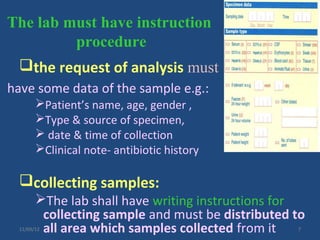

This document discusses quality in microbiological laboratories. It defines quality as meeting customer needs and compliance with standards. Ensuring quality involves controlling pre-analytical, analytical, and post-analytical factors. Pre-analytical factors include proper sample collection, transport, and preventing rejection. Analytical quality is maintained through equipment calibration and validation, reagent and media quality control. Documentation of equipment, procedures, results and data storage are important post-analytical factors. The overall goal is producing accurate and reliable test results.