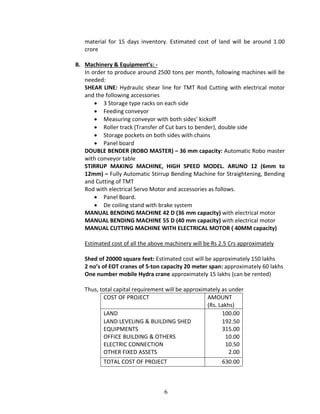

The document discusses the necessity for modernization in the construction industry, highlighting the environmental, safety, and cost benefits of utilizing ready-to-use cut and bend reinforcement bars (TMT bars). It outlines the cut and bend process, which involves using specialized machines to provide customized rebar shapes, thereby reducing waste, improving working conditions, and enhancing profitability. Financial projections for establishing a cut and bend service are included, detailing capital requirements, operational costs, and projected income, emphasizing the importance of timely delivery and efficiency in meeting customer demands.