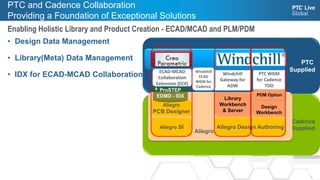

The document discusses integrating PTC Windchill with Cadence PCB design data to create a single source of truth for electronic product creation. This would consolidate disconnected data sources, decrease time to market, and improve quality and compliance by centralizing ECAD libraries, automating data storage and retrieval, and enabling traceability at the component level. The integration would provide benefits such as a centralized library and product configuration database, integration of component compliance and lifecycle information, and an automated new part introduction process.