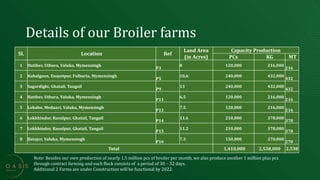

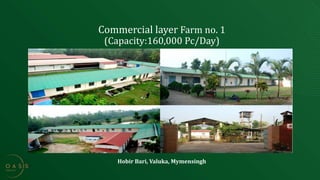

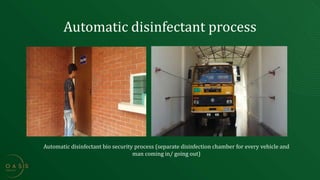

Oasis has been operating 18 high-density poultry farms in Bangladesh since 2008, producing broilers, layers, pullets, and hatcheries. The farms are fully automated and use advanced technology to meet international standards. They focus on efficiency, safety, and environmental sustainability. Oasis produces over 1.5 million broilers per month through its own farms and contract farming. It also produces over 710,000 layers per day. The farms use closed biosecurity systems and automated equipment to ensure hygienic and antibiotic-free meat and egg production.