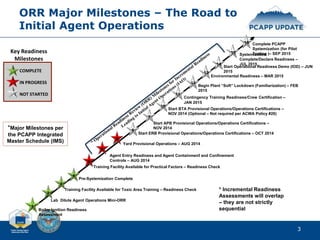

Provisional operations at the chemical plant will begin in October 2014, lasting two months. During this period, operations and maintenance staff will gain proficiency and complete certifications through normal operations and contingency exercises. Four areas will be focused on: the yard utilities, enhanced reconfiguration building, agent processing building, and biotreatment area. Training is underway to prepare emergency response teams, operations, and maintenance staff for operations.