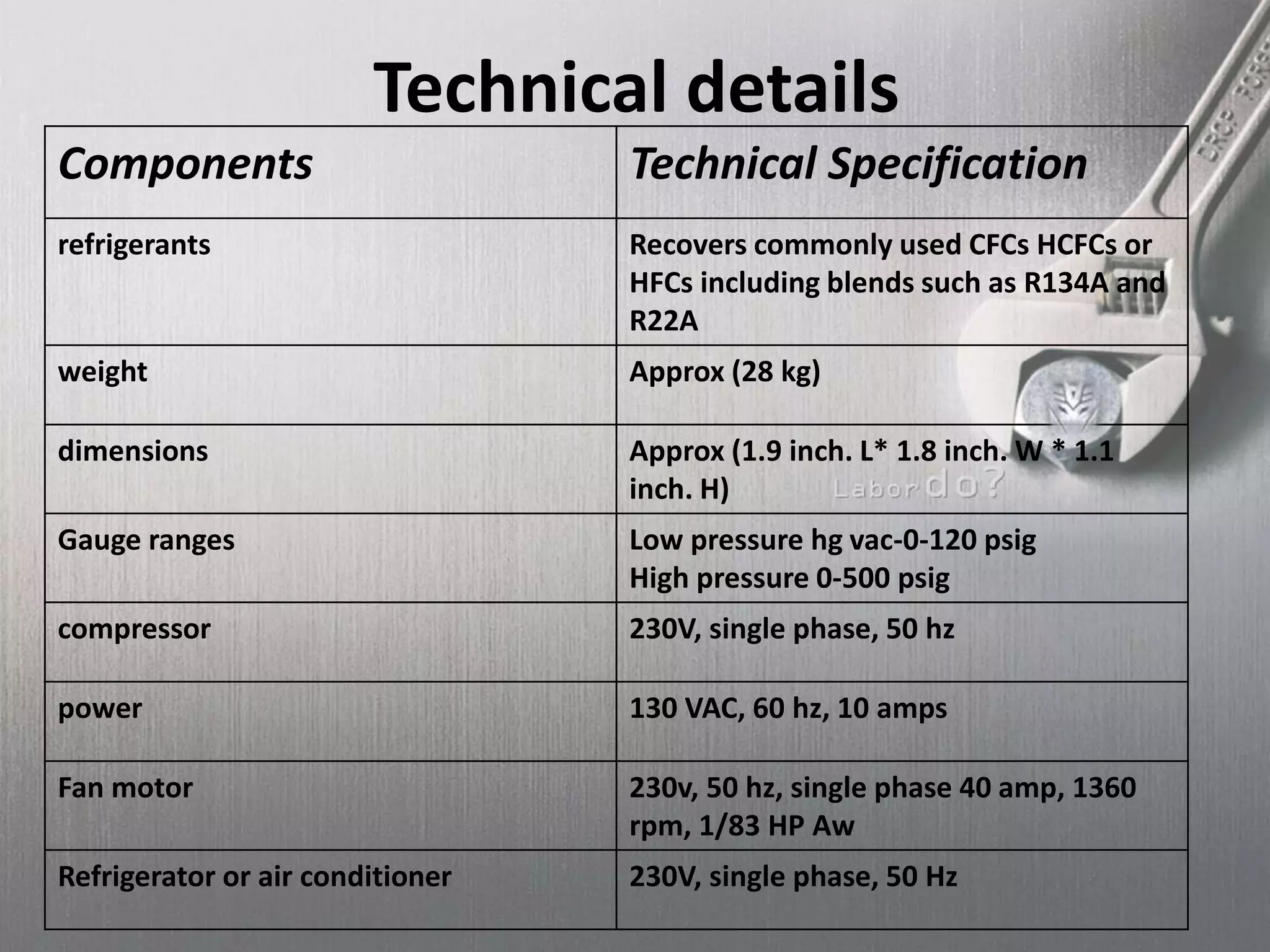

The document summarizes a seminar presentation on a Refrigerant Recovery Unit developed by students at Umrer College of Engineering. The recovery unit was designed to recover and reuse refrigerants from appliances like air conditioners and refrigerators in order to reduce their environmental impact. It consists of components like a compressor, condenser, fan motor, filter drier and acrylic sheets. The presentation describes the purpose and specifications of each component as well as the objectives, assembly process, and maintenance of the refrigerant recovery unit. It aims to reuse refrigerants, reduce their atmospheric effects, lower appliance repair costs and help prevent ozone layer depletion.