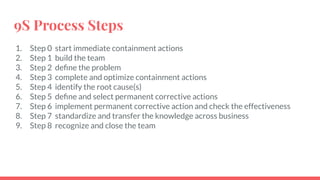

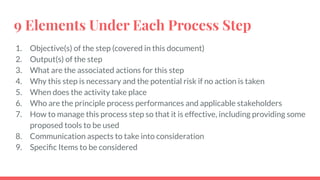

The document outlines the 9-step problem-solving methodology by Michael Venner, detailing each step from immediate containment actions to recognizing and closing the team. Each step's objective, outputs, necessary actions, risks, timing, stakeholders, management strategies, communication aspects, and specific considerations are discussed. The process aims to effectively identify and correct issues while preventing future occurrences and sharing knowledge across the organization.