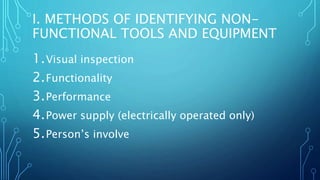

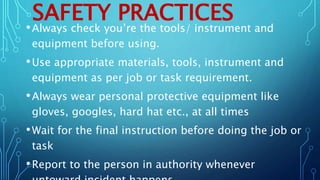

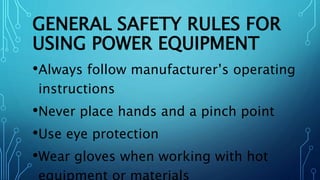

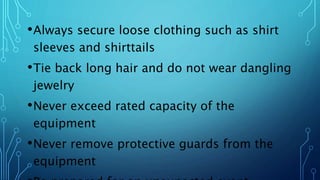

This document discusses electrical tools, equipment, and safety practices. It defines tools as implements used to modify raw materials, and equipment as large machineries needing electricity to power up. Advantages of using proper tools include efficiency, quality, speed, and accuracy, while disadvantages include availability of materials, worker experience, and tool quality. Types of tools covered include hand tools, power tools (electric, pneumatic, hydraulic), and measuring tools. Electrical safety practices and causes of accidents are also outlined. Preventative maintenance and scheduling are discussed.