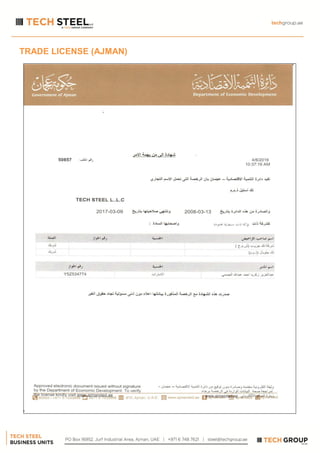

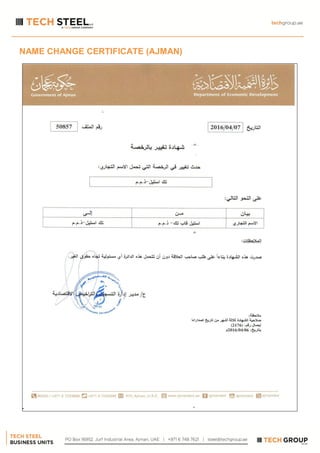

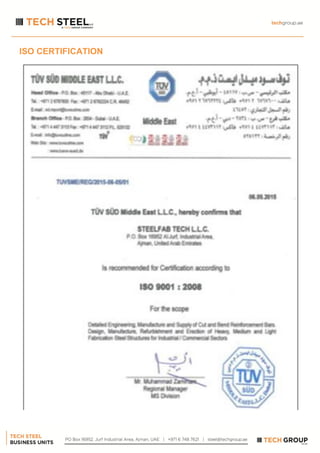

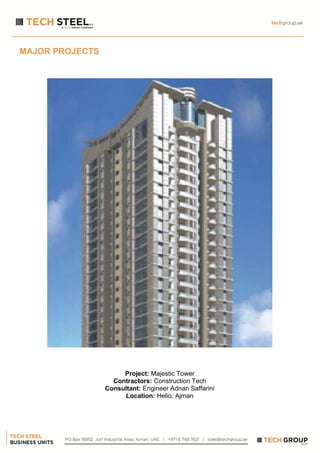

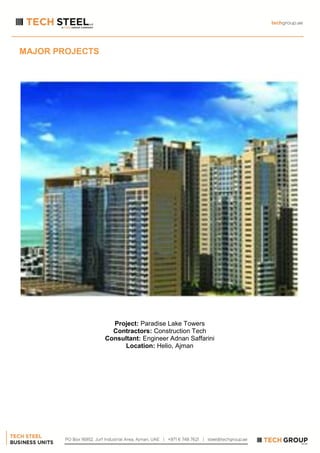

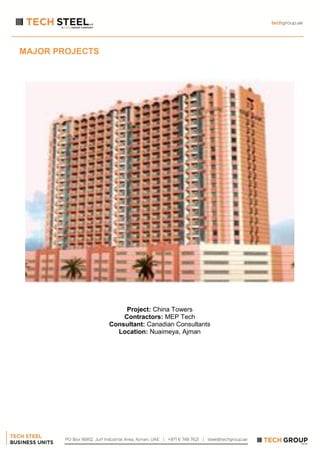

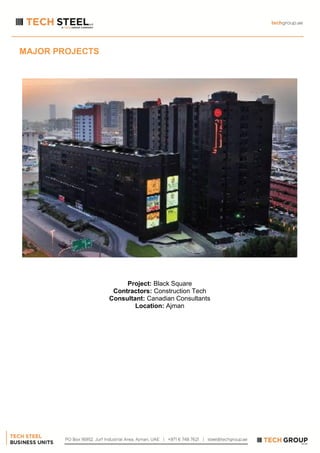

The document provides information about Tech Group Pvt JSC, a construction group based in Ajman, UAE. It includes an overview of the group and its 10 business units, vision, mission, values, and a message from the CEO. It then focuses on Tech Steel LLC, one of the group's steel manufacturing business units, describing its facilities, equipment, machinery, methods, licenses, and major projects. The document concludes with Tech Group's organizational chart.