1. The document describes a waste disposal and recycling system that uses a patented molecular transformation process to convert various waste types into water vapor, nitrogen gas, electricity, and recyclable materials.

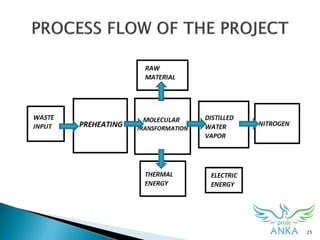

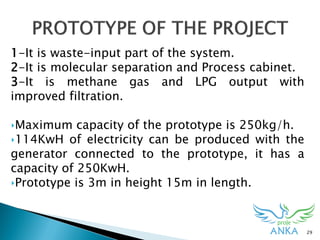

2. It involves collecting, transporting, separating, shredding, and processing wastes through several steps before applying the molecular transformation module that eliminates harmful molecules.

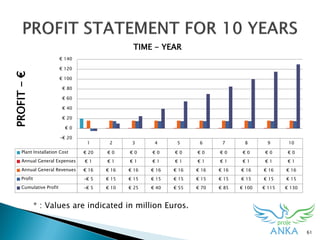

3. The system is projected to generate a profit of 15 million euros annually from electricity production, waste disposal fees, and recycling gains while converting 150 tons of waste daily with no landfilling or harmful emissions.