Embed presentation

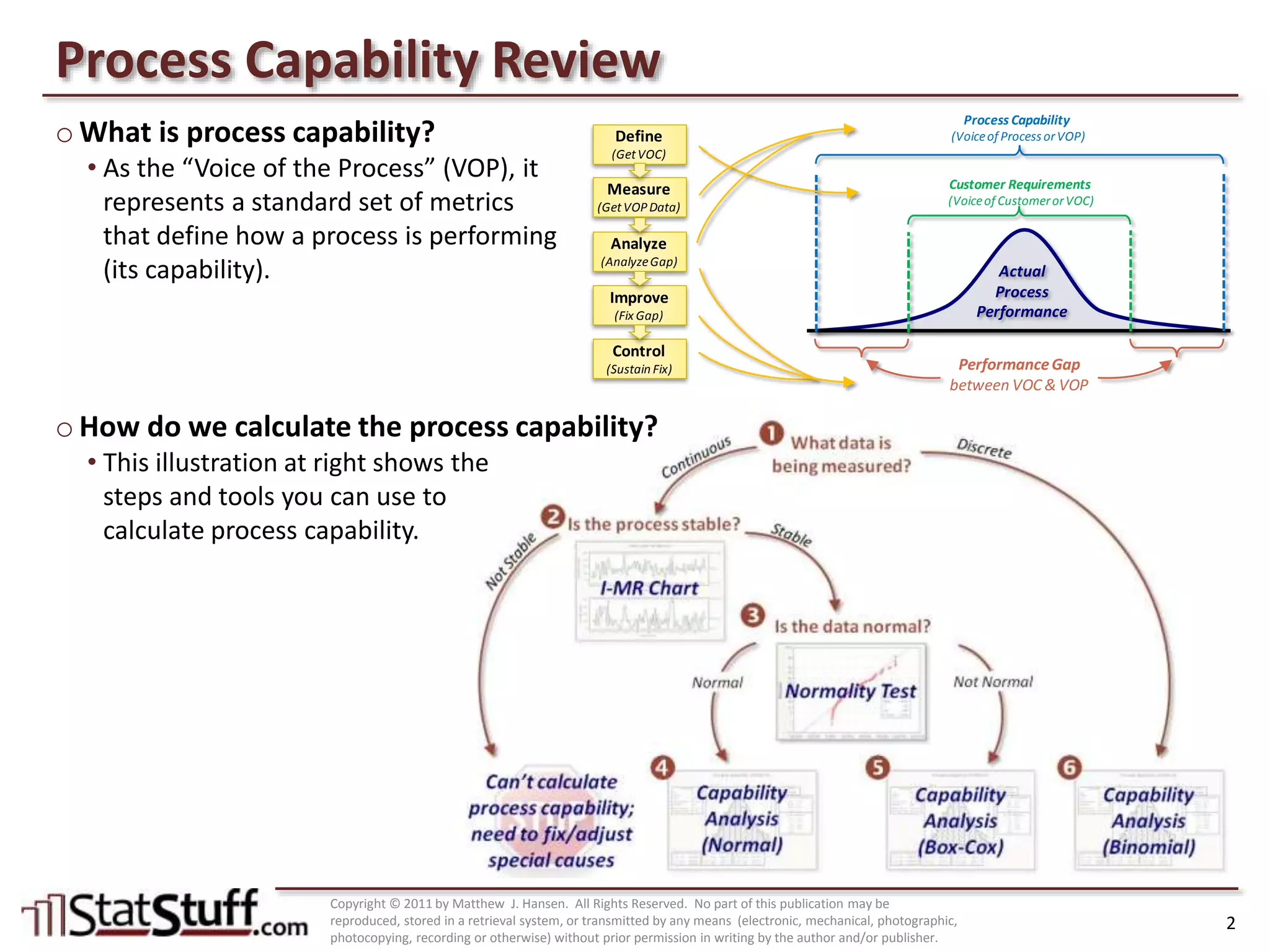

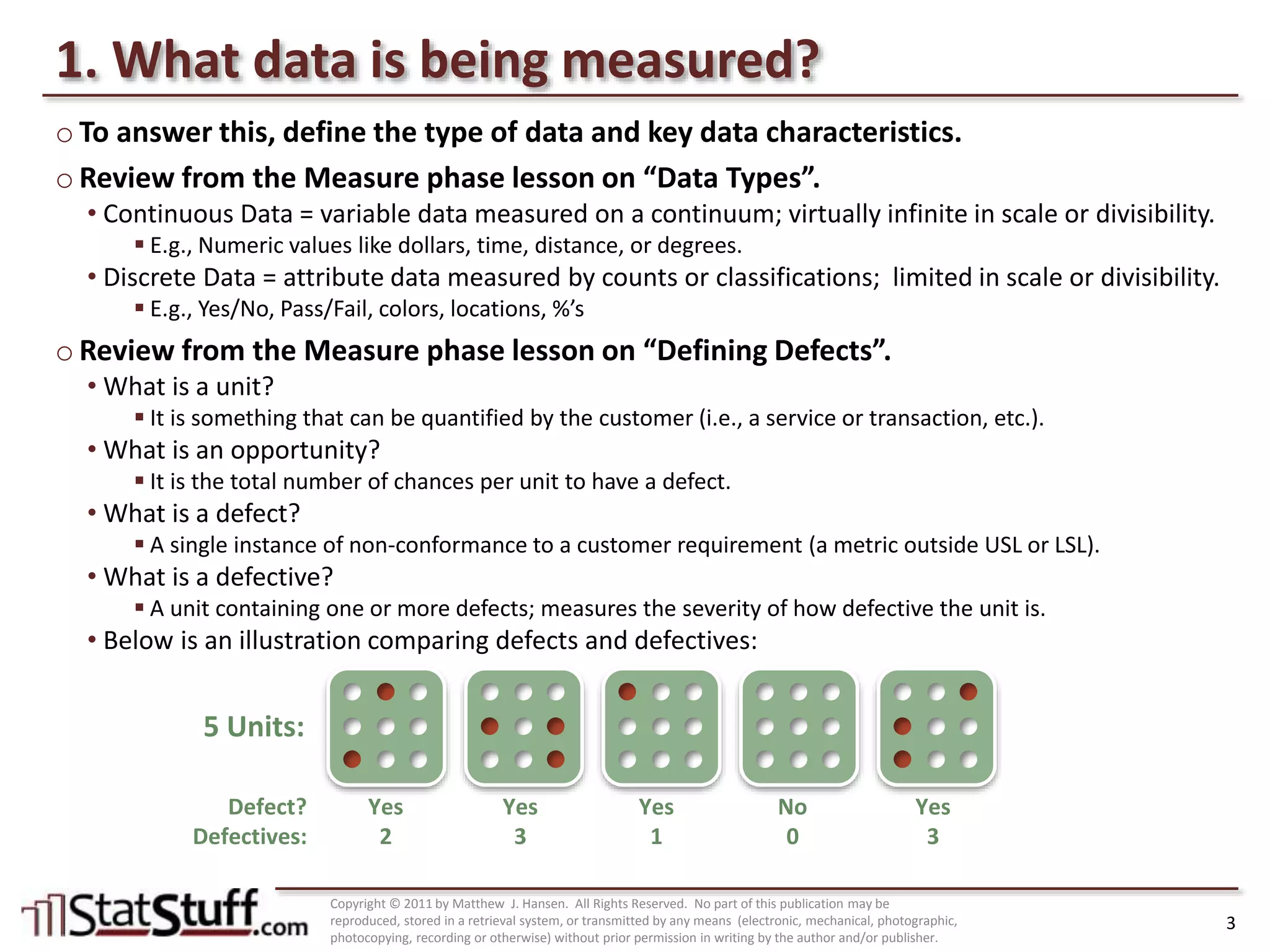

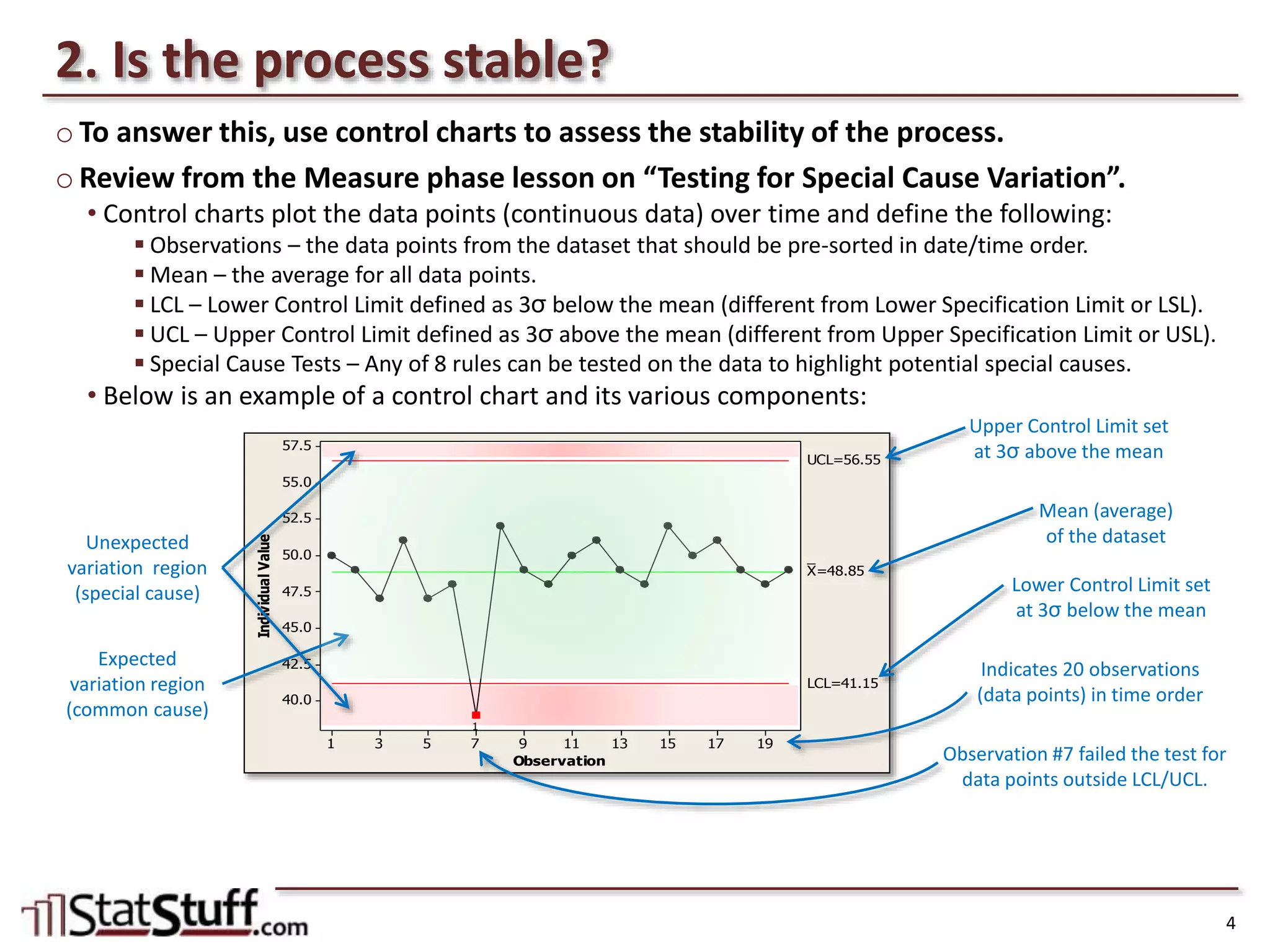

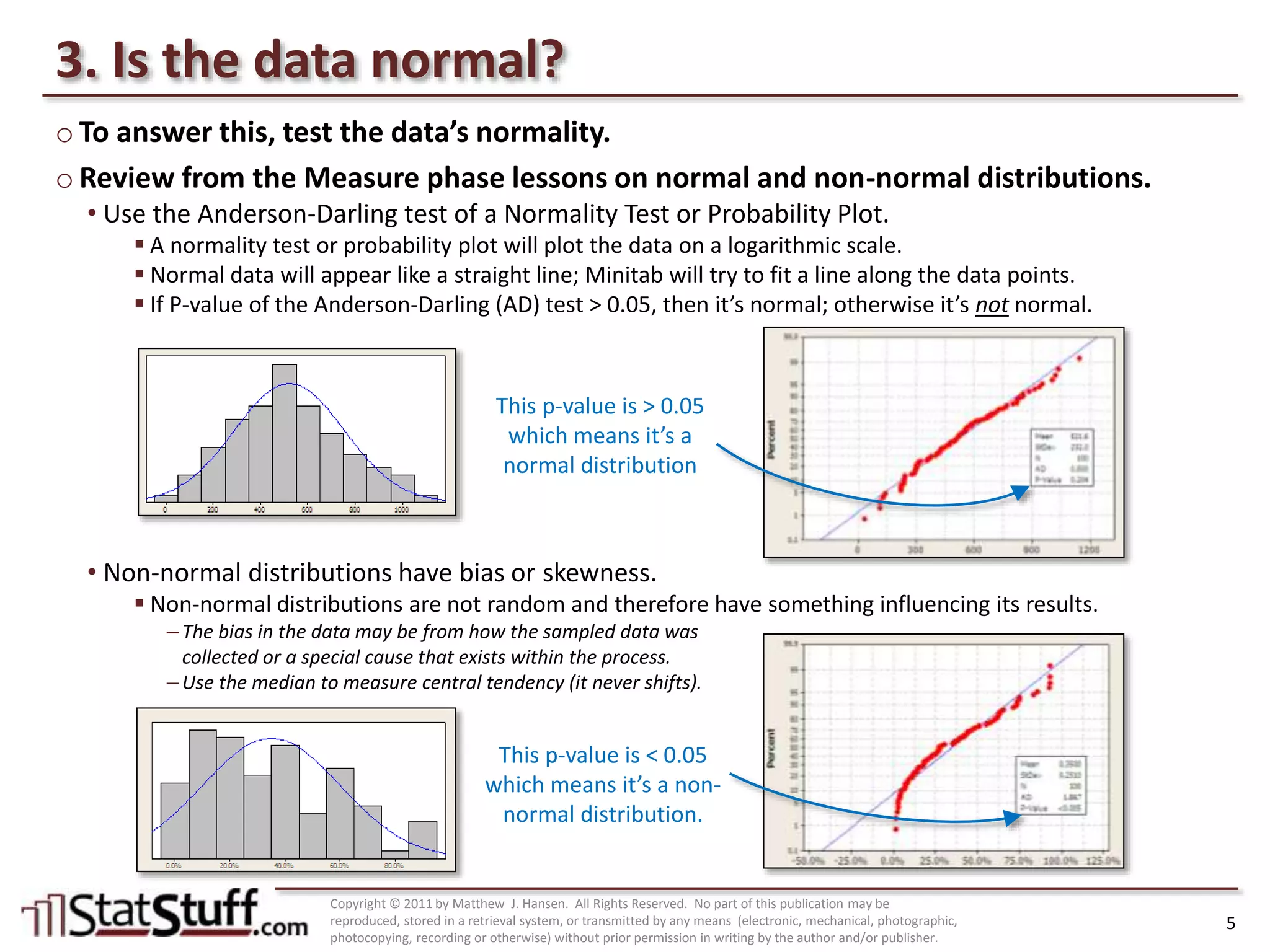

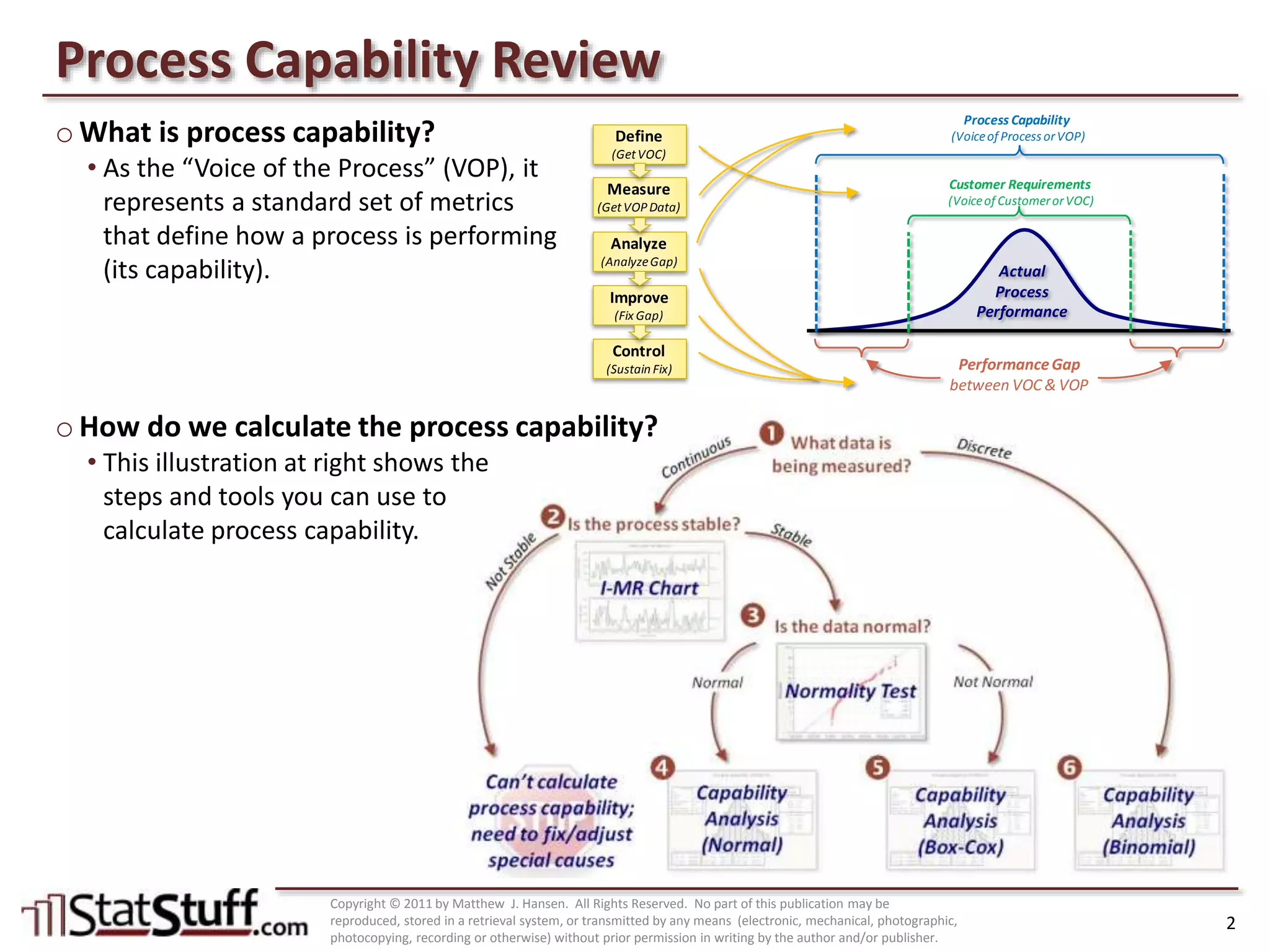

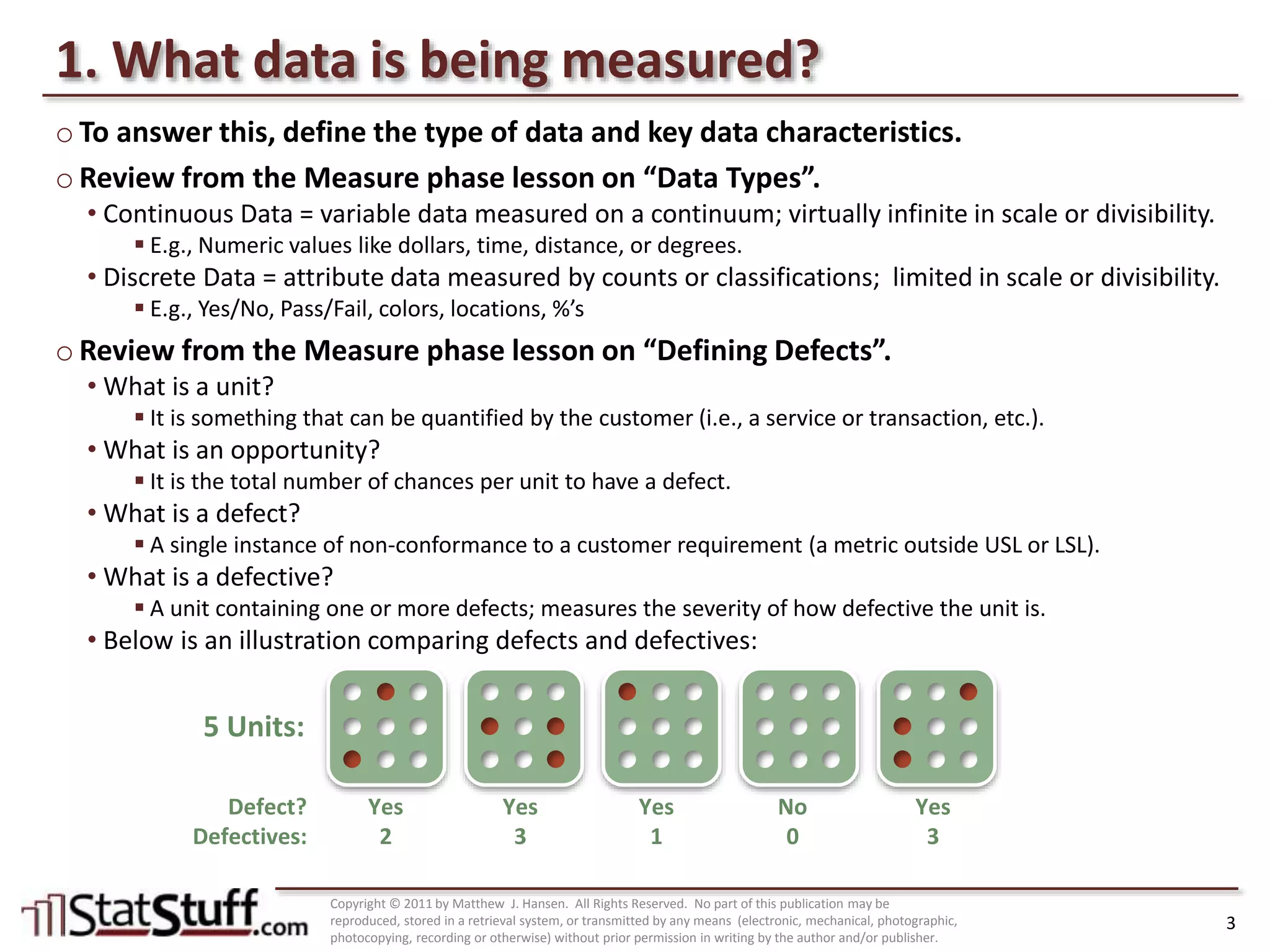

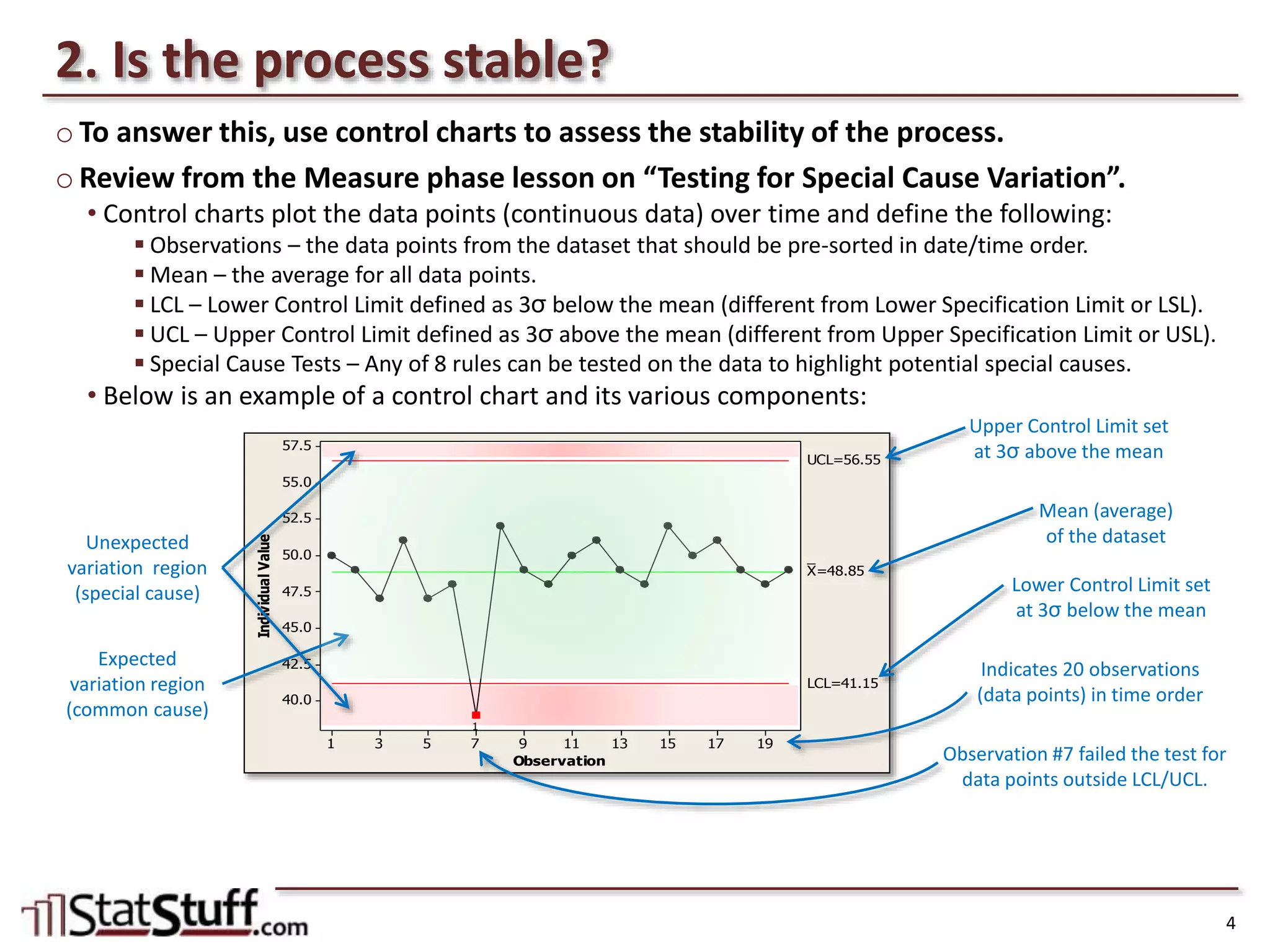

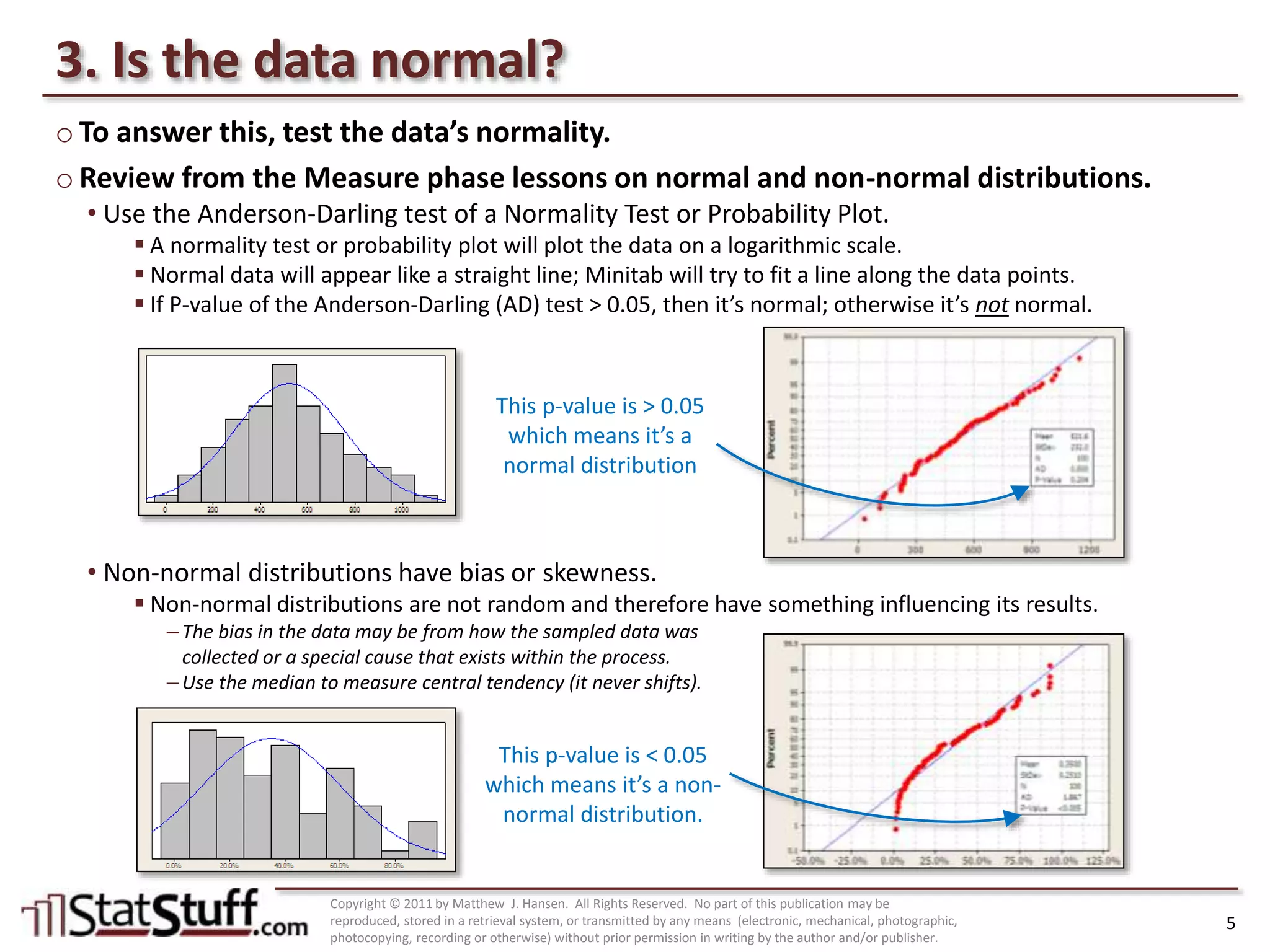

This document covers the initial steps of calculating process capability in a Six Sigma context, emphasizing the need to define the type of data being measured, assess process stability, and determine data normality. It introduces key concepts such as continuous and discrete data, and outlines the importance of identifying defects and defectives in the analysis. The document also discusses the use of control charts and normality tests to evaluate process performance against customer requirements.