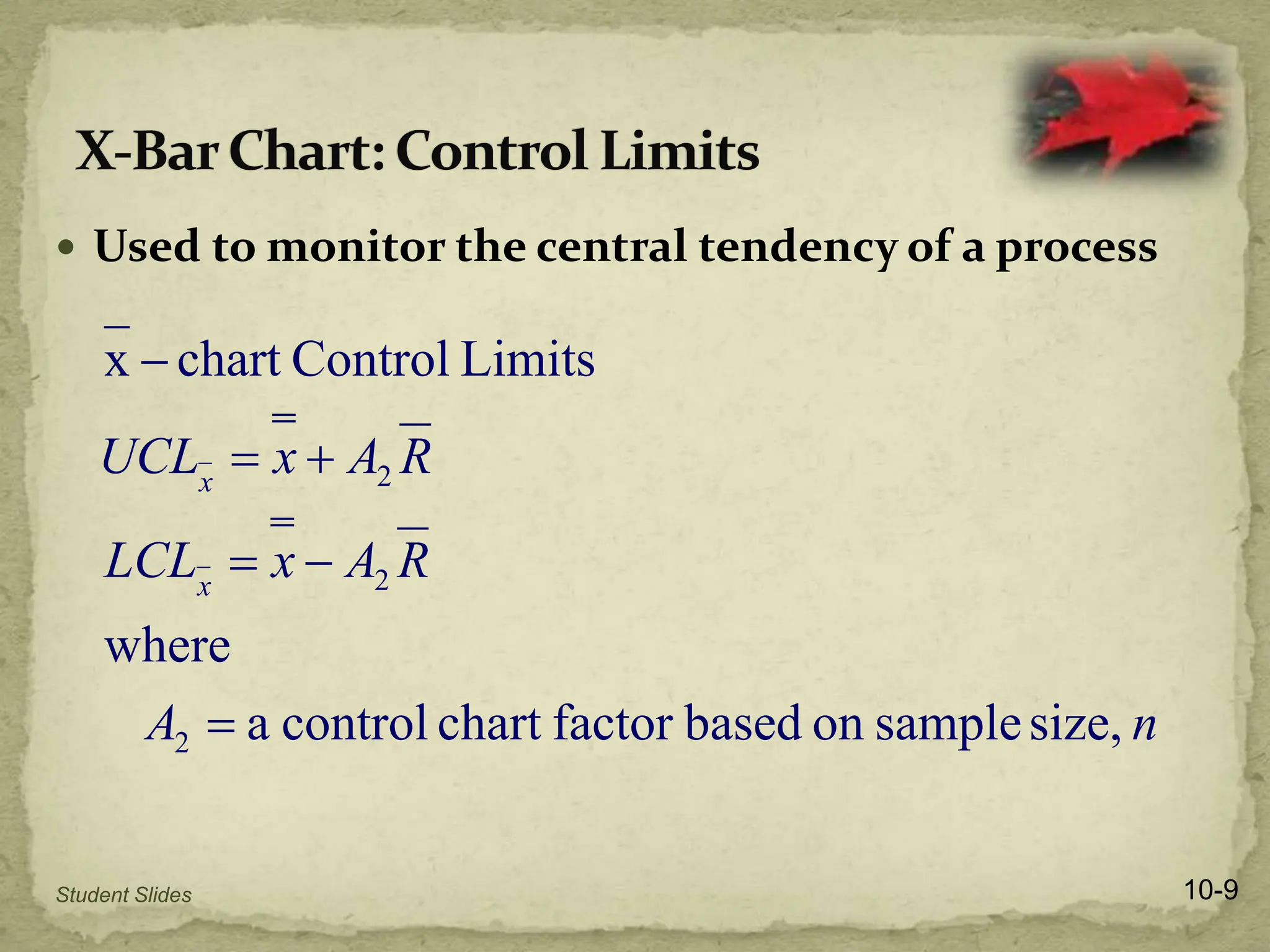

The document outlines the key elements of quality control processes, including the use of control charts to monitor processes and assess process capability. It explains the distinction between random and nonrandom variability through control limits and describes different types of control charts like mean and range charts, as well as attribute charts. Emphasis is placed on the importance of maintaining quality standards for business organizations to meet customer expectations.