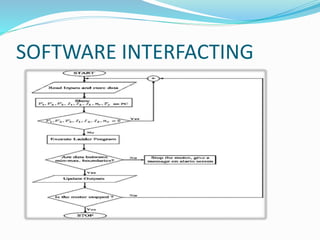

This document describes a PLC-based protection system for three-phase induction motors. The system monitors operational parameters like currents, voltages, temperature to detect faults like under voltage, over voltage, single phasing or overloading. It uses sensors, analog and digital I/O to interface with the motor. A PLC is used for motor control and protection. The system provides accurate monitoring, protection and cost-effective maintenance for induction motors used in industries like textiles, pumps and elevators.