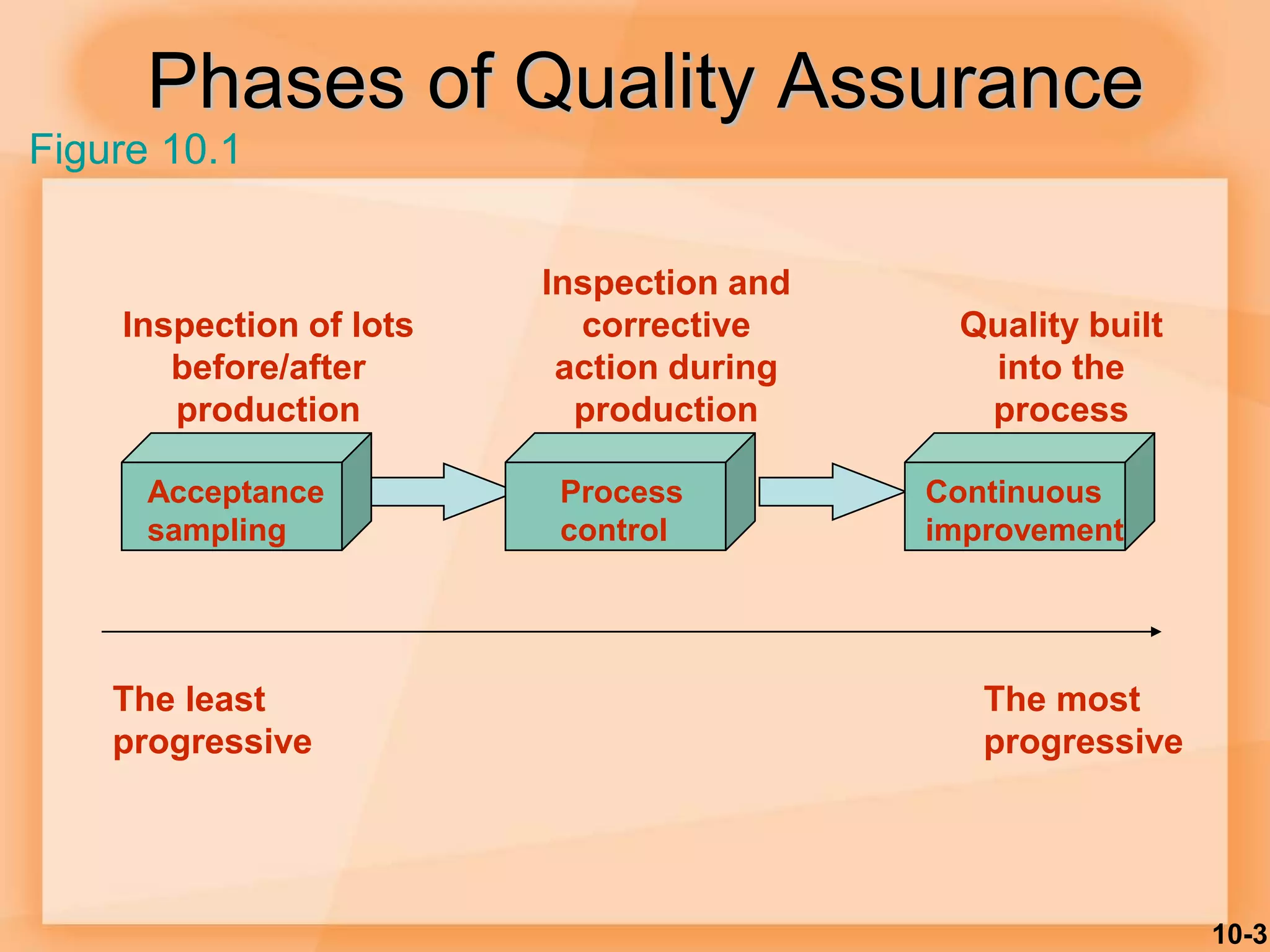

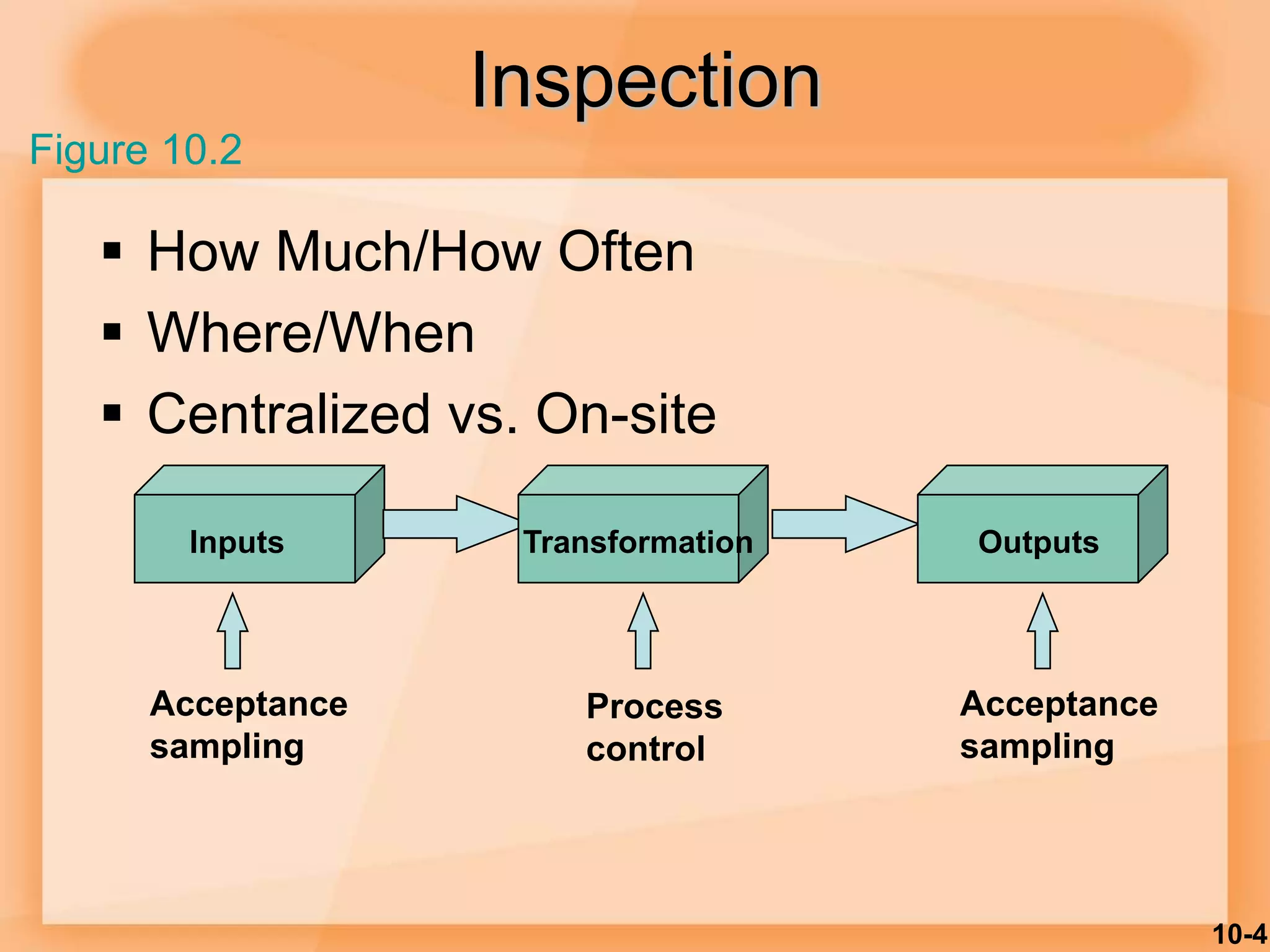

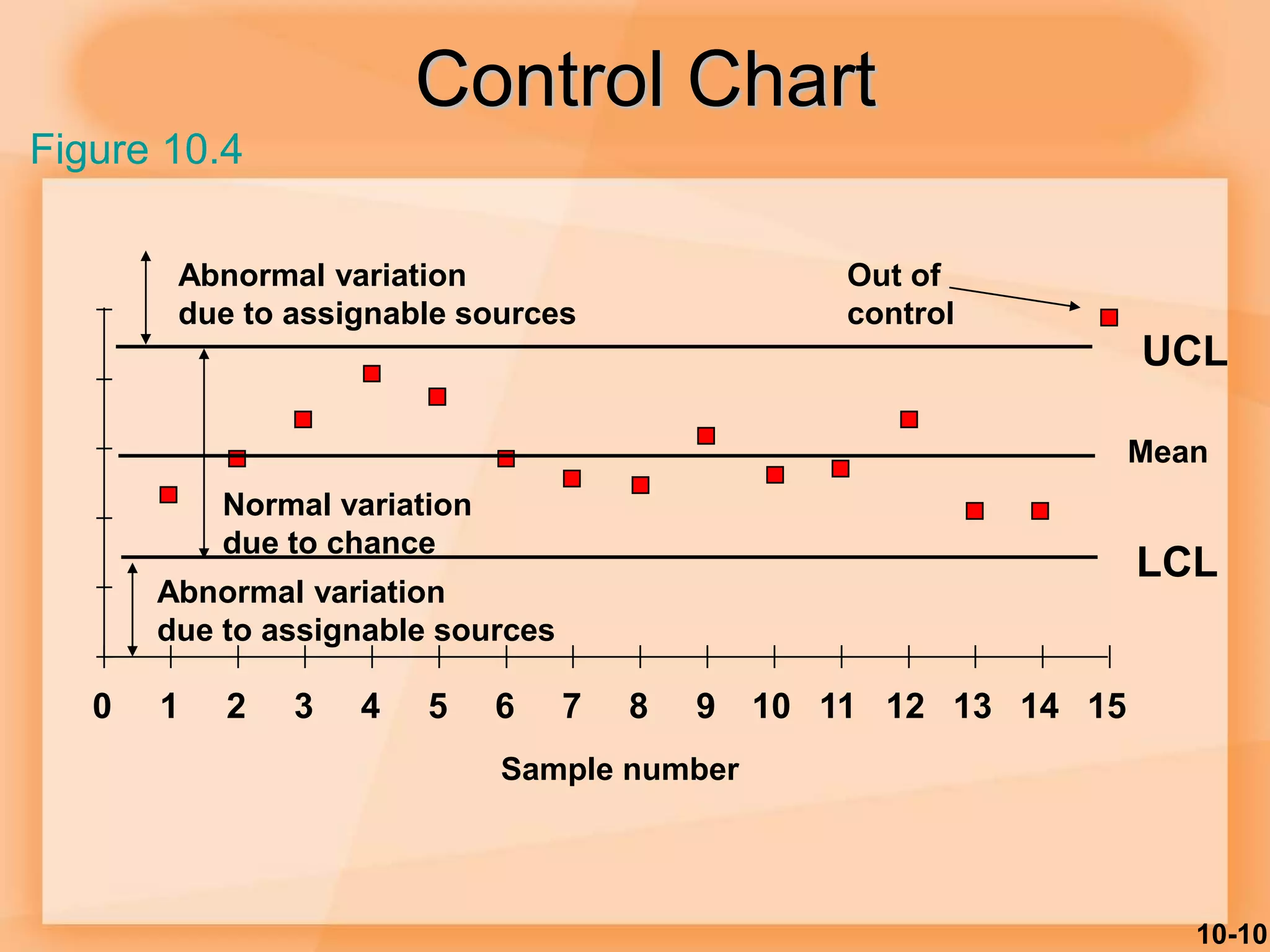

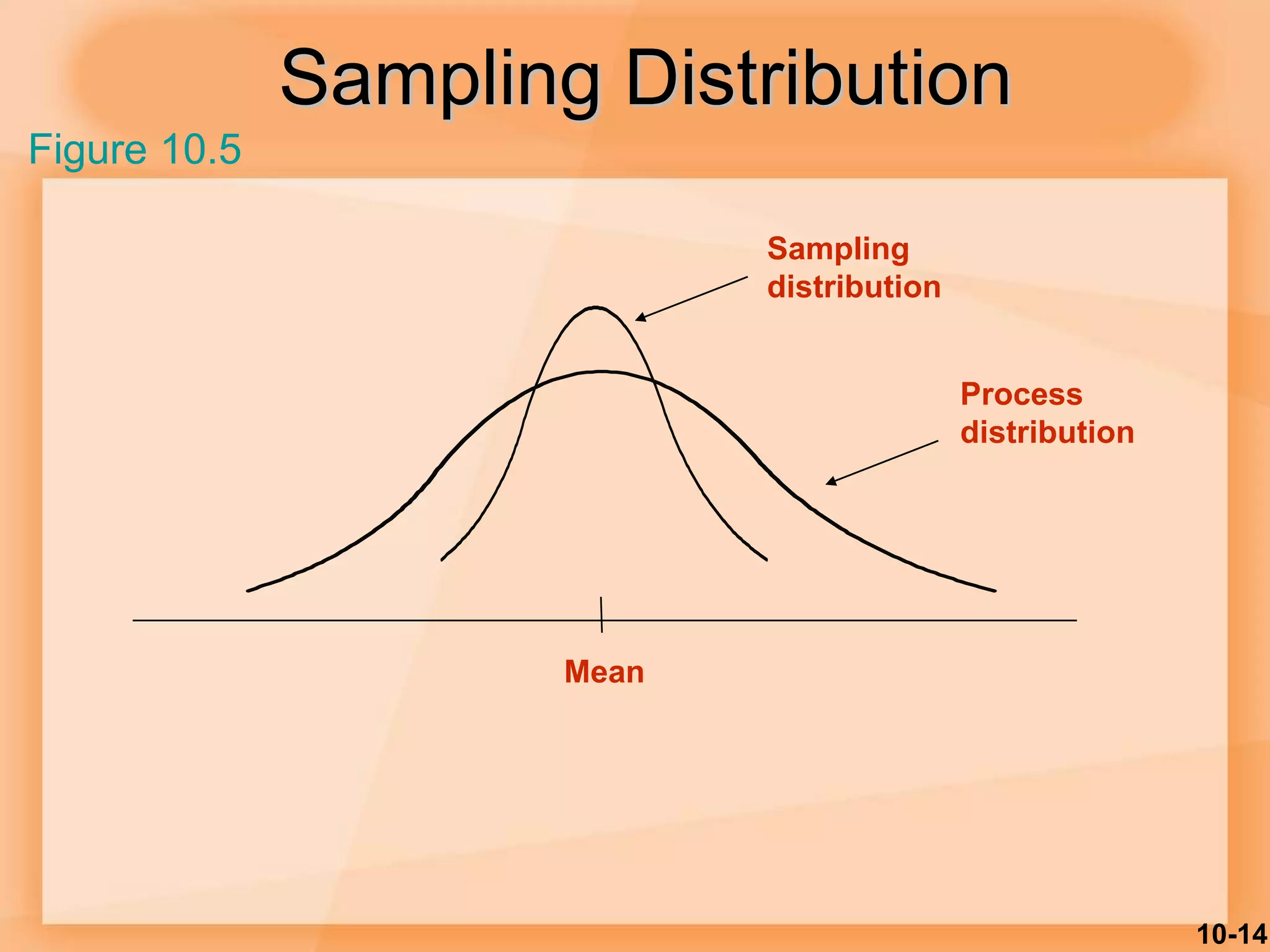

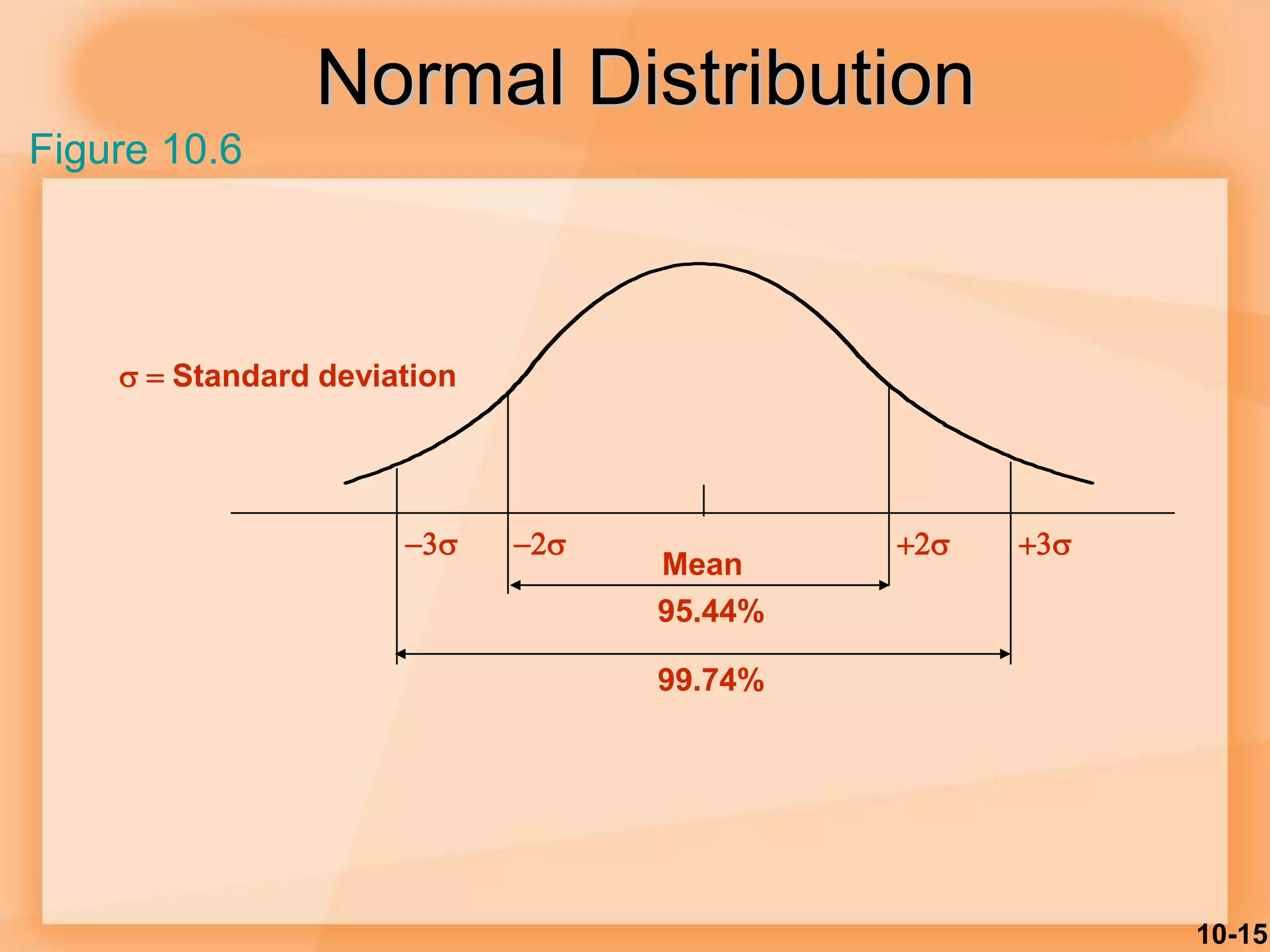

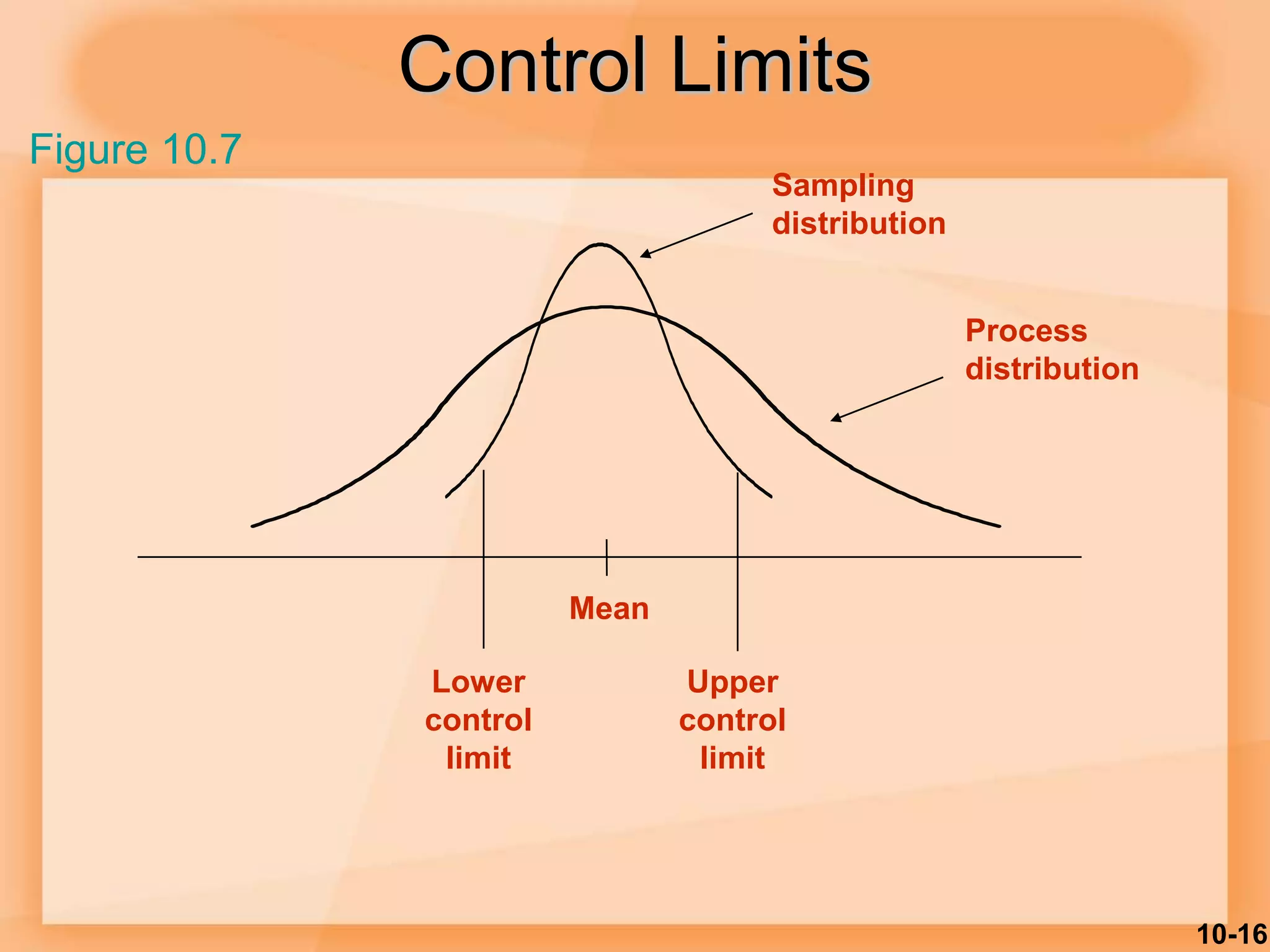

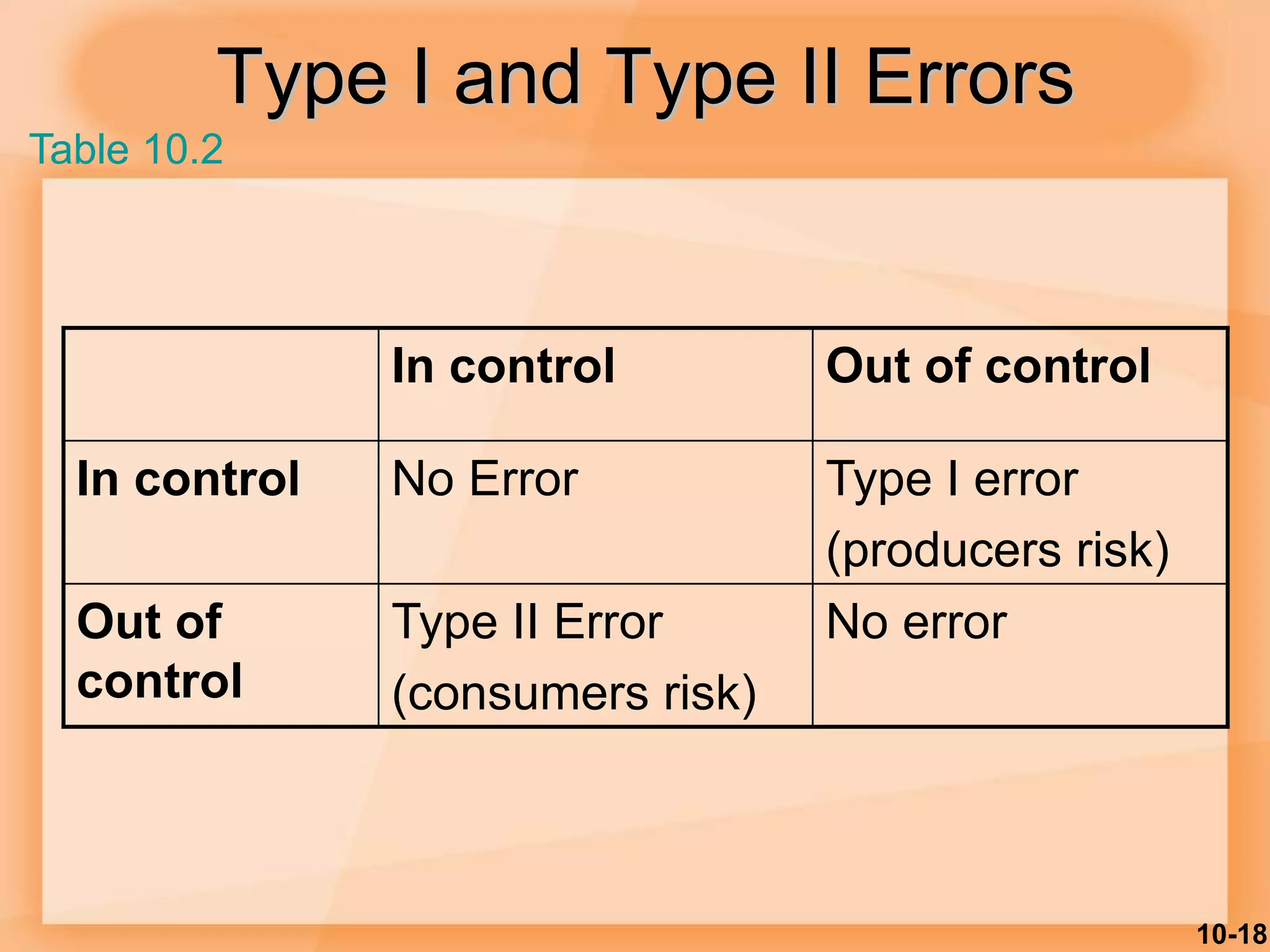

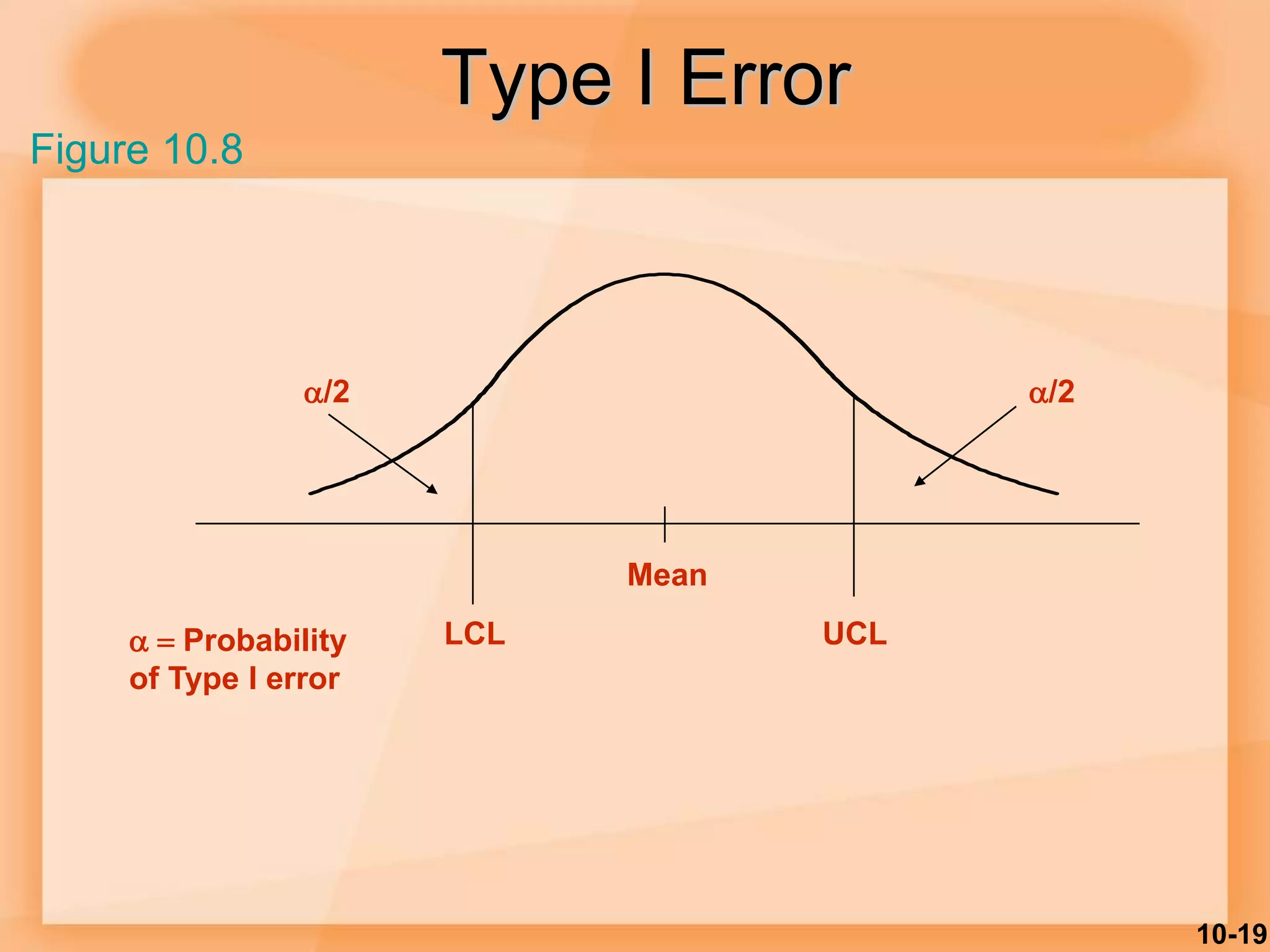

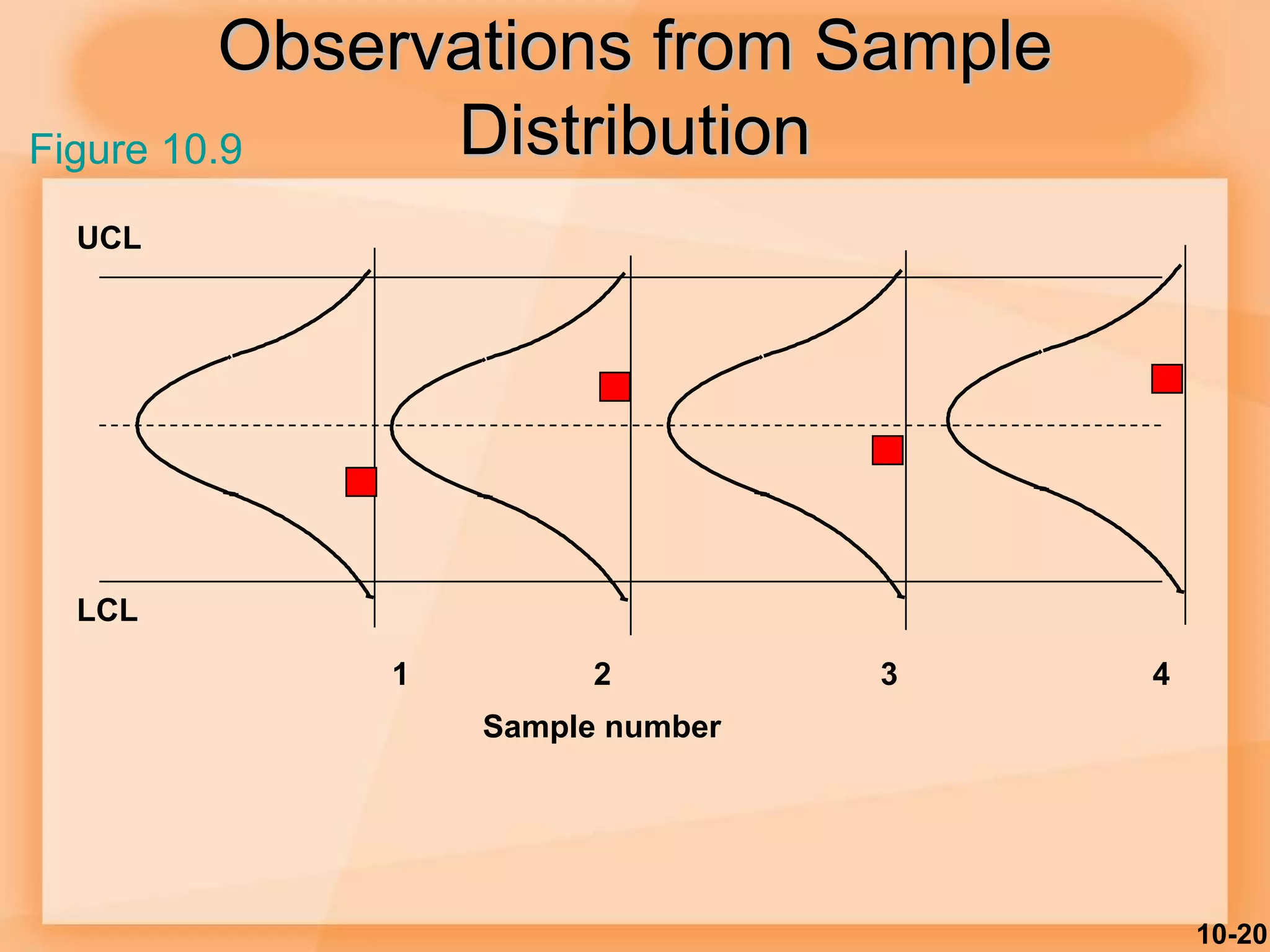

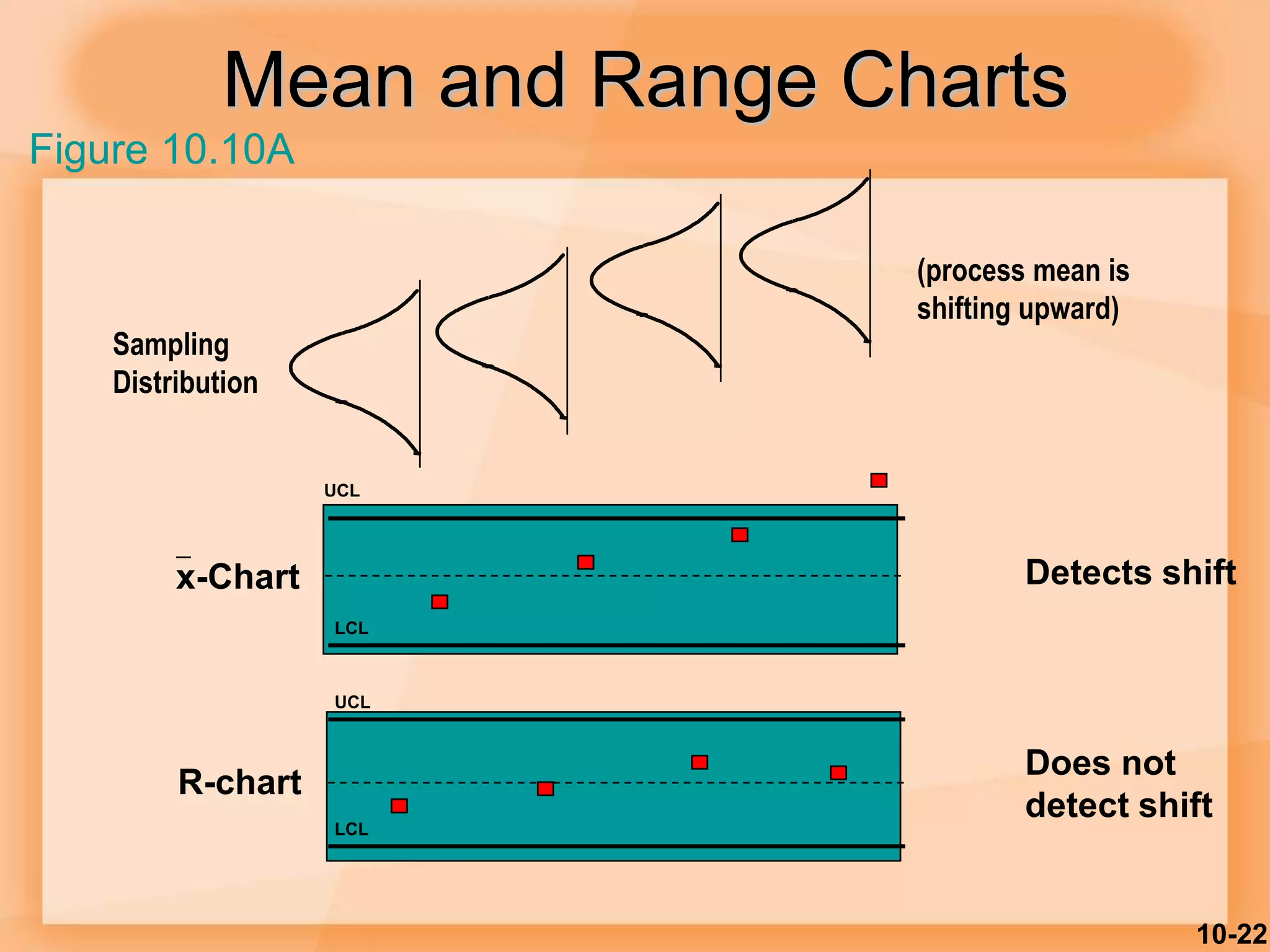

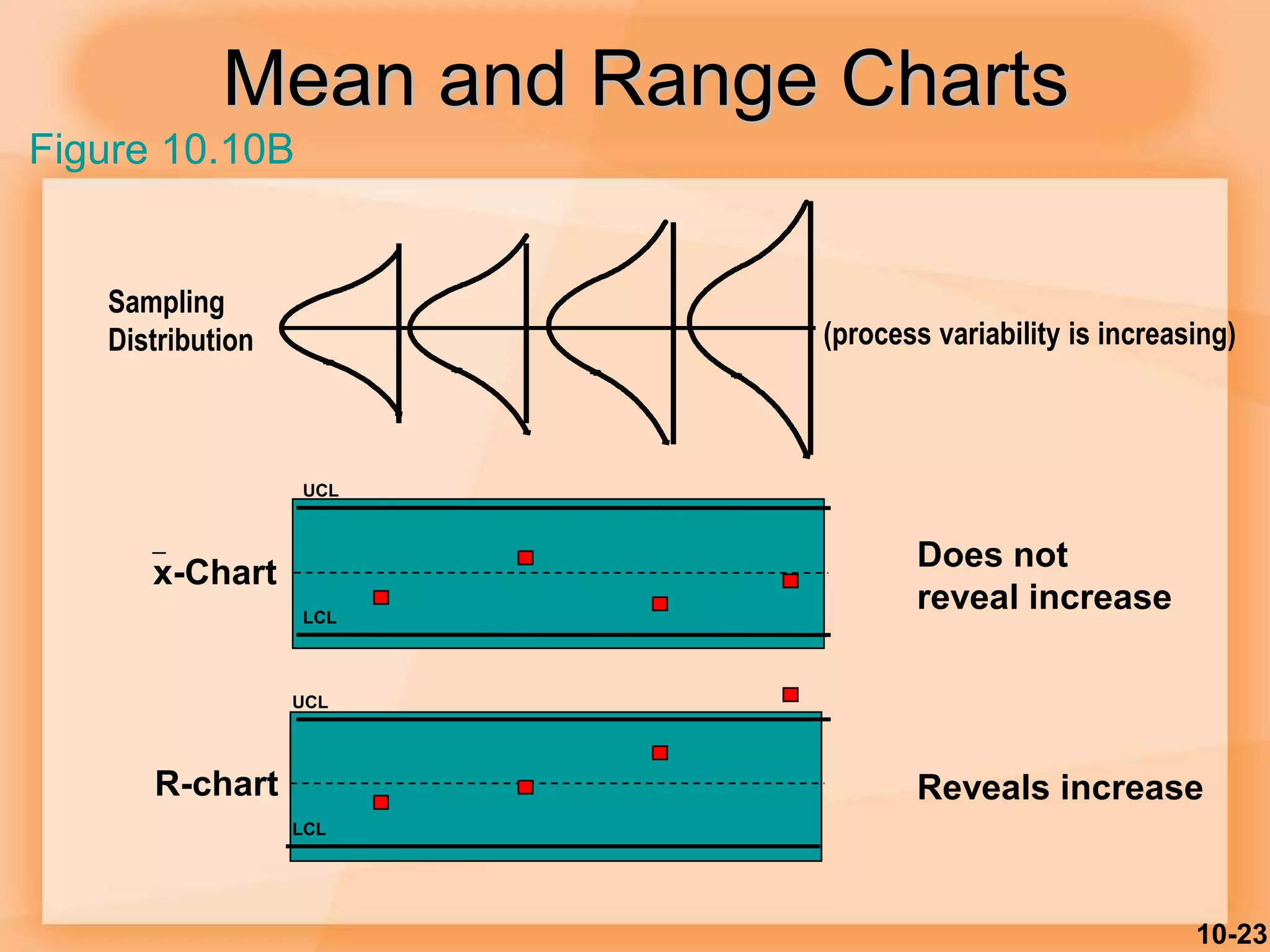

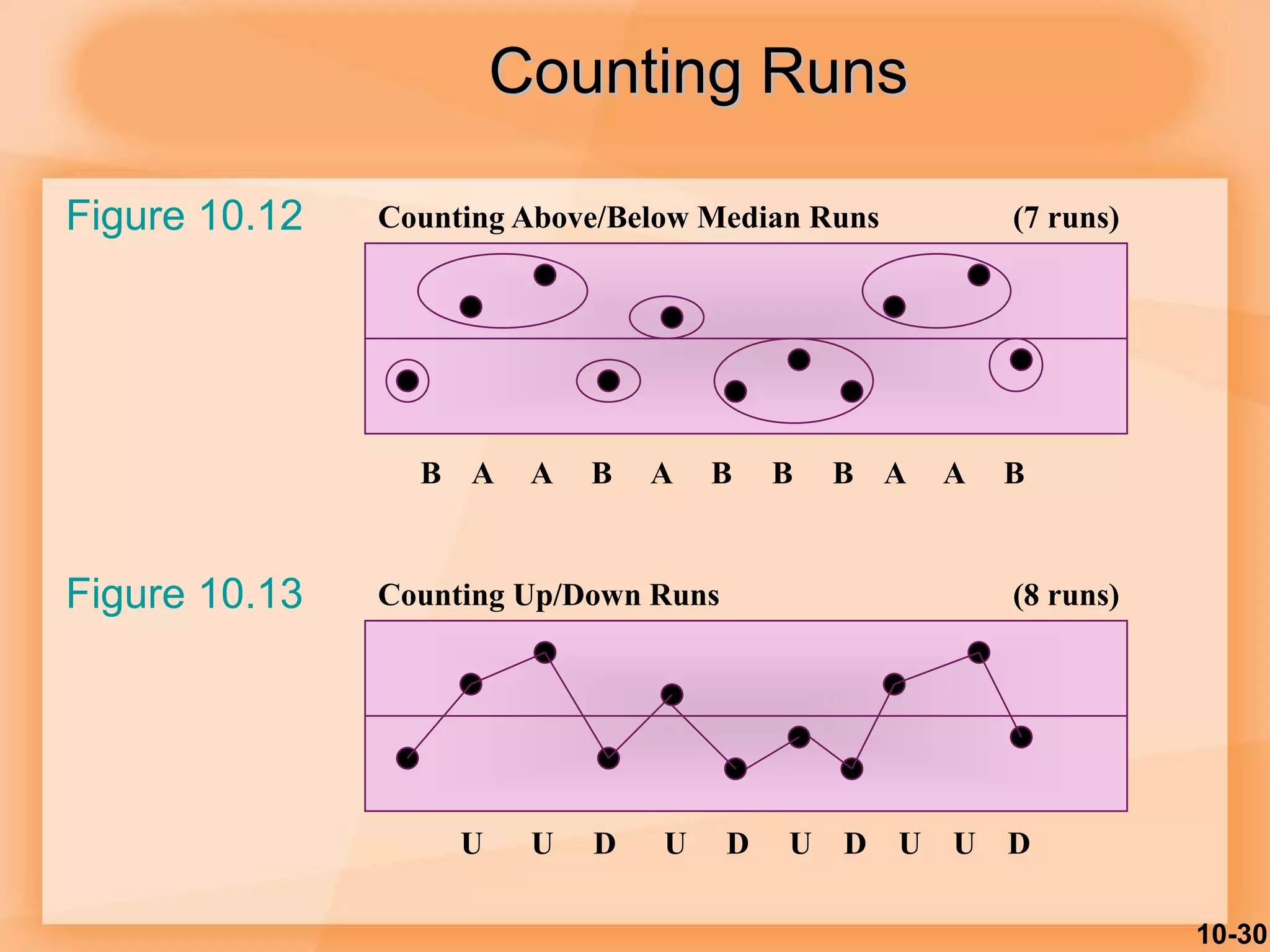

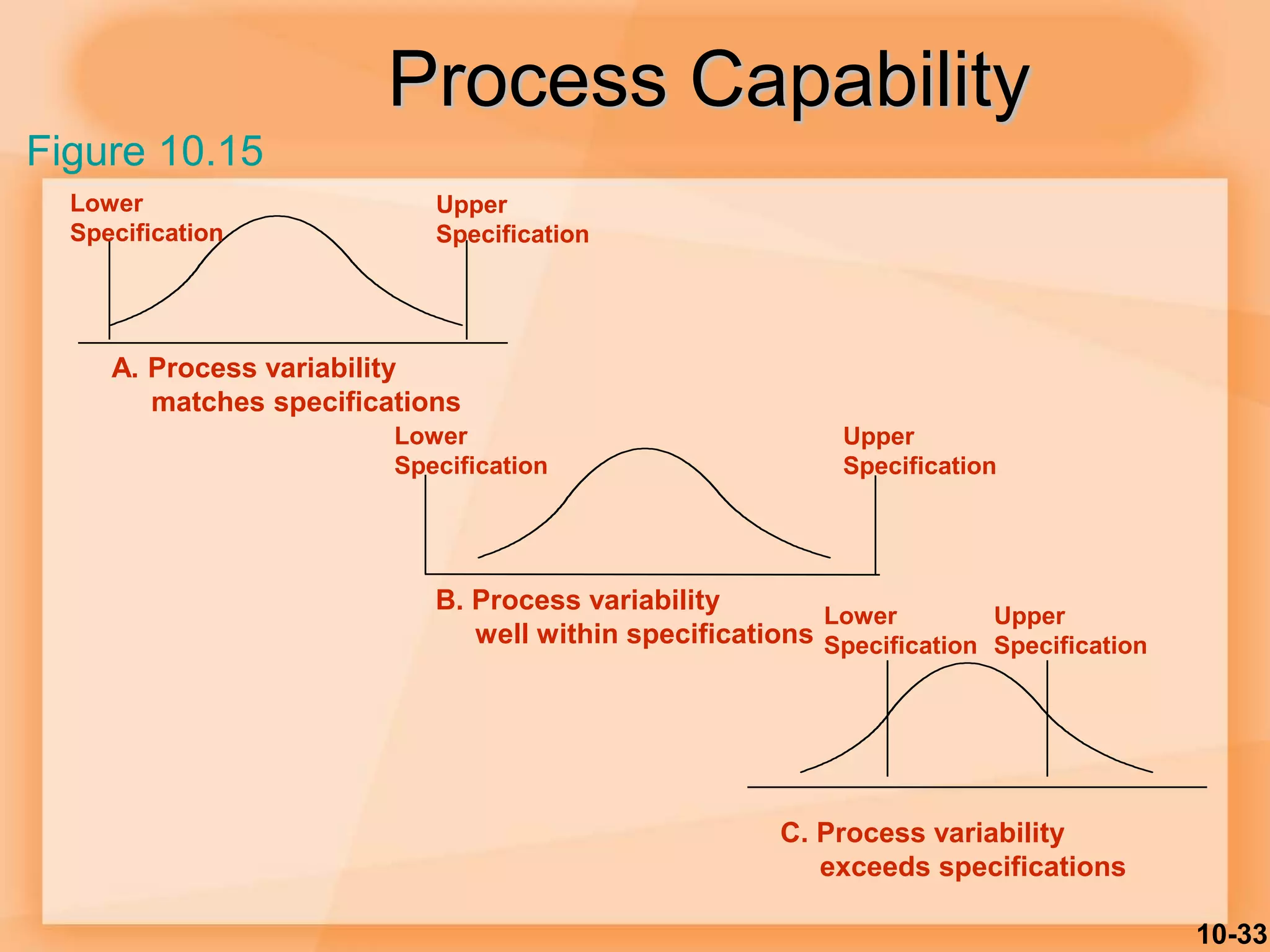

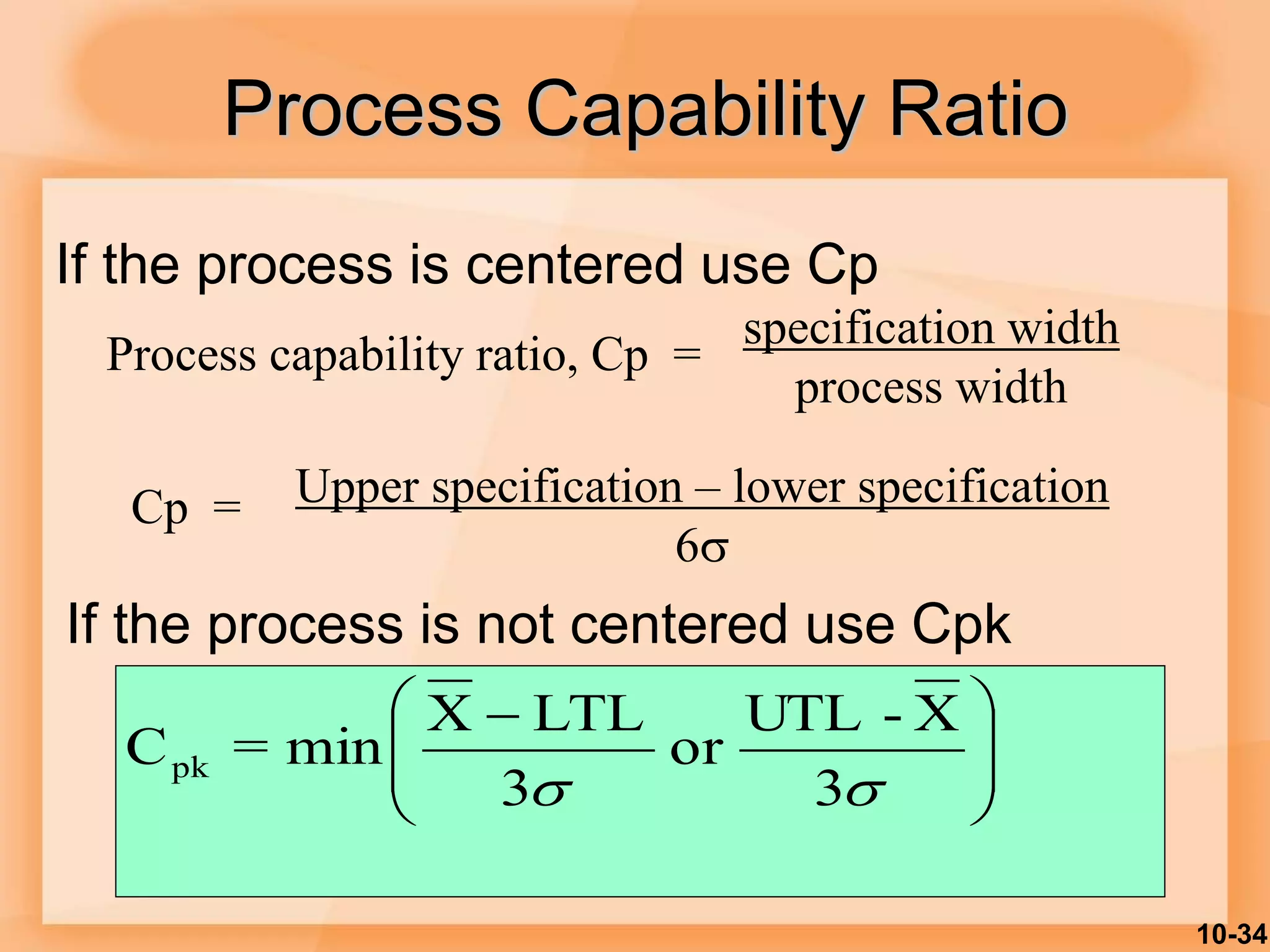

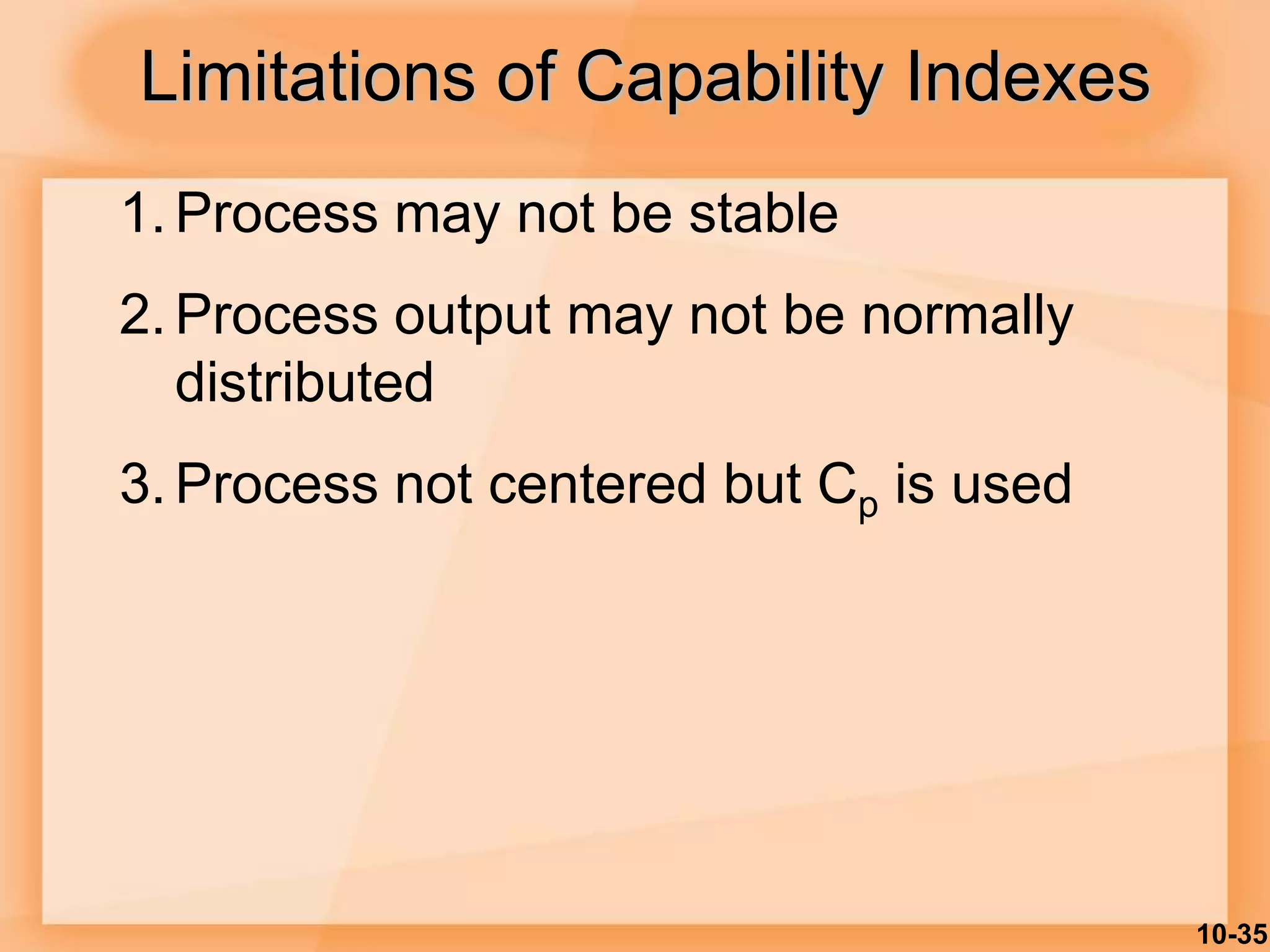

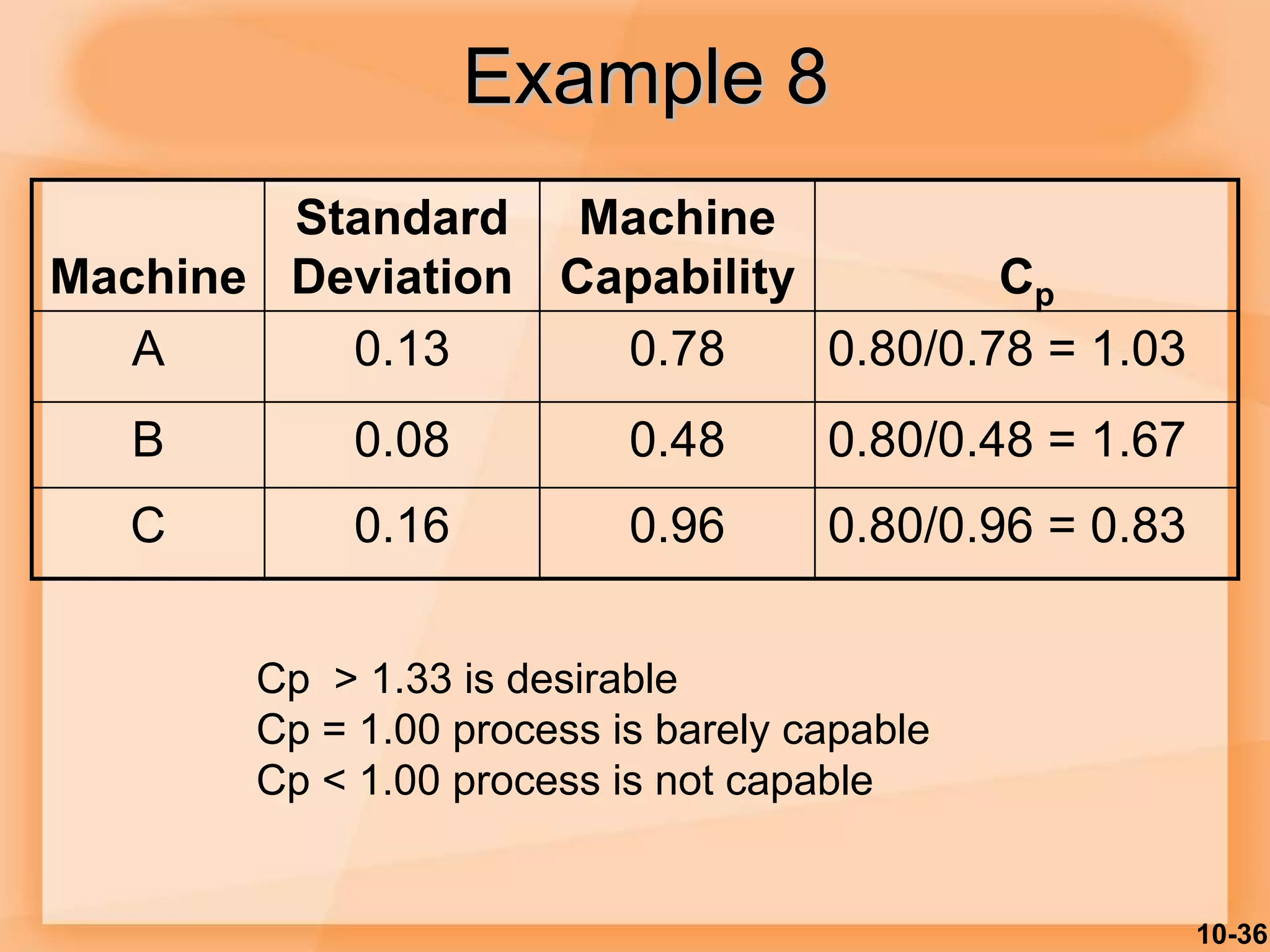

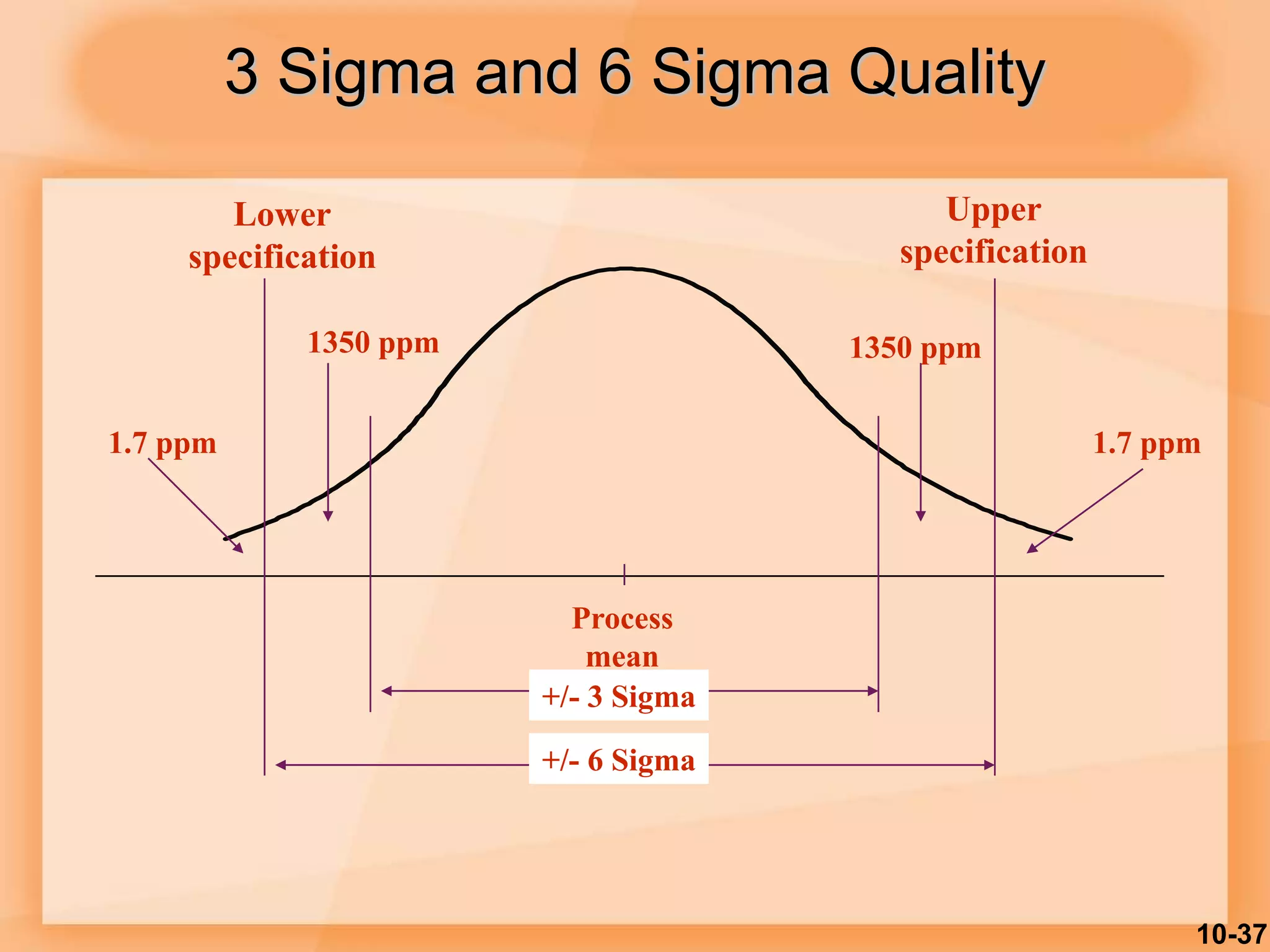

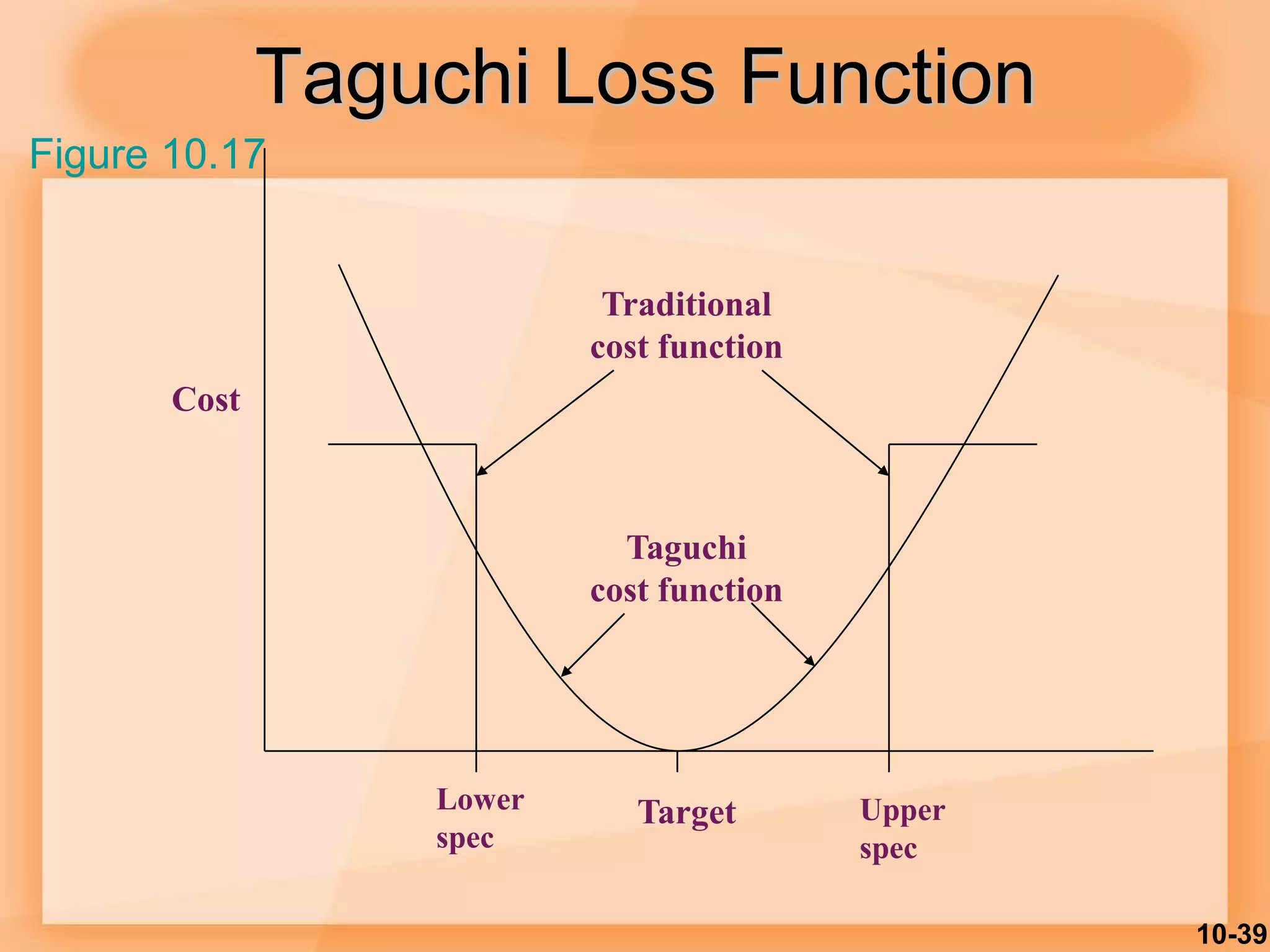

The document discusses quality control and statistical process control. It covers the phases of quality assurance from inspection to continuous improvement. It describes using control charts to monitor processes and ensure output remains random. Control charts can detect shifts in the mean or increases in variability. The document discusses calculating process capability to determine if a process meets specifications. Improving processes involves simplifying, standardizing, preventing mistakes, upgrading equipment, and automating.