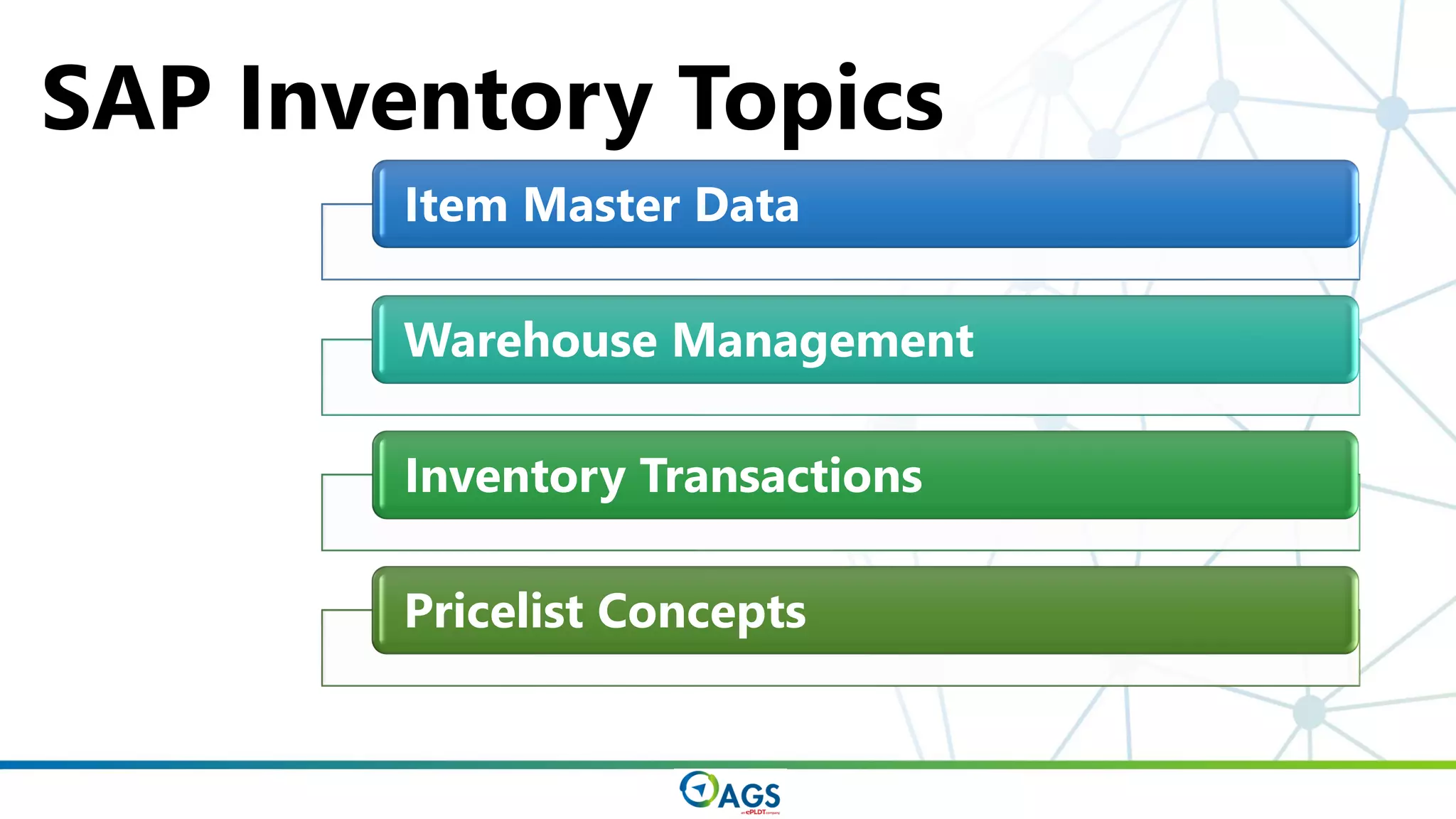

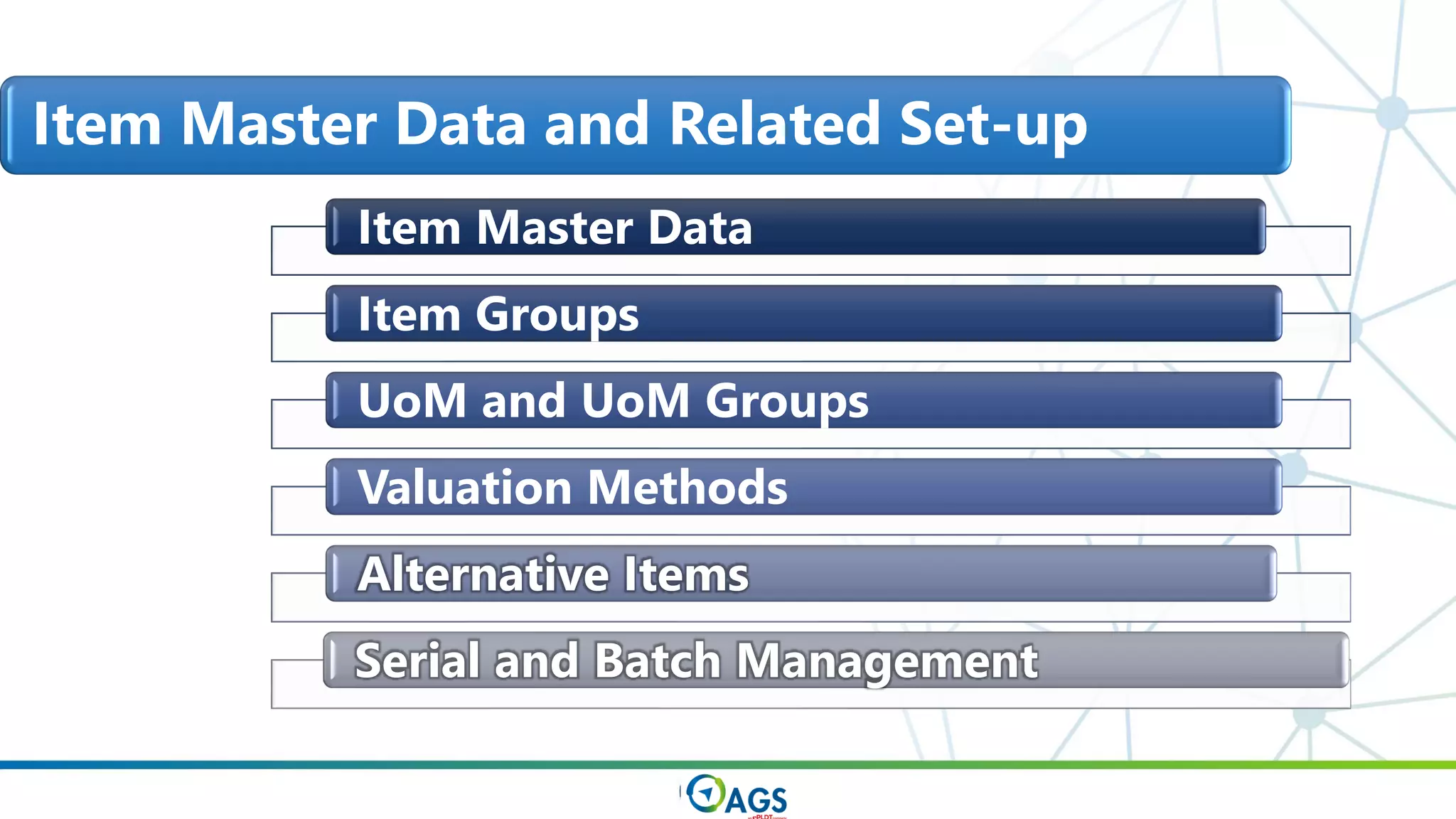

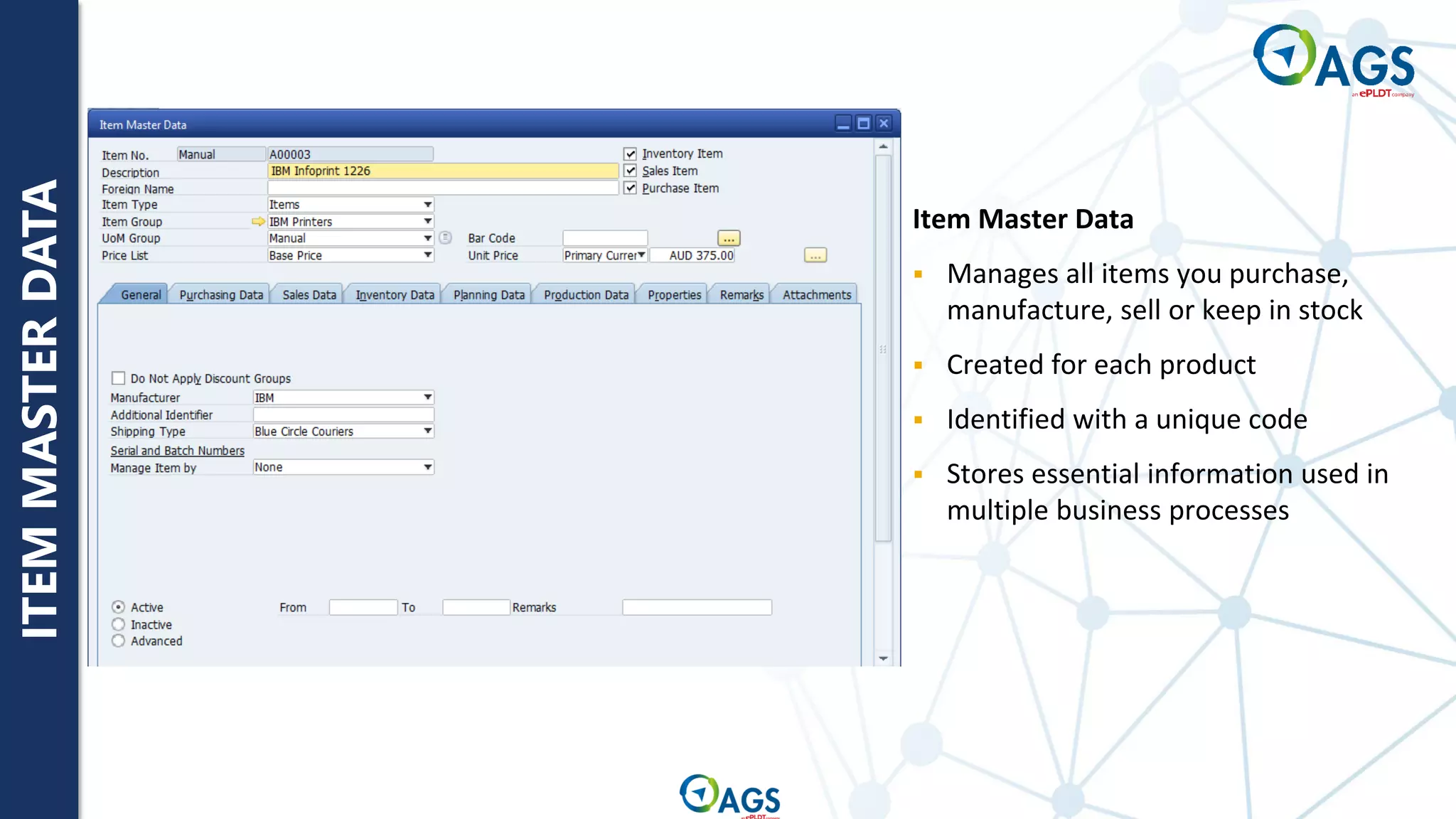

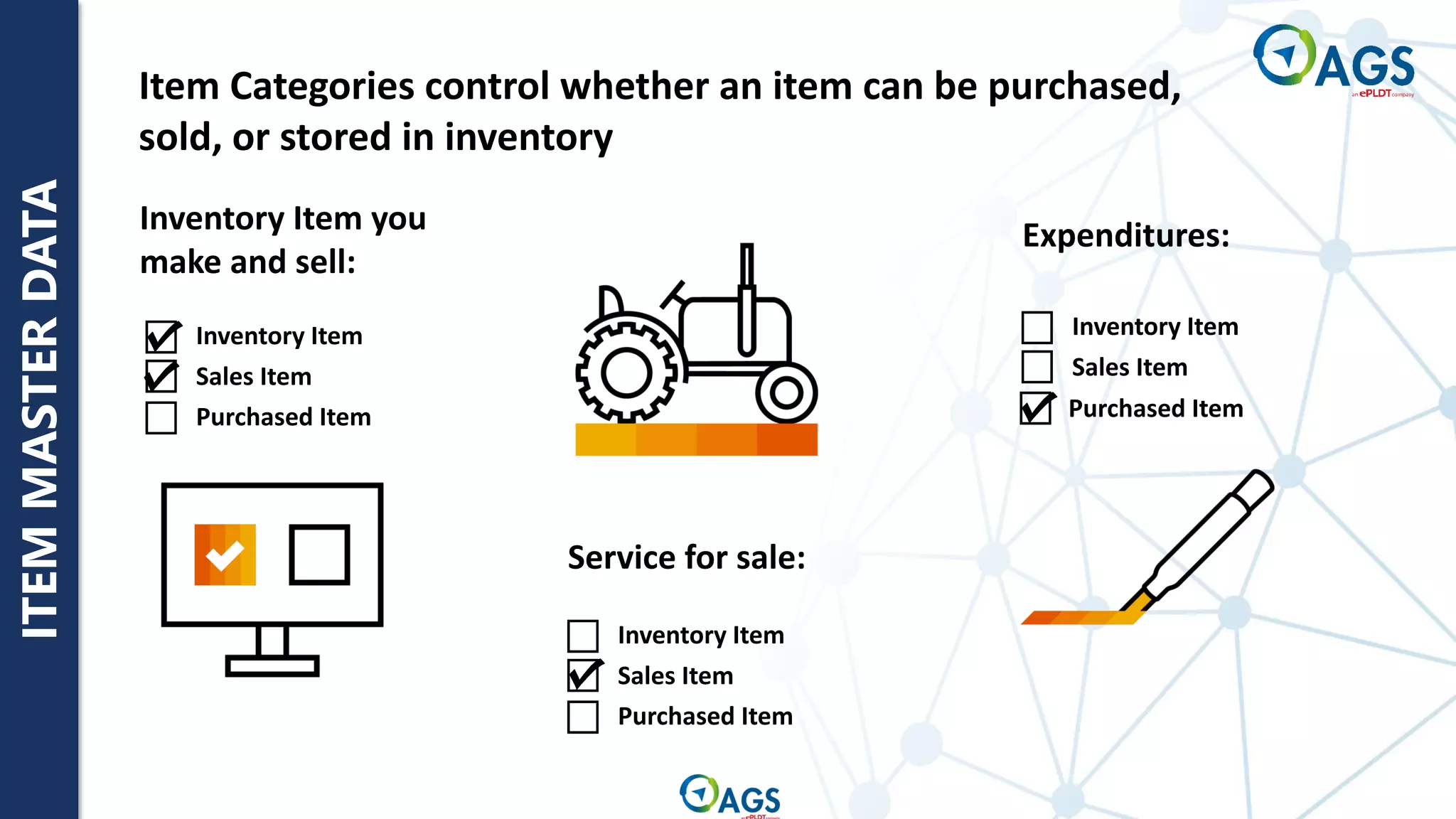

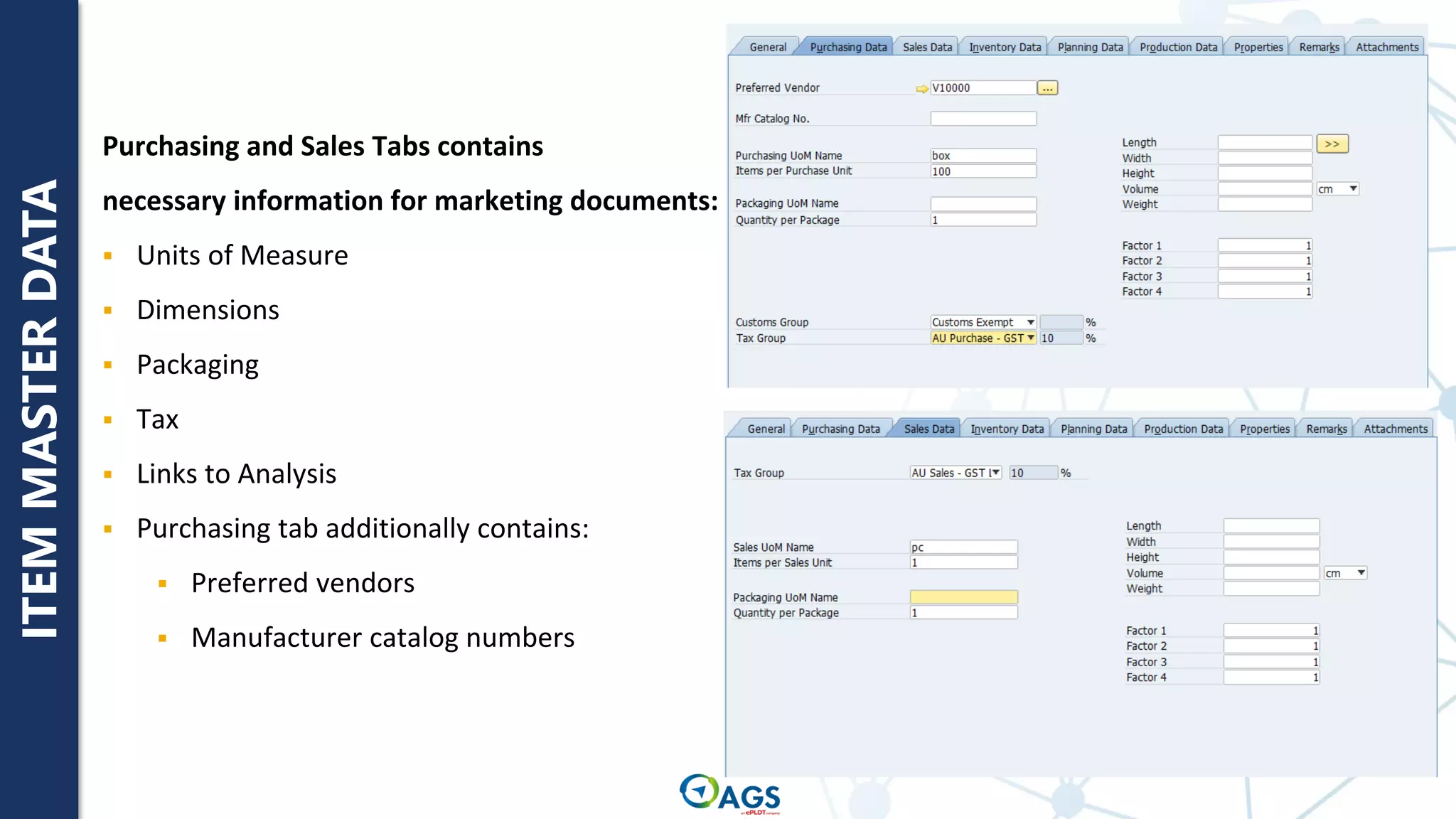

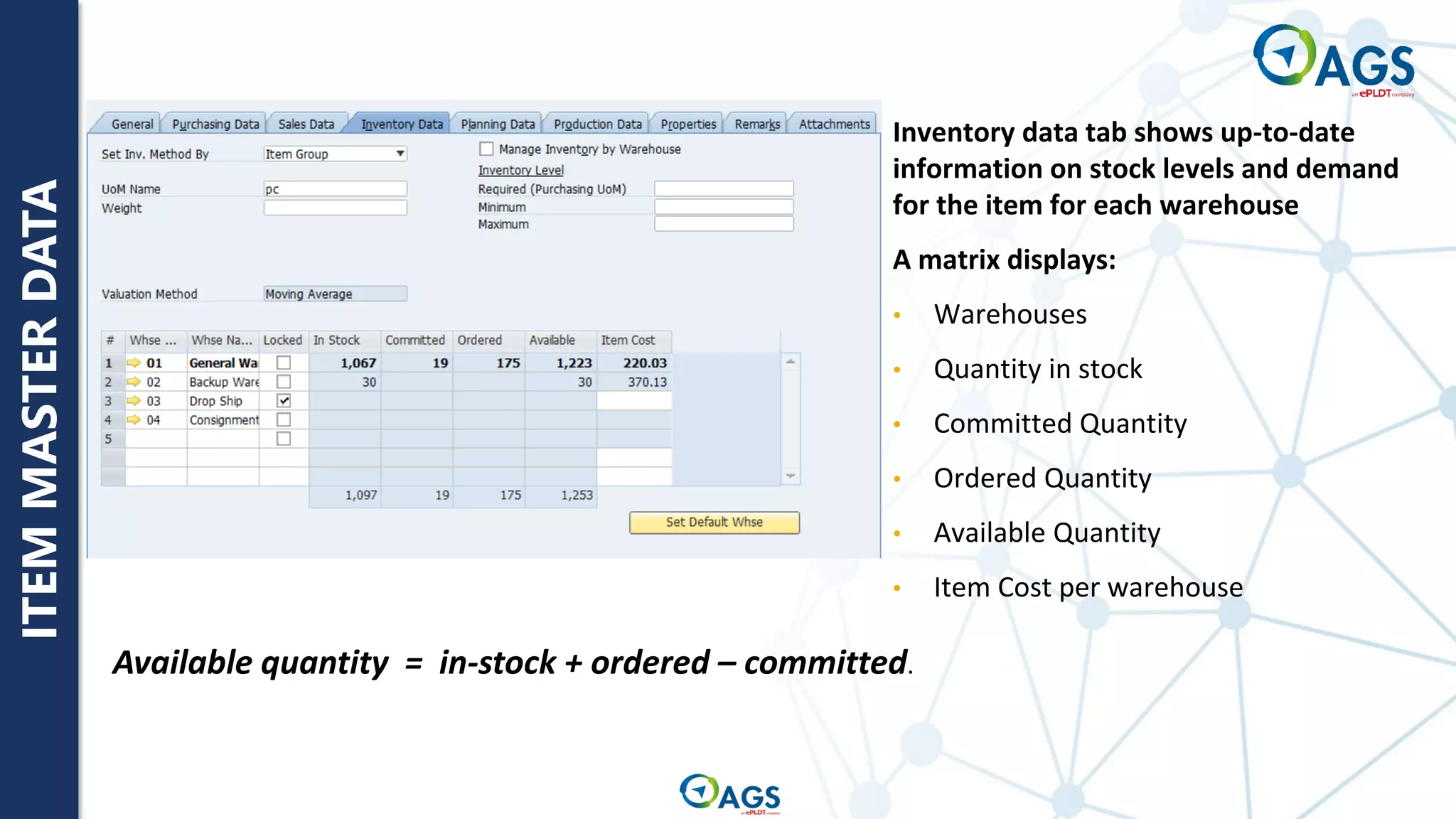

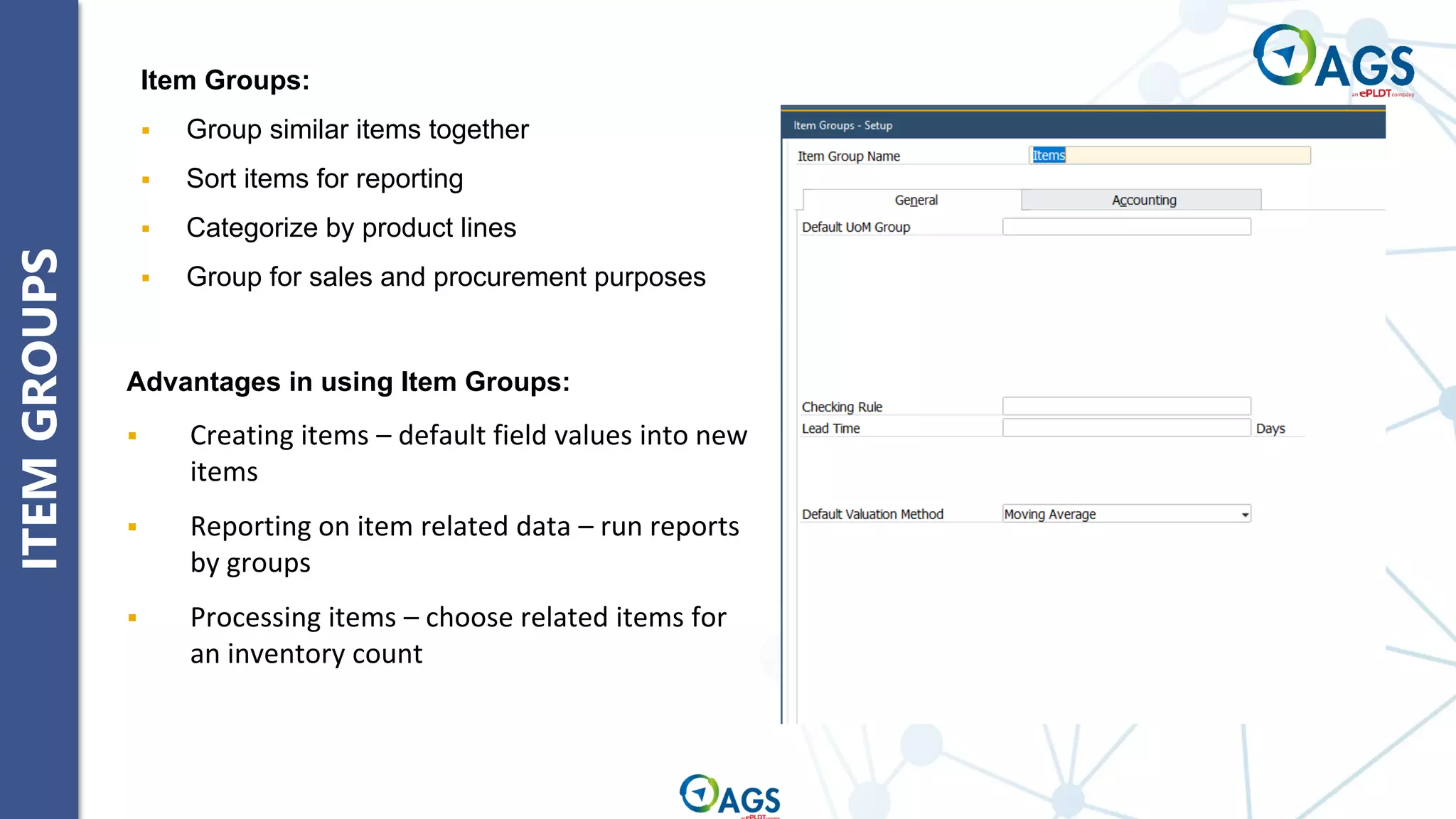

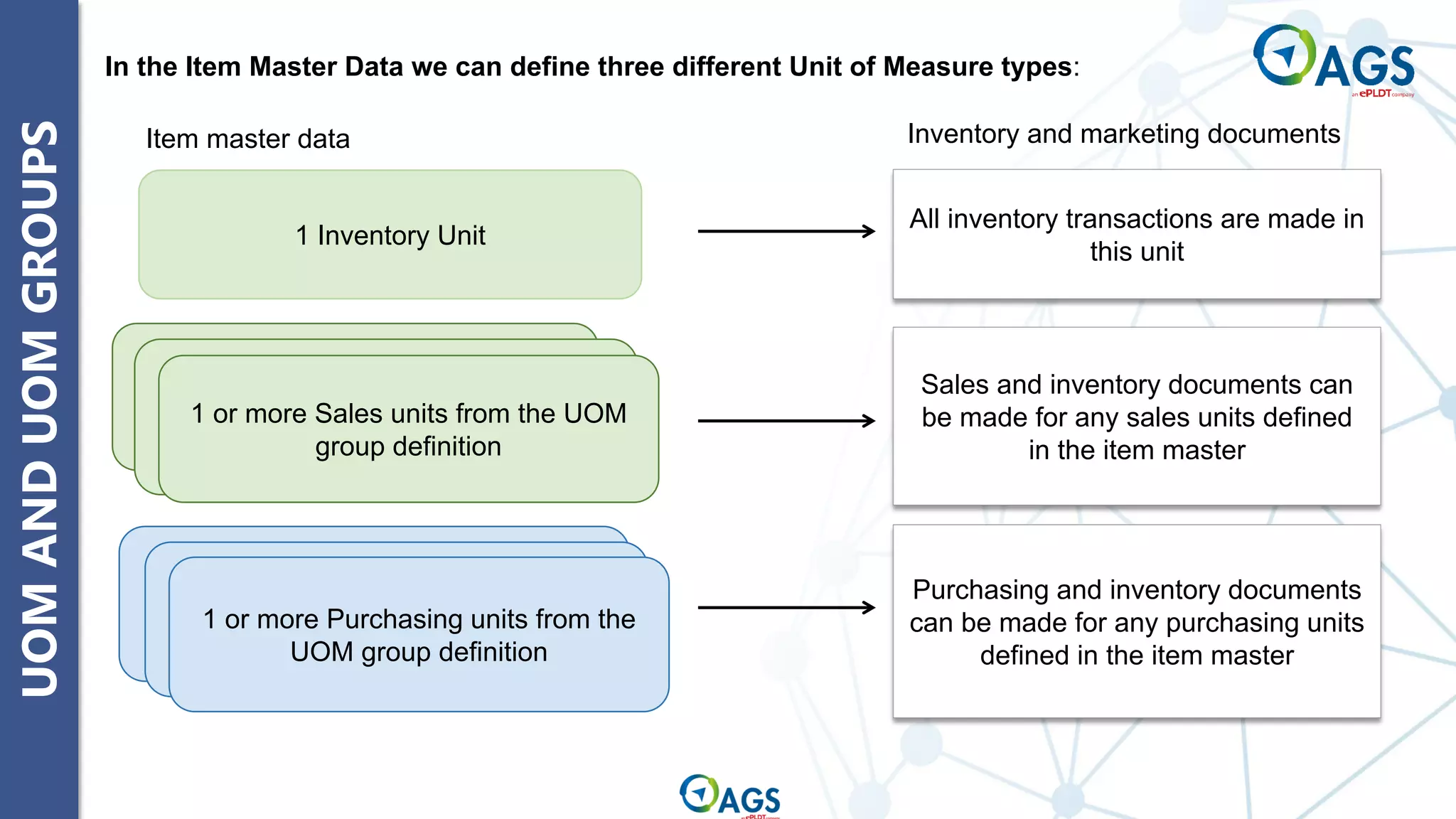

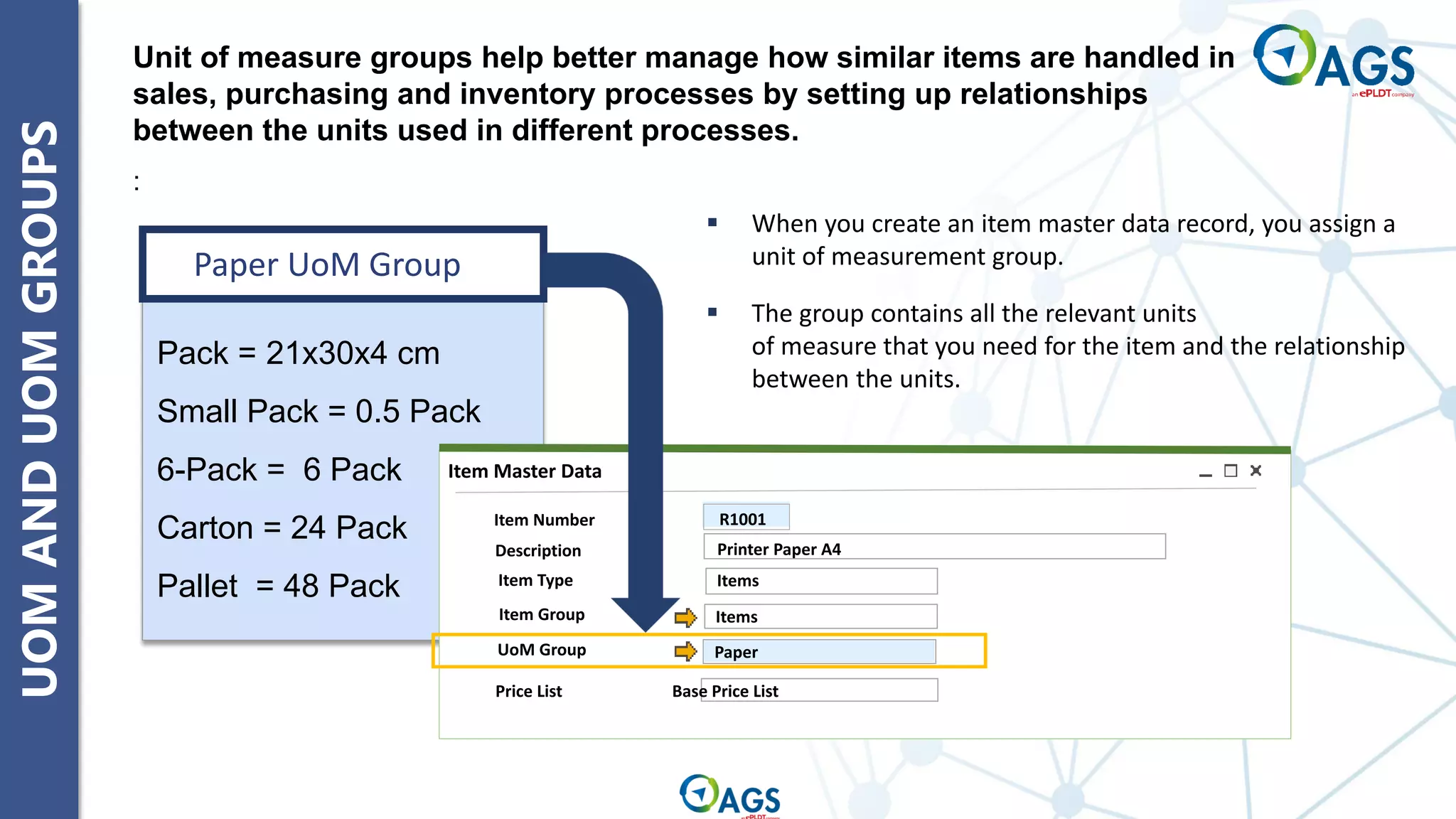

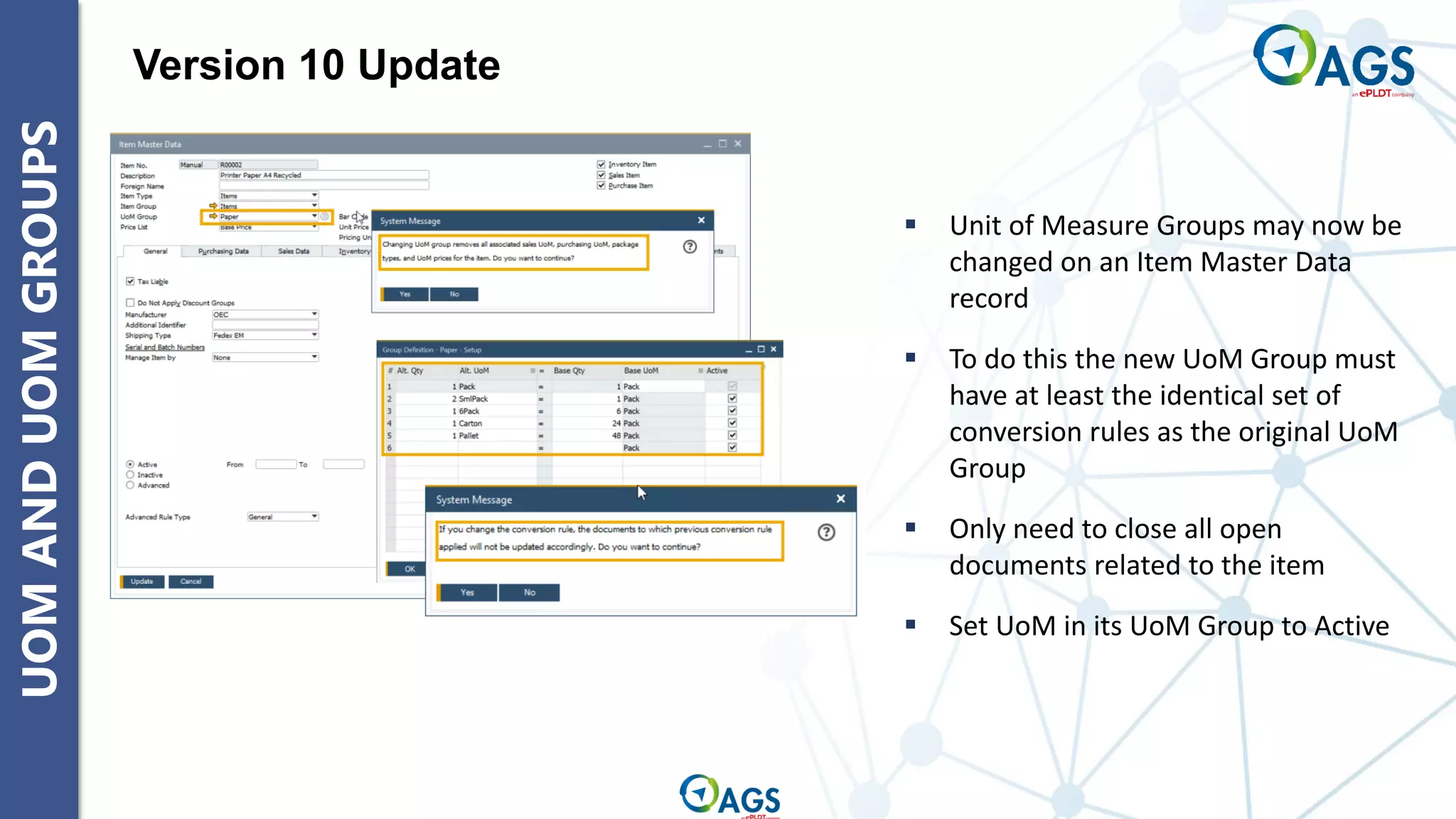

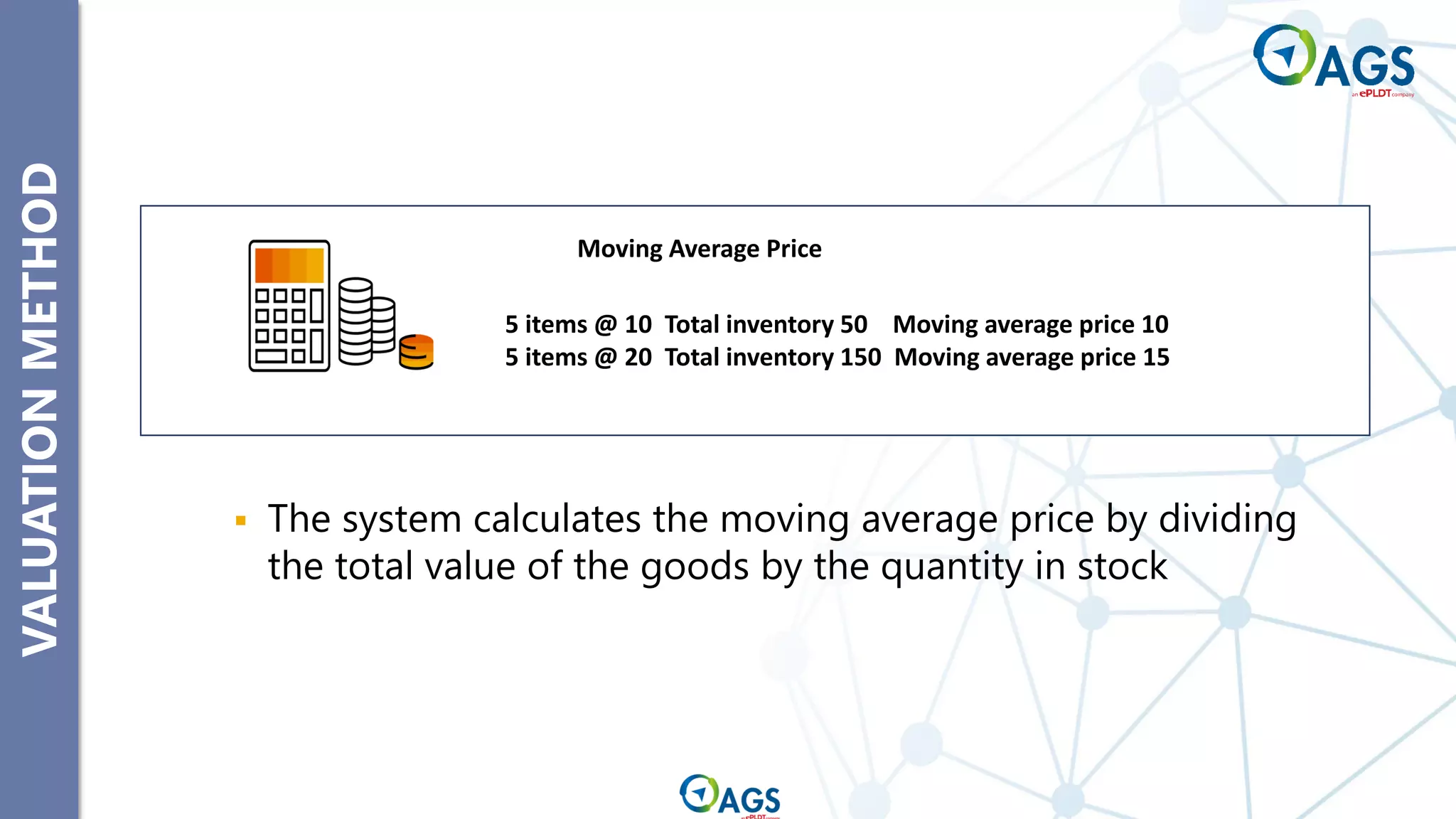

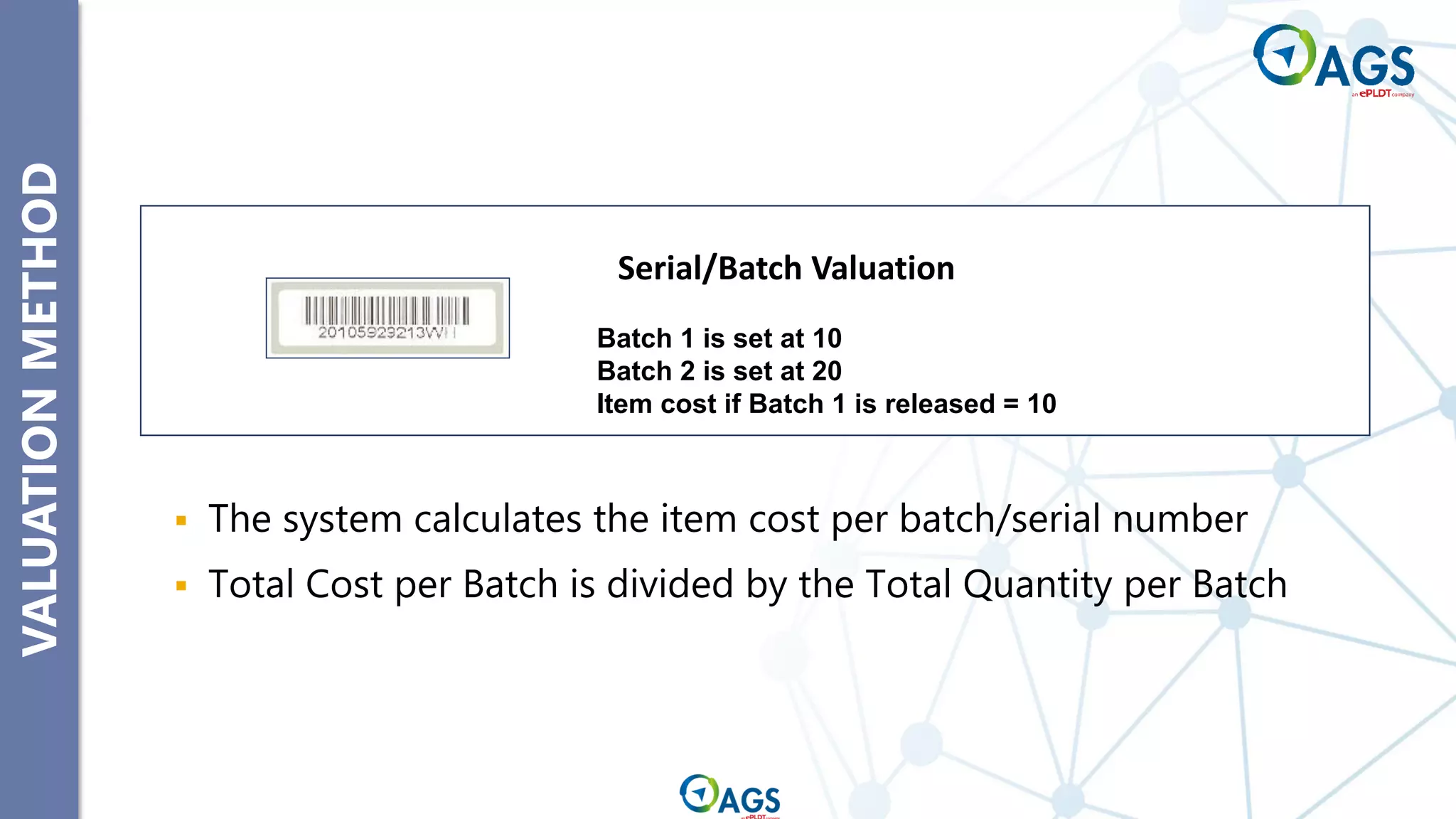

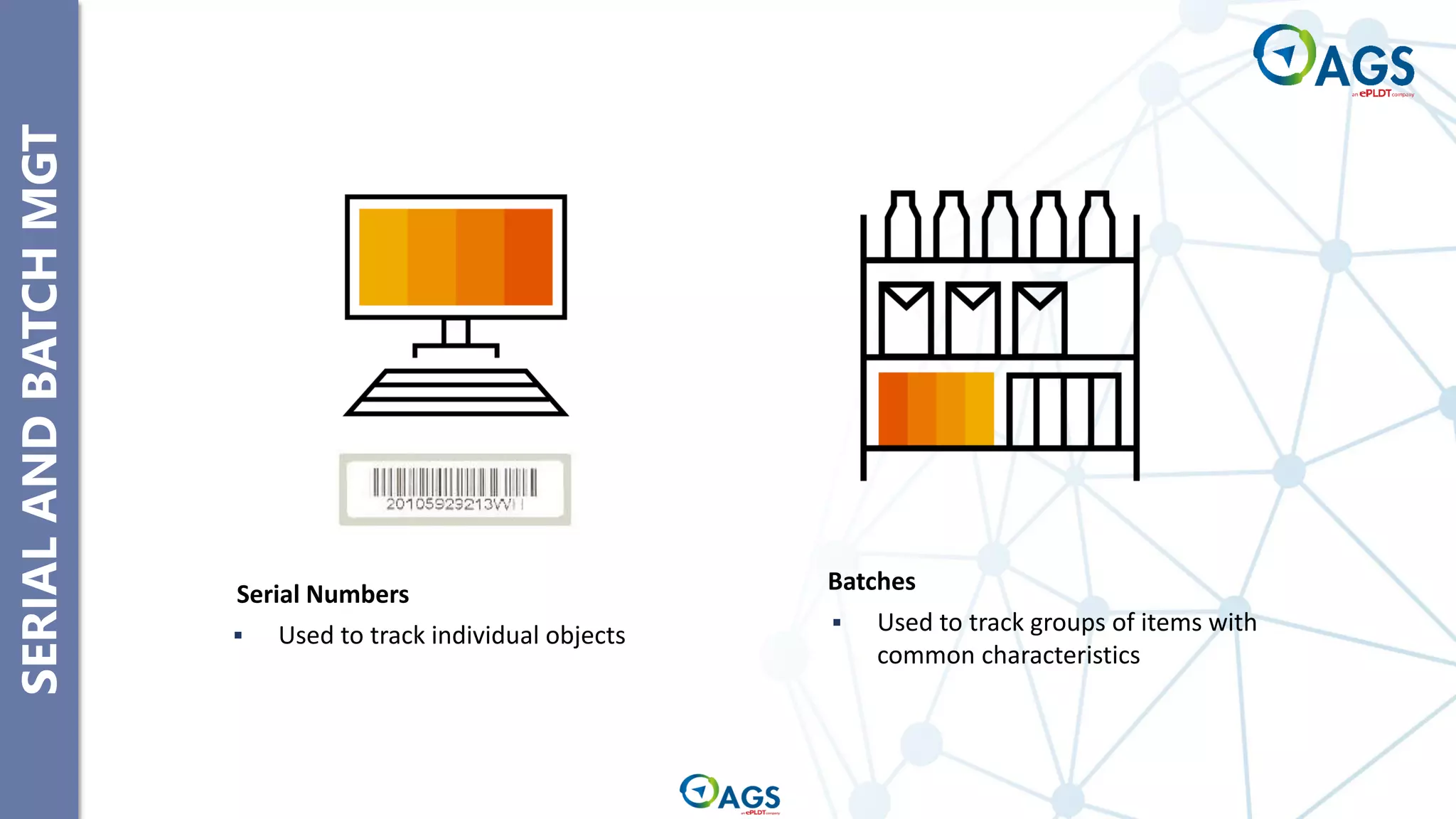

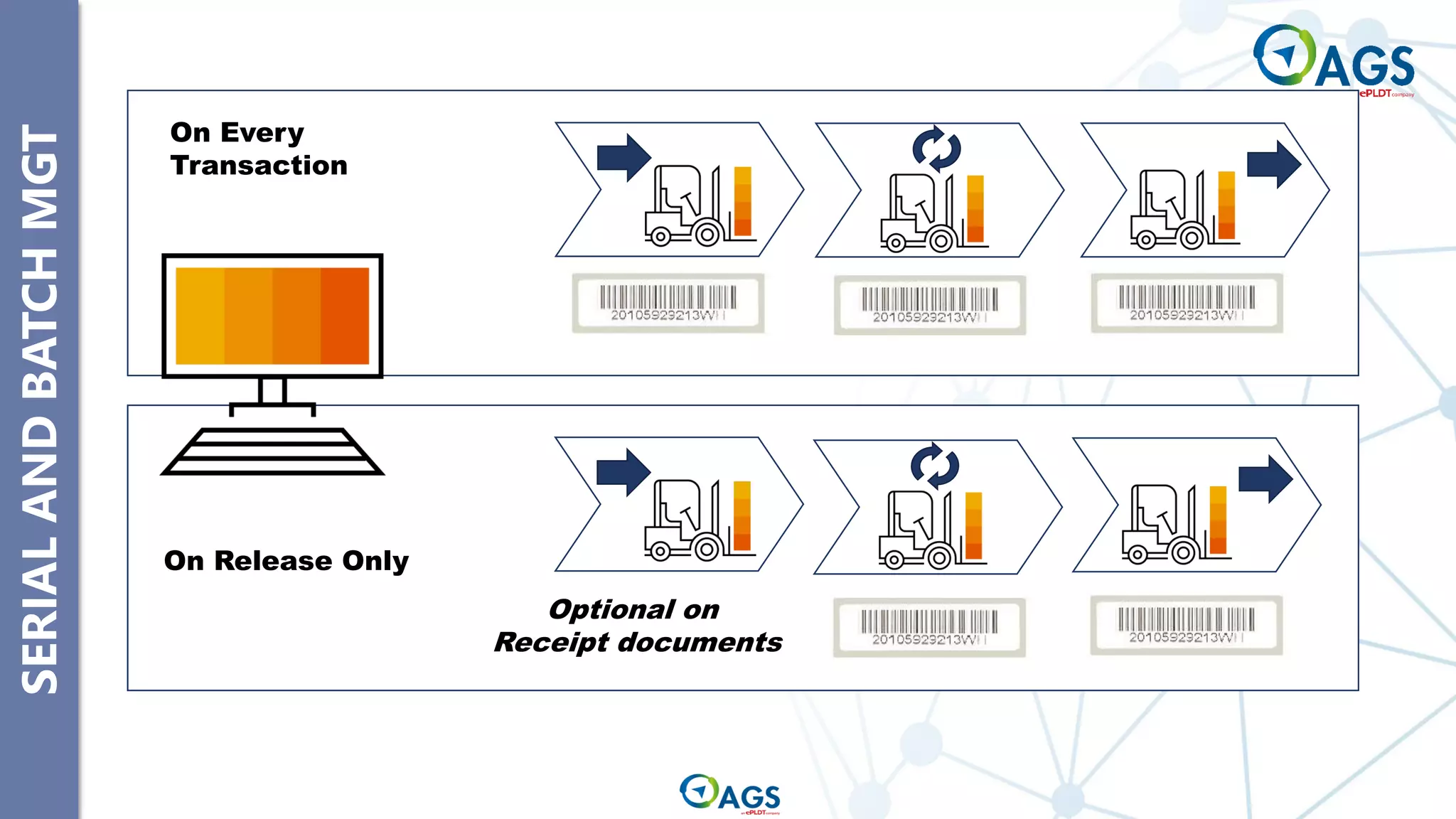

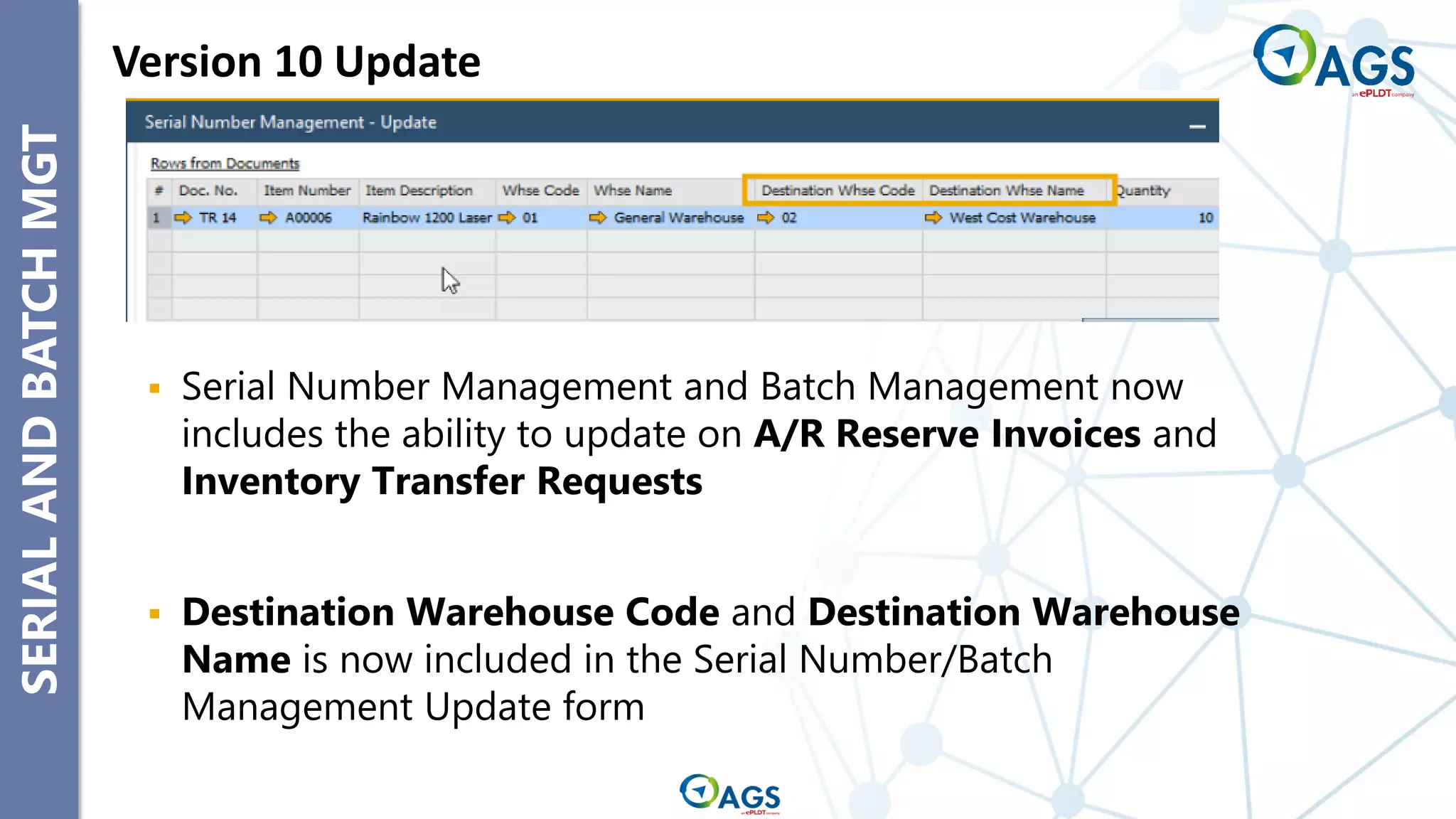

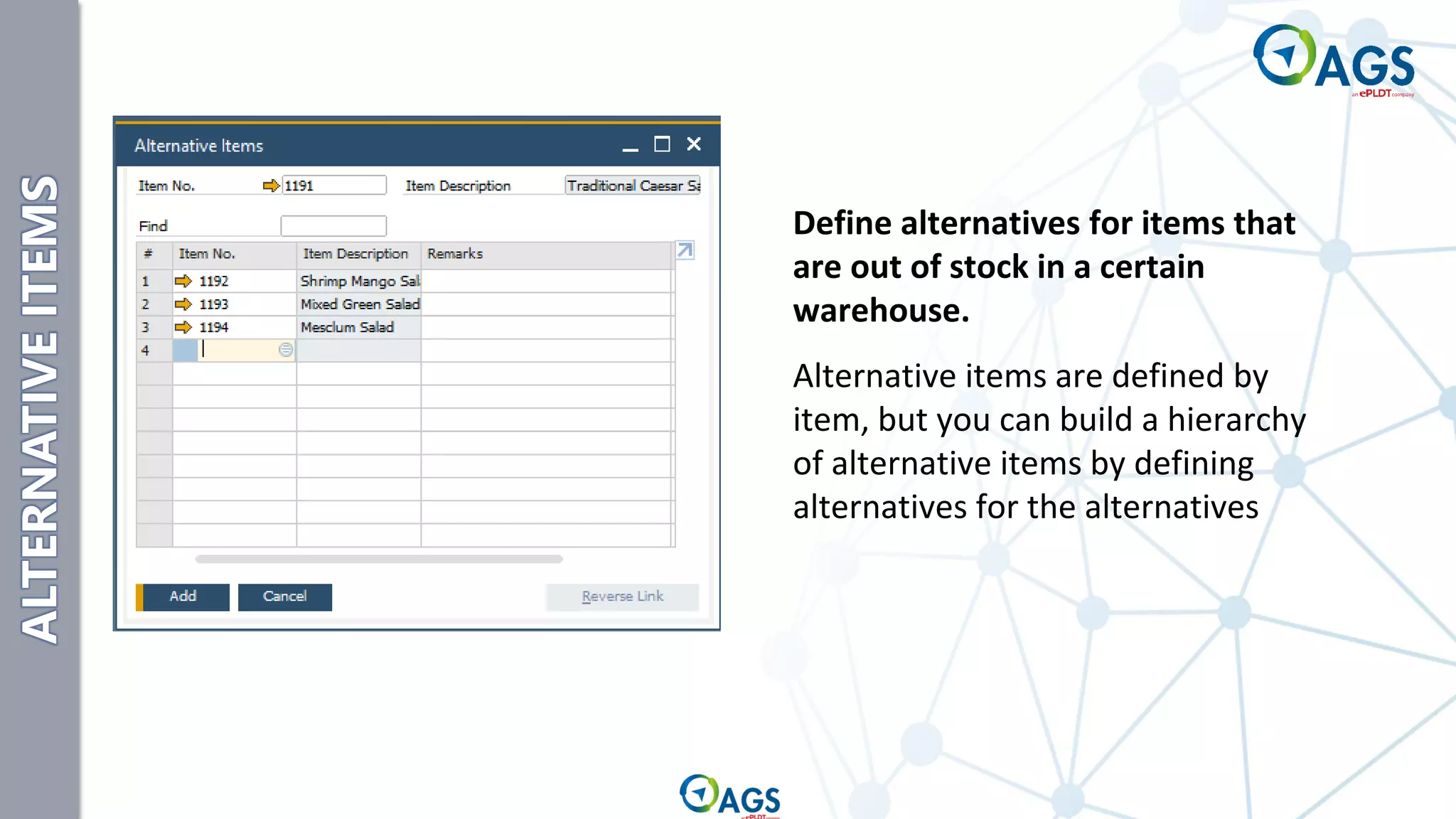

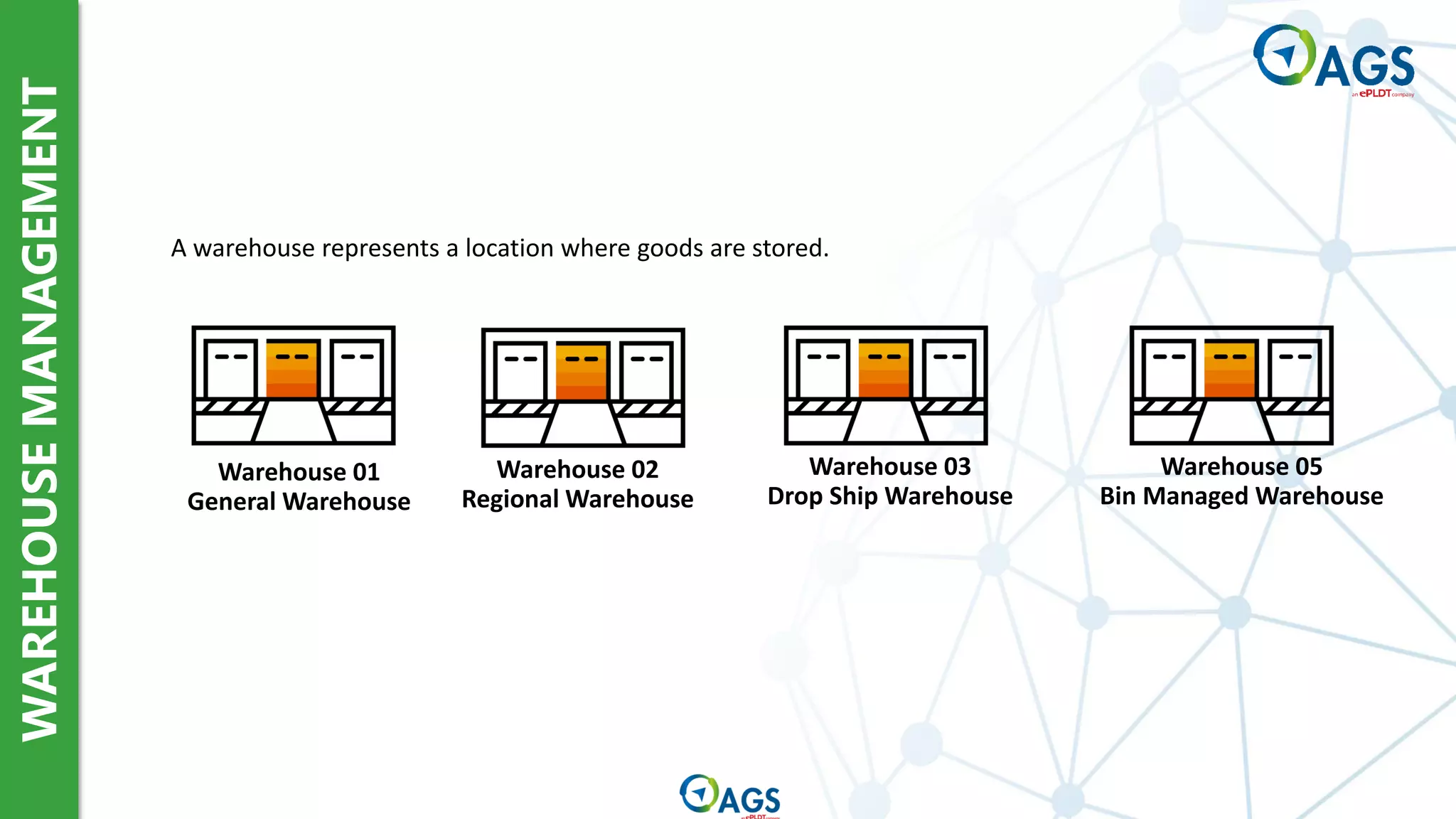

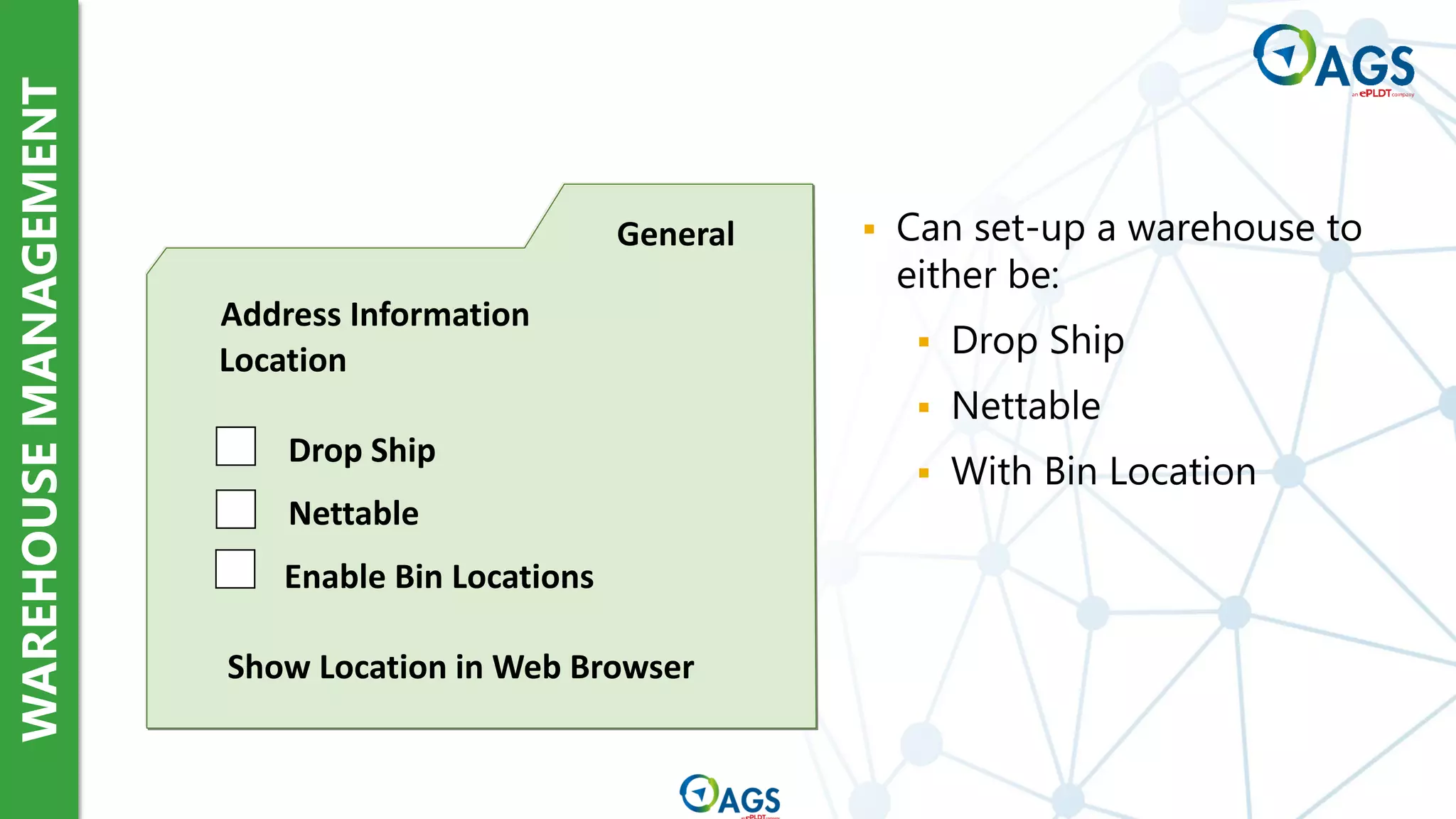

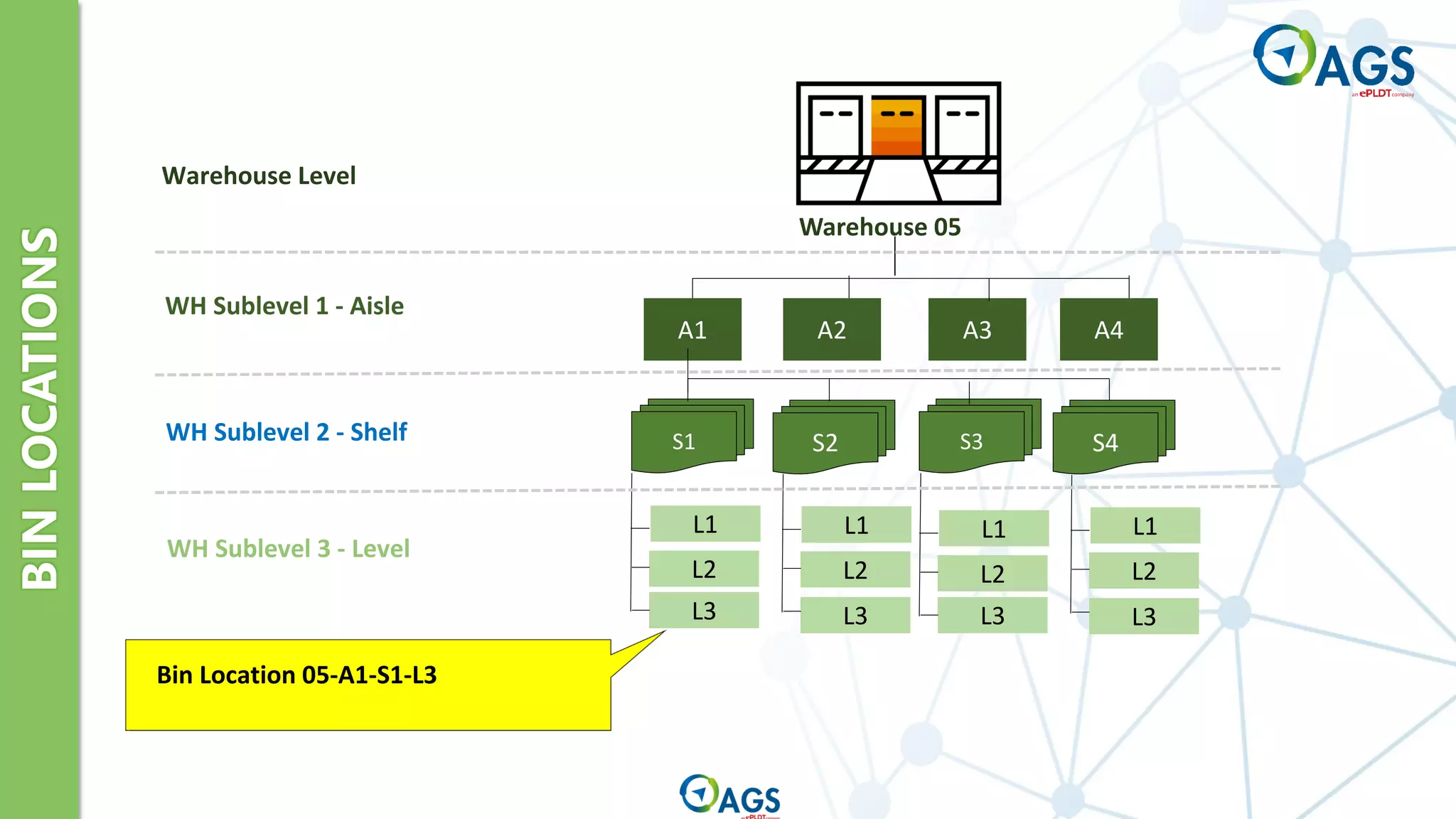

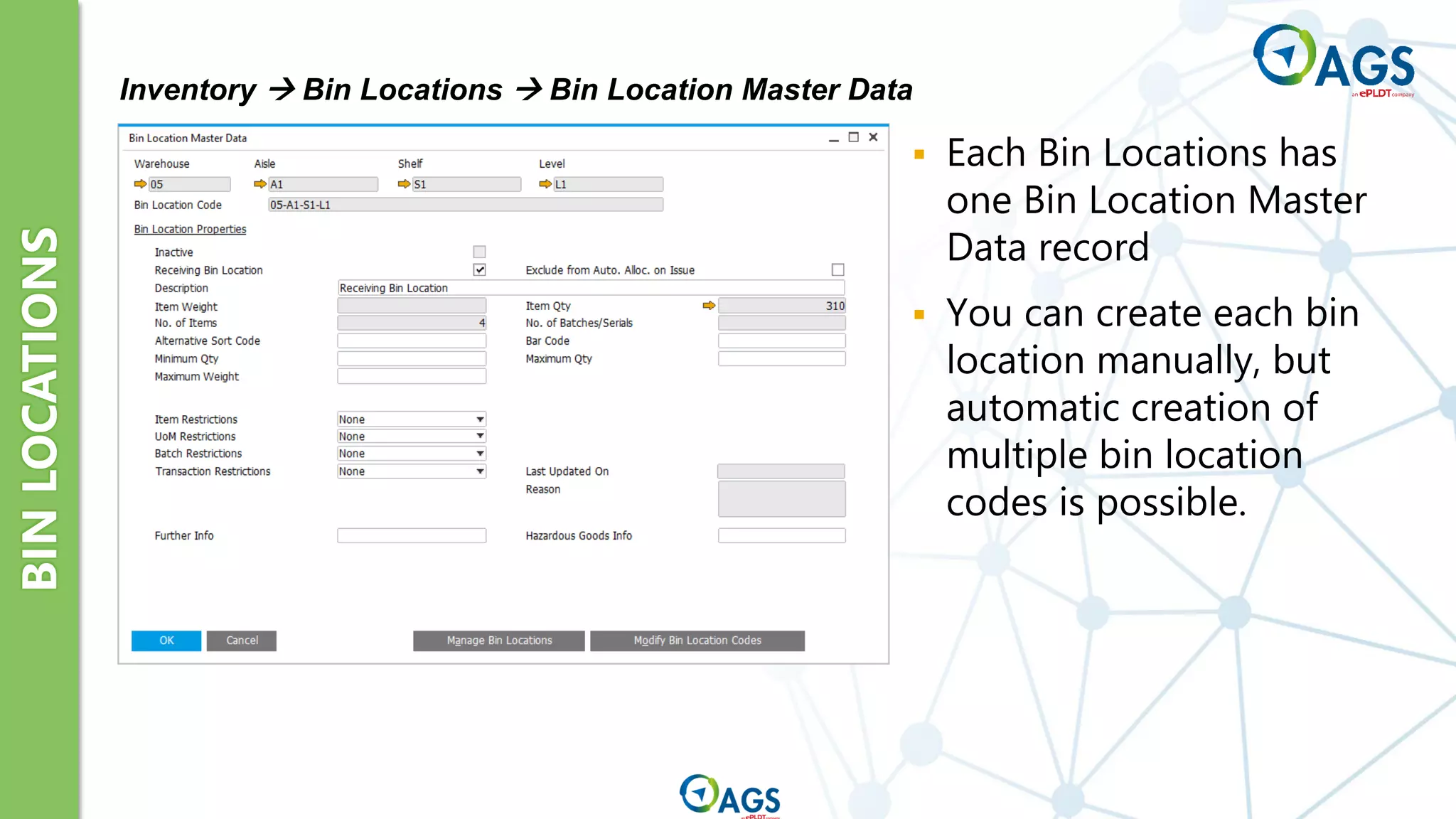

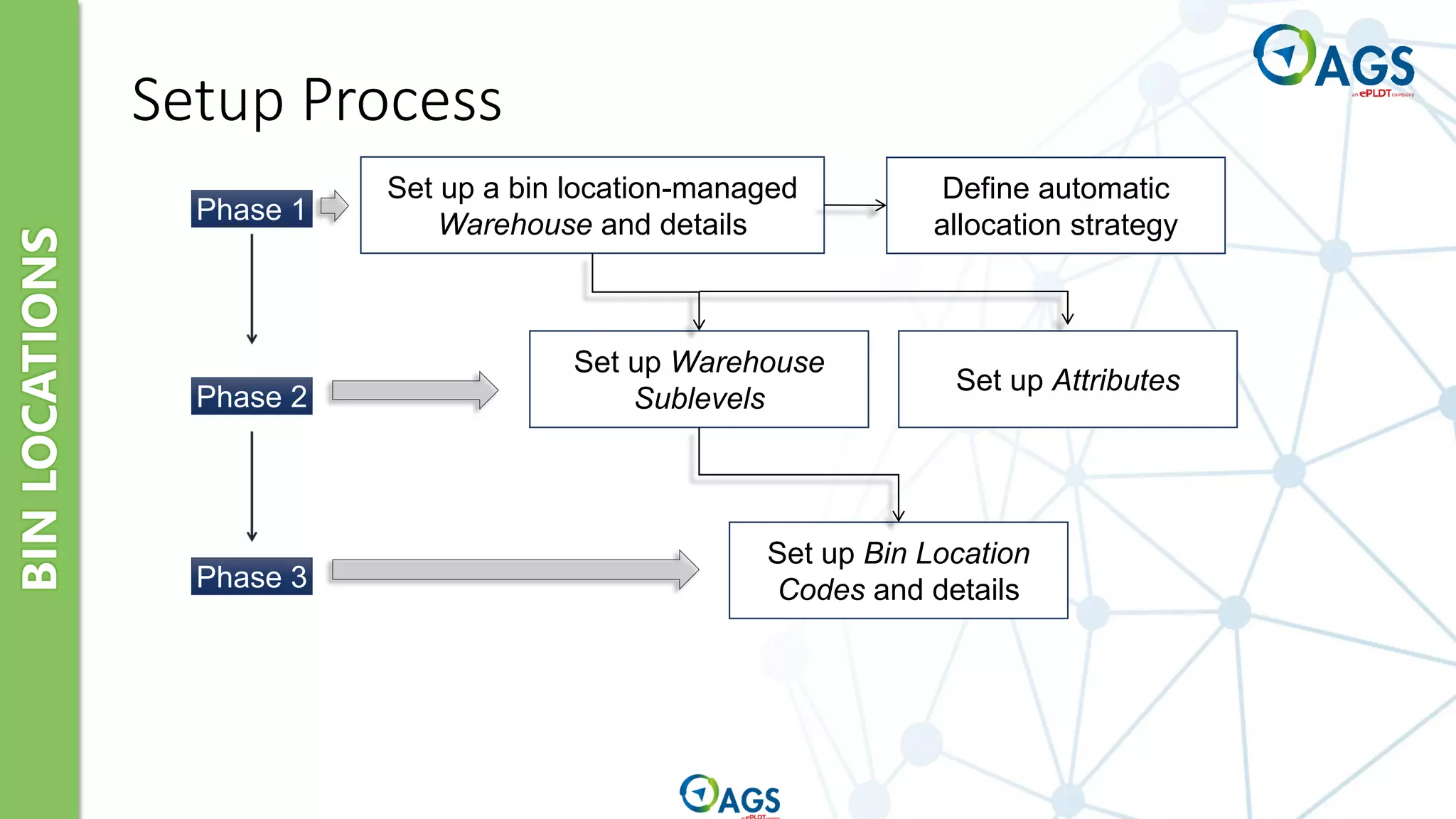

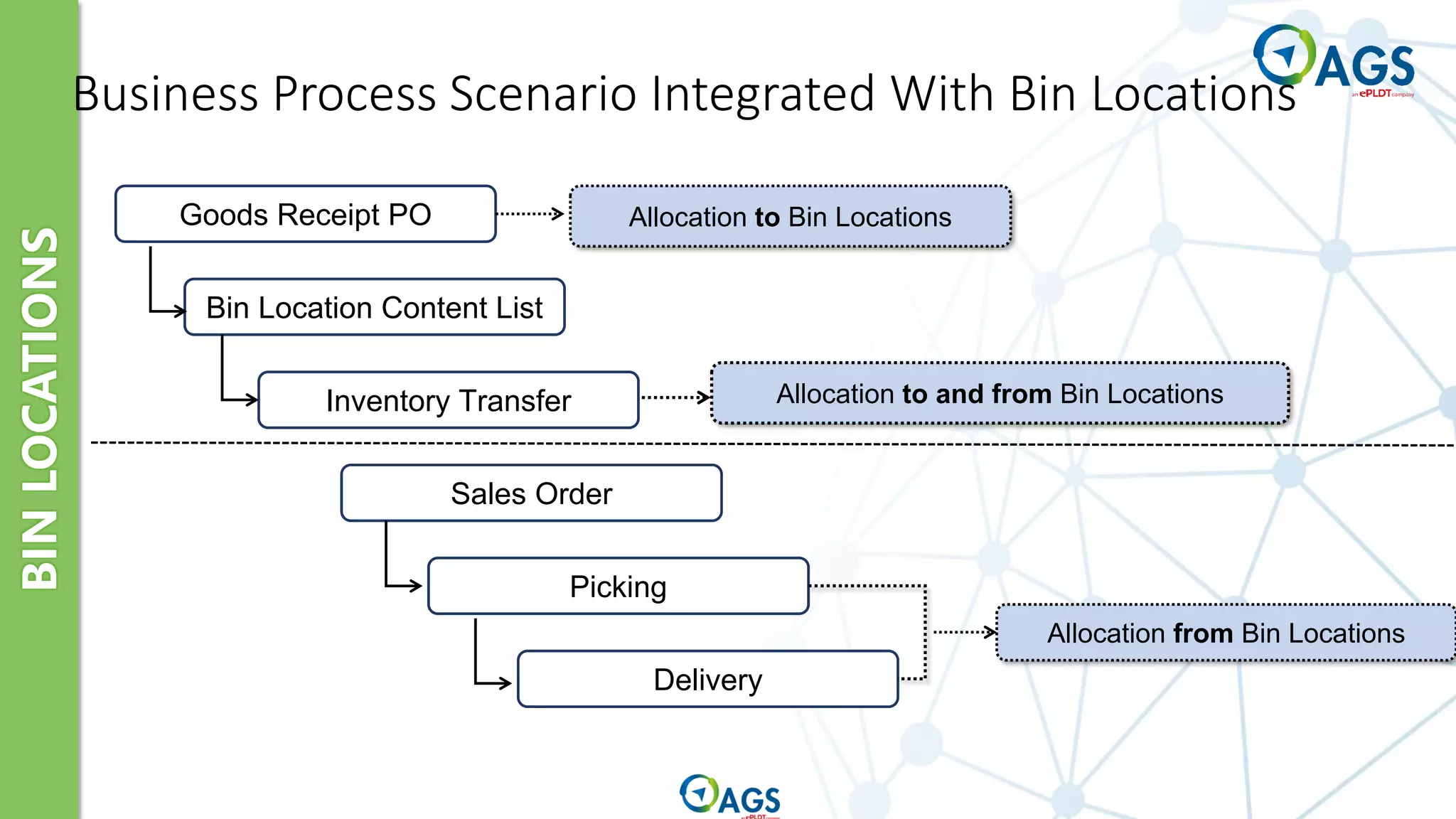

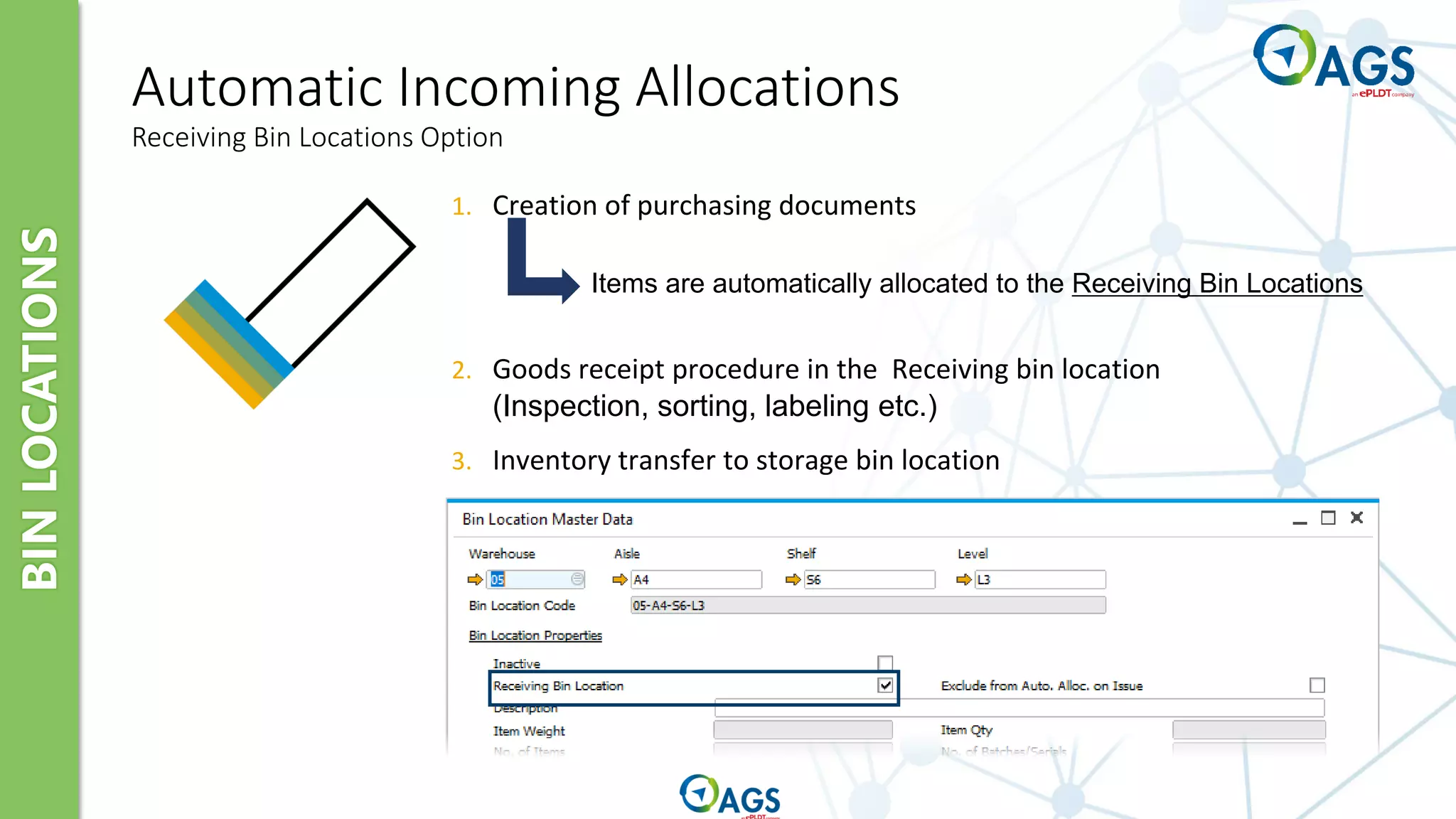

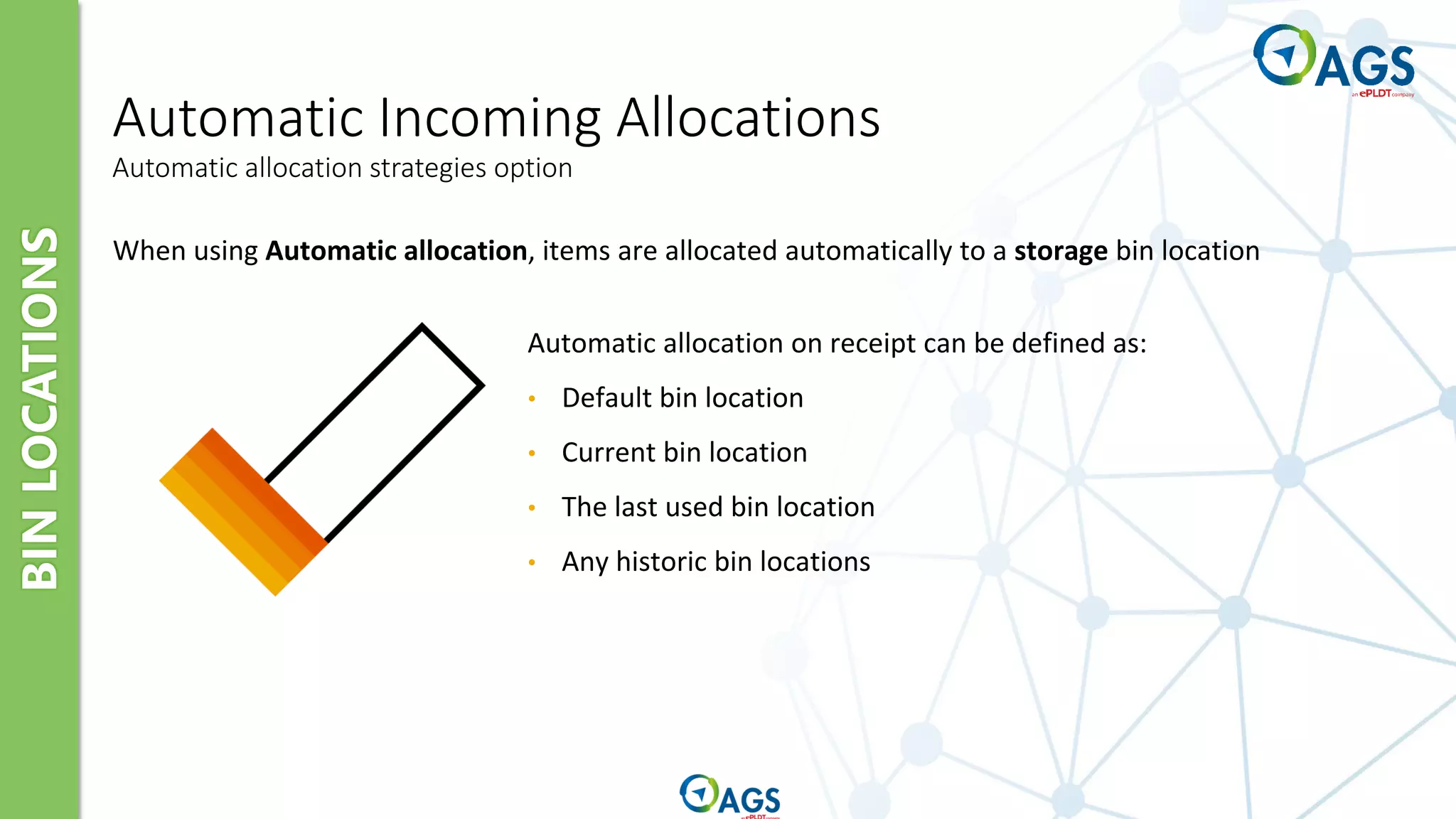

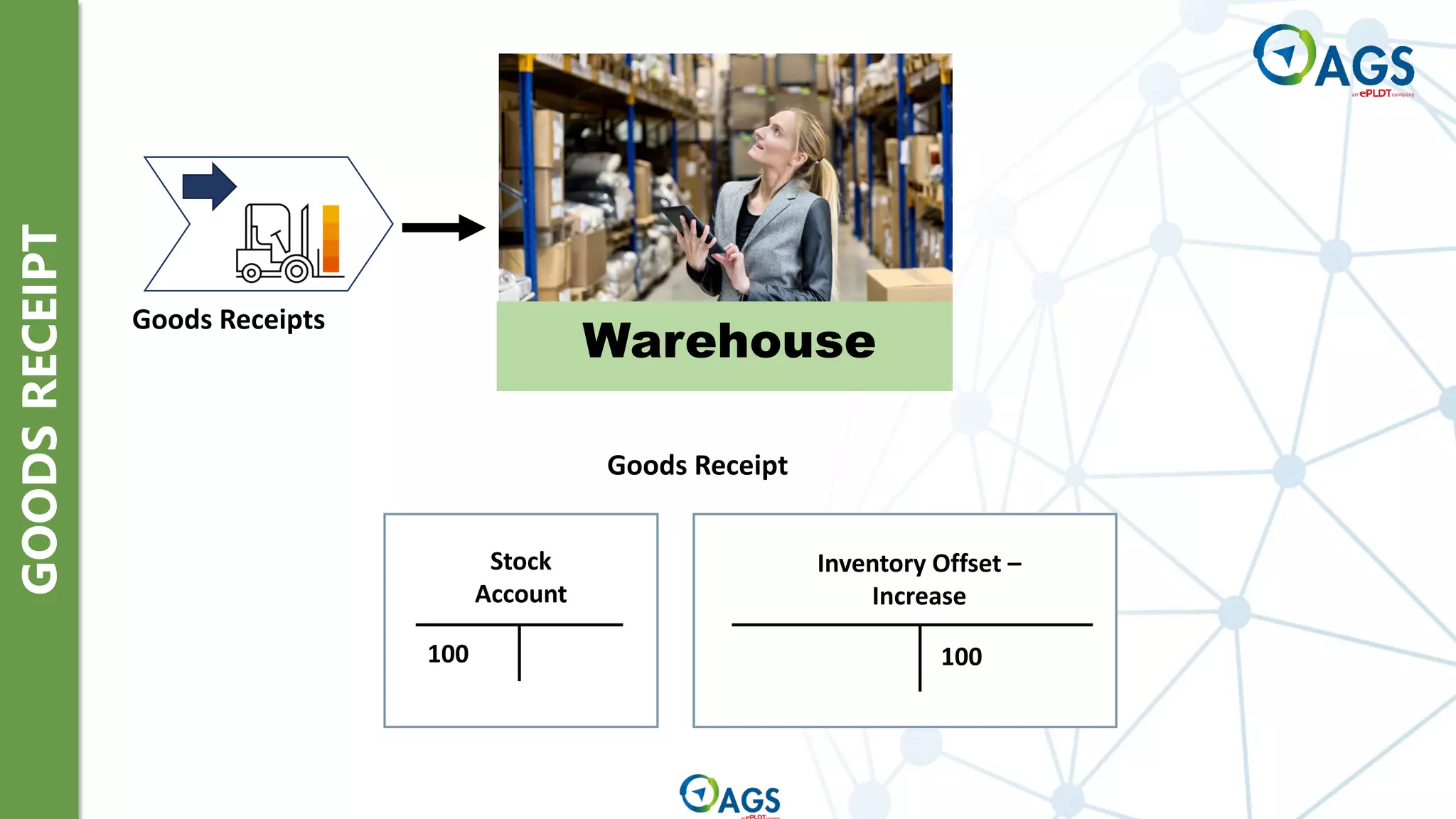

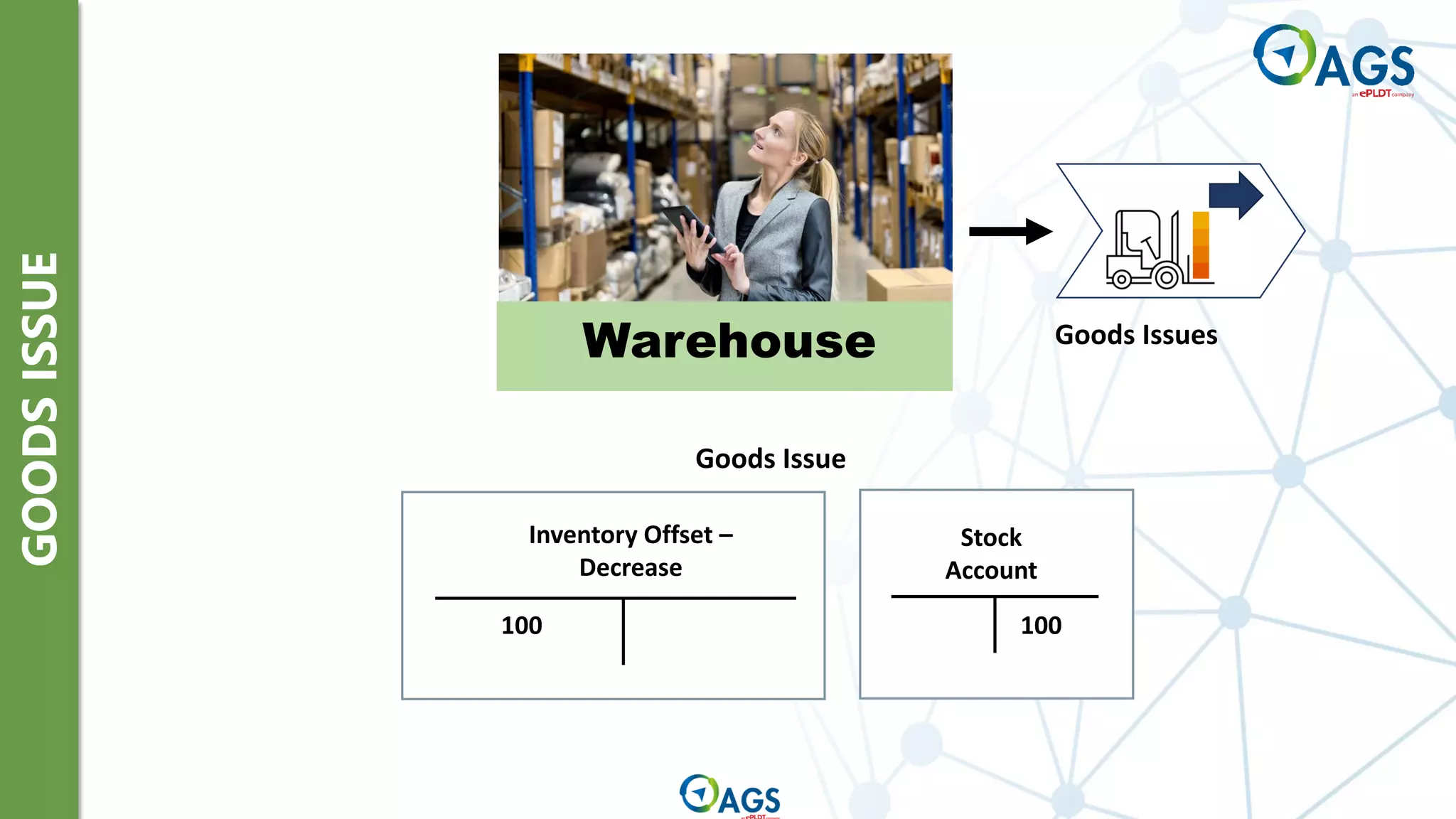

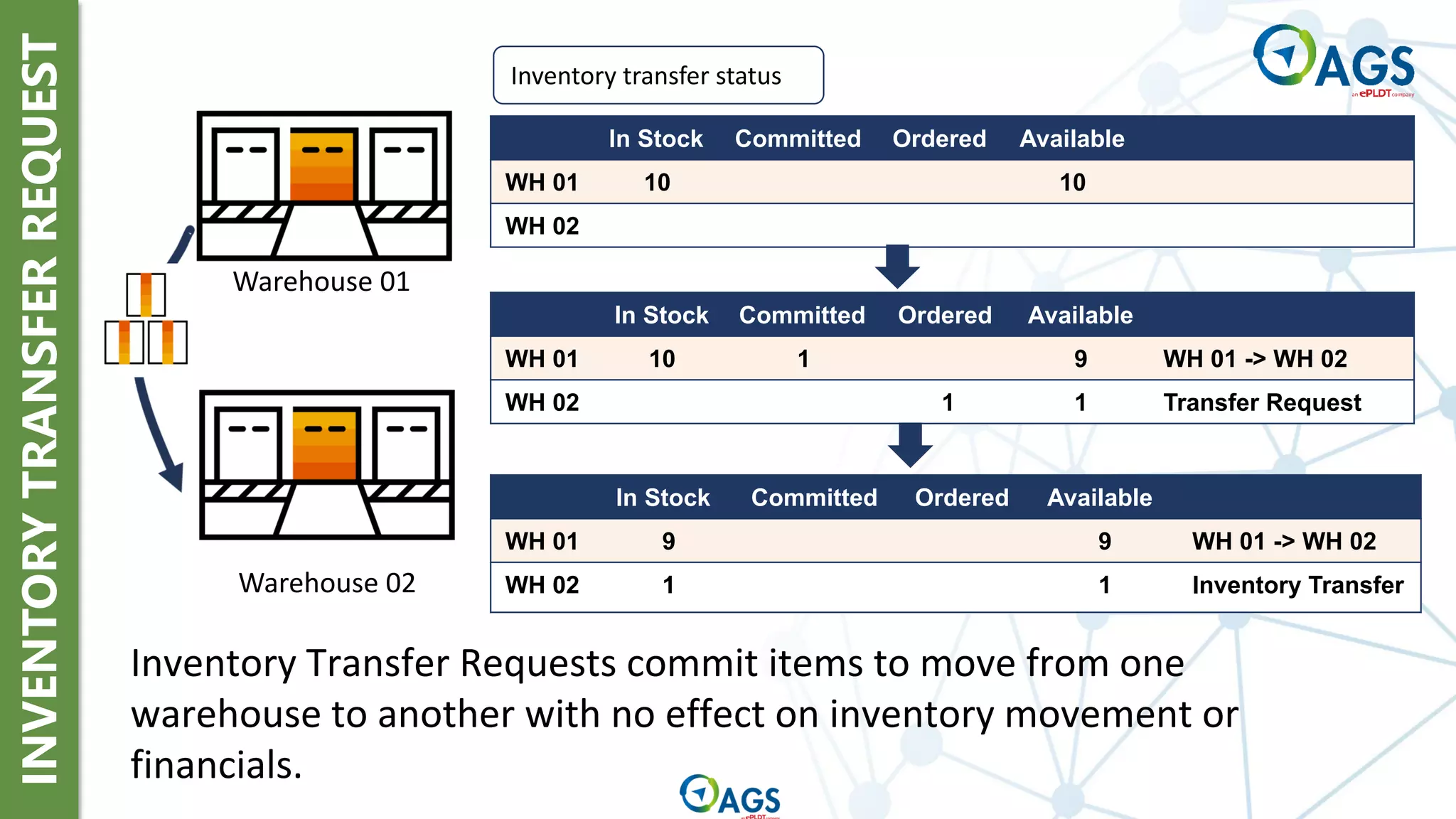

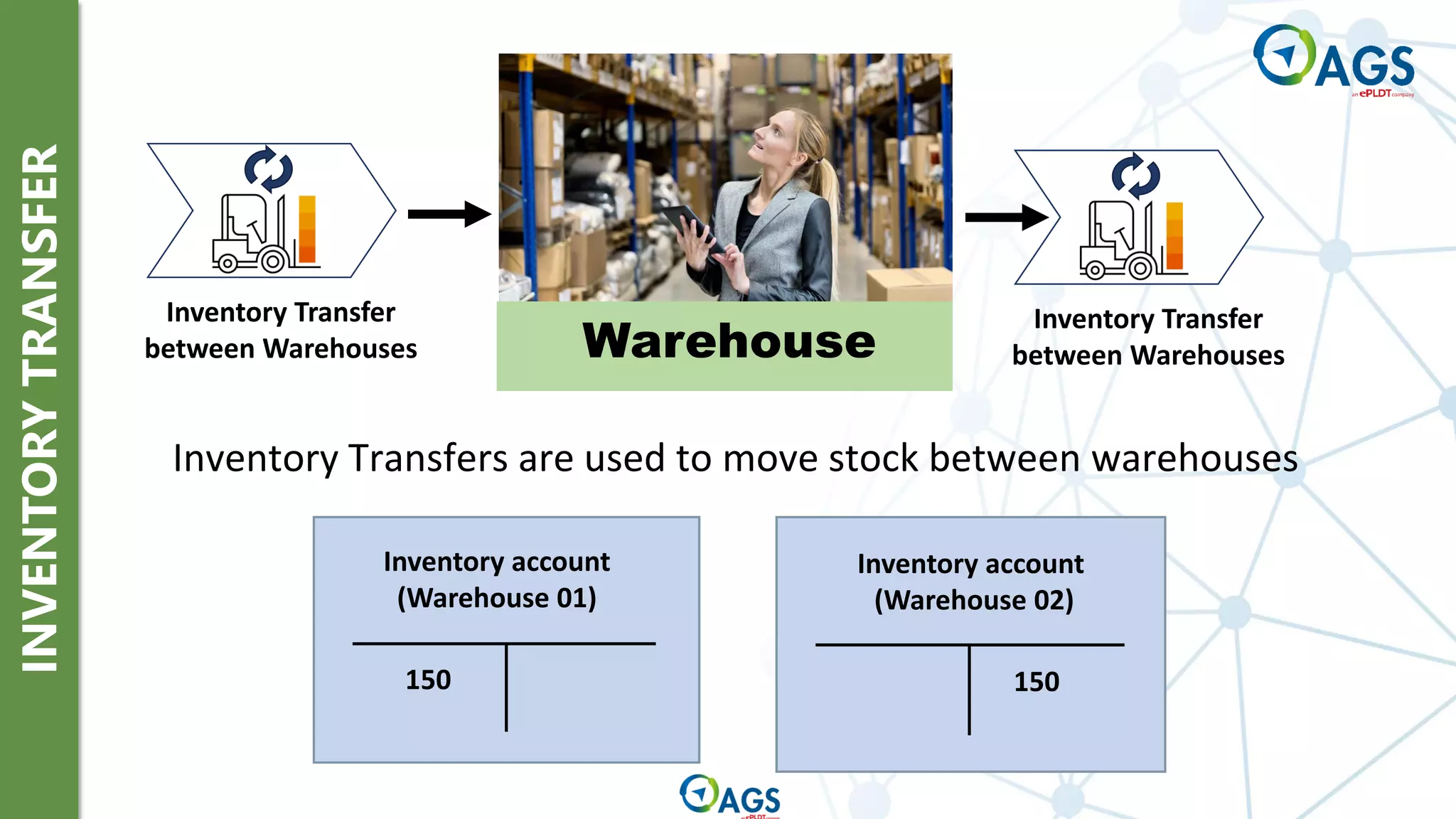

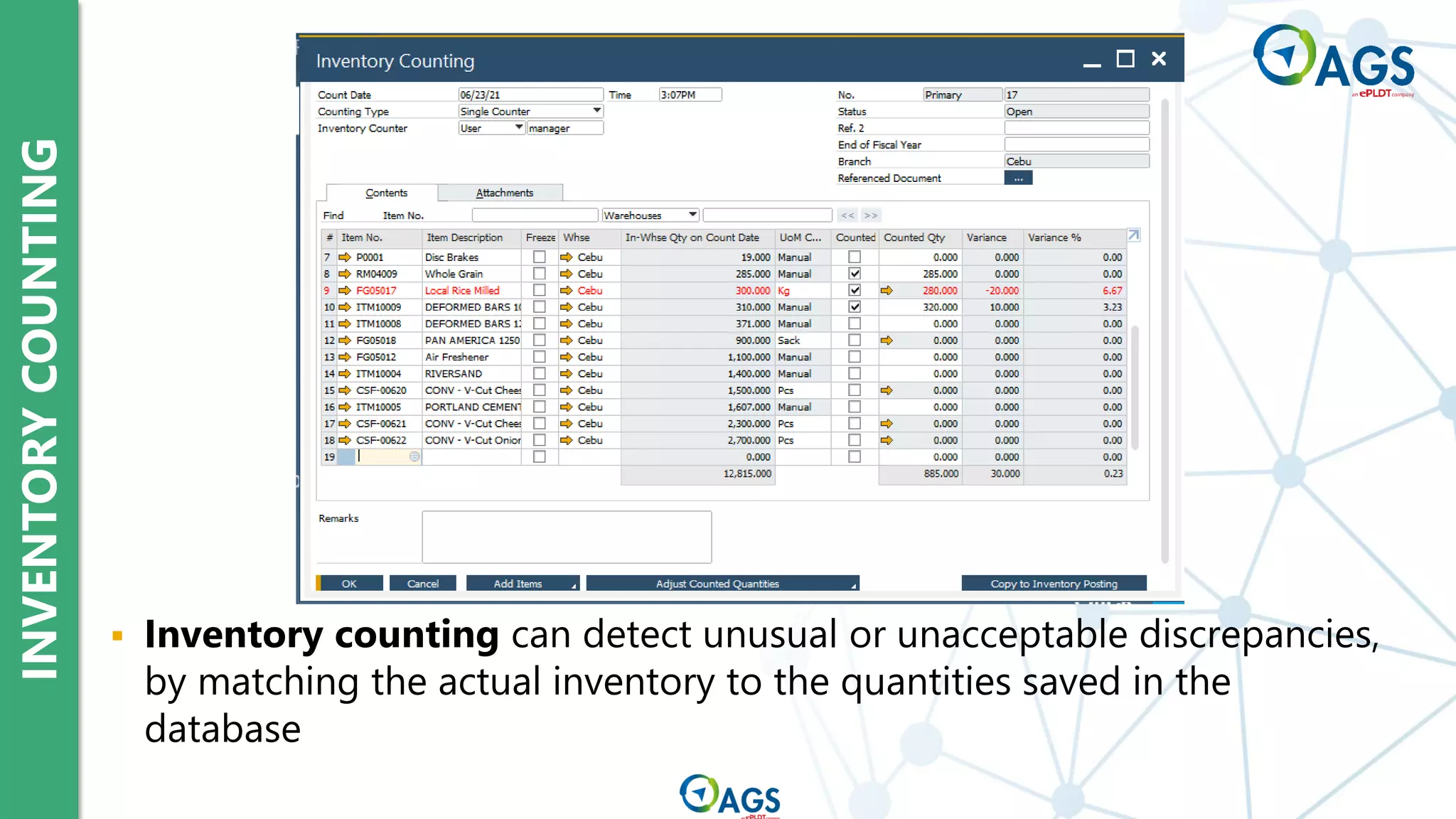

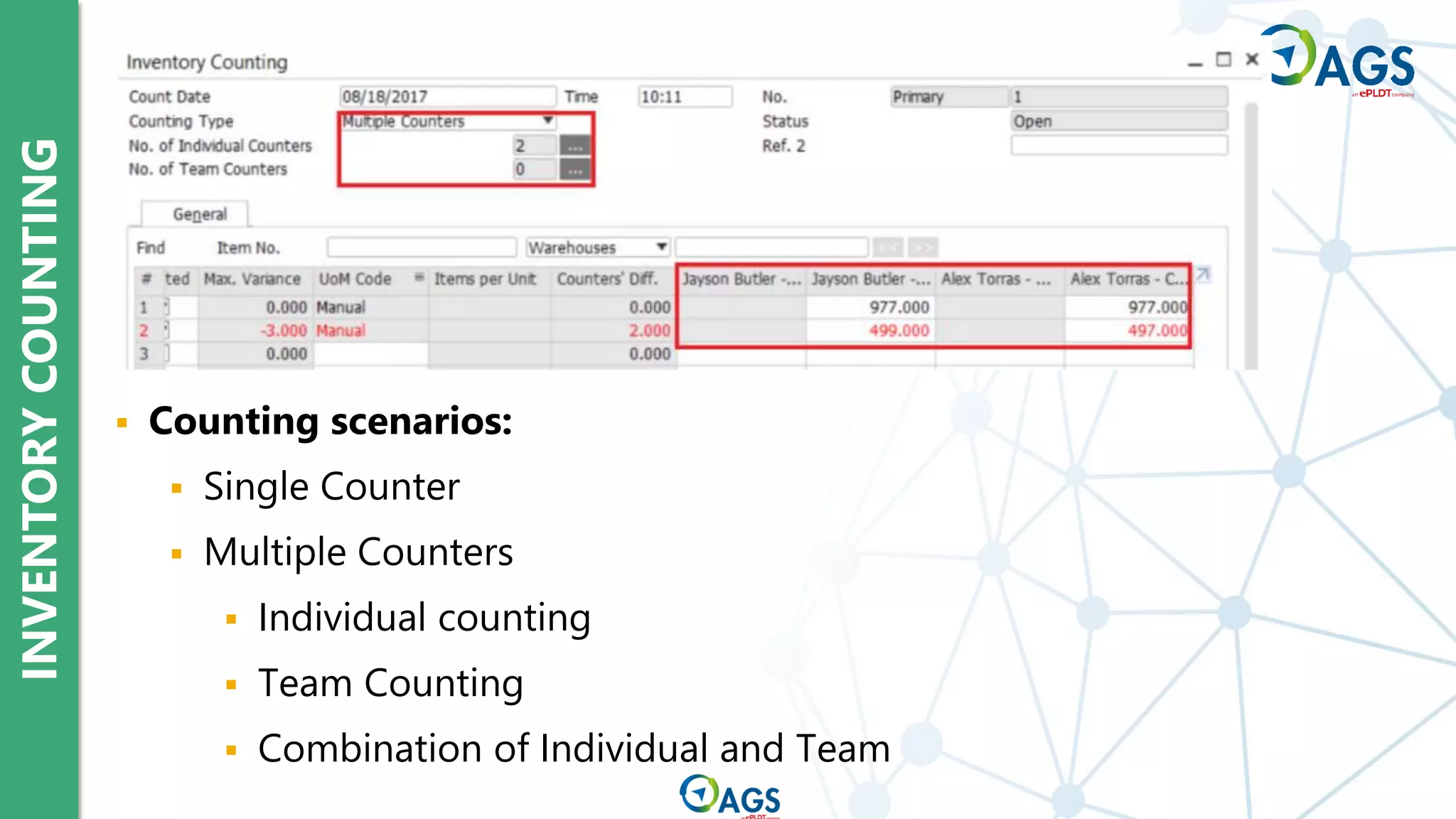

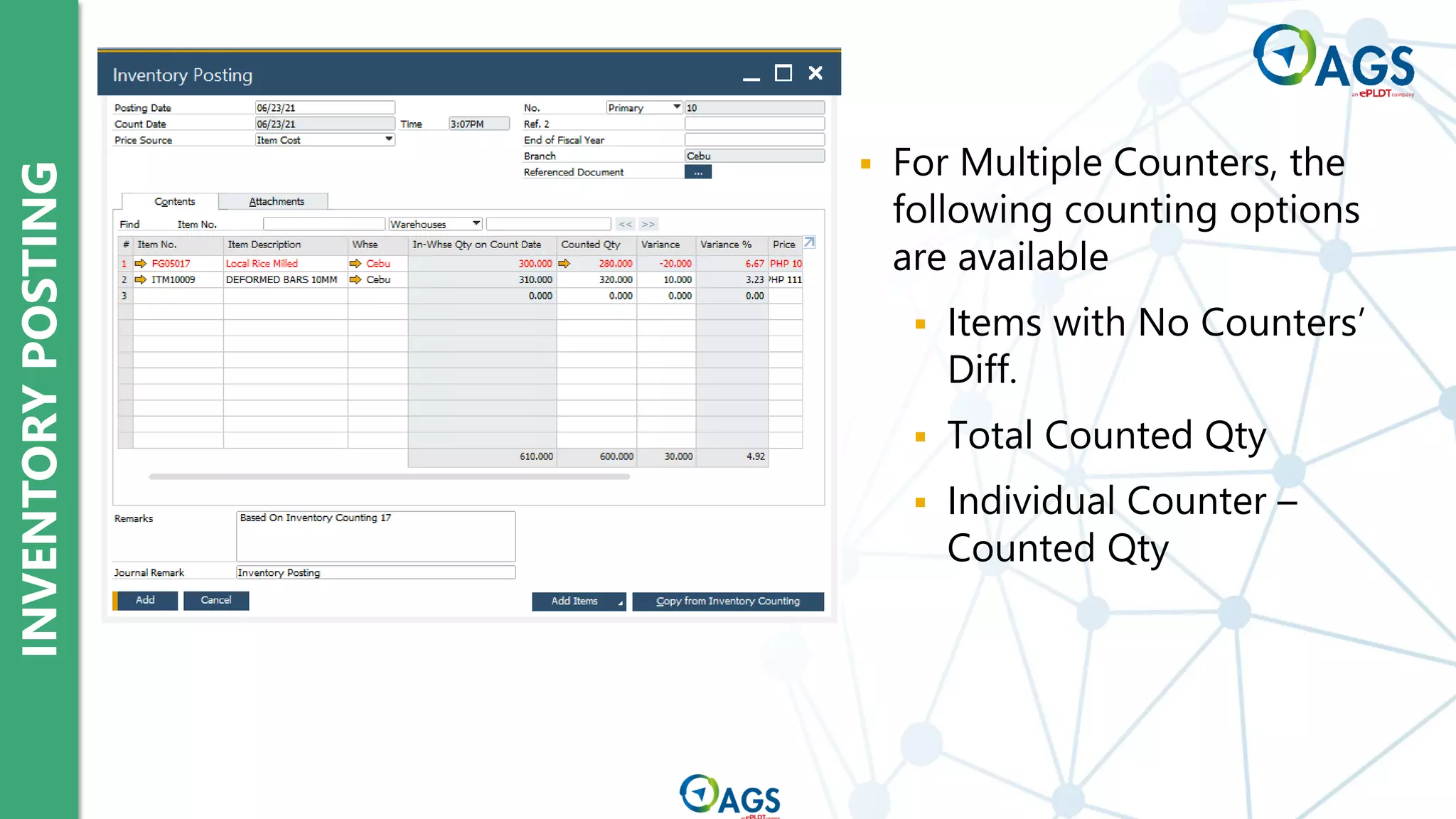

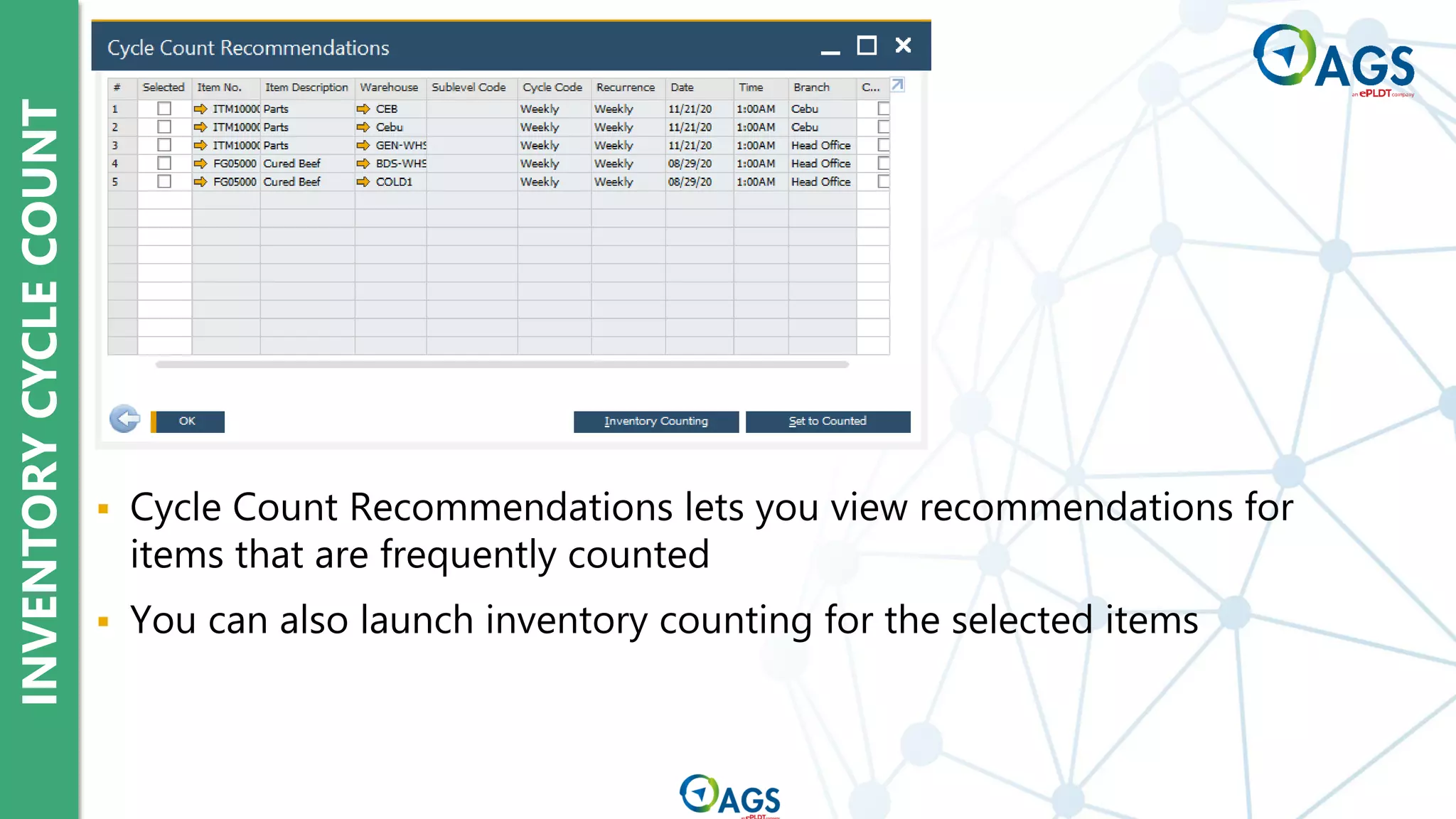

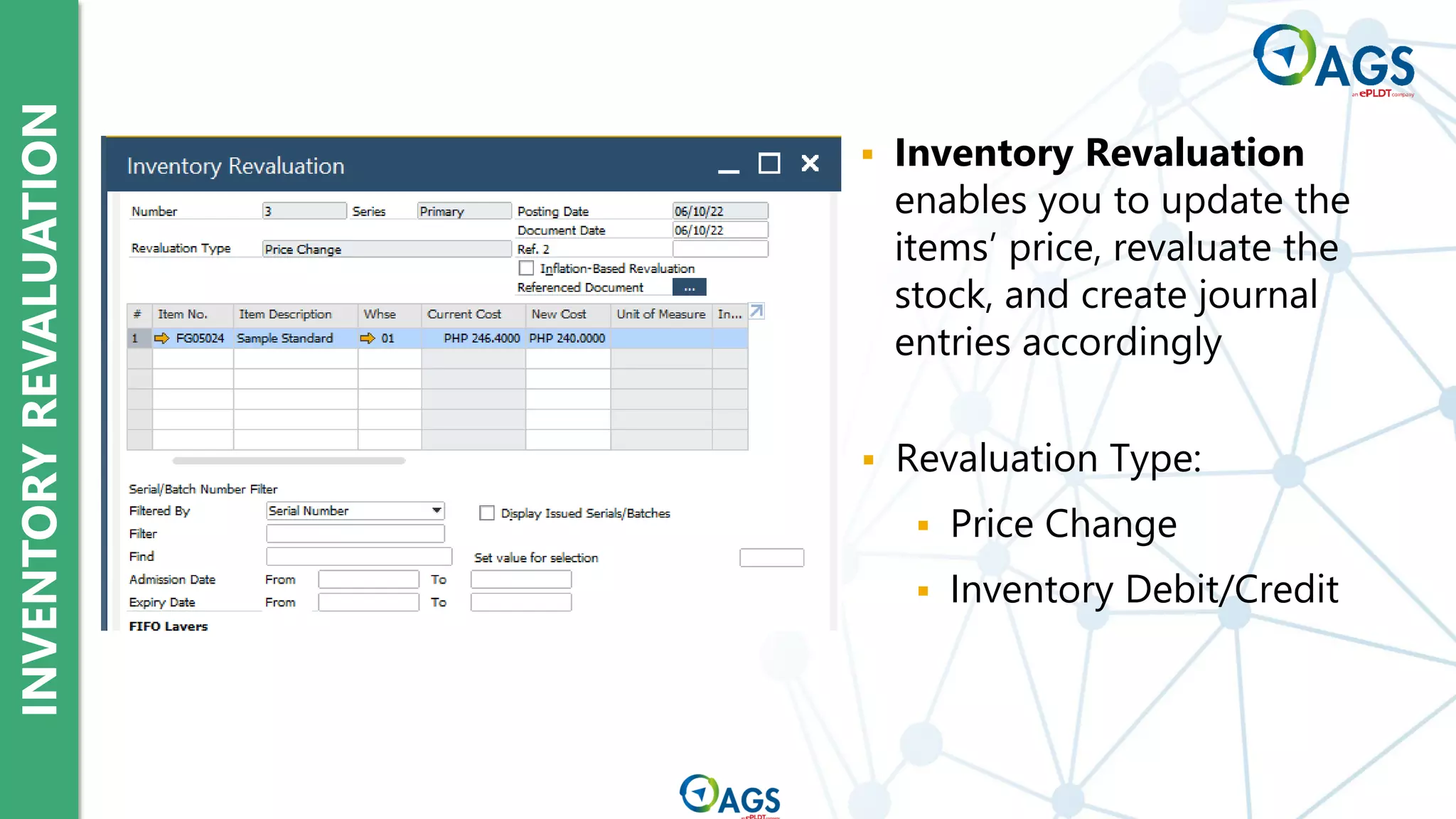

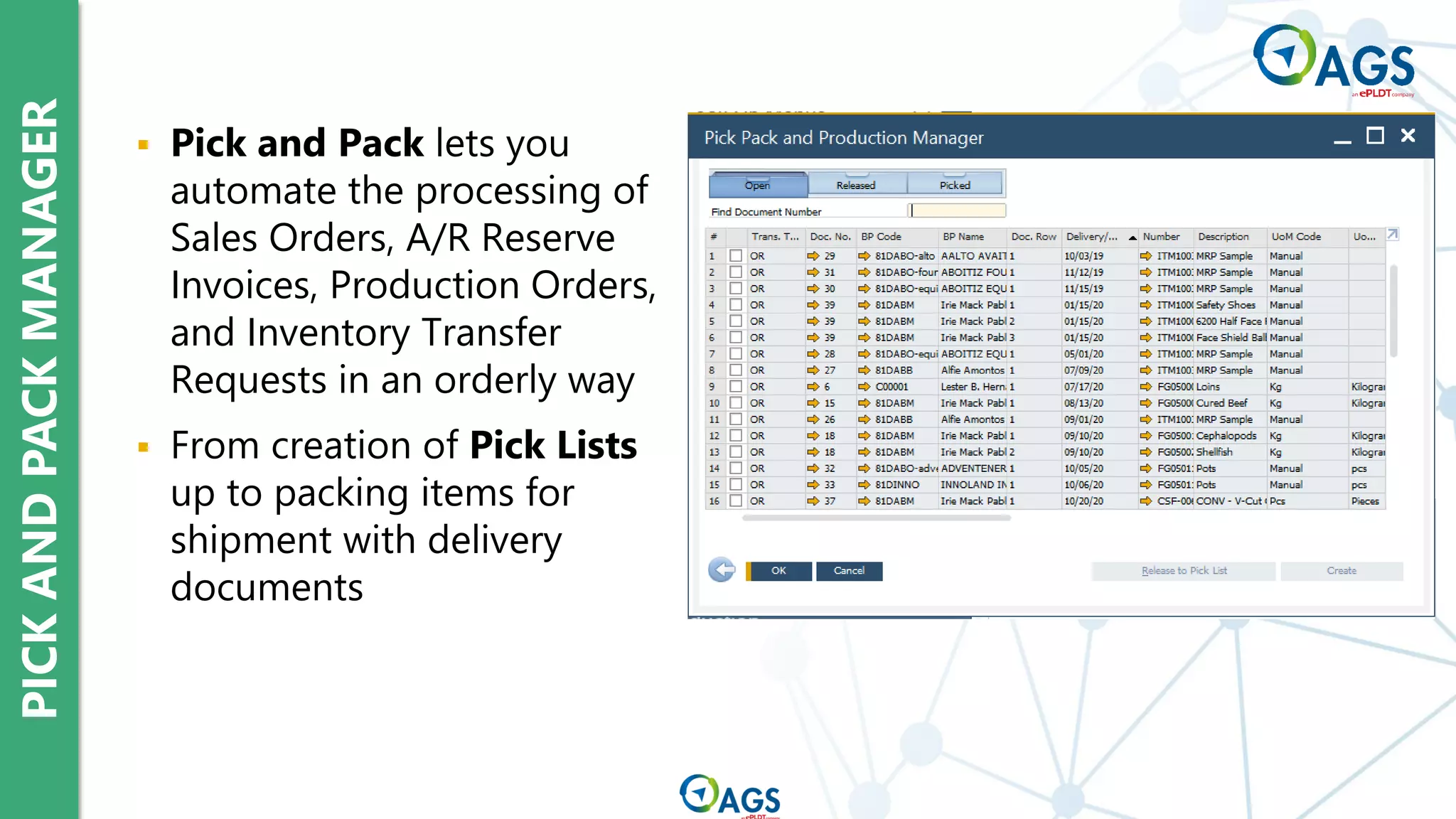

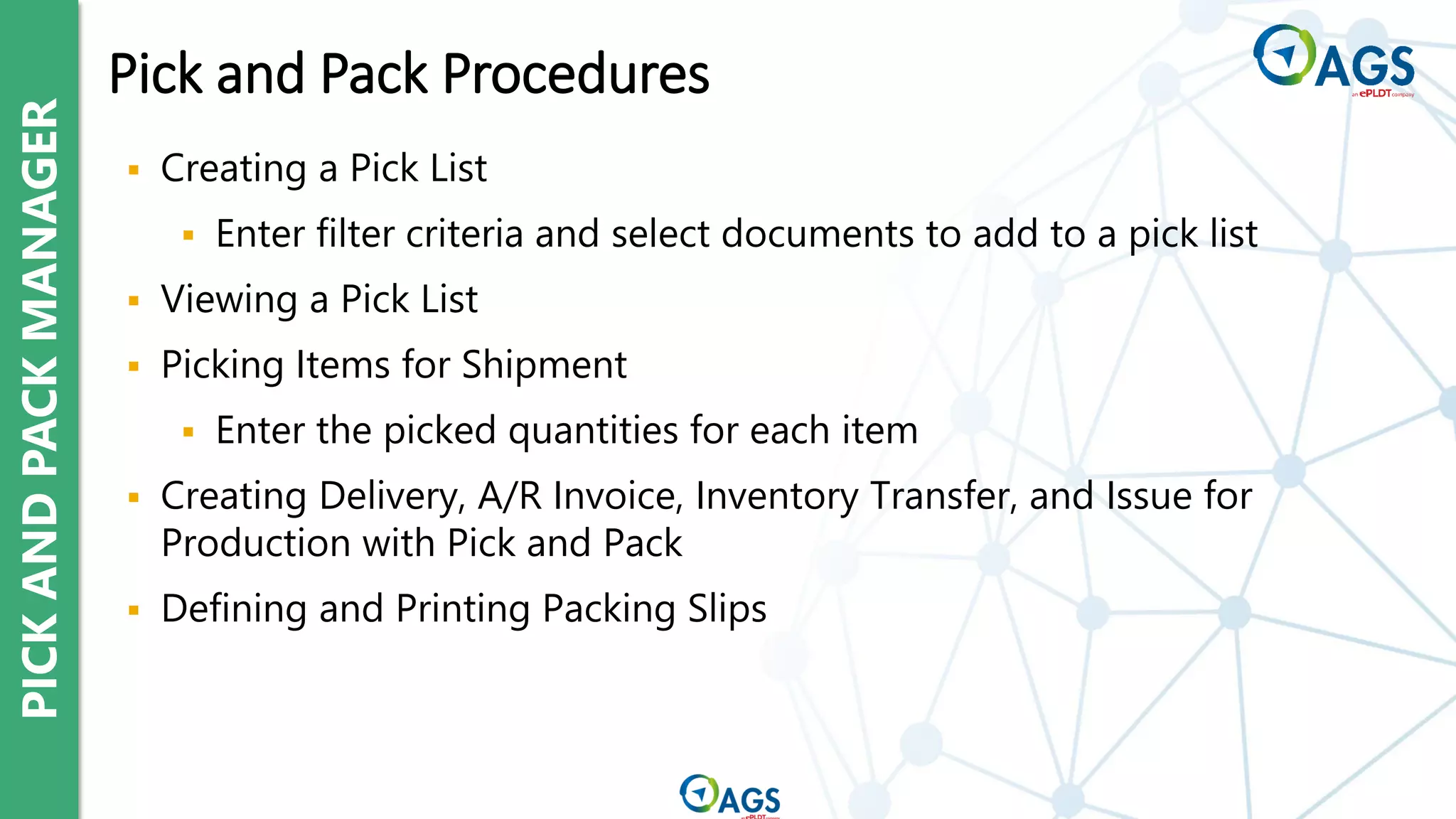

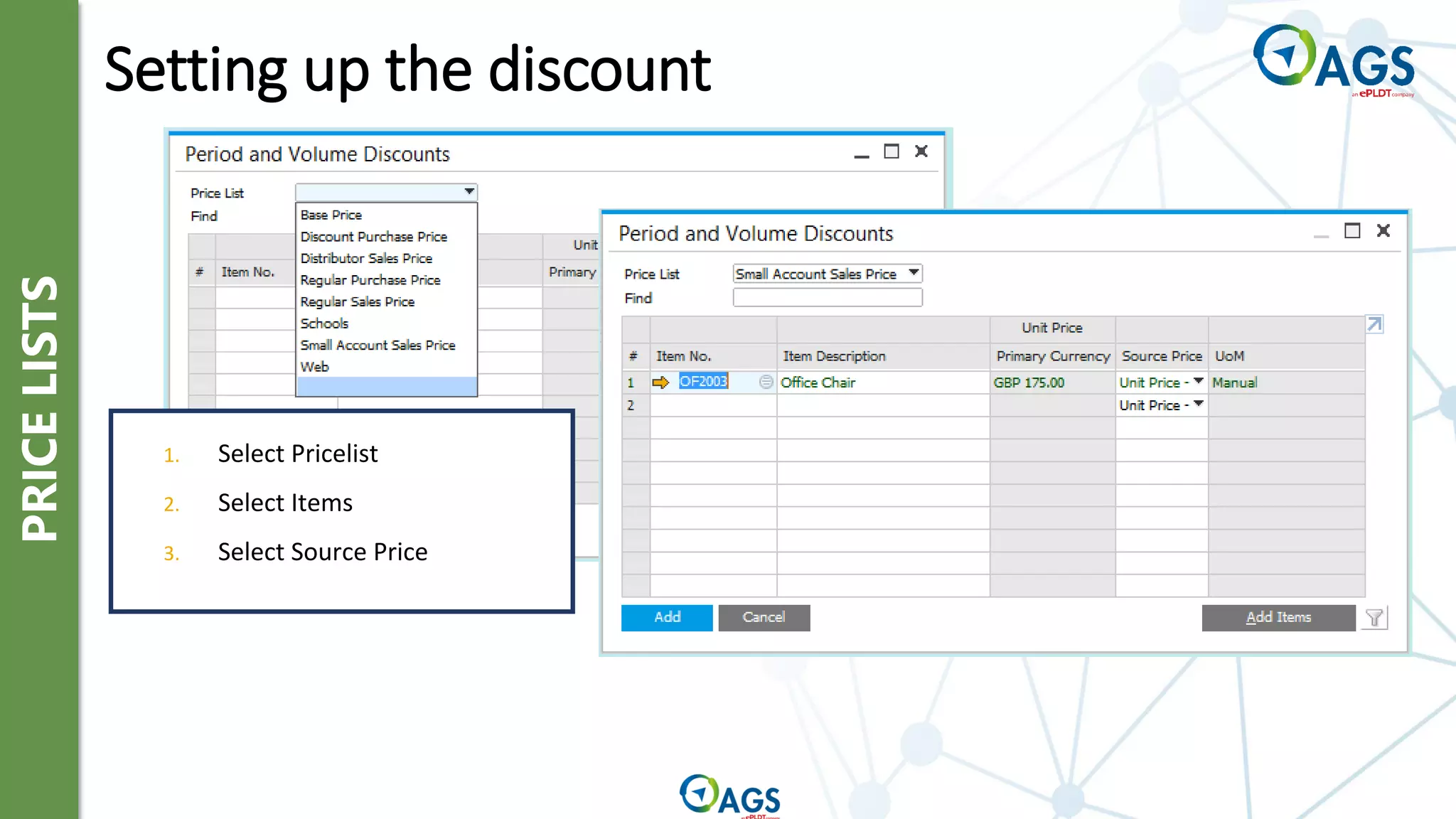

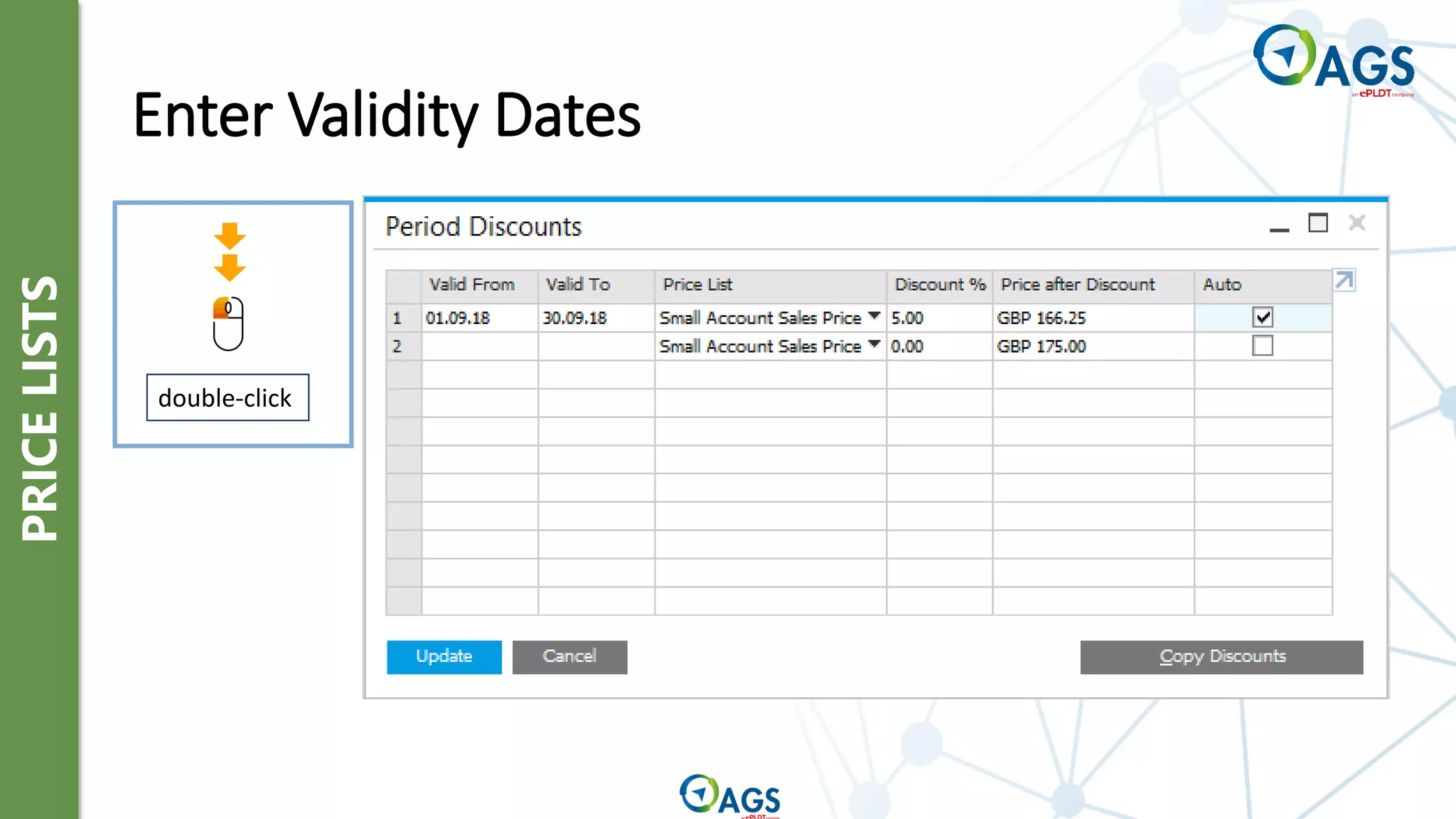

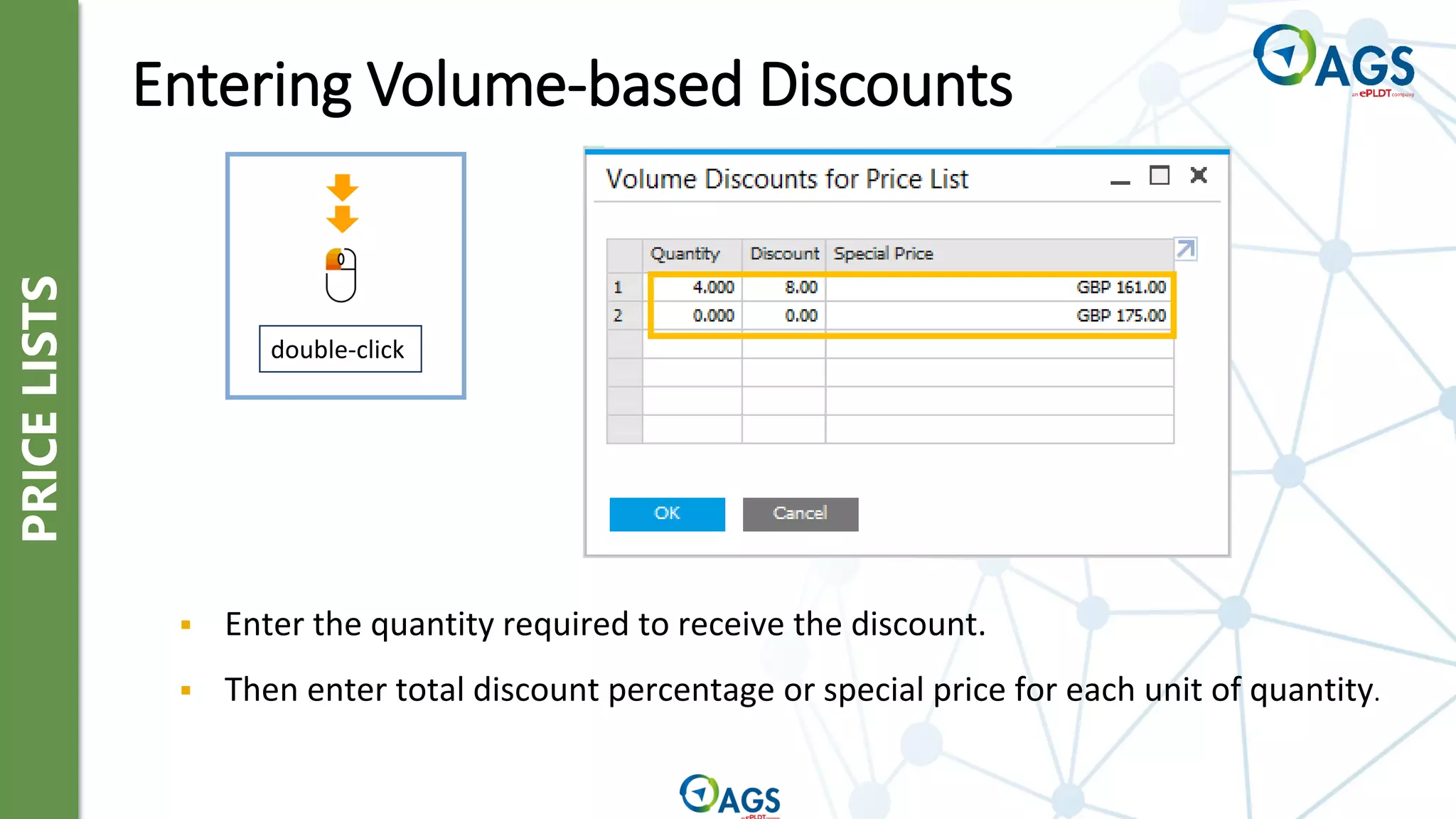

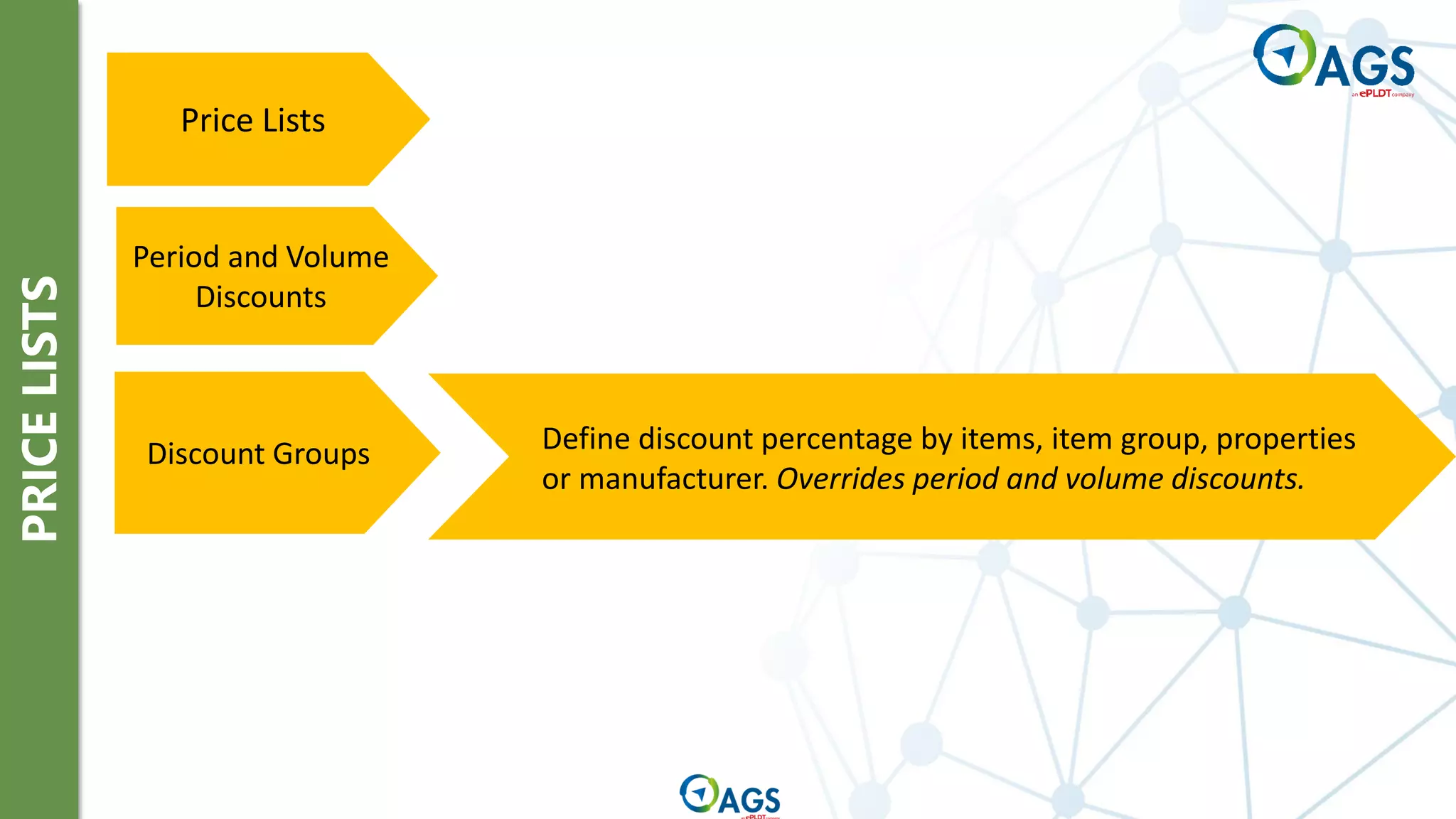

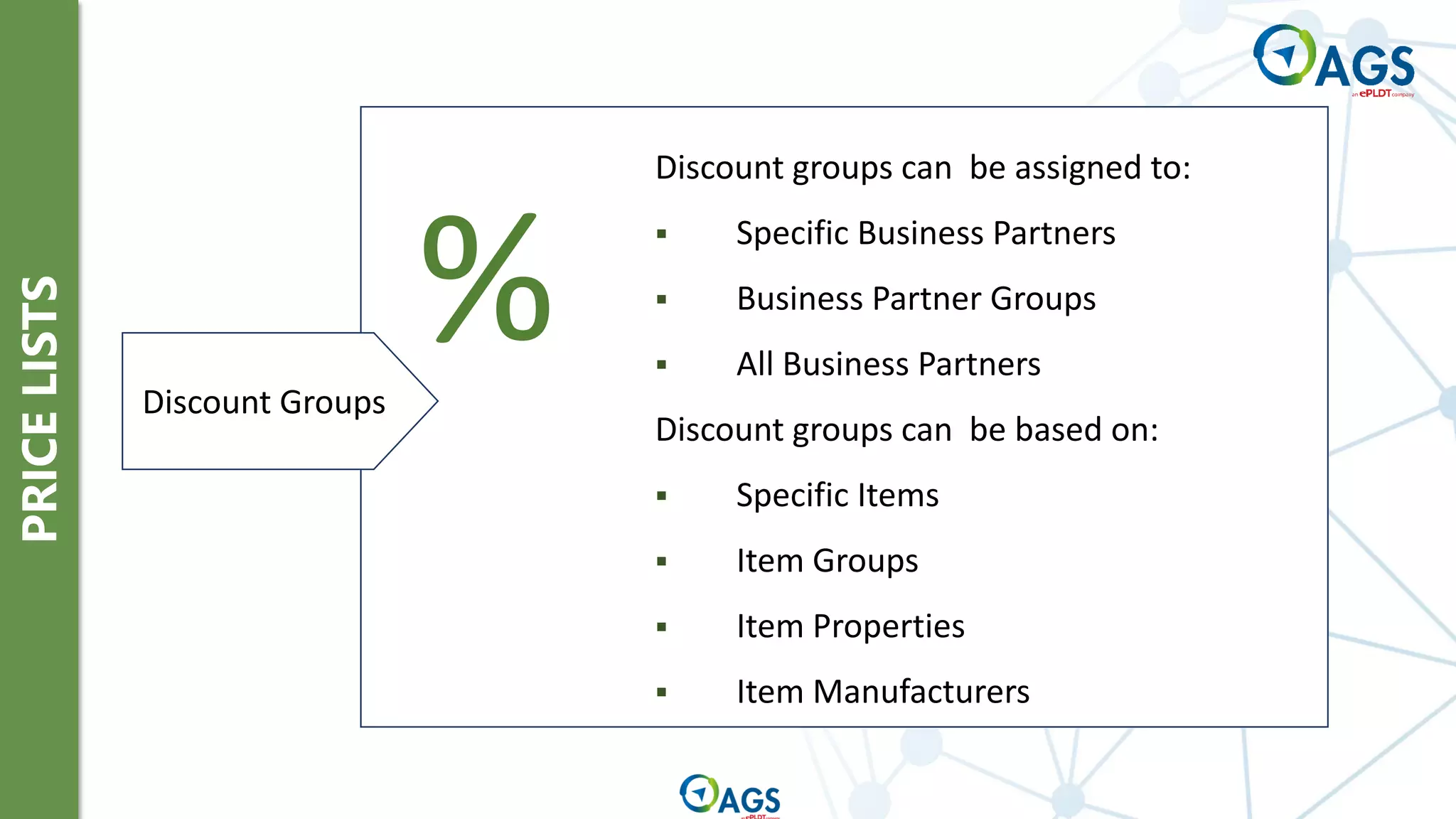

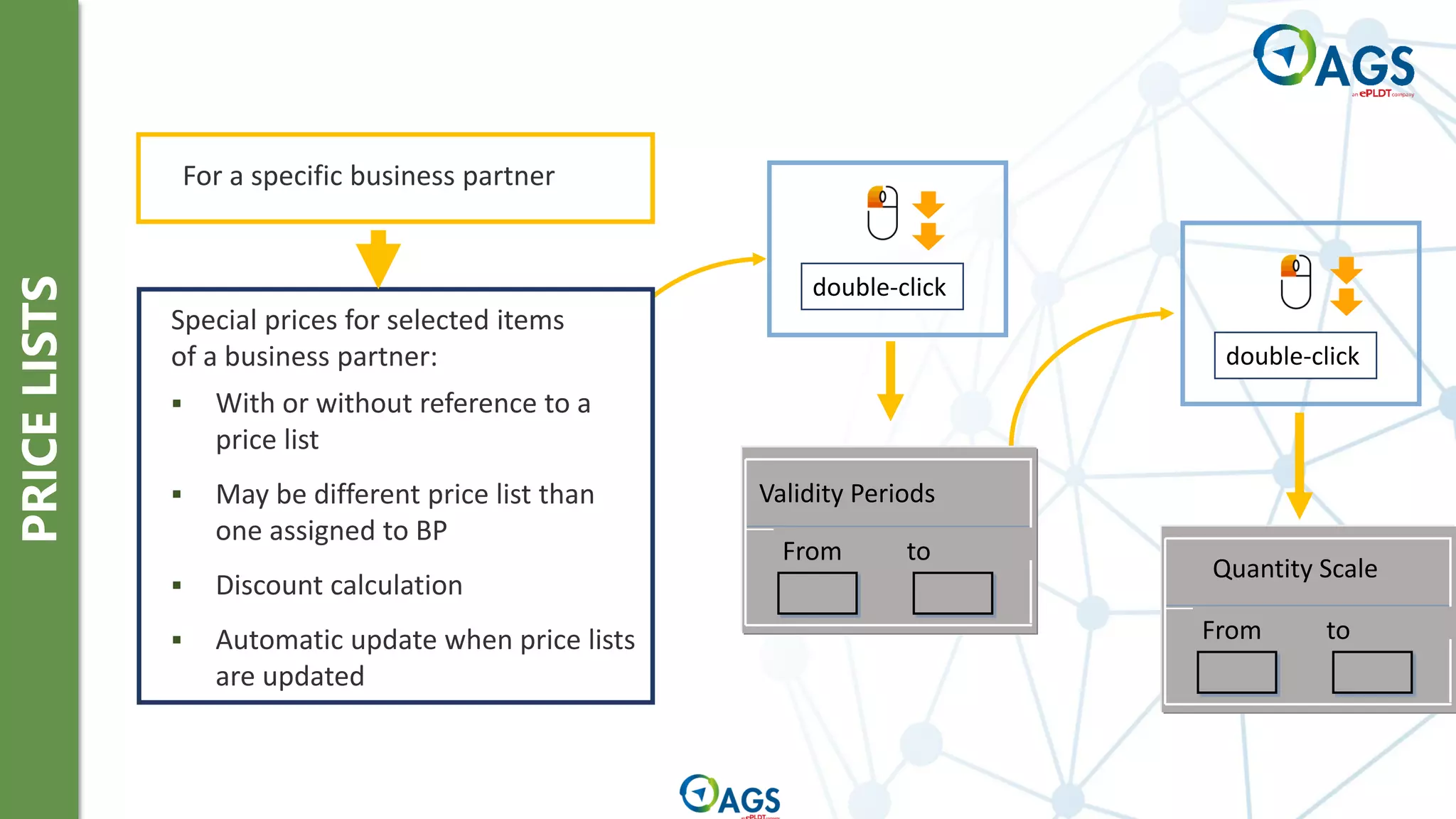

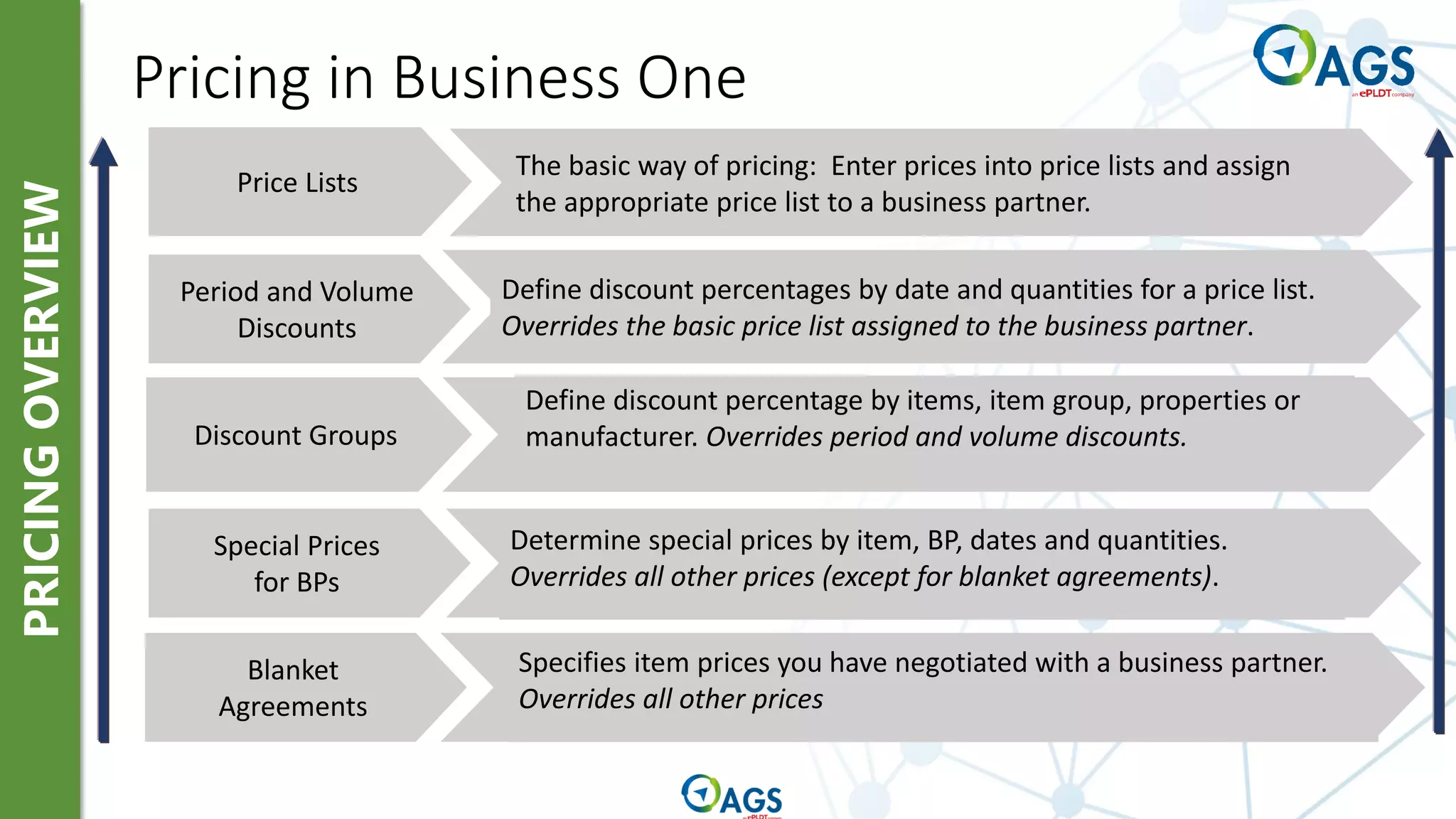

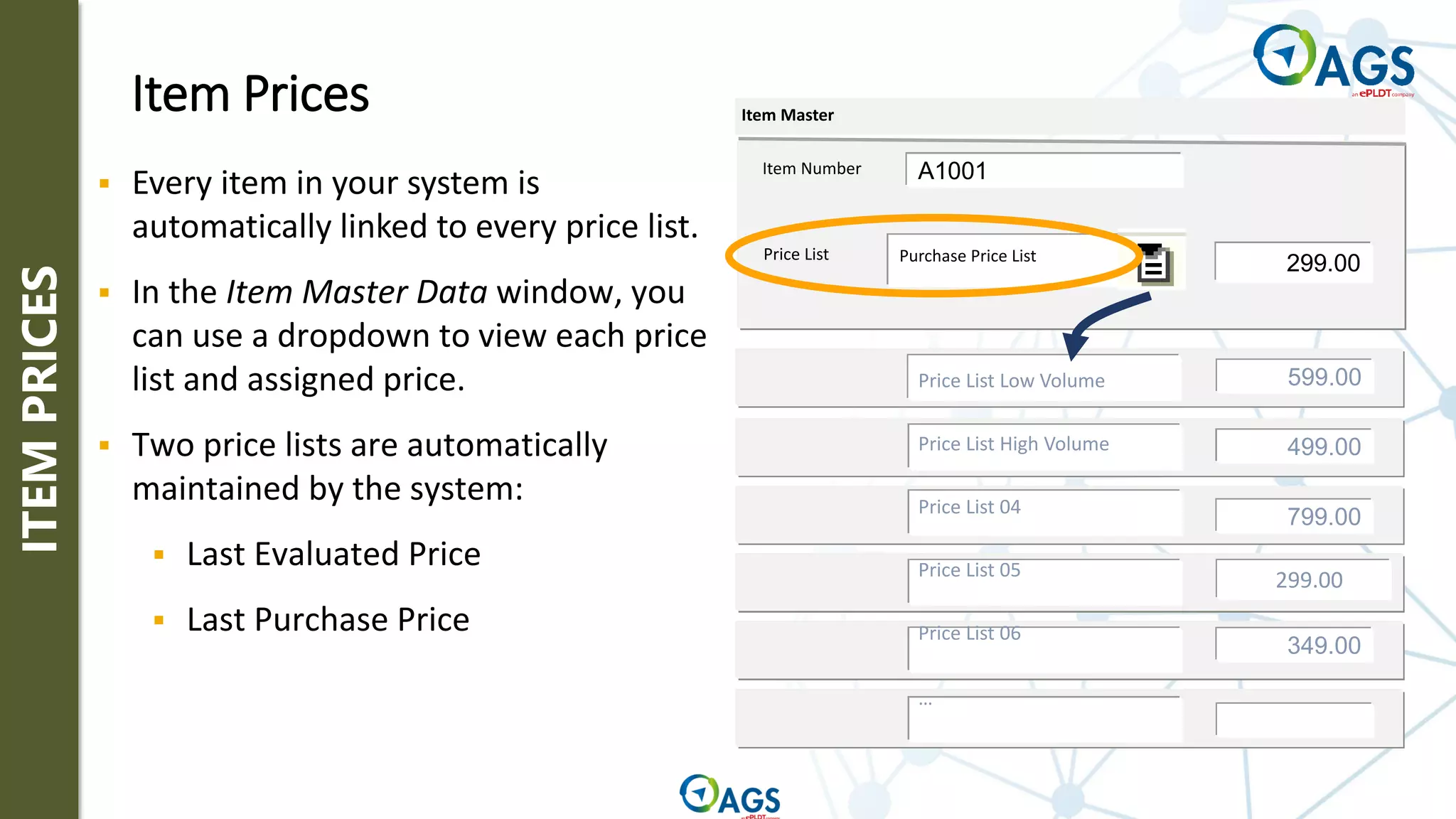

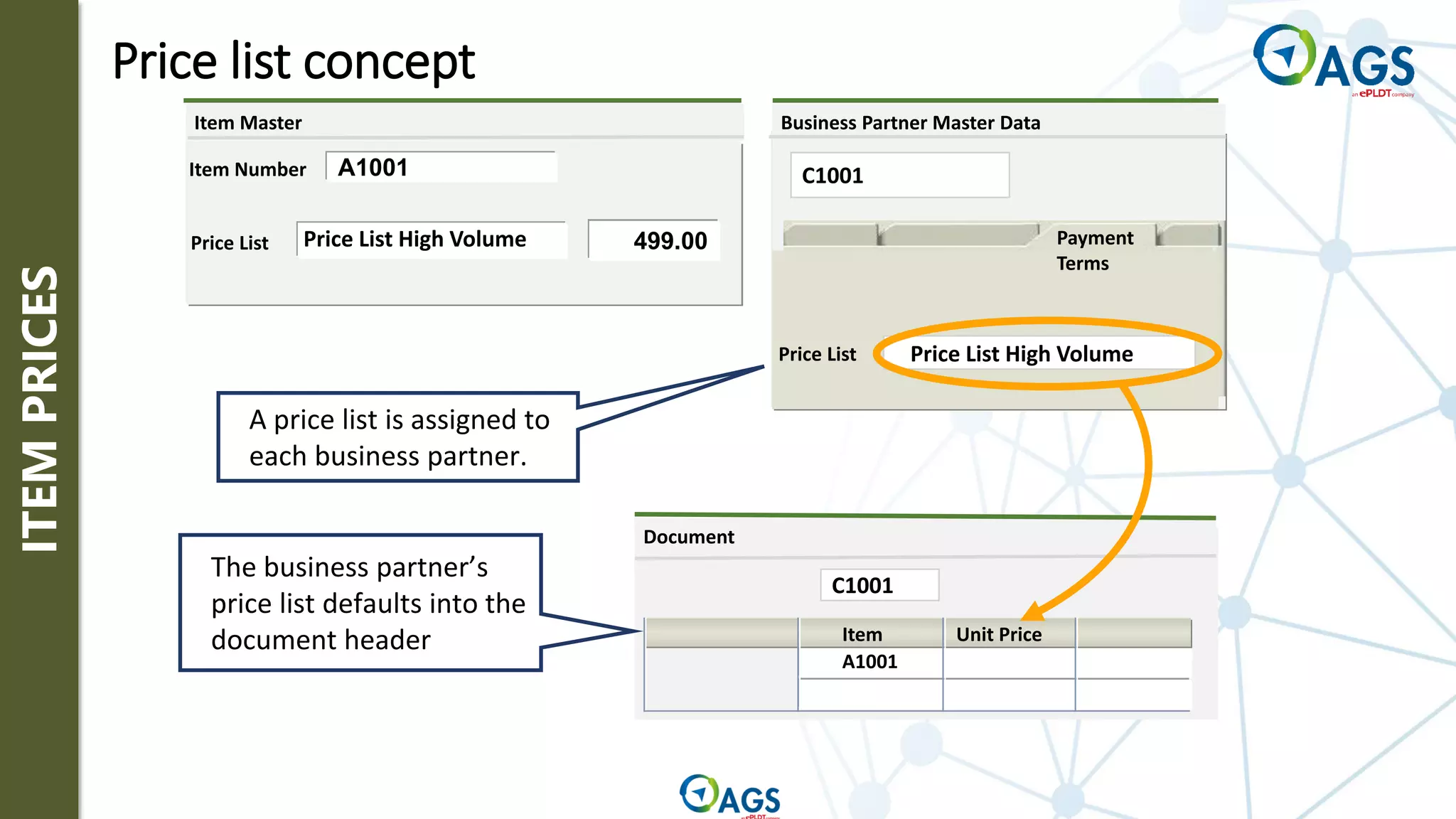

The document discusses key concepts in SAP inventory management including item master data setup, warehouses and bin locations, inventory transactions, pricing lists, and SAP inventory topics. Item master data includes defining items, units of measure, valuation methods, and serial/batch numbers. Warehouses setup includes defining warehouse properties, bin location structures, and allocation strategies. Inventory transactions cover goods receipt, goods issue, inventory transfers, counting, revaluation, and pick and pack processing.