This document provides information about ready-mix concrete (RMC), including its history, composition, production process, and use in India. Some key points:

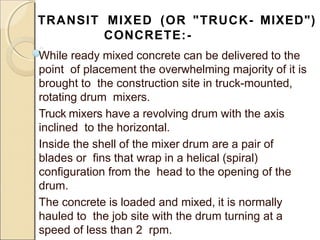

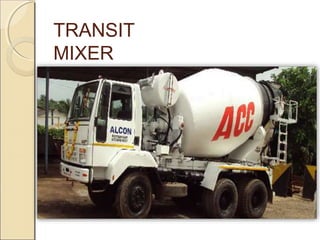

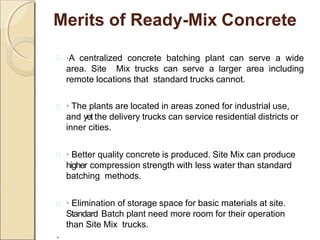

- RMC was first developed in Germany in 1903 and introduced in the US in 1913. It involves premixing concrete ingredients off-site and delivering it via transit mixer trucks.

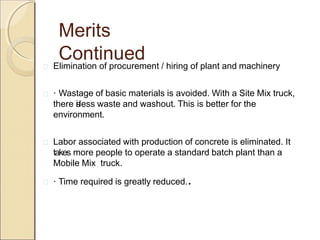

- RMC provides better quality control than on-site mixing and eliminates the need for construction sites to store raw materials. India's first major RMC projects were dams in the 1950s.

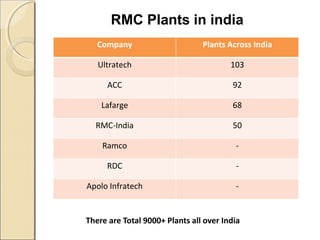

- RMC is composed of cement, aggregates like sand and gravel, water, and sometimes admixtures or fly ash. Major companies in India operate over 100 RMC plants