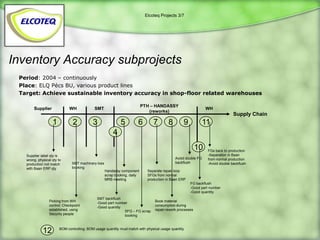

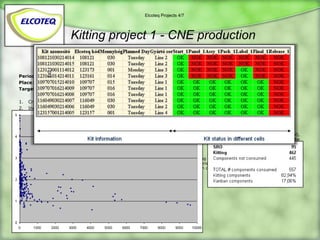

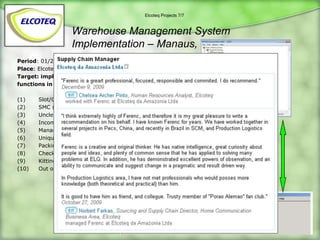

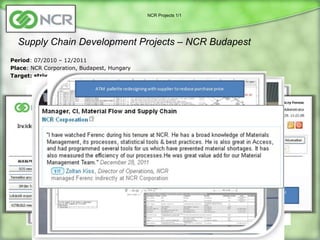

Ferenc Rakoczy's presentation package provides a summary of his project experience as a supply chain manager from 2004-2013, including logistics agreements, inventory optimization, and warehouse management system implementation projects for automotive, electronics, and other manufacturing customers in Hungary, Brazil, Sri Lanka, and China to improve operations and reduce costs.