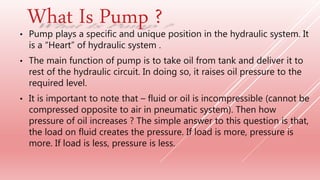

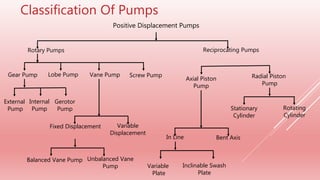

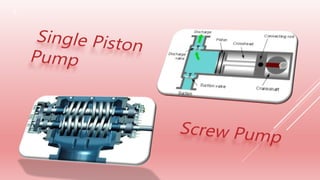

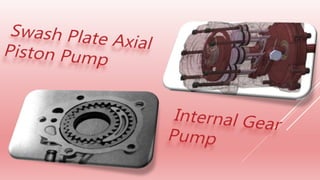

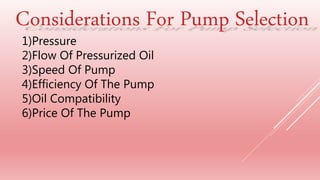

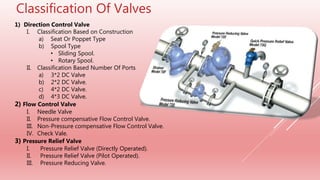

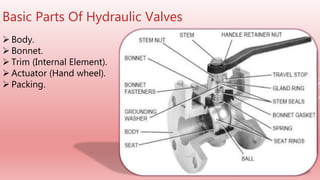

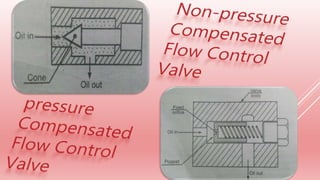

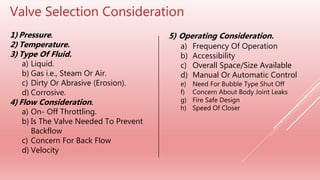

The document discusses hydraulic pumps and valves. It begins by explaining that pumps are the "heart" of hydraulic systems and their main function is to draw oil from a tank and deliver it at sufficient pressure throughout the system. There are two main types of pumps - positive displacement pumps and centrifugal pumps. Positive displacement pumps work by physically displacing a fixed volume of fluid with each cycle, while centrifugal pumps use a rotating impeller to impart centrifugal force and propel fluid outward. The document also covers the basic workings of reciprocating and centrifugal pumps. It then discusses considerations for selecting an appropriate pump type. Finally, it defines valves, their functions, common classifications, basic components, and factors to consider when selecting a valve for