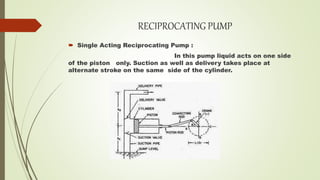

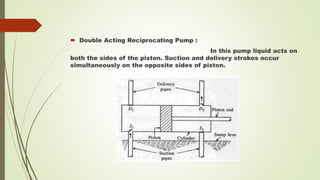

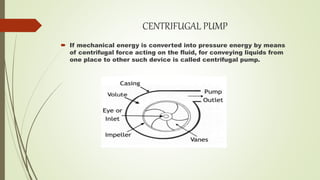

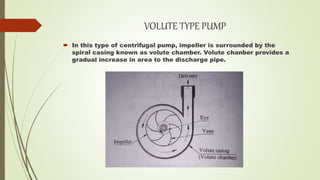

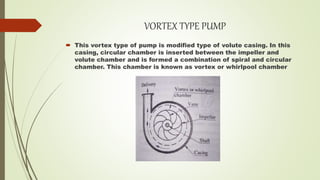

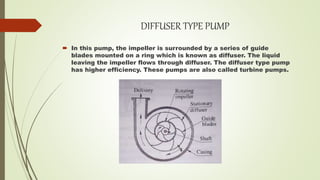

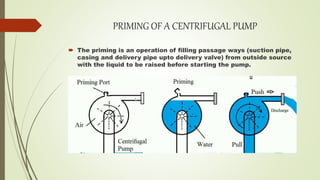

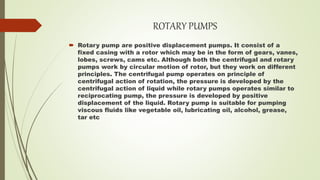

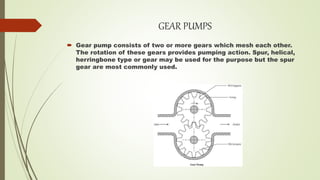

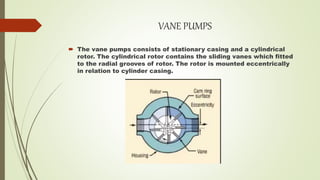

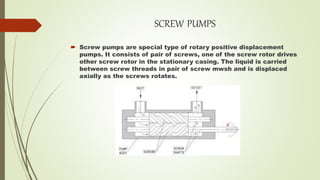

The document provides an overview of pumps, defining them as mechanical devices that convey liquids and classifying them into positive displacement and roto-dynamic types. It details various types of pumps, including centrifugal pumps, their subtypes (volute, vortex, and diffuser), and rotary pumps (gear, vane, and screw). The document also discusses the operation of priming in centrifugal pumps and the differences between centrifugal and rotary pump mechanisms.