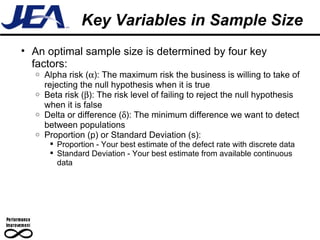

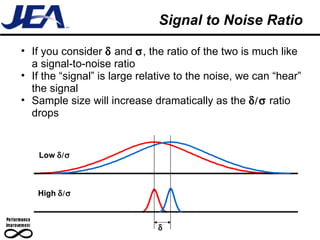

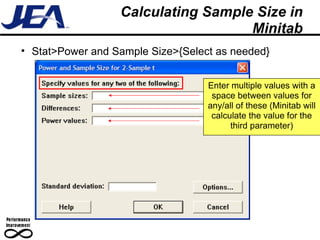

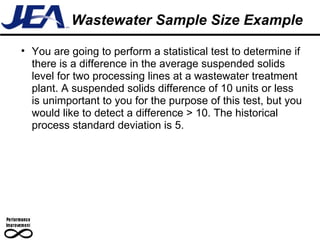

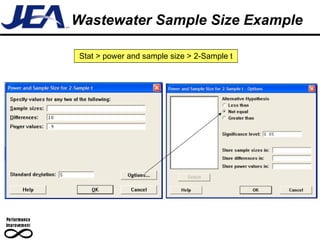

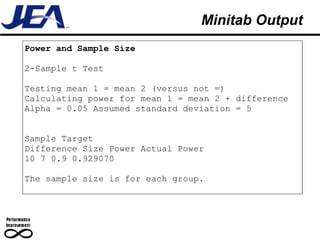

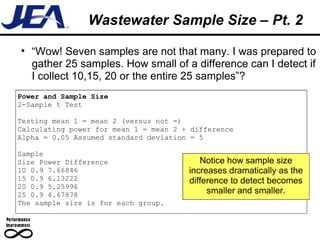

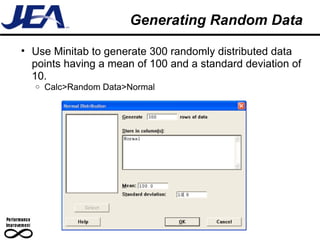

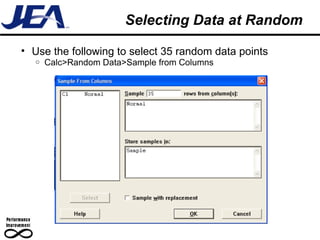

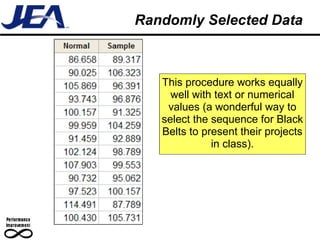

This document discusses key factors in determining sample size for statistical analysis: alpha risk, beta risk, delta or difference, and proportion or standard deviation. It provides examples of calculating sample size using Minitab for a wastewater treatment example comparing two processing lines, and selecting a random sample from a larger data set. The homework asks the reader to calculate sample sizes needed to determine if an invoice defect rate is different than 10% if the observed rates are 12%, 15%, 20%, or 25%.