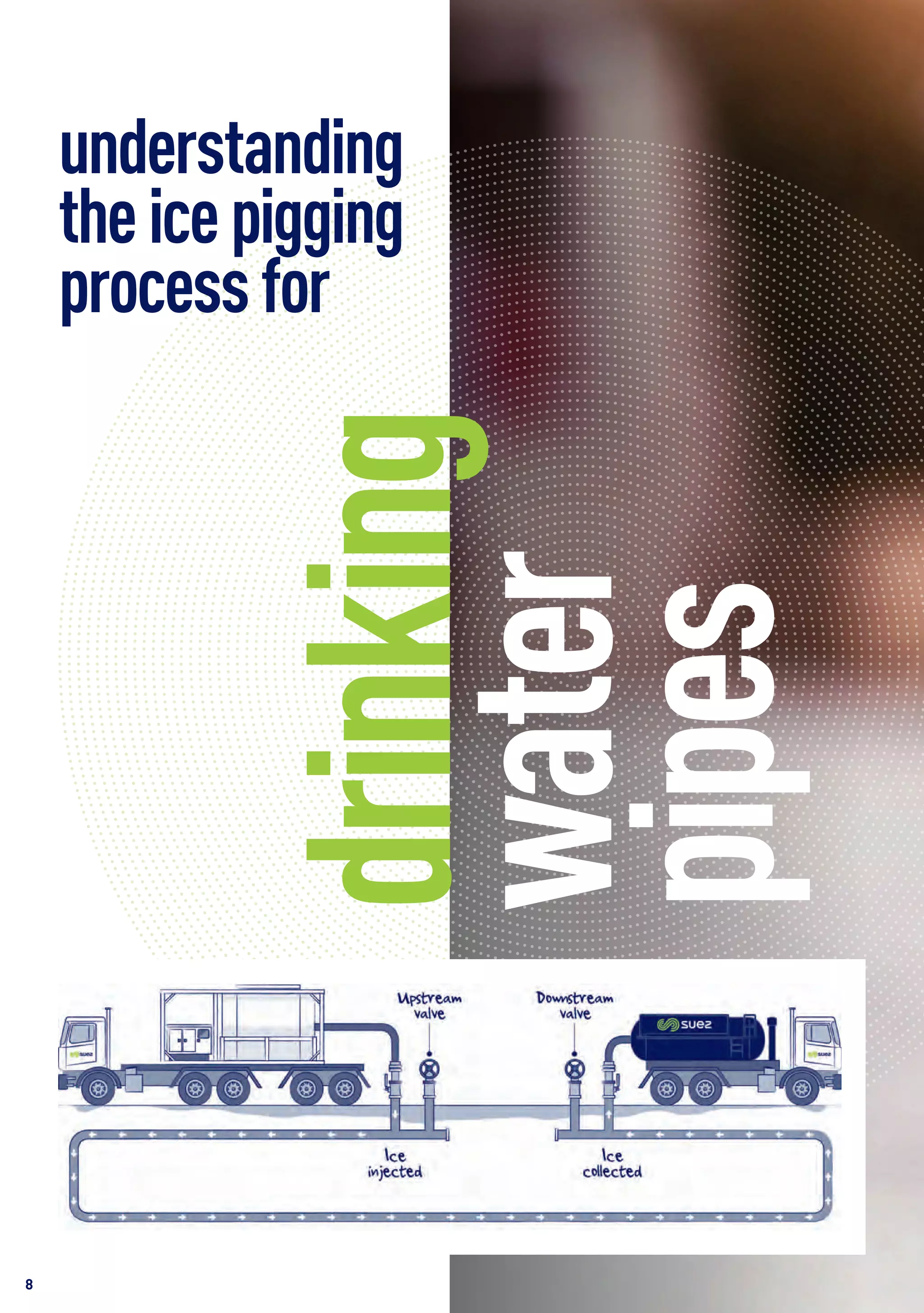

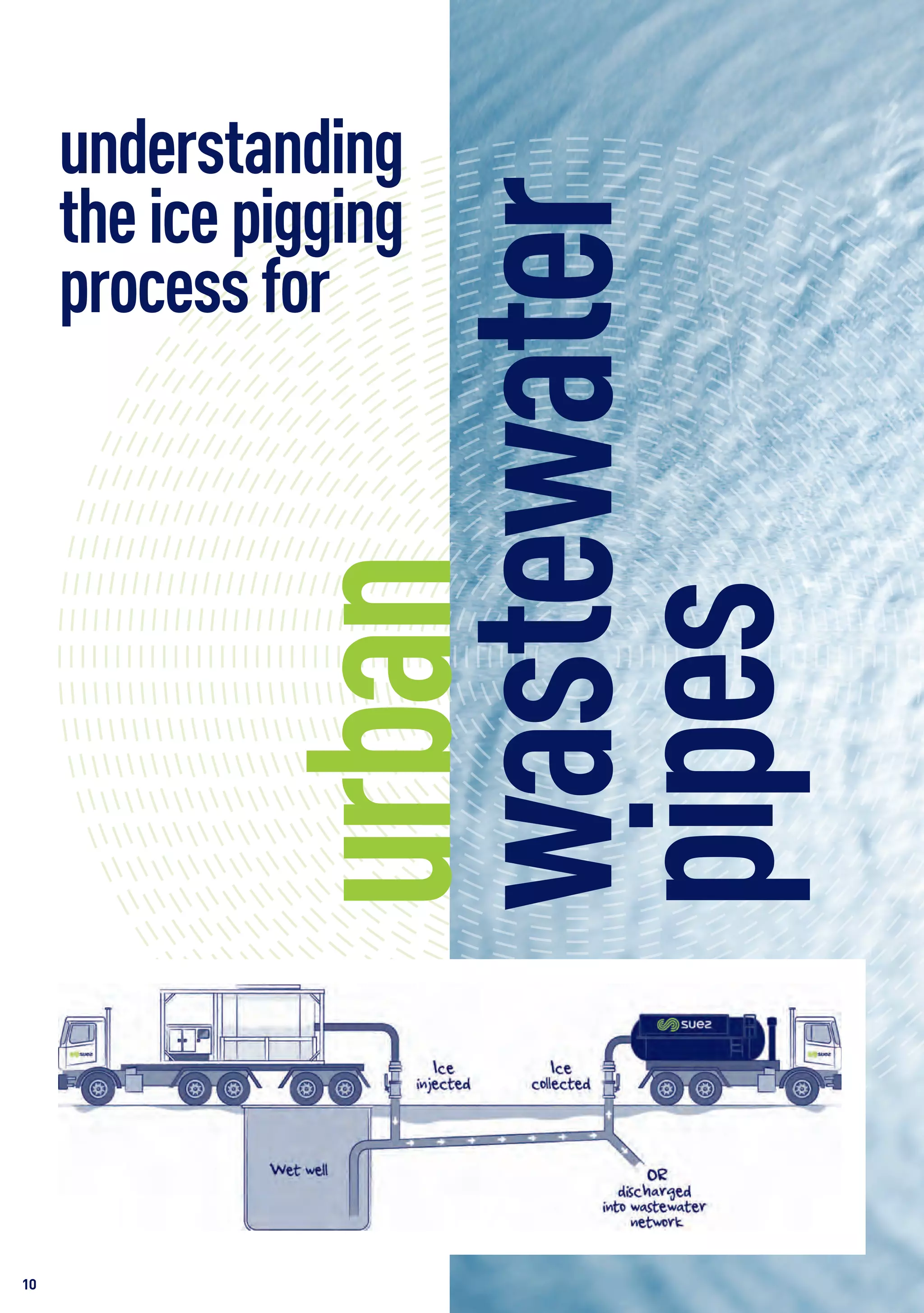

Ice pigging is a chemical-free, cost-effective pipe cleaning method that uses an ice slurry to remove sediment and biofilms from drinking and wastewater infrastructure. This innovative process is efficient, reducing service disruption and utilizing significantly less water compared to traditional techniques. Ice pigging is applicable across various industries, contributing to improved operational efficiency and water quality.