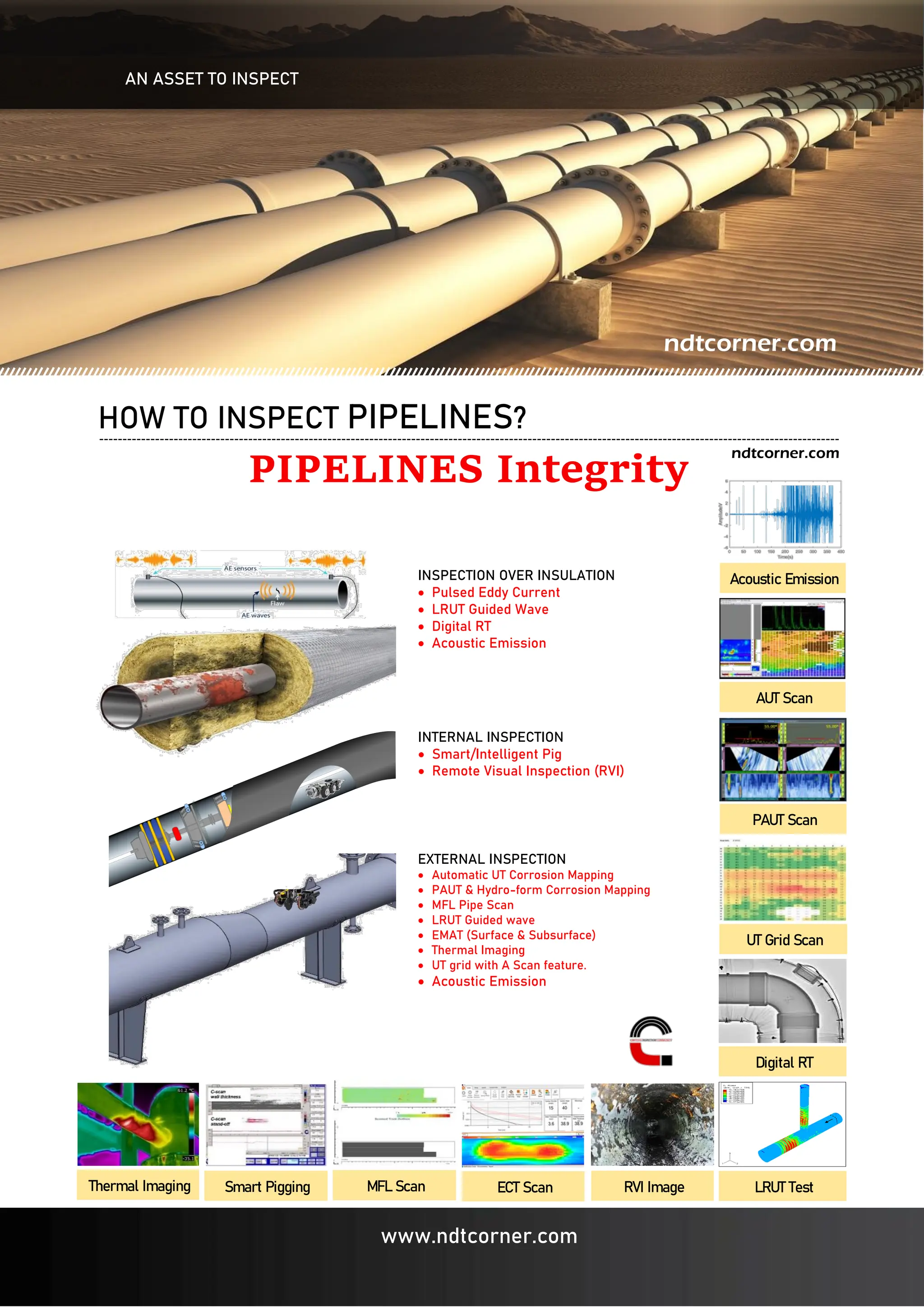

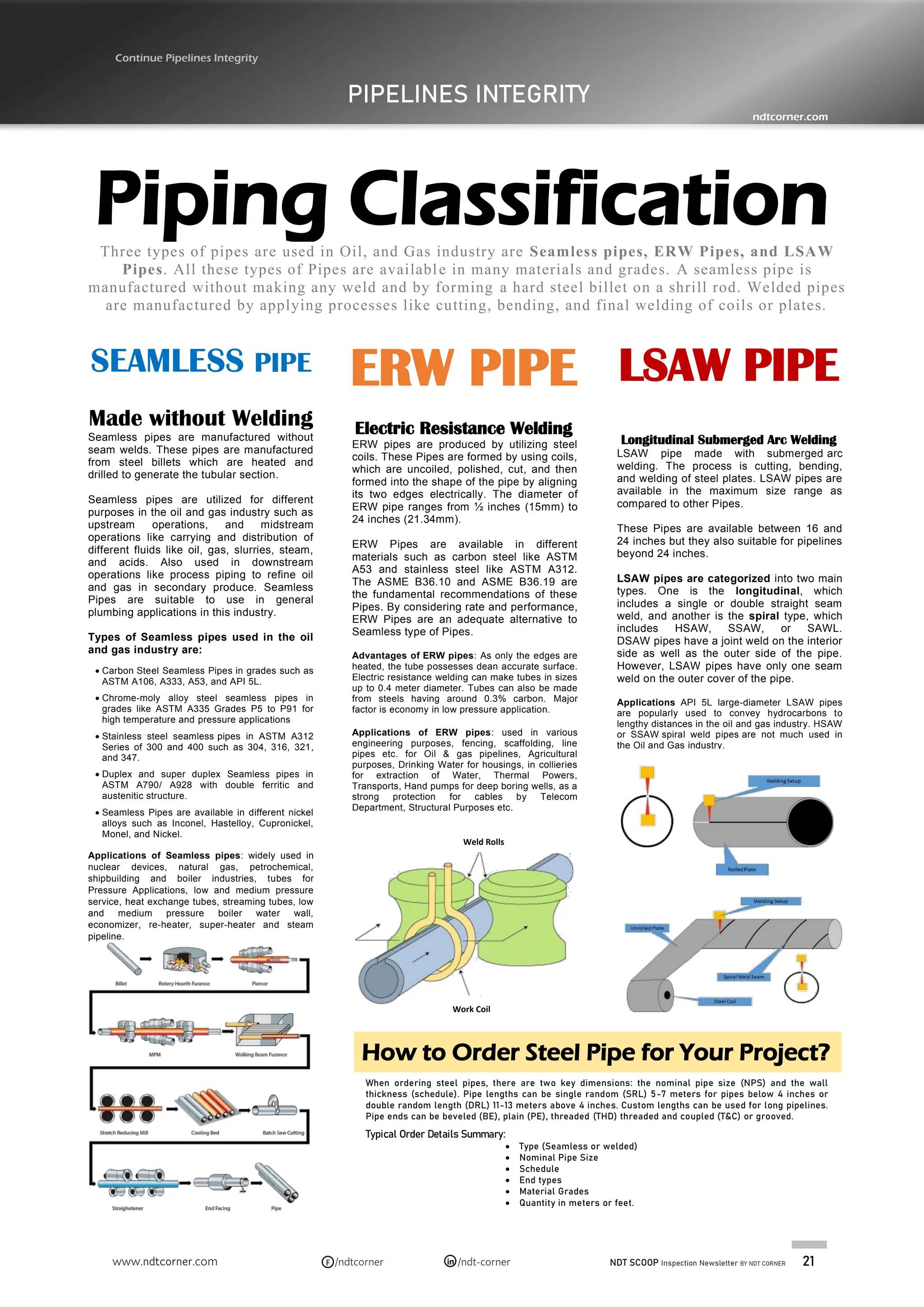

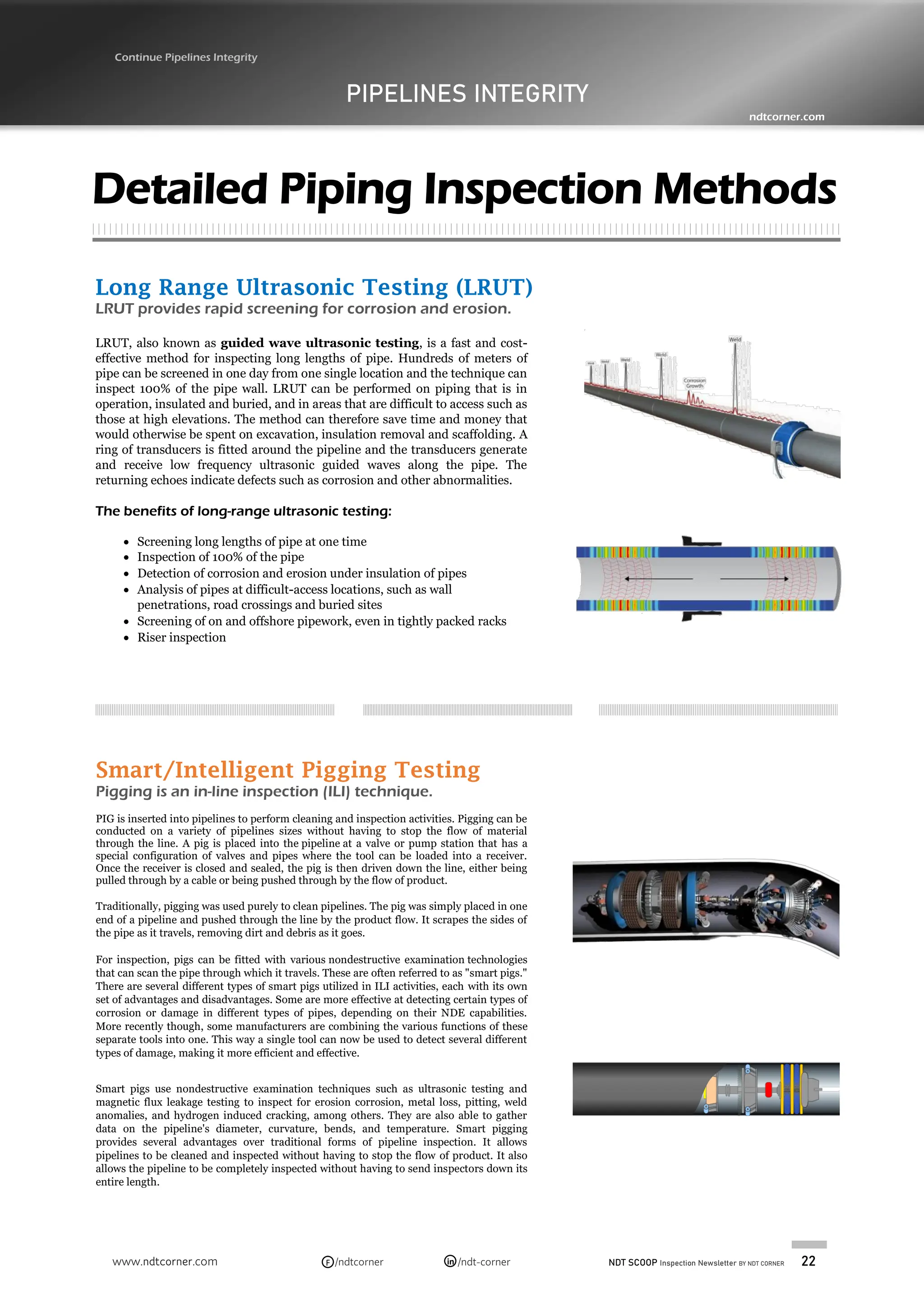

This document provides information on various non-destructive testing (NDT) methods for inspecting pipelines, including internal and external inspection techniques. Internal inspection methods discussed include intelligent pigging, remote visual inspection (RVI), and digital radiography (DR). External methods mentioned are automatic ultrasonic corrosion mapping, magnetic flux leakage testing (MFL), pulsed eddy current (PEC) testing, long range ultrasonic testing (LRUT), and thermal imaging. The document also covers topics like seamless pipes, welded pipe types, and how to order steel pipes for projects.