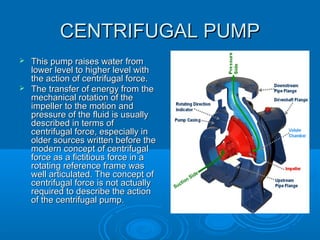

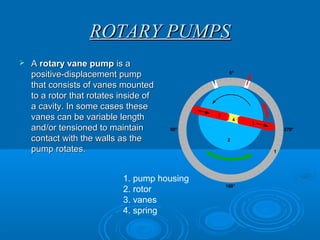

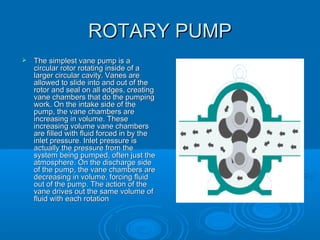

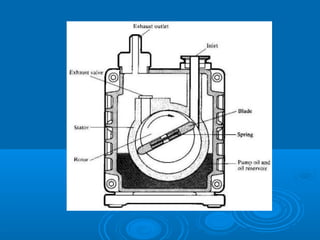

The document discusses different types of pumps, including centrifugal and rotary pumps. It explains that centrifugal pumps use centrifugal force to raise water from a lower to higher level, while rotary pumps have vanes mounted on a rotor that rotates inside a cavity to pump fluids. The document also provides examples of common uses for different pumps and lists advantages such as low cost, maintenance, and space requirements for centrifugal pumps and the ability to handle high viscosity fluids for rotary pumps.