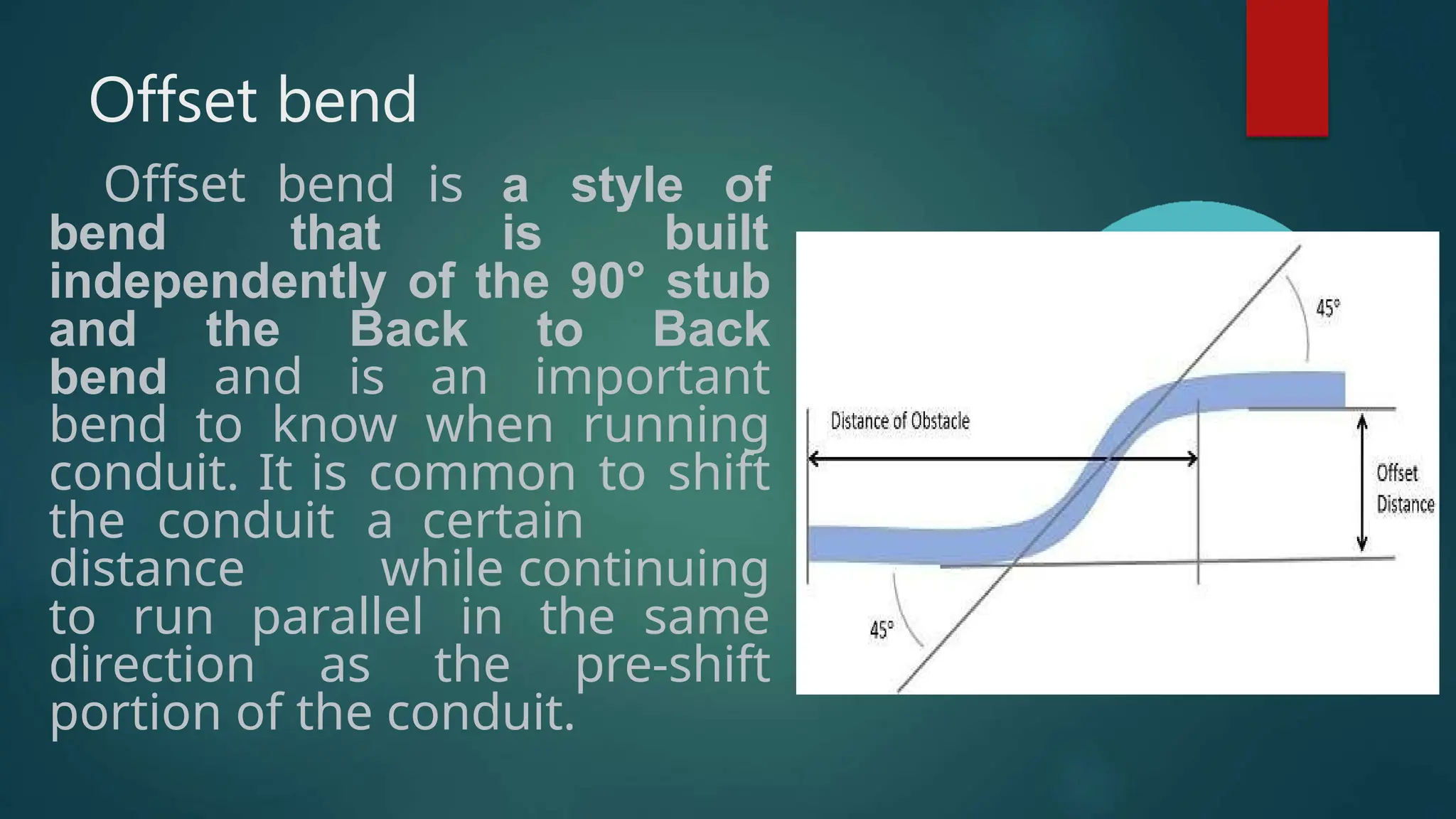

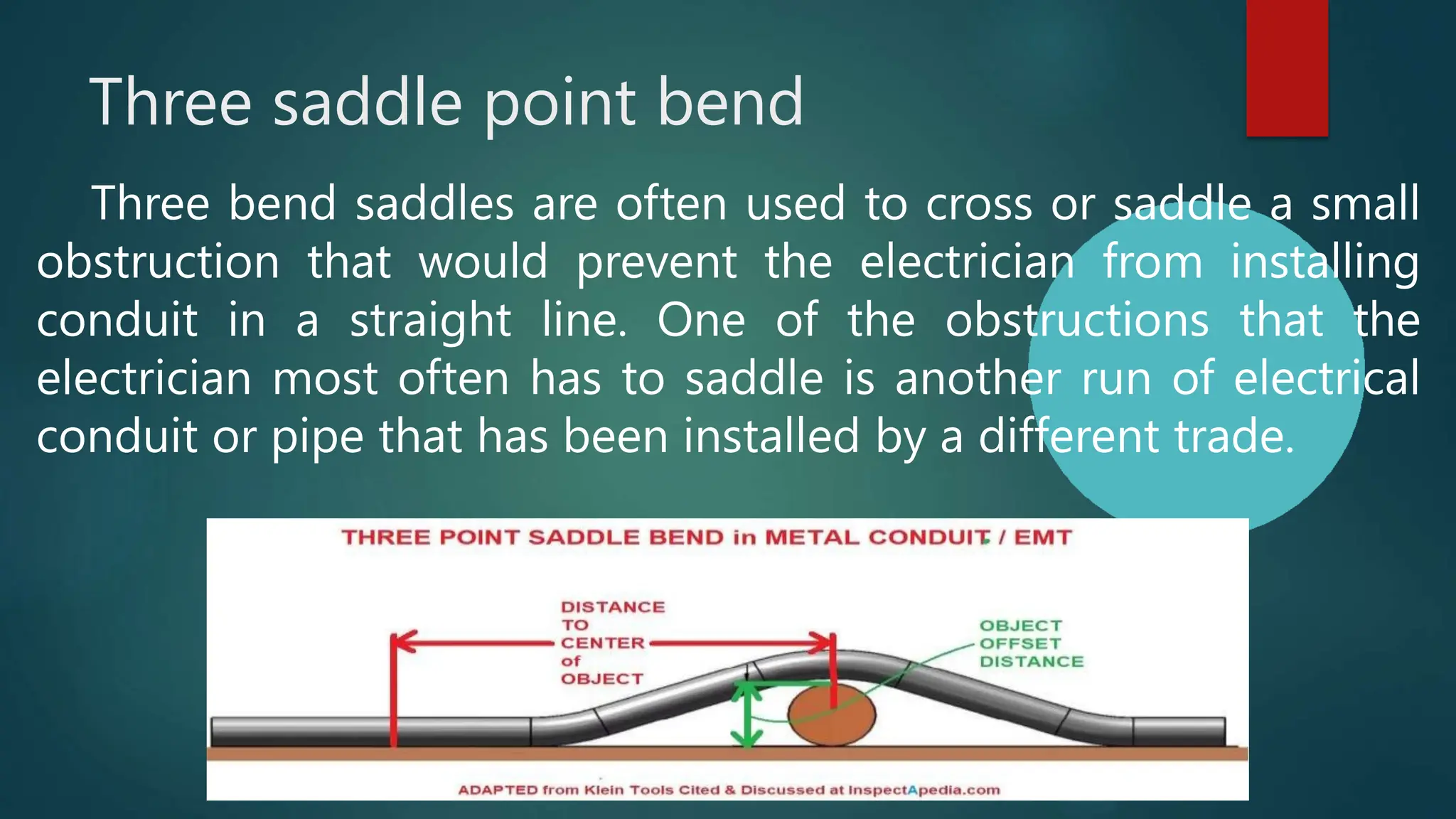

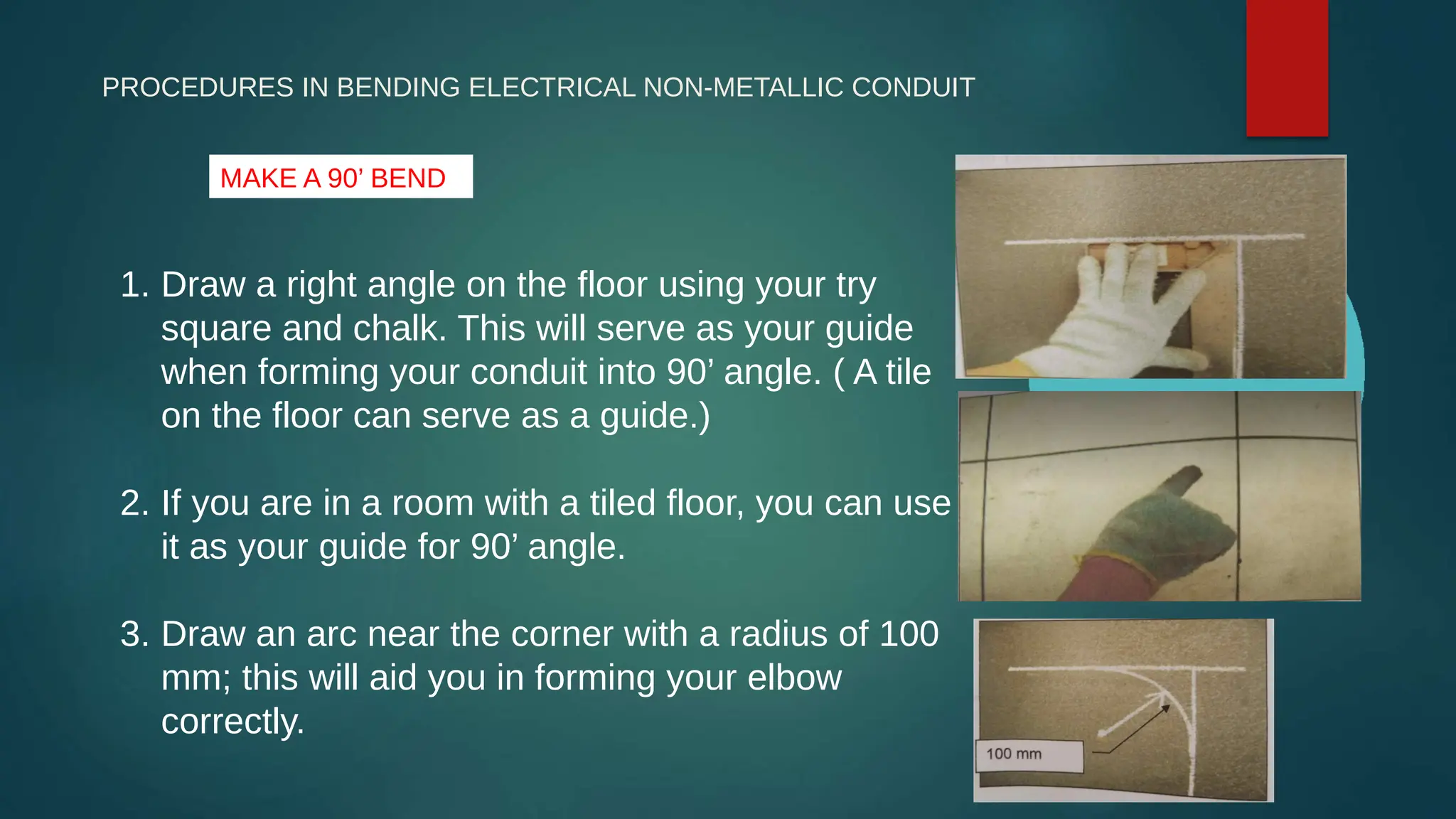

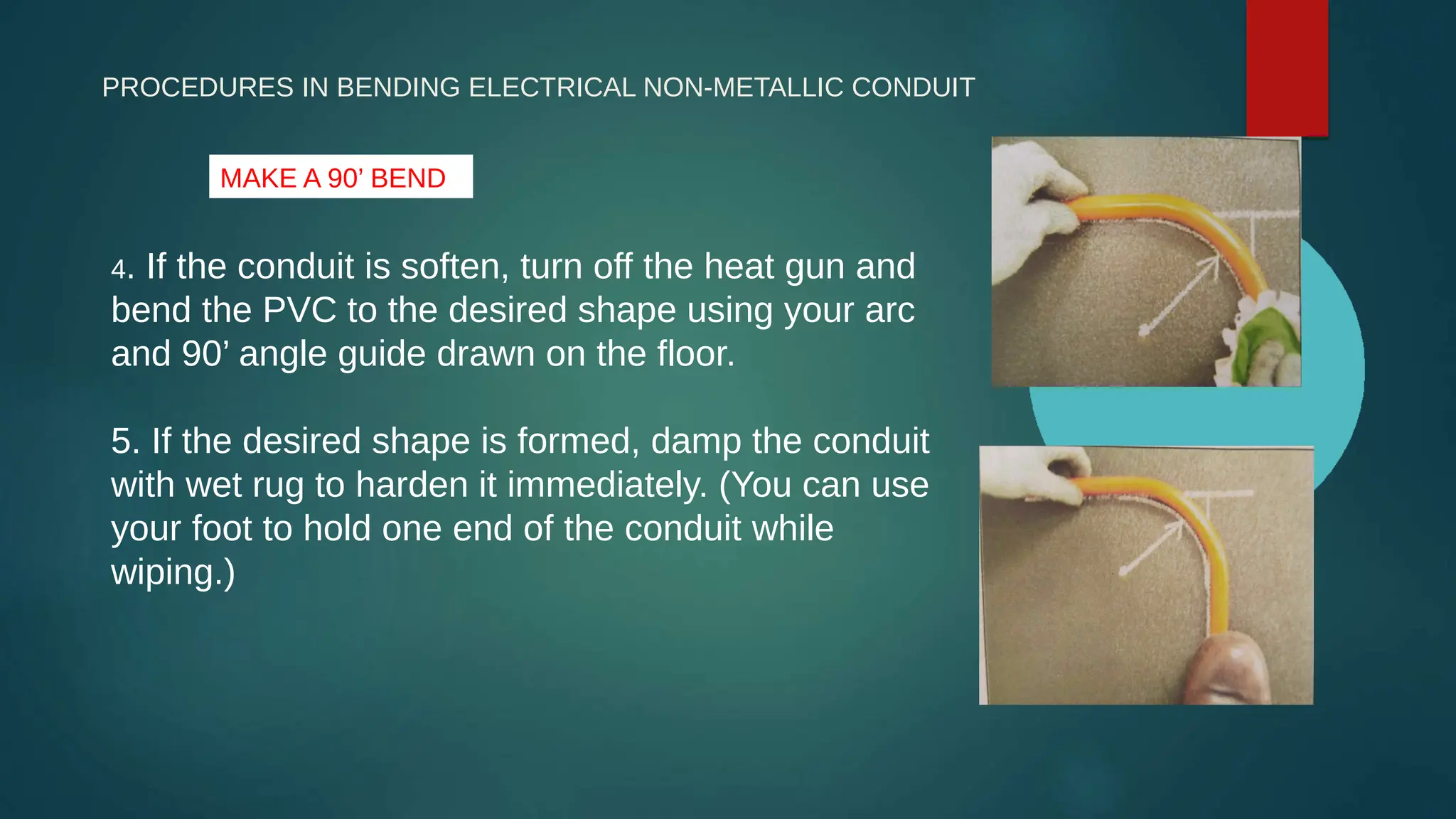

The document outlines the procedures for bending electrical conduits, including various types of bends such as 90 degree, offset, and three saddle point bends. It details the equipment and methods required for properly bending different types of conduits, including steps for creating both a 90 degree bend and a PVC offset bend. This guidance is crucial for electricians and plumbers to ensure installations meet job requirements and function effectively.