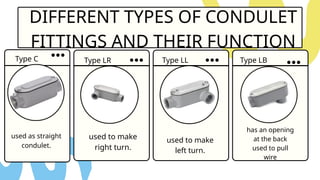

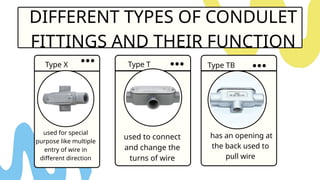

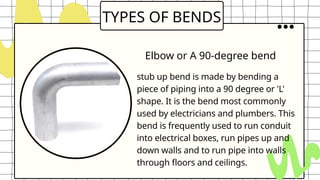

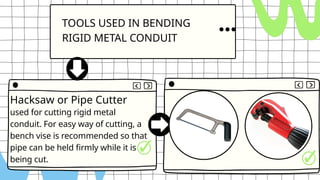

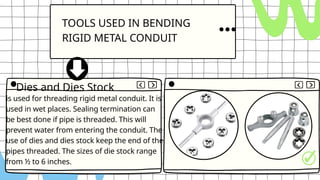

The document describes the functions and installation methods for rigid metal conduit, emphasizing its role in protecting electrical wiring from hazards. It details various types of conduit fittings and bending techniques, including stub up bends, elbow bends, and saddle bends. Additionally, it outlines the tools required for cutting, bending, and threading rigid metal conduit, highlighting the importance of proper preparation for effective sealing and insulation.