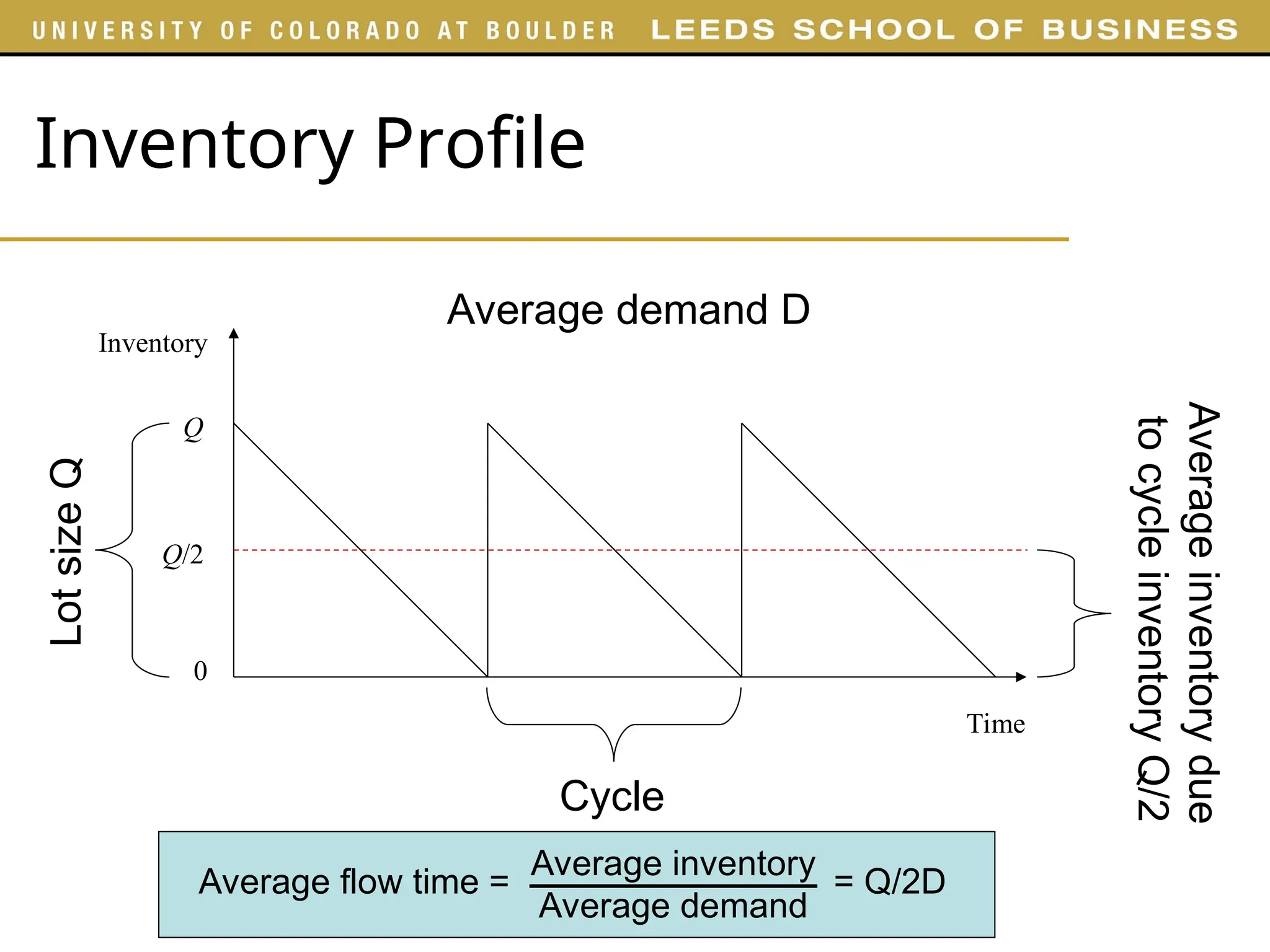

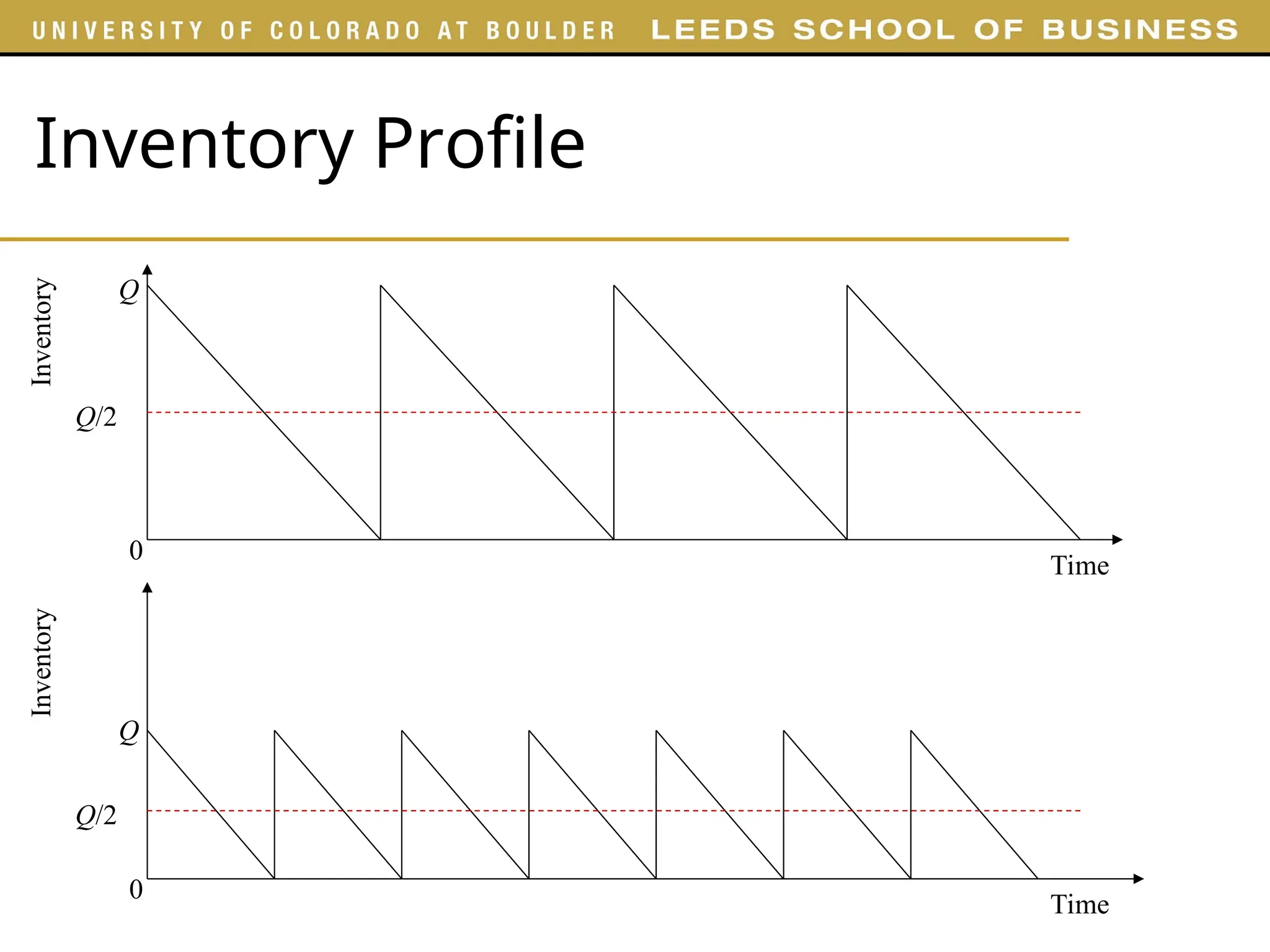

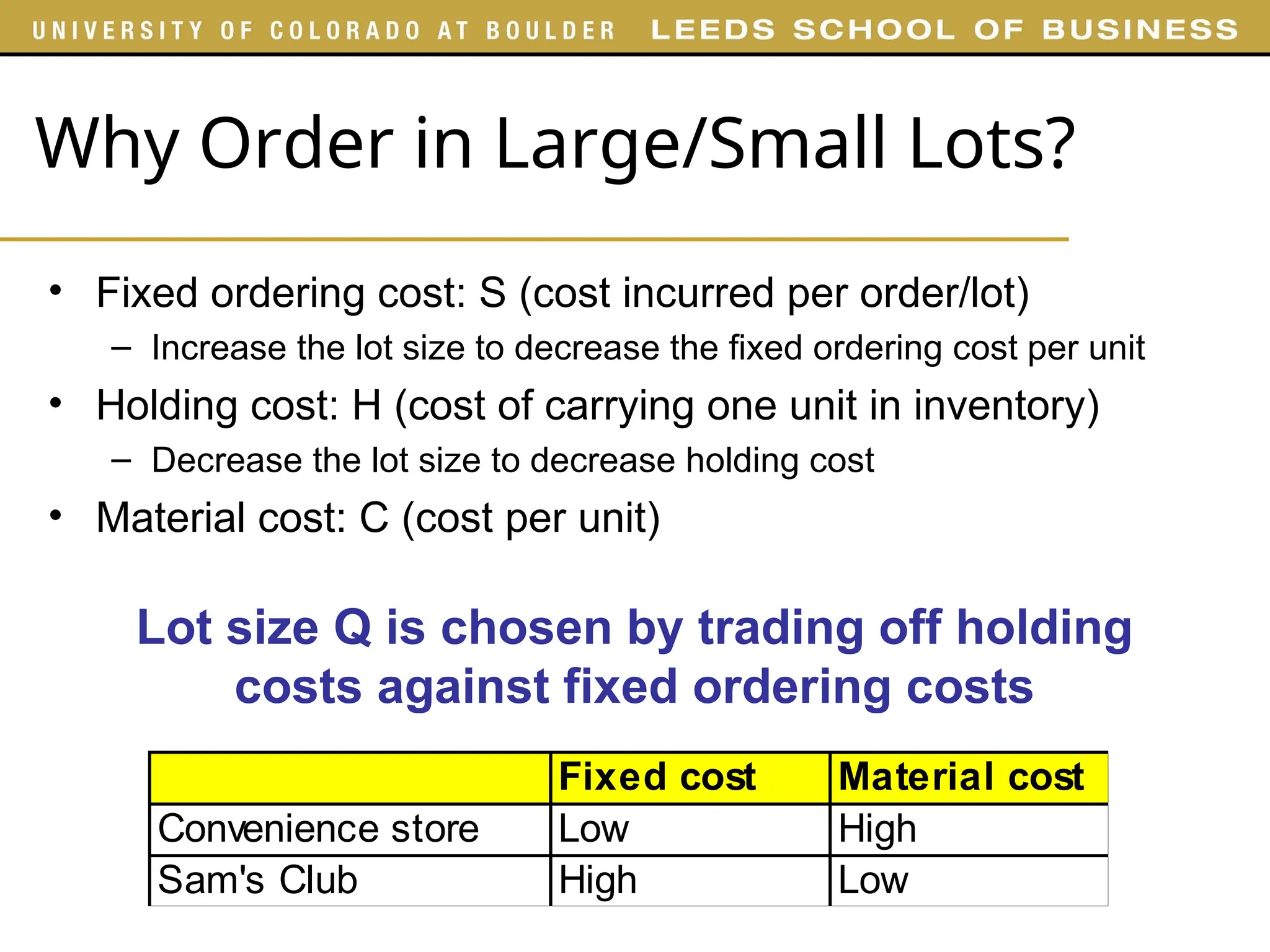

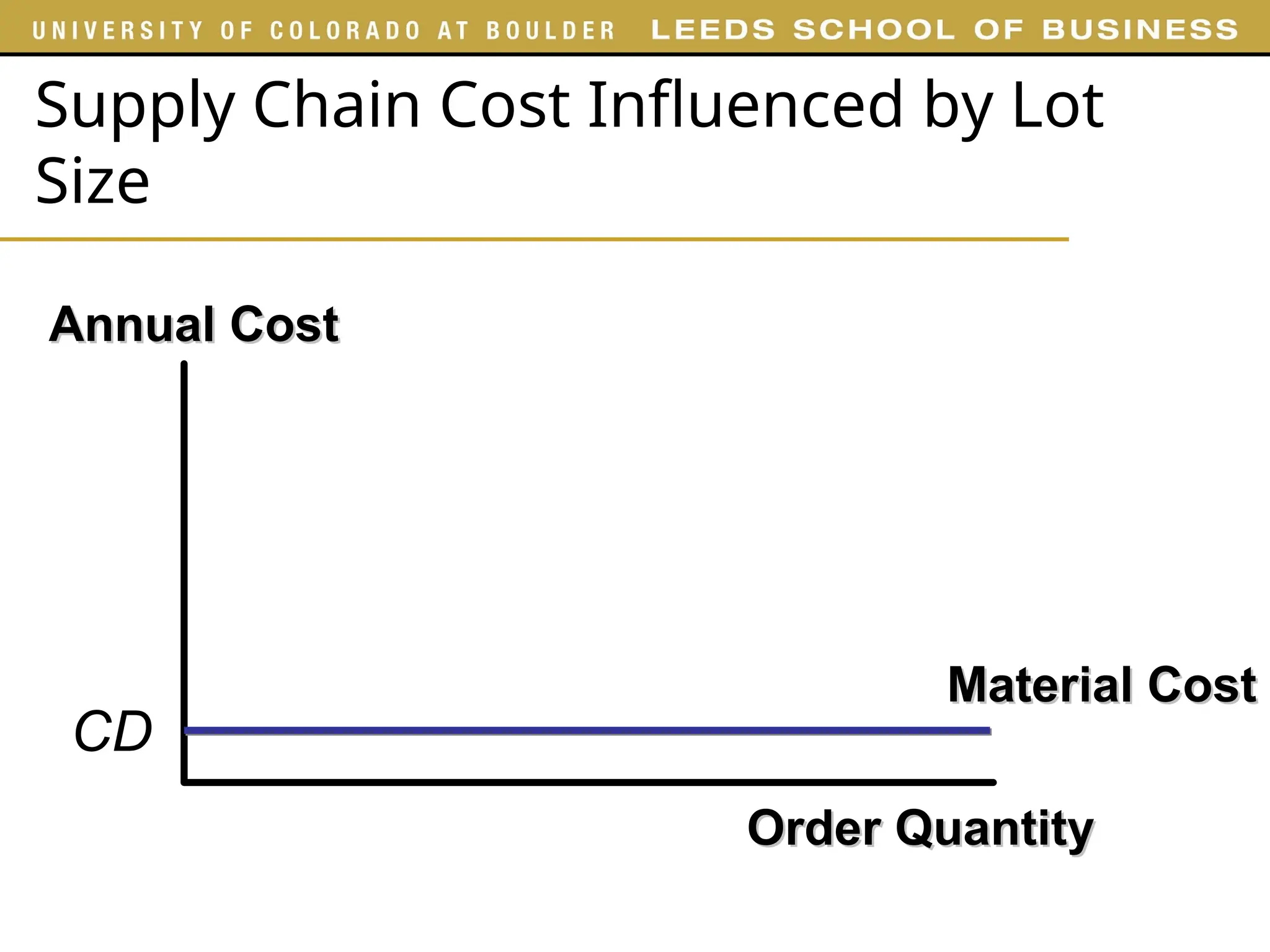

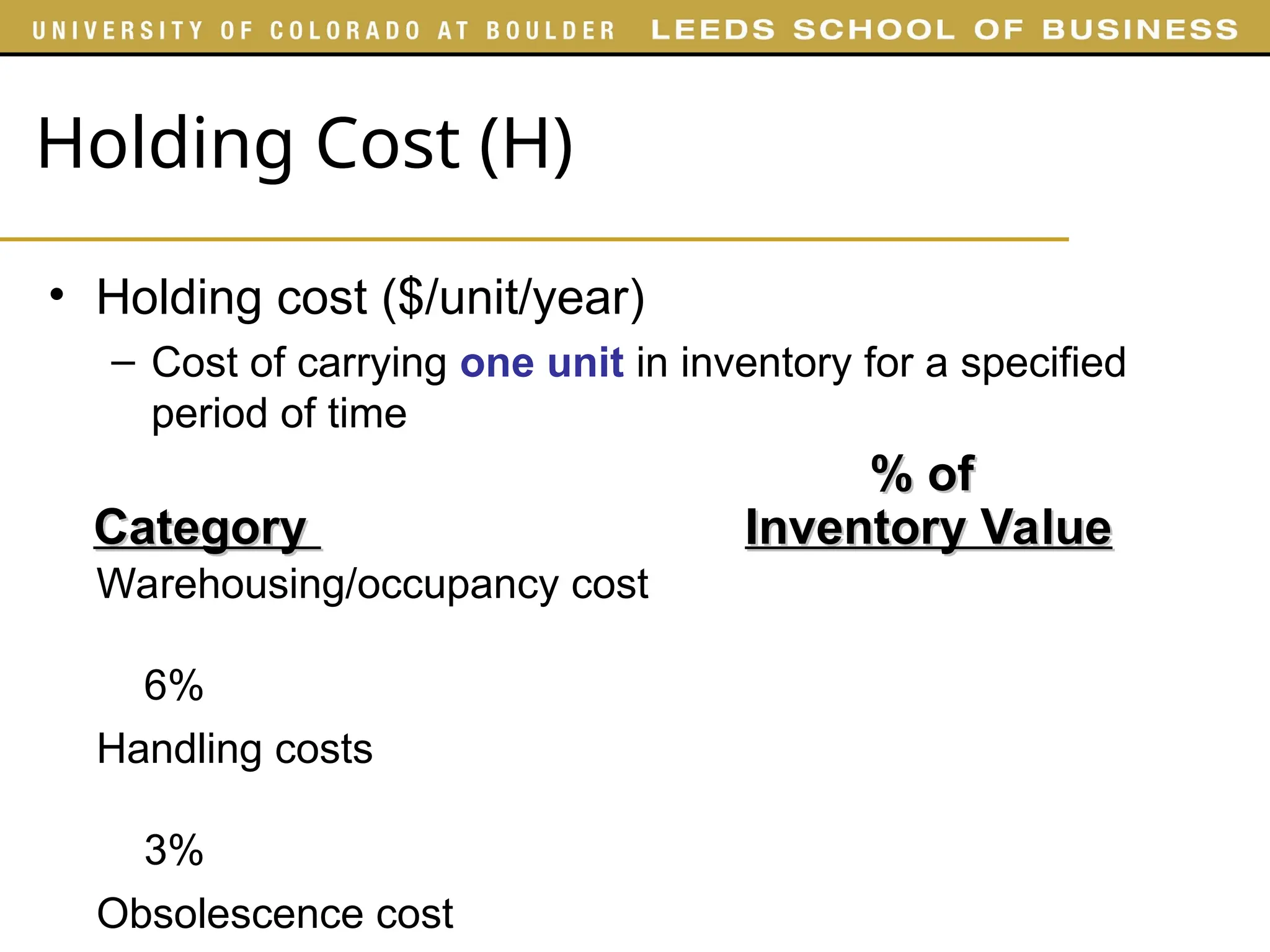

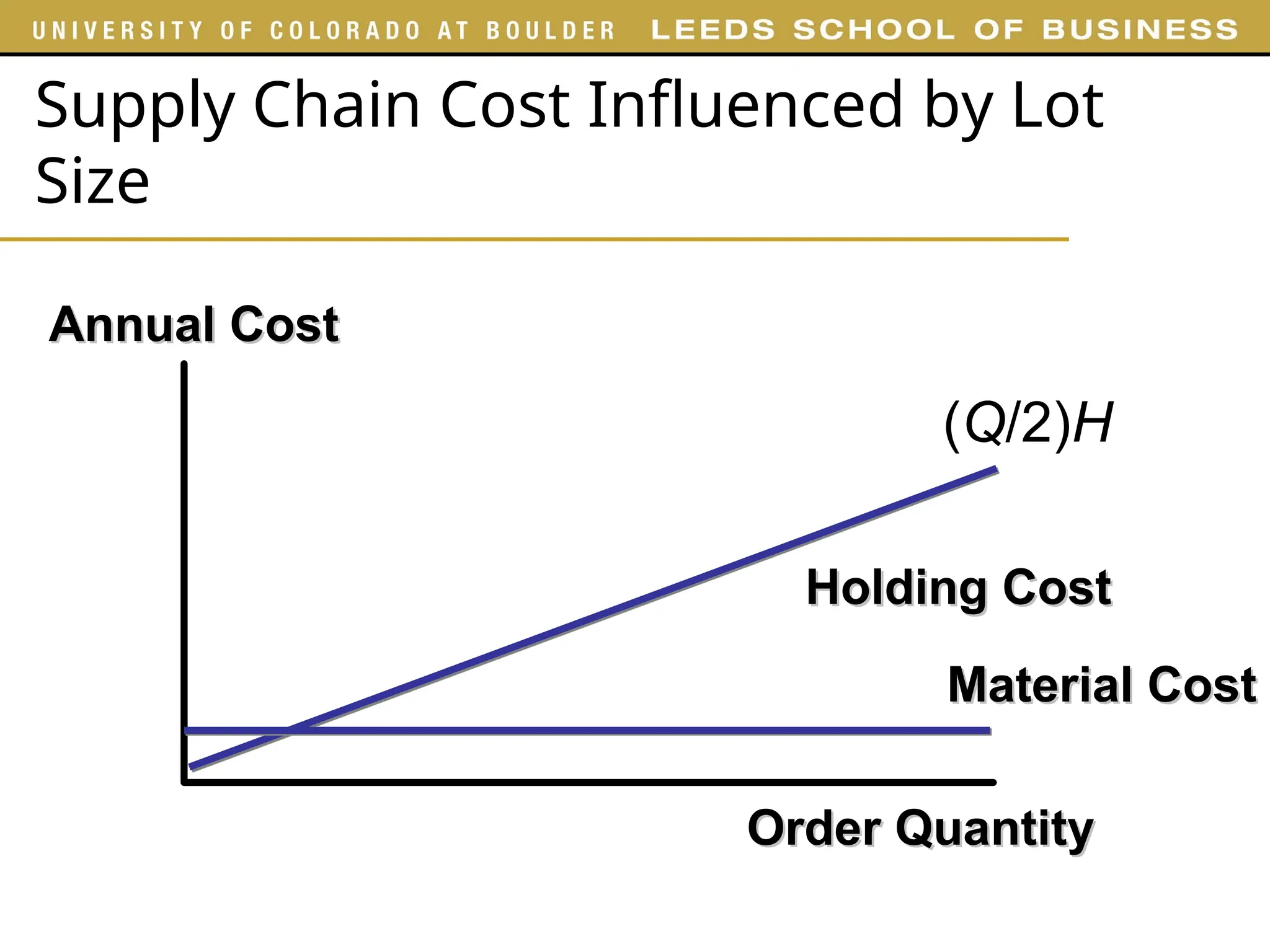

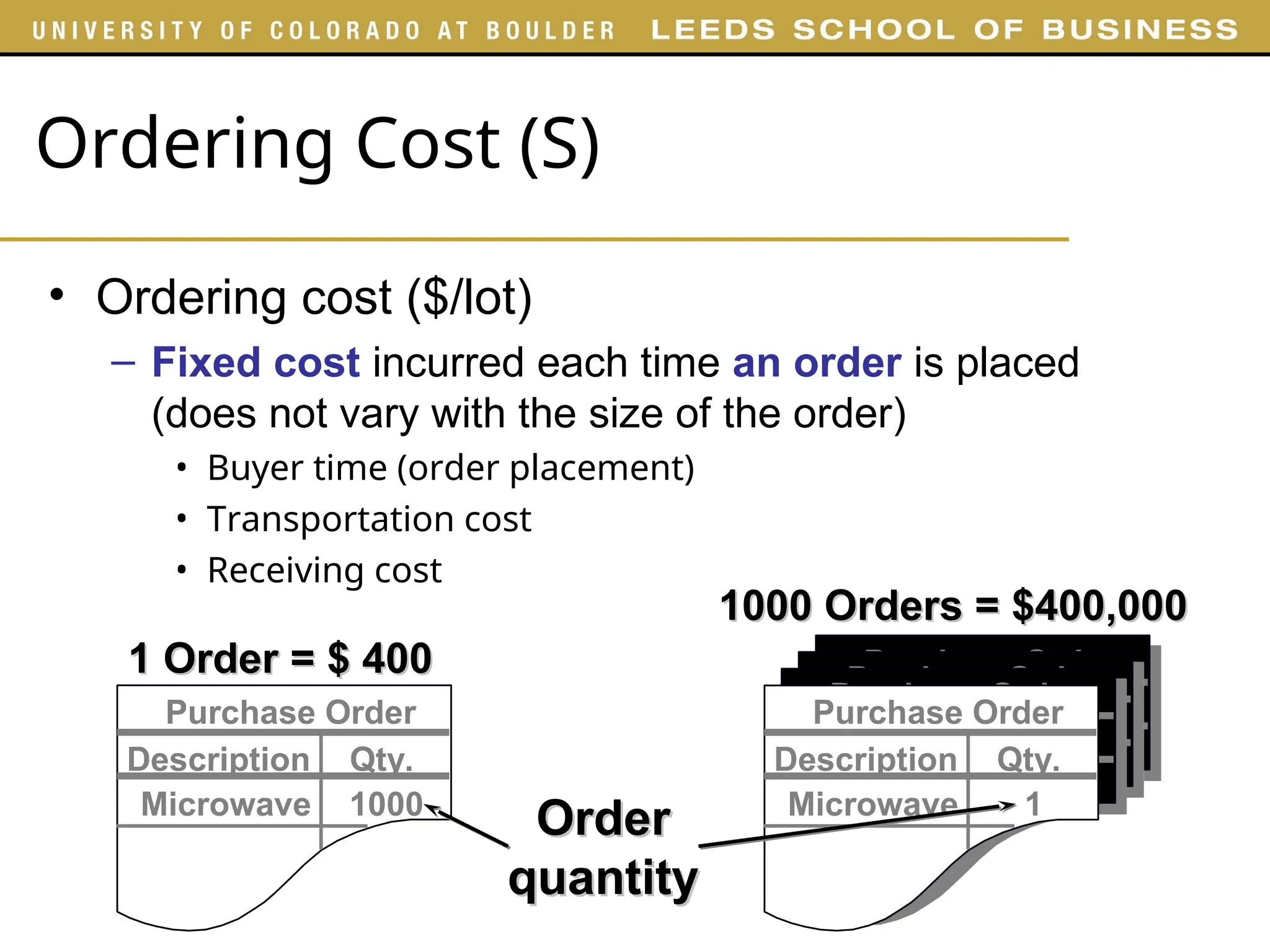

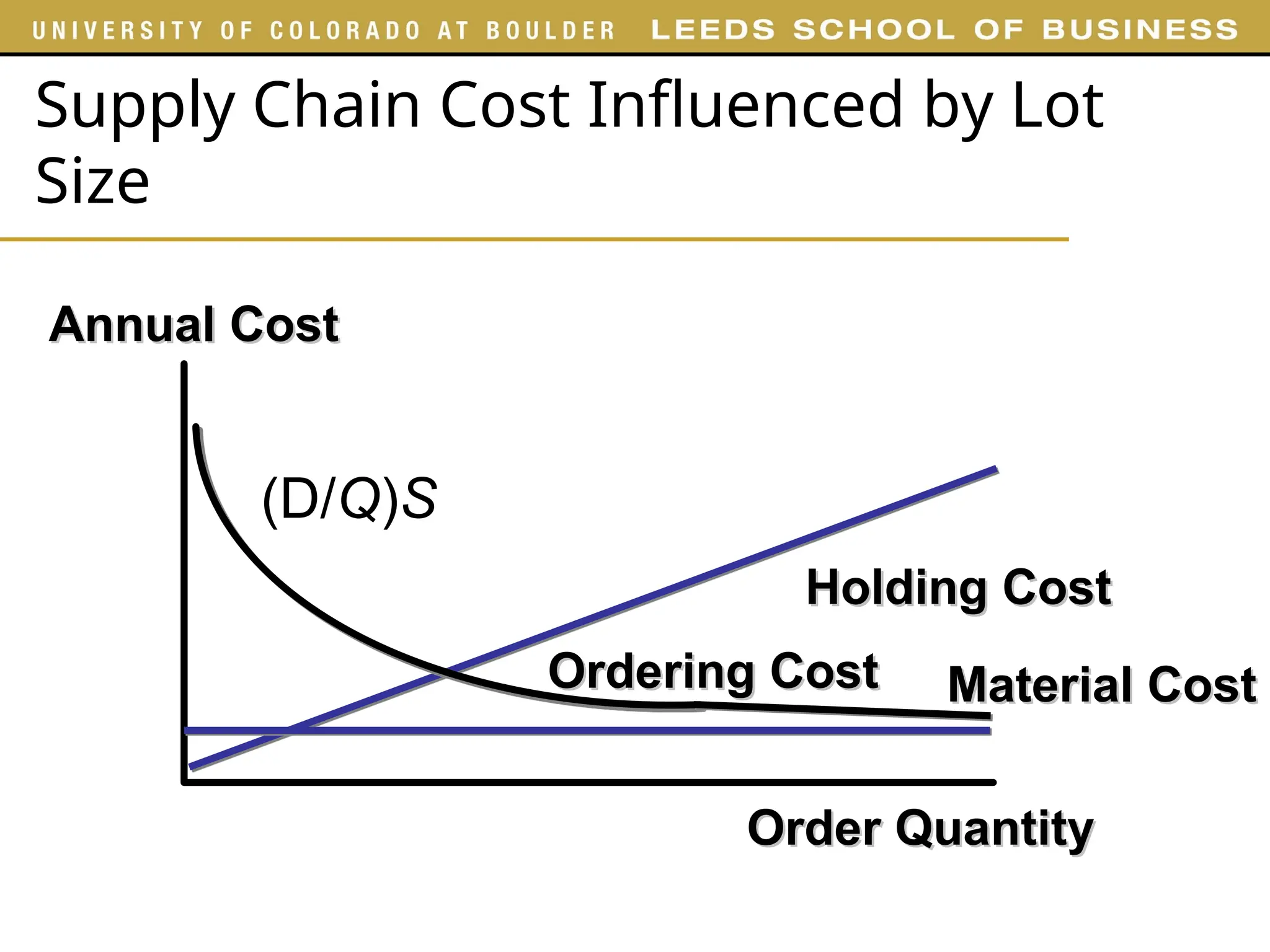

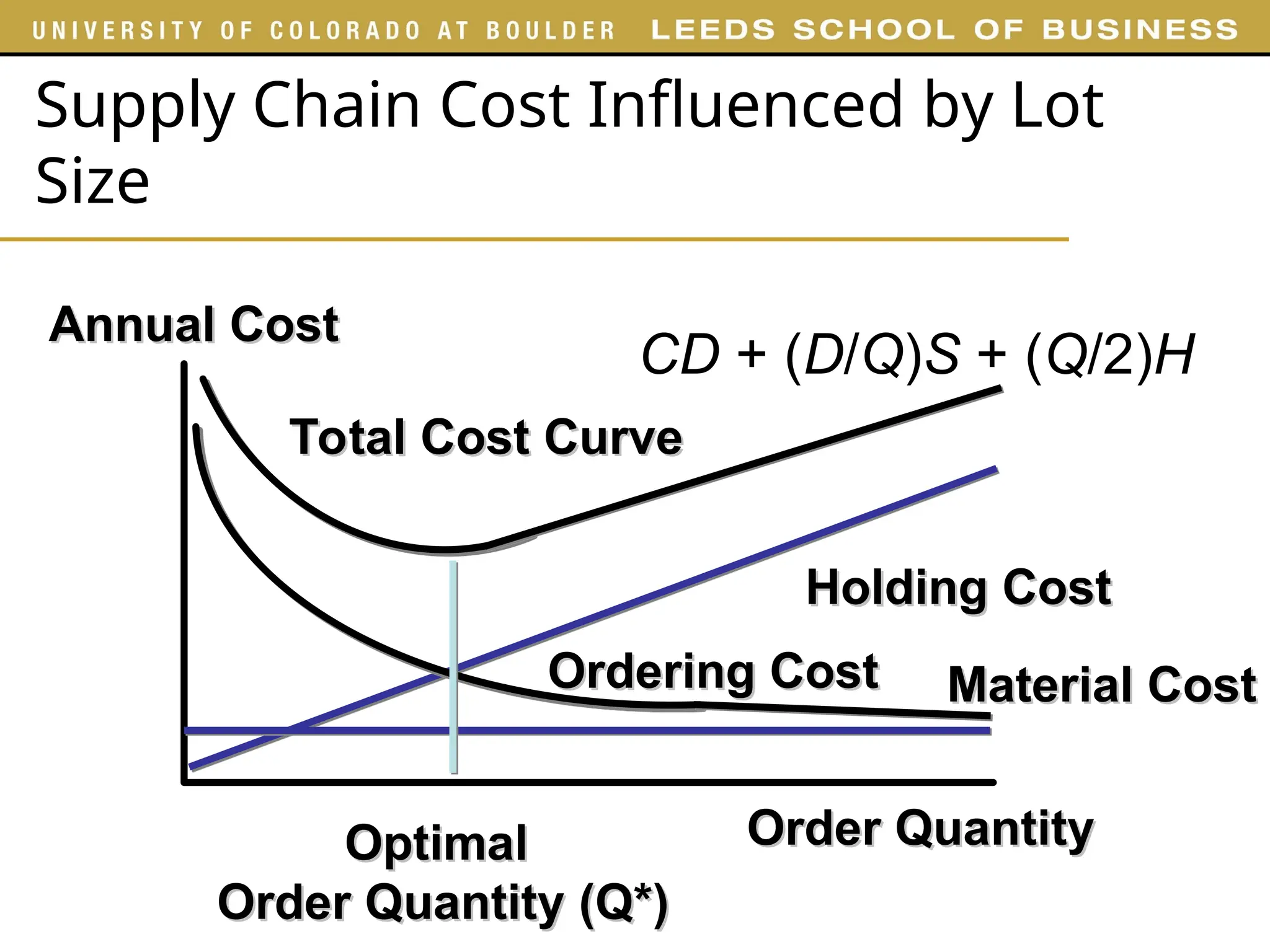

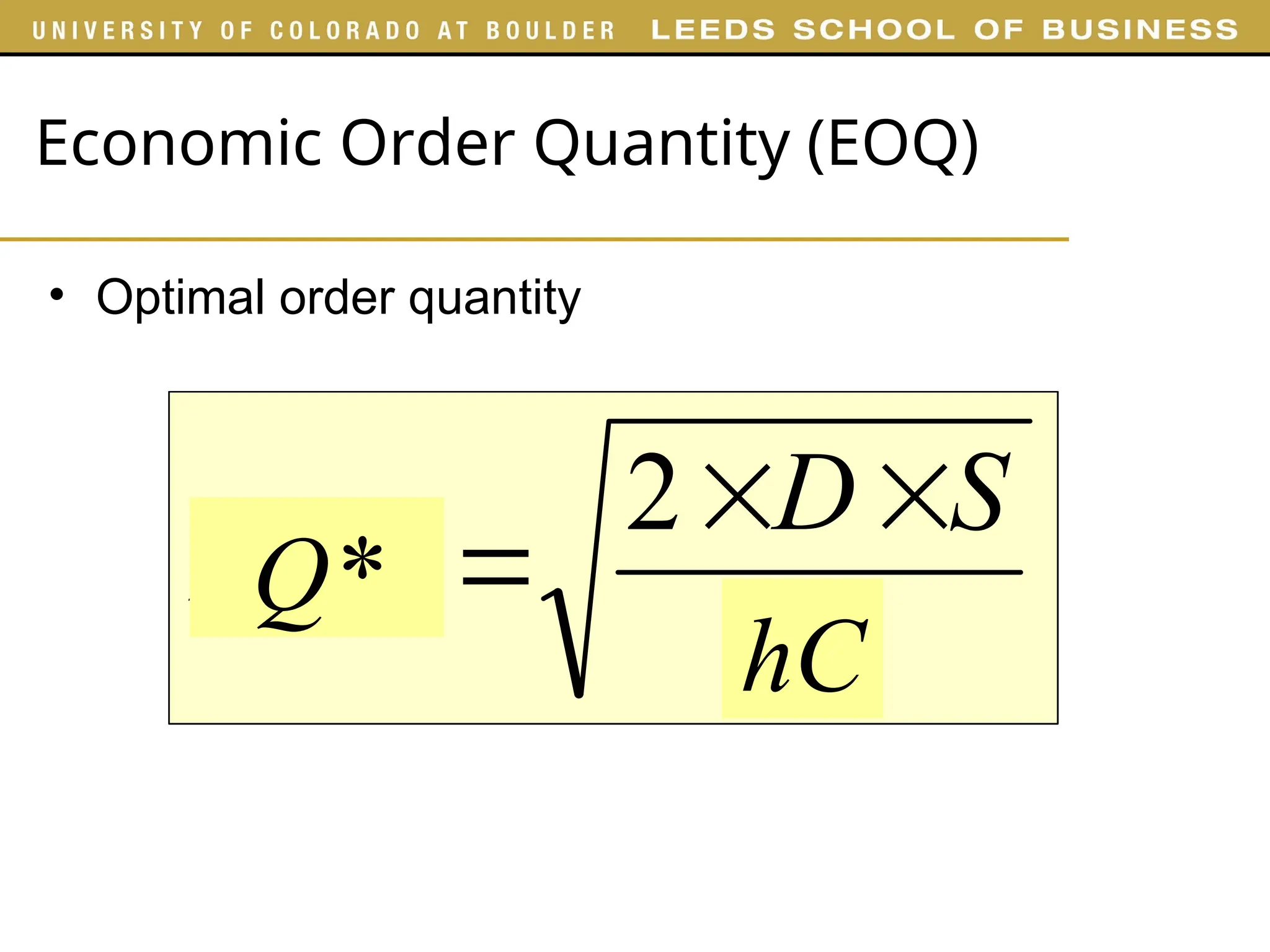

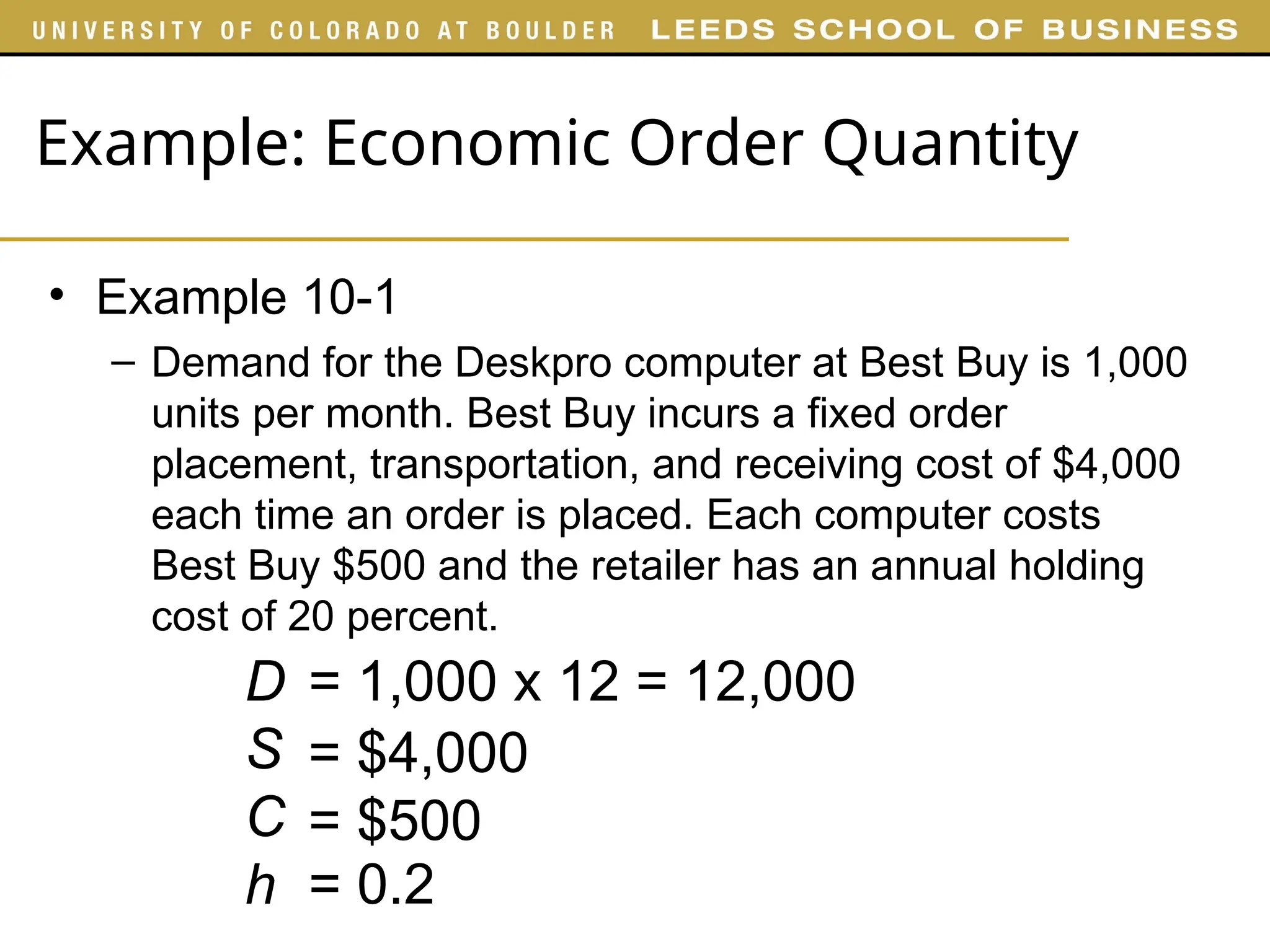

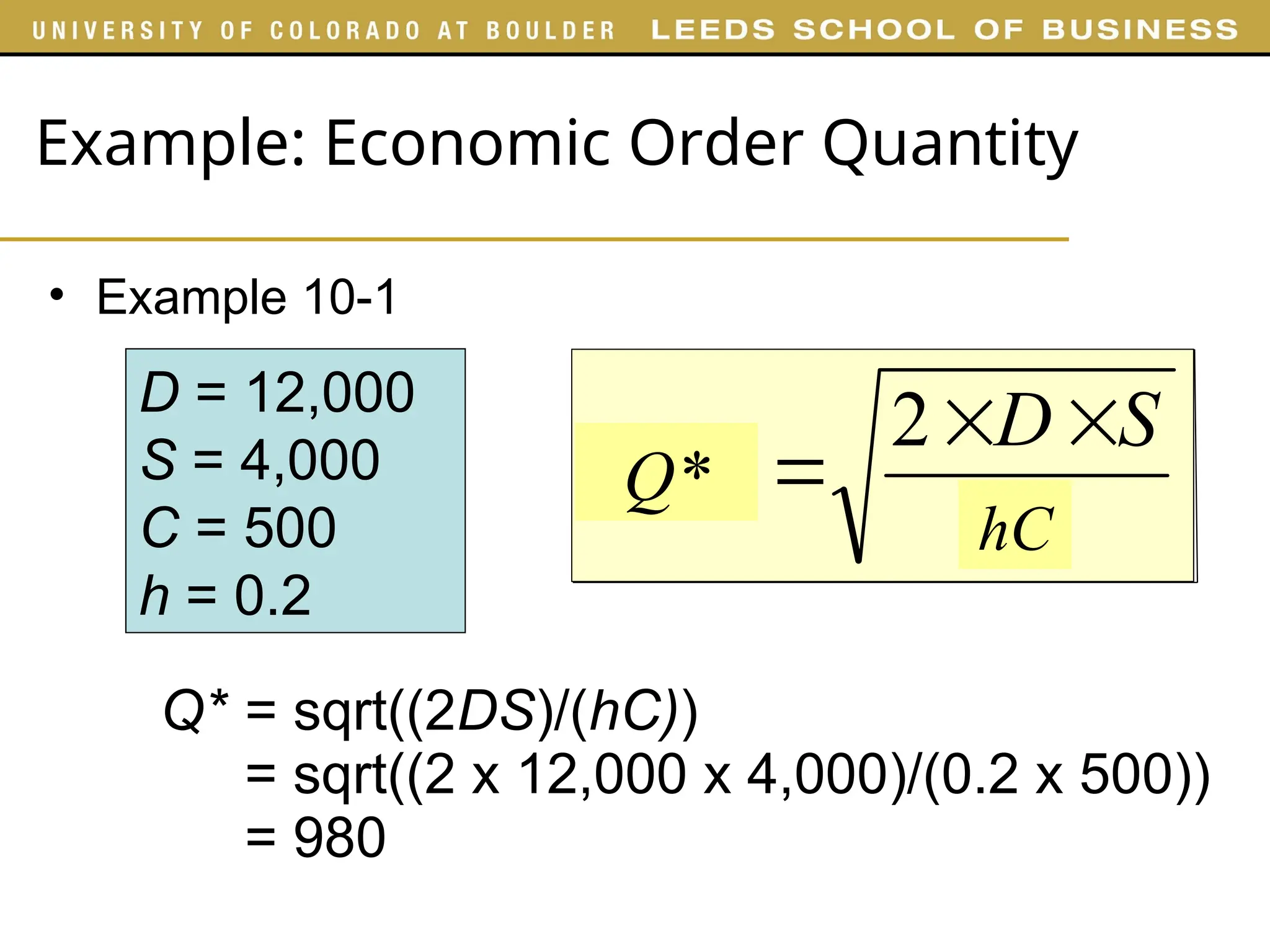

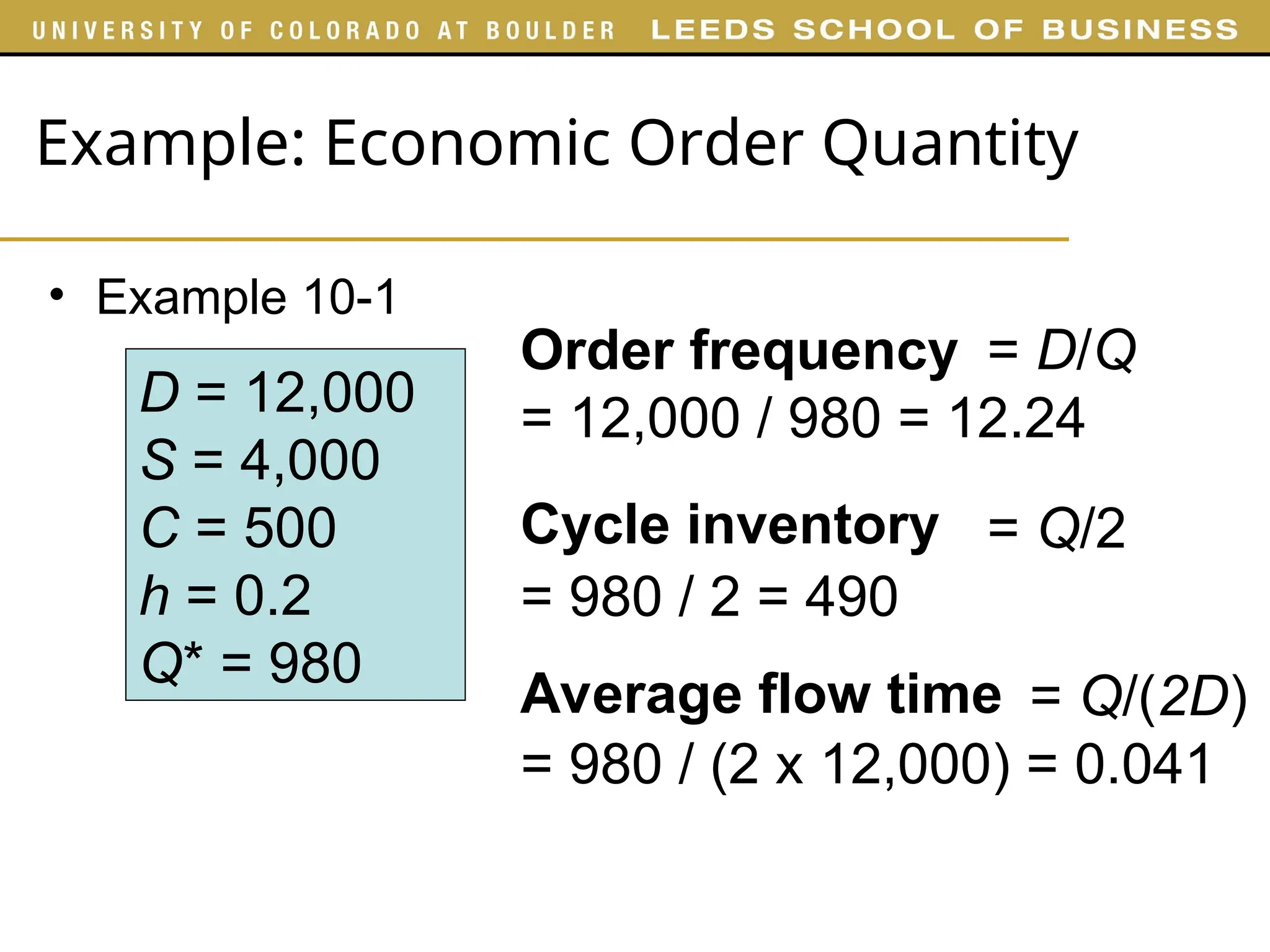

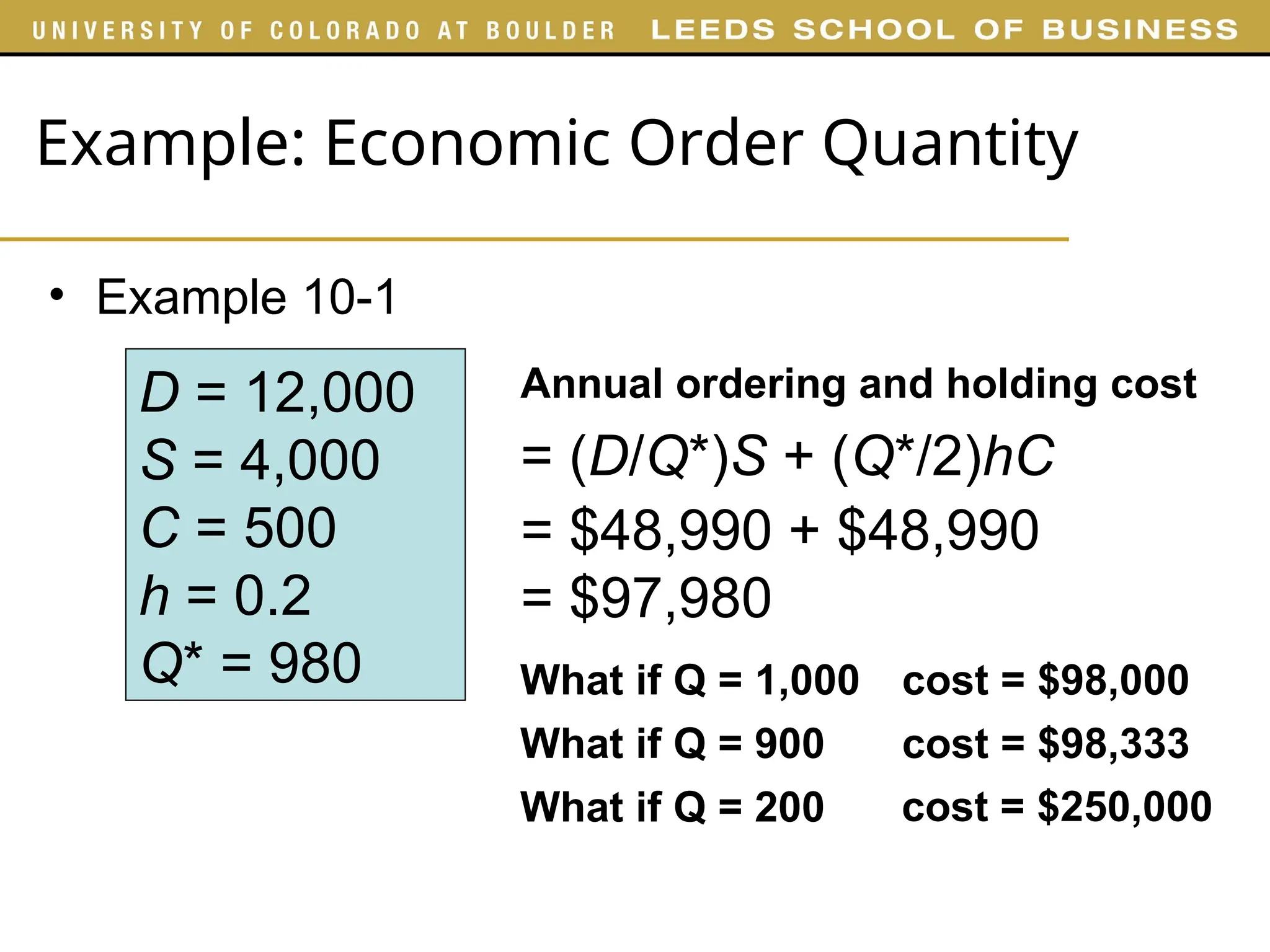

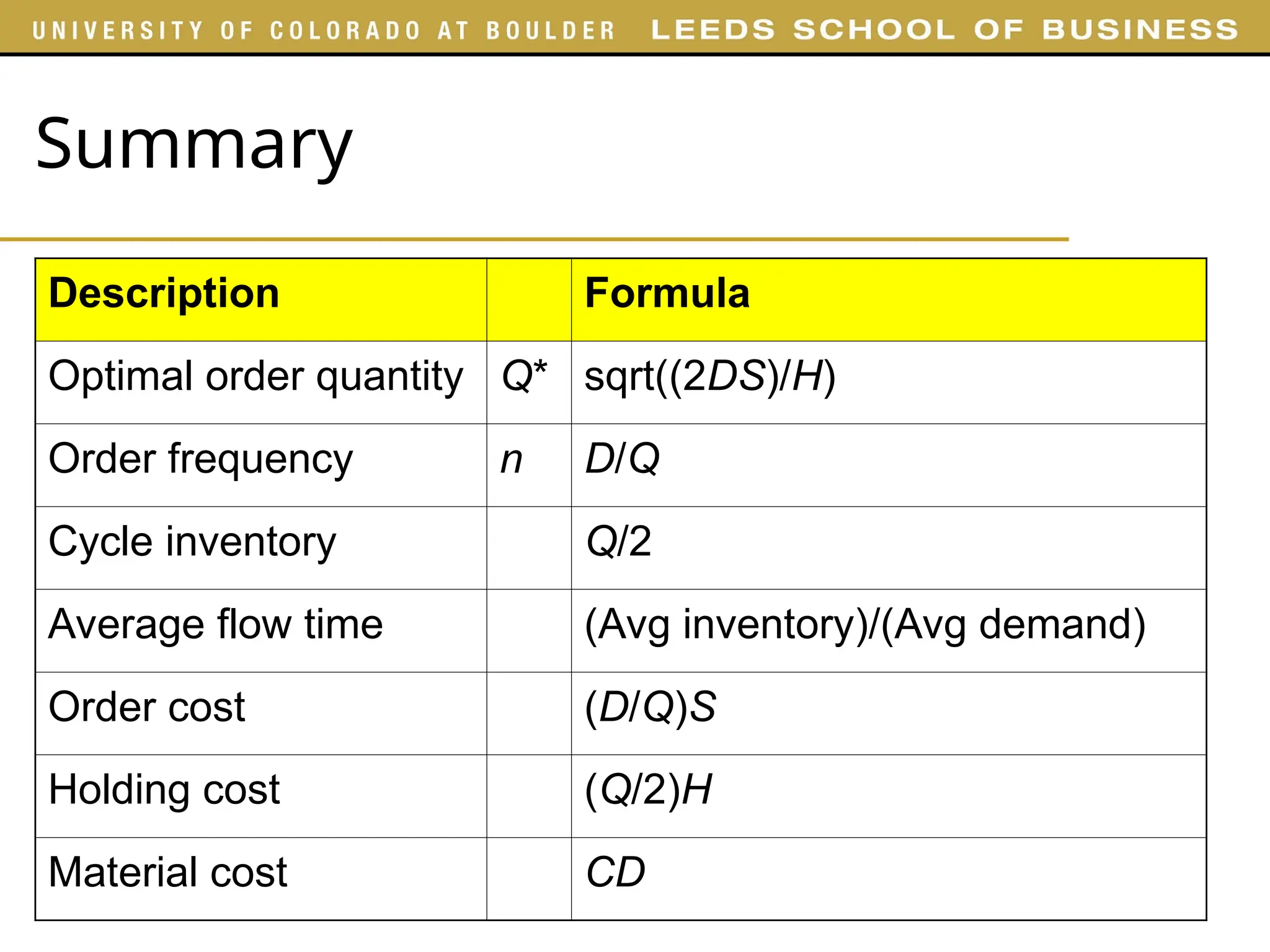

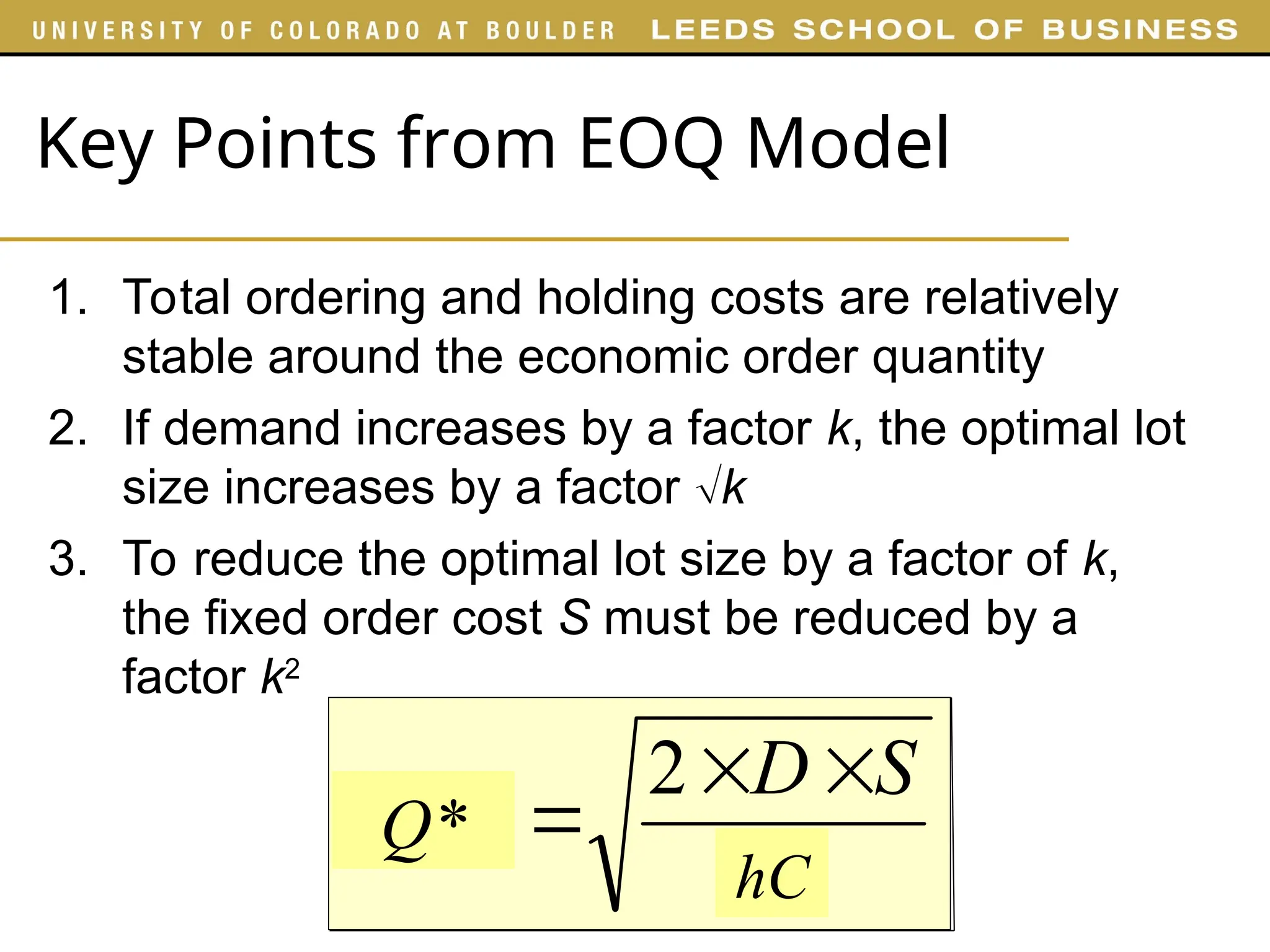

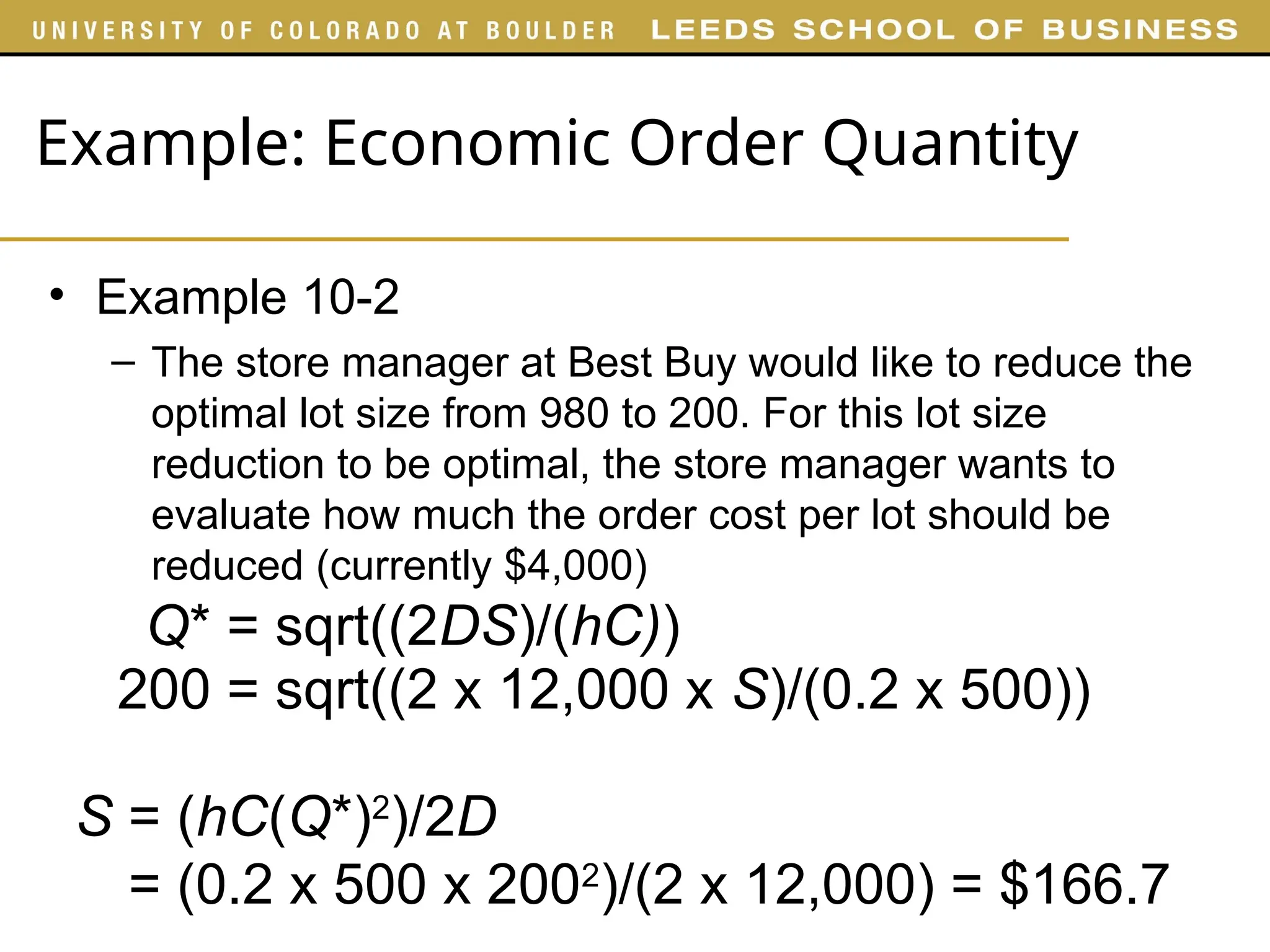

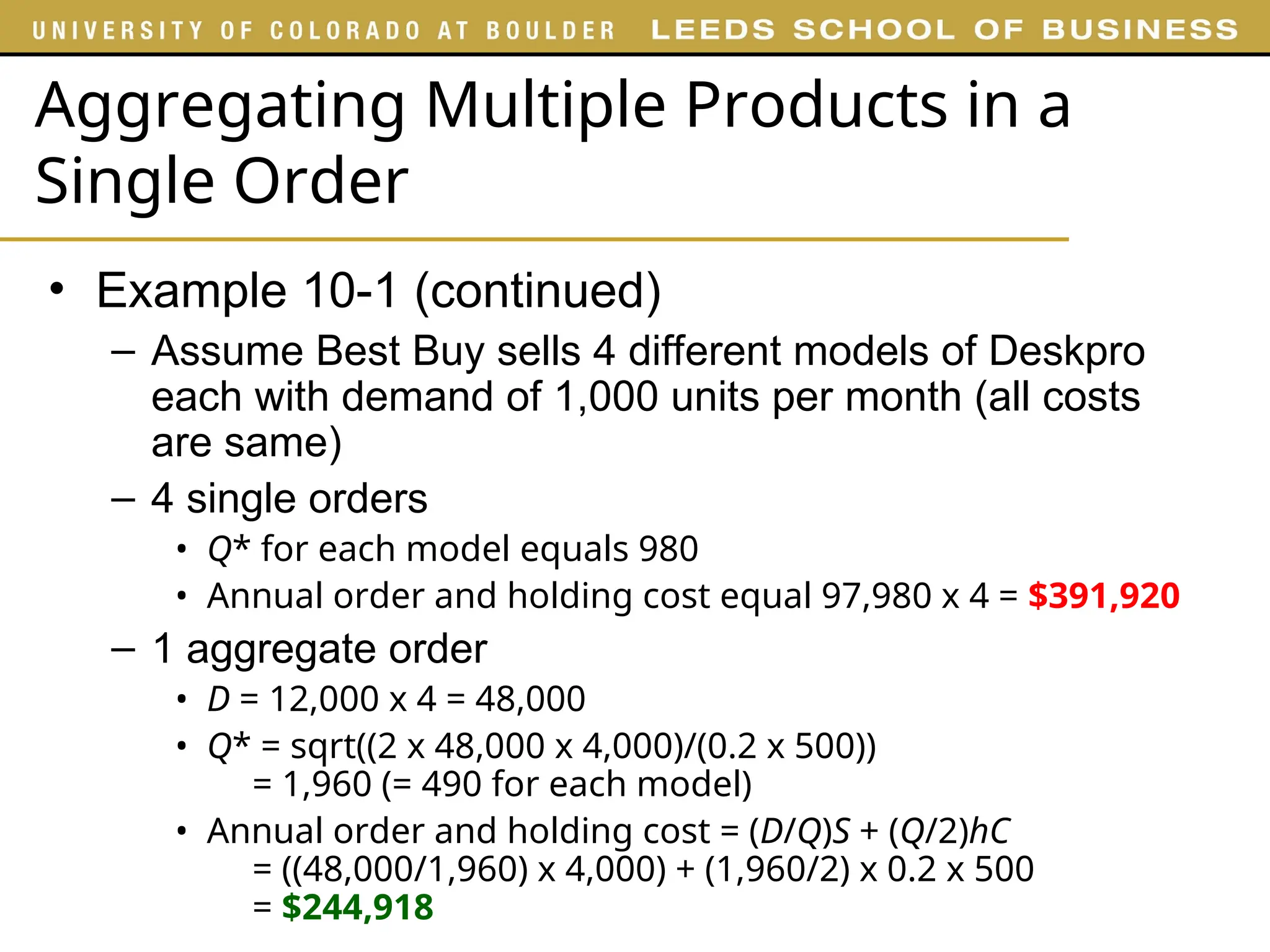

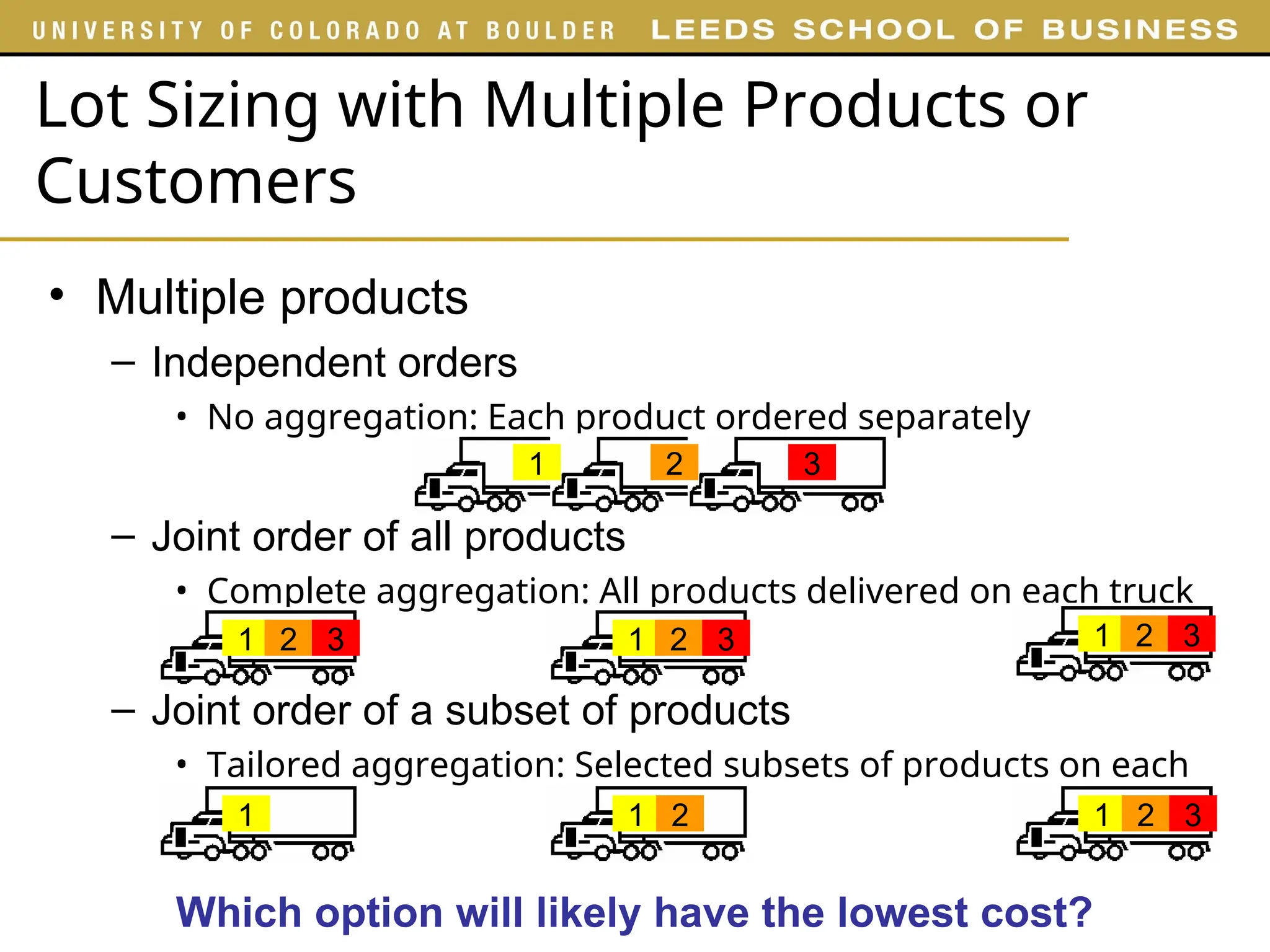

The document outlines the content of a supply chain management lecture, focusing on inventory management, including the economic order quantity (EOQ) model and its implications for cost reduction. It discusses key concepts such as inventory profiles, ordering costs, holding costs, and strategies for optimizing order quantities. Additionally, it includes examples illustrating the calculation of optimal order quantities and the benefits of aggregating orders for multiple products.